Showing 3189 items

matching repair

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Hammer small sledge, c1900, c1900

A hammer is a tool consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This is a small sledgehammer whose relatively light weight and short handle allow single-handed use. It is useful for light demolition work, driving masonry nails, and for use with a steel chisel when cutting stone or metal. Among the early settlers in Moorabbin Shire were blacksmiths who made tools for the other settlers who were establishing the homes, market gardens, farms, orchards and various businesses. Early settlers were self reliant and repaired their own equipment for kitchen,dairy, farm, horses, carts using various tools . This hammer is typical of the type used by early settlers in Moorabbin Shire c1900This is a small sledge hammer with a wood handle and double sided round metal headearly settlers, market gardeners, blacksmiths, tools, building equipment, hammers, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Knife, curved, Sheffield c1900, 20thC

John Oxley was a shoe and butchers’ knife manufacturer, who was listed in Whitecroft UK in 1822 . By 1825, he was based in Hollis Croft. John apparently died in about 1837. He had two sons – George (1808-1879) and James (1811-1881) who took over the business. George moved to Indianna, USA and in 1868 James continued to manufacture 'Cooks’ and palette knives and steels" Oxley’s trade mark was a butcher’s knife crossed with a sharpening steel (and the letters ‘JO’). The firm stayed in the family until 1960. Early settlers were self reliant and repaired their own equipment for kitchen,dairy, farm, horses, carts using various tools . This strong steel knife is typical of the type used by early settlers in Moorabbin Shire c1900Heavy duty curved steel knife with a wide blade encased in 2 thick leather straps secured with steel rivets Blade ; James Oxley with Trade Mark - a butcher’s knife crossed with a sharpening steel (and the letters ‘JO’). scratched into leather handle ; J EVANSknives, sheffield steel, oxley james ltd. , leatherworkers, saddles, horses, bootmakers, shoes, boots, builders, carpenters, early settlers, market gardeners, blacksmiths, tools, building equipment, hammers, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

National Wool Museum

National Wool MuseumSpinning Wheel

Part of the Zakrzewski Collection of spinning wheels donated to the National Wool Museum by Mr Wlodzimierz Zakrzewski. For many years, Mr Zakrzewski collected, researched and repaired spinning wheels from all over the world. This spinning wheel is Australian and is made from Queensland Kauri pine. It dates from c.WWI and was designed by someone inexperienced in spinning wheel design, but who was able to solve the problems encountered in an innovative way. For instance the flyer and bobbin mechanism were made from the sort of bits and pieces that would have been found laying around a workshop. The wheel was acquired from a private home in Glen Iris, from the owner who knew nothing about it.Spinning Wheelhandicrafts - history, spinning wheels, highlights of the national wool museum: the zakrzewski spinning wheel collection - exhibition (28/07/2001 - 02/12/2001), zakrzewski, mr wlodzimierz -

Otway Districts Historical Society

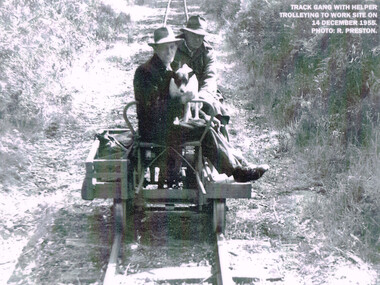

Otway Districts Historical SocietyPhotograph, R. Preston, Trolleying to work site, 1955, 14 December 1955

At its peak the Beech Forest railway employed more than 21 staff between Colac and Crowes. Gangers (men in charge of the track gangs) tended to be promoted into the Otways but many of their subordinate repairers were local recruits. A few of the men who worked in the original construction gangs of 1900-1902 remained and obtained positions in the track gangs along the line. The track was maintained by seven three-man gangs based at Colac, Barongarook, Gellibrand, Banool, Beech Forest (2), and Lavers Hill. However, track gangs lessened as the line shortened. After 1954, the sole surviving track gang, in charge of Paddy Balcombe, stayed until the line closed.A railway track gang, with helper, trolleying to a work site, on 14 December, 1955.beech forest; railways; track gang; -

Otway Districts Historical Society

Otway Districts Historical SocietyPhotograph, Barongarook track gang, c.1925, c.1925

At its peak the Beech Forest railway employed more than 21 people between Colac and Crowes tending the line the trains ran over. The gangers (the men in charge of the track gangs) tended to be promoted into the Otways but many of their subordinate repairers were local recruits. A few of the men who worked on the original construction gangs of 1900-1902 remained and obtained positions in the track gangs along the line. The track was maintained by seven three-man gangs based at Colac, Barongarook, Gellibrand, Banool, Beech Forest (2), and Lavers Hill. The ganger for Beech Forest 2 gang resided at Wyelangta. However, the track gangs lessened as the line shortened. Three men with spades on the line, thought to be at Barongarook, c.1925. B/W.barongarook; railways; track gangs; -

Queenscliffe Maritime Museum

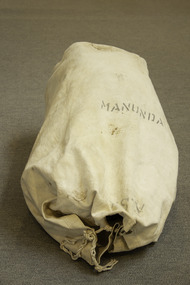

Queenscliffe Maritime MuseumEquipment - Sea Bag [kit bag]

The TSMV Manunda was requisitioned in September 1939 and she was converted into a fulltime hospital ship. HMAS Manunda was officially commissioned on May 25 1940 after which she operated four voyages to the Middle East to bring back wounded troops to Australia. On February 19, 1942 during a Japanese bombing raid whilst the ship was at anchor in Darwin harbour, a bomb hit right through the music room skylight, which exploded down on C deck tragically killing 12 and injuring 157 others. The next day she sailed for Fremantle with 266 patients. Whilst in Fremantle she was repaired and made ready for her next chapter in the war effort.This sea bag belonged to an unknown sailor who served on the hospital ship HMAS Manunda during WWIIA sailor's canvas sea or kit bag used on the TSMN Manunda in WWIIManundatsmv manunda, hmas manunda, hospital ship, wwii, kit bag, sea bag -

Vision Australia

Vision AustraliaAdministrative record - Text, Royal Blind Society of N.S.W. : A Vision to Share Annual Report 1981, 1981

Articles in the annual report include: establishment of the Charter for the Eighties committee to develop on the role and direction for the organisation, decision to close Alexis Albert Hostel and move residents to Lighthouse Hostel Roselands or cottage style accommodation due to increasing repair costs, increased demand for field service (but not funding) and standard cassettes from the library, new Braille production unit shared with RIDBC, further bicycle order for Dubbo Zoo, large order for PVC sleeves justified new PVC welding equipment, Talking Book of the Year award and "Art in Touch" exhibition (both created to celebrate 100th birthday in 1980) will continue, and departure of Graeme Bradshaw, Jack Chamberlain and Mavis Threlfo.1 volume of text and imagesroyal blind society of new south wales, corporation records -

Vision Australia

Vision AustraliaAdministrative record - Text, Twenty Fourth Annual Report of the Association for the Advancement of the Blind 1919, 1919

Annual report of the Association for the Advancement of the Blind outlined activities and events over the year, including withdrawal of the Country Concert Party due to the influenza epidemic, efforts being made to develop a Sewing Guild, continuation of Bark Plaiting to make small baskets, introduction of a French Polishing and Boot Repairing classes, the need for a separate building at Brighton to house the ill and the establishment of fund towards this with a 100 pound donation from the Felton Bequest, and the unfortunate increase in deaths amongst members due to the epidemic including past President T. Lowe, Country Concert Party singer Miss N Gray, and the return from active service of Dr Grey.1 volume of printed material with some illustrationsassociation for the advancement of the blind, annual reports -

Wodonga & District Historical Society Inc

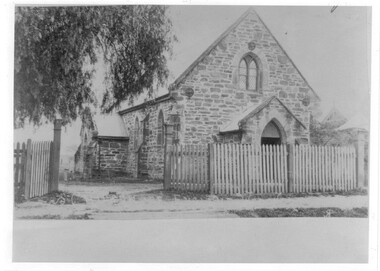

Wodonga & District Historical Society IncPhotograph - St Luke's Church, Wodonga

St Luke’s Anglican Church officially opened on 15 March 1863 and originally operated as a branch of the Albury church. The first minister to conduct a service there was Rev. Robert Potter, followed by Rev. B. Brownrigg , Rev. J. H. May, Rev. D. E. Jones and Rev. J. K. Tucker. The first resident minister at Wodonga was Rev. J. H. White who came in 1879. The Church was constructed from locally hewn stone. After serving the congregation for more than a century, the Church was closed by the Health Commission due to its deteriorated condition which was judged to be beyond repair. It was demolished by voluntary labour on the 10 – 11 August 1968. A collection of 4 black and white photos depicting St. Luke's Church Wodonga at different times in its development.st luke's church wodonga, churches wodonga, early churches wodonga -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)FCV testing meter

After the 1939 bushfires, the Forests Commission invested heavily in a radically new communications network. After suffering some inevitable delays due to the War, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. The communication systems were regarded at the time to be more technically advanced than the police and the military. These pioneering efforts were directed by Geoff Weste, and later technical experts like Rex Philpot, John Whitehead, Charlie Reisinger and many others who designed, built and repaired most of the radio equipment. There was a dedicated radio laboratory at Surrey Hills in Melbourne. The purpose and operation of this particular instrument is unknown.FCV testing meterMade in the radio laboratory of the Forests Commission Victoriaradio, forests commission victoria (fcv) -

Ithacan Historical Society

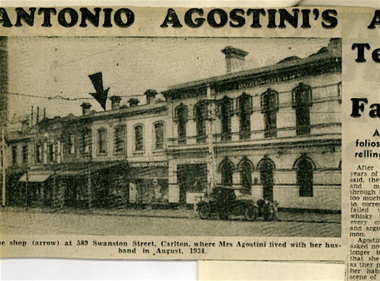

Ithacan Historical SocietyPhotograph, Newspaper Photograph of Swanston Street businesses, 1944

When Andrew Black took occupancy of the shop ate 589 Swanston Street, Carlton, he was unaware that a few years earlier it had been the scene of a murder and became known as the 'pyjama case murder'. On 1st September 1934, the body of an unidentified woman dressed only in pyjamas was found near Albury, NSW. For the following decade it remained an unsolved mystery until 1944 when Tony Agostini was arrested and confessed to killing his wife. At the time of the murder, the Agostinis were living in the building, where Andrew later ran his shoe repair business. While the case was newsworthy in 1944, the Carlton shop featured in Melbourne's newspapers.A photograph of a portion of a newspaper article about a 1944 cold case murder in Melbourne.carlton, swanston street, andrew black, shoe repairs -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: THREE CUT-THROAT RAZORS

Three cut-throat razors, boed units in deteriorated condition: 22b - box marked Pittock,blade marked Bengall, manufacturers name on reverse side T. R. Cadman & Sons, Sheffield England 22c - red box has remains of Sheffield England marked on the smaller end of box. Blade is damaged and rusted. Blade black handle is notated with Bengall, while blade itself is etched Made Specially for A. Edments Pty. Ltd.; reverse notes manufacturer as T. R. Cadman & Sons, Sheffield England 22d - box has no discernible markings, but has minor taped repair on larger section. Black handle is unmarked, blade is marked Bengall, the reverse notes manufacturer as T. R. Cadman & Sons, Sheffield England. Items stored in Pittock coach builders box, reference 13000. -

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 27 mm sq slide/s - set of 7 - track removal, Lilian Butler, c1971 to 1972

Series of 7 photos showing track removal following the closure of the Ballarat Tram system.Yields information about the removal of the tram tracks in the city area.Set of 7 colour slides - 1 x Agfa blue and white plastic slide mount, 4 Hanimex cardboard mounts and 2 Kodachrome cardboard mounts of track removal works in Ballarat, c1971 to 1972 .1 - Saw cutting the road pavement at the Dawson St Crossover. .2 - Rolling the crushed rock pavement in Sturt St after track removal - near Doveton St. .3 - Track repairs or starting to remove the railway crossing at Lydiard St North - has an SEC truck in the background and the Kennedy Murray Pty Ltd General Carriers building in the background. .4 - commencing work on the Dawson St Crossover removal with St Patrick's Cathedral in the background. .5 - as for .2 .6 - L. G. Pearce excavating track near Dawson St. .7 - ditto Photo from the collection of Lilian Butler. ballarat, tramways, trams, track removal, dawson st, trackwork, sturt st, level crossings, lydiard st north -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Tramway and Motor Omnibus Employees Association (ATMOEA), "Memorandum of Agreement/ The Australian Tramway Employees' Association / The Tramway Board of Melbourne", 1917

Twenty page booklet, off white paper, saddle stapled, with additional dark grey paper cover titled "Memorandum of Agreement/ The Australian Tramway Employees' Association / The Tramway Board of Melbourne". Dated on cover 1917. Agreement dated 28/7/1919 to apply from 2/12/1916 to 2/12/1918, Defines track repairers, ropeman, gripman and students. Details work hours, meals, time between shifts, payment for wase work (running between one line and another), Sunday sheets, overtime rates, call back, overtime, holidays, payment for 'sleeping in office', passes, uniforms, seniority, misconduct, Board of Reference and penalties. Defines minimum rates of wages and temporary allowances. Signed by Colin Templeton Chairman, Fred Thos Hickford Member and W.O. Strangward Secretary and Lionel L. Hill President and T. Jewell Secretary for the Union. "Ballarat Tramway Preservation Society Catalogue No. 214" in ink on top of first page, "Recd 22/2/1917" on front cover in ink, .trams, tramways, melbourne, tramways board, atea, unions, agreements, mmtb -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Tramway and Motor Omnibus Employees Association (ATMOEA), "Tramway Board/ The Australian Tramway Employees' Association Agreement", 1919

Sixteen page booklet, off white paper, saddle stapled, with additional dark brown paper cover titled "Tramway Board/ The Australian Tramway Employees' Association Agreement". Dated on cover 1919. Agreement dated 28/7/1919 to apply from 28/7/1919 to 5/5/1922. Defines track repairers, ropeman, gripman and students. Details work hours, meals, time between shifts, payment for wase work (running between one line and another), Sunday sheets, overtime rates, call back, overtime, holidays, payment for 'sleeping in office', passes, uniforms, seniority, misconduct, Board of Reference and penalties. Defines minimum rates of wages and temporary allowances. Signed by Colin Templeton Chairman, Fred Thos Hickford Member and W.O. Strangward Secretary and John Abfalter President and T. Jewell Secretary for the Union. "Ballarat Tramway Preservation Society Catalogue No. 215" in ink on top of first page.trams, tramways, melbourne, tramways board, atea, unions, agreements, mmtb -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Digital image Set of 15, Warren Doubleday and Paul Mong, 11/12 to 18/12/2004

Set of 15 Digital Images of the aftermath of the sub-station repairs, wiring it up and the installation of the isolating transformer taken between 11/12/2004 and 18/12/2004 .1 - Garry Wood with some concrete for the substation floor .2 - Alan Snowball and Paul Mong laying the floor. .3 - Part of the Switchboard modified to position the new Isolating Transformer .4 - ditto .5 - the Transformer arrives - 15/12/2004 .6 - being positioned in the depot .7 - the manufacturers plate - Illawarra Transformers Wollongong .8 - unpacked .9 - being positioned .10 - In position .11 - the door to no where - the platform across to the store and archives yet to be built .12 - some of the equipment installed but found not to be suitable for the purpose. Was ex an PTC sub .13 - wiring it up .14 - Paul working .15 - the new control panel. trams, tramways, btm, substation, testing, isolating transformer -

Moorabbin Air Museum

Moorabbin Air MuseumArchive (Item) - Box WP1 Prowse Collection See details under Description, Box WP1 Prowse Collection

-

Melbourne Tram Museum

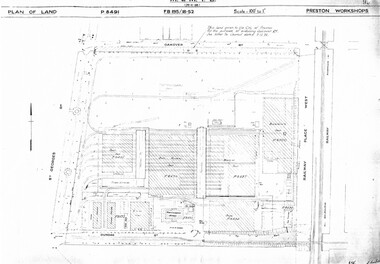

Melbourne Tram MuseumDrawing, Melbourne & Metropolitan Tramways Board (MMTB), "Preston Workshops", c1938

Set of nine photocopied plans or drawings on A3 sheets of the "Preston Workshops" - c1939 .1 - P8491 - Plan of land showing layout and associated drawings including Reservoir railway line - 19-4-1939. .2 - P8492 - Plan of Timber stacks and Hall - 3-2-1939 .3 - P8493 - Plan of Offices and location of sub-station - 13-12-1938 .4 - P8494 - Plan of Store including Oil store - c1939. .5 - P8495 - Plan of Paint Shop and relationship to timber stack - 1-3-1939 .6 - P8496 - Plan of Car building and Repairs shop - 6-12-1938 .7 - P8497 - Plan of machine shop - 10-12-1938 .8 - P8500 - Plan of Blacksmiths shop - 1-12-1938 .9 - P8590 - Plan of Substation - 1-12-1938trams, tramways, drawings, depots, property, preston workshops, workshops, substation -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Digital Image, W6 1000 on the opening day of the service in Bourke St, 26/06/1955 12:00:00 AM

Set of 4 digital images of W6 1000 on the opening day of the service in Bourke St via High St Northcote to East Preston on 26/6/1955. .1 - 1000 (East Preston route 89) at Spencer St, note the sign behind the tram and the newly painted safety zone. Has the Mail Exchange in the background. .2 - ditto at Spencer St with Carlyon's Hotel and the Spencer St Railway station in the background. .3 - tram arriving at the East Preston depot leads - has adverts for Milo, Kiwi boot polish and Pleshur's shoes. .4 - ditto with a Book Repairs Shop, R. P Evans, Goweville Hotel advertising Fosters Lager, and the Melody Picture theatre, In the background is Bell St with a set of clock traffic lights and two tower wagons and a Pura Milk truck just behind the tram.trams, tramways, w6 class, opening, route 89, bourke st, east preston, high st, northcote, tower trucks, traffic lights, bell st, tram 1000 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Taps and Dies set, Wiley and Russell Mfg. Co, C. 1884

This set of taps and dies tools was owned by Frederick William McDowell (Fred) (1880 to 15-6-1967). He was a wheelwright by trade. He made and repaired vehicles such gigs, buggies, jinkers, sulkeys, spring carts and farm wagons. His workshop was on the corner of Cramer Street and Raglan Parade in Warrnambool., previously the site of Fotheringhams, and after McDowell's, and still in 2023, occupied by Reece Plumbing Fred's workplace prior to retiring was at Bryant & Waterson's in Kepler Street, opposite the Criterian Hotel, making rubber tyred horse-driven farm wagons. This Wiley and Russell hand operated, thread cutting Die and Stock, or Die and Tap, set’s patent carries the description “The taper-headed screws adjust the size; the four side screws hold the cutters firmly in the holder. Marketed as the Wiley & Russell LIGHTNING SCREW PLATE. The taper-headed screws are carried over from the J.J. Grant October 21, 1871 patent (no. 120,266). This patent was improved by Smart's Oct. 21, 1884 patent (no. 306,783).” Dies are used to cut external screw thread, stocks are the tools that hold the dies in place with countersunk adjustable screws, and taps are the tools that make the internal threads. The tools would be used by farriers, blacksmiths, wheelwrights sailing and steam ship engineers for making new, or repairing old, threads in metal. WILEY AND RUSSELL Manufacturing Company The company Wiley and Russell was established in 1872 by Solon Wiley and Charles P Russell, whose uncle founded the J. Russell Cutlery Co. The company began with the purpose of manufacturing thread cutting tools in Green River U.S. This tap and die set is an example of tools used by blacksmiths, farriers, wheelwrights and engineers on sailing and steam ships. It is also an example of early U.S. made engineering tools.Tap, Die, Die Stock set of industrial tools, fitted inside original timber box with three instruction labels attached inside lid. The set is the “Wiley and Russell LIGHTNING SCREW PLATE Pat. Aug. 5, 1884”. The lid has three metal hinges and is secured by two metal hook and eye fittings. This set of Whitworth standard threads has metal die and stocks (seven), and taps (three - the case has provision for four more die). The manufacturer’s details and the sizes of the threads are impressed into the tools. The paper labels have instructions and a diagram for the use and care of the tools. Tools have a protective oil coating. Made by Wiley and Russell Manufacturing Co. of Greenfield, Massachusetts, U.S., c. 1884; the tools were patented in August 1884, U.S. Patent 303,060. “Wiley & Russell MFG.CO, Greenfield, Mass, Pat Aug 5 1884.” “WHIT. STD.”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tap and die set, 1884 engineering tools, wiley and russell mfg co, lightning tap and die set, tap, die and stock set, screw thread cutting tools, taps and dies, stocks and dies, lightning screw plate, cutters, j.j. grant, patent no. 120266, solon wiley and charles p russell, wiley and russell, j. russell cutlery co, green river u.s, whitworth thread, fred mcdowell, frederick mcdowell, wheelwright, gig, buggy, jinker, sulkey, spring cart, farm wagon, 2-wheeled cart, horse cart, horse cart parts, jinker buggy, transport, vehicle, horse drawn, horse jinker, bryant & waterson -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 29/071956

The Slingsby T31 is a two seat training glider that came available in 1951. It is, in effect, a two seat version of the single seat Kirby Tutor. The T31 was marketed by Slingsby Sailplanes both as complete aircraft and kits of parts for assembly. The Australian Gliding Museum’s example (currently registered as VH-GDB) is one of five of this type to grace Australian skies. Three including GDB were assembled in Australia from kits supplied by Slingsby’s in England, the other two were delivered as completed airframes. To date only four remain of which two are airworthy. This aircraft began flying in at Caversham in Western Australia (the then home of the Gliding Club of Western Australia) in July 1956. It was badly damaged in a crash in June 1958. The wreckage was sent to Schneiders in Adelaide for repair. However, the Club decided against having the repairs done, opting instead to buy a new ES52 Kookaburra. After a couple of years, the wreck was purchased by a member of the Waikerie Gliding Club whereupon the glider was rebuilt with some modifications, including a more rounded and better streamlined fuselage nose. It returned to the air in October 1961 at Clare in South Australia. The ownership of VH-GDB passed through a number of clubs, including at Dubbo in New South Wales, Wimmera in Victoria and Pioneer Valley at Mackay in Queensland. Eventually, it came into the hands of Bill Riley of Tocumwal in New South Wales who held it in storage for many years. Riley donated the aircraft to the Museum. It has been restored to airworthiness and is flown at vintage glider rallies and on Museum open days. This exhibit is an excellent example of a Slingsby T31 Tandem Tutor, a type of glider that was used by a number of clubs in the 1950s and 1960s for dual training of pilots to the solo capability.The Slingsby T31b Tandem Tutor is an open cockpit, tandem, two-seater glider with high, pylon mounted two piece wing supported by double, wire braced, steel tube struts. The glider is fitted with a main wheel, rubber-block sprung, wooden nose skid and steel leaf sprung, brass shod tailskid. The basic controls of aileron, rudder and elevator are not supplemented with pitch trim. Wing lift spoilers and both aerotow and winch releases are fitted. The instrument panels in both cockpits are fitted with an airspeed indicator, cosim variometer and altimeter. This red and silver painted wood and fabric covered aircraft is in excellent condition having been restored to full airworthy status by the Australian Gliding Museum. SLINGSBY – T31b (nose – both sides) DB Australian Gliding Museum (rudder – both sides) It has been given Serial Number GFA/HB/12 and is registered as VH-GDBaustralian gliding, glider, sailplane, slingsby, tandem tutor, t31, gliding club of western australia, waikerie gliding club, wimmera soaring club, pioneer valley soaring club -

Bay Steamers Maritime Museum

Bay Steamers Maritime Museummodel steam engine

This model was found in the collection of Bay Steamers Maritime Museum. It is not knowt who created it but it is supposed that it was constructed to educate the many masters of the Wattle in the operation of a steam engine - a not so common mode of power these days. A Bay Steamers Maritime Museum examined the model in March 2012 and discovered that is was in poor repair. Using his existing knowledge, and with reference to some historic texts, he made some repairs and returned the model to working order. Here is his anaylsis of the situation as an excerpt from the Bay Steamers Maritime Museum newsletter Steamlines May 2012 "I was confronted with a model of a steam engine used years ago as a training aid for hopeful steam engineers. Already having a knowledge of steam operations, I considered a museum write-up for that model a ‘piece of cake’. However, on turning the model’s crankshaft, the valve timing seemed ‘out of kilter’ with the movement of the piston. Problem was that the two eccentrics on the crankshaft were not properly secured to it. Eventually I fastened the two eccentrics to the crankshaft where I felt that they should be and then realized that one of them had a chain-driven valve-timing device attached. This would be adjusted while an engine was running to achieve best performance and fuel economy whilst in operation by accurately controlling the period of time during which steam under pressure from the boiler would be admitted to the cylinder and give greater time for the steam to expand in the cylinder, move the piston and turn the crankshaft and thus, drive the attached apparatus. When the valves were correctly set up it was then possible to get the model to function properly.The model comprises a green section, which is the actual the model mounted on a brown painted board. There are two parts of the model, painted white representing the steam passages, and black representing the cast- iron portions of the cylinder-block casting, and of the main valve sliding between the cylinder a second sliding valve. Of the black portions, one slides back and forth being connected to a rod which is connected to an eccentric clamped to the crankshaft and is the nearer to the flywheel of two eccentrics. This eccentric is attached to the crankshaft at an angle of 90 degrees to the crank-pin attached to the flywheel. To operate the model simply turn the flywheel by means of the handle attached to its crank-pin. A second eccentric is also attached to the crankshaft, further away from the first eccentric, and it is adjusted to operate 90 degrees from the first eccentric (that is, 180 degrees from the crank-pin) A piston (painted silver) is located in a plastic cylinder and has a piston rod which passes through one end of the cylinder, (in actual practice a steam-proof gland seals the cylinder against loss of steam) terminating in a cross-head slide between four rails guiding it. From this cross-head, a connecting rod joins the piston-rod to the flywheel via the crank-pin attached to the flywheel which is part of the crankshaft. (In actual practice, a flywheel may not be used, particularly in a multi-cylinder engine.) The white portions of the model painted nearest to the cylinder represent the two steam ports cast into the main cylinder block, whilst one section painted in between those two represents the exhaust outlet (which may be connected to a condenser to conserve water, or to the open air). The main slide valve has three white-painted portions painted thereon. It has two white-painted marks representing the steam passages to the steam ports into the cylinder, and a third section in between the other two, being that part of the valve through which exhaust steam passes in line with the ports in the cylinder block. By rotating the flywheel, the operations of an engine will be observed as steam is admitted to the main valve via the gap between the two jaws of two moveable portions of a second sliding valve which is operated by the second eccentric attached to the crank-shaft. This eccentric is used to finely tune the valve timing of this model to obtain best running results of an engine. There are various methods used for reversing a steam engine. model compound steam engine, steam engine, model, crankshaft, valve, flywheel, wattle, engineer, eccentrics -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument, State Electricity Commission of Victoria (SECV), SEC "Rules Governing Depot Employees", 1960s

Set of documents - copies and originals titled 2440.1 - Copy of original document on heat sensitive photocopy foolscap size paper - Photostatted. 2440.2 - copy - from above on toner printed photocopy and reduced to A4 size - made June 2003 by Alan Bradley. 2440.3 - original copy on foolscap paper, stapled in top left hand corner - two copies held. Document details General rules such as hours of duty, fire, accidents behaviour; Depot Operation - Safety Rules detailing many procedural rules about work safety on trams. The 5th page details rules governing track repair employees, such as safety, breaking of rail circuits and use of bitumen boilers. See Also Reg Item 3705 for an earlier version. 2nd copy added 12/5/2021 - original copy. Scanned and added. 2440 - Copy of original document on heat sensitive photocopy foolscap size paper - Photostatted. 2440 - copy - copy from above on toner printed photocopy and reduced to A4 size - made June 2003 by Alan Bradley. Document details General rules such as hours of duty, fire, accidents behaviour; Depot Operation - Safety Rules detailing many procedural rules about work safety on trams. The 5th page details rules governing track repair employees, such as safety, breaking of rail circuits and use of bitumen boilers. See Also Reg Item 3705 for an earlier version. 2nd copy added 12/5/2021 - original copy. Scanned and added.Demonstrates a SECV Safety and procedures document.Photocopy and original of 'State Electricity Commission of Victoria / Ballarat Electricity Supply and Tramways / Rules Governing Depot Employees' consisting of four pages.trams, tramways, sec, safety, depot, rules, instructions -

Warrnambool and District Historical Society Inc.

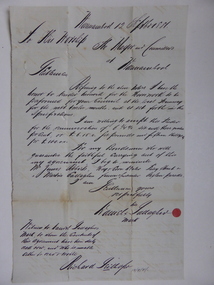

Warrnambool and District Historical Society Inc.Document, Gallagher, C 1881

In 1858 a tramway was constructed to move goods between Warrnambool township and jetty on Lady Bay which was over a mile away The terminus was established on the southern side of Merri Street. and the track went around the edge of Lake Pertobe reserve. Large stores were also built near where the present railway station is situated to hold produce and carriages. These documents relate to the contract to perform the horse work for the tramway for a period of one year. The horse work involved the transporting of goods by horse drawn tram trucks, all repairs to the tracks , shunting and delivery duties. The tramway operated from 7 am to 6 pm six days a week and a team of six horses was required to perform the work.The tramway was an important part of Warrnambool's infrastructure and history and the documents also include names of local people.001261.1 Pale blue lined paper with red lined outline.Hand written in black pen with names and some other words underlined in red. Two signatures on bottom right with red seal beside each. Witness signature below on left hand side. Of the four pages of the document , only the first page is used. 001261.2 Cream paper lined in blue with heavy black ink writing. A red seal attached beside the tenderer's mark and name. on right side of page. Witness's signature at bottom centre of page.001261.1 James Roberts hay and corn dealer ,Fairy Street Warrnambool, Martin Callaghanfarmer and contractor Raglan Parade Warrnambool. Daniel Gallagher, contractor of Warrnambool. September 1881. 001261.1 Daniel Gallagher .James Roberts Martin Callaghan September 12, 1881.warrnambool, warrnambool history, daniel gallagher, james roberts -

Otway Districts Historical Society

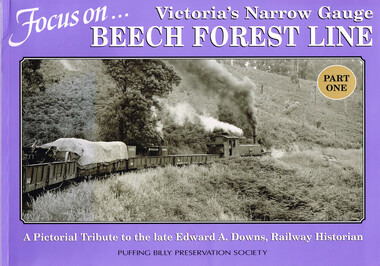

Otway Districts Historical SocietyBook, Puffing Billy Preservation Society, Focus on Beech Forest Line, Part One, January 2004

In the earliest years of the Colac-Beech Forest-Crowes line all trains were hauled by NA-class 2-6-2 tank locomotives. From 1926, with the introduction of articulated Beyer Garrett locomotive G41, it hauled the majority of trains with the NAs providing supplementary service as required. Late in 1945 Garratt G41 was again out of action undergoing repairs at the depot in Colac so regular traffic again was handled by an NA for a short time. The line continued to survive on pulpwood long after other VR narrow gauge lines had ceased operation but finally, on 30 June 1962, a dilapidated G42 hauled the last train of goods wagons and vans to Beech Forest and return.Focus on Victoria's Narrow Gauge: Beech Forest Line, Part One. John E. Thompson. Puffing Billy Preservation Society; Belgrave (Vic); Jan 2004. vi, 42 p.; illus; maps. Soft cover. ISBN 0 9579792 4 Xvictorian railways; narrow gauge; beech forest; colac; crowes; edward a. downs; john e. thompson; -

Otway Districts Historical Society

Otway Districts Historical SocietyPhotograph, Langford, Weston, Beech Forest: Goods trail departing for Colac, 1961, 9 August 1961

The Garratts were approaching 35 years of age and needed constant repairs to keep them in service, the other rolling stock was between 45 and 60 years old, the track was generally in poor condition, and the amount of traffic offering was only a faction of that carried previously and came from one station, Beech Forest. A further sign of decay was in the transfer of goods between the gauges. Where eight or nine men had worked full-time transferring between gauges only one man was seen by 1960, with several other men hired on the basis of '$2 a truck', assuming they could be found. In 1961 VR announced its intention to close the line which it did on 30 June 1962. Colour. On 9 August 1961 a G42 locomotive and goods train departing for Colac with the coal stage on the left, the saw mill and Gangers Shed on the right, and houses in the right background.. beech forest; railways; -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Abandonment SEC tramways, the Hon J C M Balfour MLA, 9/1970

Document regarding the abandonment of tramways in Ballarat and Bendigo. Presented to State Parliament Sept. 1970 by the MInister for Fuel and Power, the Hon J C M Balfour MLA. Outlines the losses incurred by the SEC, replacement public transport system, the worn out nature of the system, the gifting of one Bendigo tramcar to the AETM, costs of track repairs and new trramcars, tenders for replacement bus services, retrenchment payments to staff, reconstruction of existing roads following removal of the tracks, and town planning and traffic aspects. Includes a photo of a bus and interior seating. A graph from 1934 to 1970 shows the service miles, passengers carried, average fare, expenditure, revenue and loss, along with dates of major fare revisions.Yields information about the 1970 proposal to close Ballarat and Bendigo tramway systems which was successful despite previous attempts when the Bolte Governments did not have the numbers in the upper house.Document 16 Quarto sheets, duplicated and one sheet with a folded colour graph.In ink on front sheet "D/T/S"tramways, ballarat, bendigo, abandonment, closure, parliament -

Melbourne Legacy

Melbourne LegacyBooklet, Legacy. An outline of the facilities offered to the dependants of deceased ex-servicemen. (H26), 1944, 1953, 1959, 1961

A brochure explaining Legacy's work and the facilities they provide. It is aimed at the widows to inform them of what is available to them and it outlines the times for classes for the children. The earliest copy in 1944 included the charter of Legacy and headings in red printing. 'Melbourne Legacy offers friendship and help to the dependants of our departed comrades.' Headings included: Help and advice to mothers or guardians; Mothers' Club; Senior Widows' Club; Housing and repairs; Legal advice; Medical, dental and optical care; Education, Employment, Camps and holidays, Christmas party, Residences, Junior Legacy groups. The notation H26 in red pen shows that it was part of the archive project that was trying to capture the history of Legacy. See other editions at 01447.A record of how Legacy portrayed itself to the widows and children in 1944,1959 and 1961/8. Black and white brochure made of white paper, folded into a 8 page booklet. 01498.1 1944 (handwritten in red pen) 01498.2 April 1953 01498.3 April 1959 01498.4 October 1959 01498.5 June 1961 with markings to edit it for reprinting in July 1968Handwritten 'H26' and '1944' in red pen. 01498.5 has edits in blue pen to revise the content for republication.legacy promotion, history -

Vision Australia

Vision AustraliaPhotograph - Image, St Kilda Road building in 2010, 6/1/2010

In 2007, Vision Australia sold it's iconic 557-563 St Kilda Road site. The historic bluestone building was in need of renovation and repair, had limited space for staff and clients and with more demand for services in suburban and regional areas, did not meet the needs of the national organisation. The purchaser was mainly interested in the Ormond Hall section, which they sub-divided off and sold to the tenant of the Belgian Beer Cafe. The remainder of the site was then sold on to another developer. Unable to quickly proceed with their plans on developing the site for residential buildings, the site fell into some disrepair in the interim which was when these images were taken. Later the site was sold again and residential buildings now occupy part of the block. 20 images taken of and from St Kilda Road buildingroyal victorian institute for the blind, buildings, myer house, ferguson and urie -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Radio Telephone with handset

After the 1939 bushfires, the Forests Commission invested heavily in a radically new communications network. After suffering some inevitable delays due to the War, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. The communication systems were regarded at the time to be more technically advanced than the police and the military. These pioneering efforts were directed by Geoff Weste, and later technical experts like Rex Philpot, John Whitehead, Charlie Reisinger and many others who designed, built and repaired most of the radio equipment. There was a dedicated radio laboratory at Surrey Hills in Melbourne. Little is known about this particular radio handsetField radio telephone with handset.radios, forests commission victoria (fcv)