Showing 1862 items

matching tests

-

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Booklet, Basil Watson 1893-1971, 2017

This booklet relates the life of Basil Watson. It tells in detail his early life, background, his home built aeroplane, his display flights and his tragic death and the story since. This year marks 100 years since one of Australia’s pioneering aviators, Basil Watson arrived in Warrnambool and delivered the first airmail to the town. Basil Watson was born in Bendigo in 1894. His interest in aviation which began at a young age, took him to England at the commencement of WW1 where he worked at Brookland in aviation workshops and as a test pilot. Despite crashing and suffering injuries he was not deterred. He returned to Australia and by 1916 Basil had built his own plane. He soon took to the air performing tricks and barnstorming to the delight of onlookers. His connection to Warrnambool lies with his delivery of the first airmail to the town, an event which was filled with much excitement. Basil Watson, pioneer aviator landed his 50hp home built aeroplane on the racecourse on Saturday January 27th 1917, after a flight from Point Cook. The trip of 166 miles took just under two hours, and set a record non-stop cross country flight for Australia. Watson was heartily welcomed by the Mayor, to whom he delivered three letters, the first aerial post to Warrnambool. One of the letters, from the Mayor of Melbourne Sir David Hennessy to the Mayor of Warrnambool is now in the W&DHS collection: I have much pleasure in sending you greetings by aeroplane piloted by my friend, Mr Basil Watson. I hope when the cruel war is over and victory crowns our efforts, we, over the Commonwealth, will be able to fly from one State to the other. With best wishes for the New Year. Yours truly, DV Hennessy. Basil Watson was unfortunately killed two months after his historic visit to Warrnambool. While participating in an air show at Point Cook, the plane he way flying that day crashed into the sea. This booklet tells the story of an interesting part of Warrnambool and Australia's aviation history. It has special significance as it enlightens two significant items in our local collection, namely the letter which he delivered and the seat from his aircraft.A small 29 page booklet with blue and white photograph of Basil Watson in his aeroplane. It contains a number of black and white and some colour photographs. Introduction from the author, "This small booklet recognises the short career of Basil Watson. He came to my attention when researching the French aviator Maurice Guillaux who carried the first official air mail in Australia, Melbourne to Sydney in two and a half days 16/18 July 1914..... Tom Lockley 1 June 2017. Handwritten inside front cover,"These items may be of interest to add to your material about Basil Watson. Its a pity that the 100 year anniversary of his flight was not more widely recognised but thank you for mounting some of his records. Tom Hockley."warrnambool, basil watson, first airmail flight, aviation career of basil watson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClocks, 1950

In 1865 James Jones Elliott of 156 Cheapside in the City of London, was apprenticed to a clockmaker"Bateman" of 82 St John Street, Smithfield, London., to learn the art of clock making. Initially, J J Elliott specialized in producing pinions and balance shafts for clocks. He eventually progressed to making, and patenting, a weight-driven movement which had chimes on tubes. This clock was very successful and resulted in considerable trade with America. James Elliott's son, Frank Westcombe Elliott, when he was 17 years old, went into business with his father after his father had bought a partnership with a jeweler called “Walden” of Brompton Road, London. In 1904, JJ Elliott died and Frank succeeded his father in clock making business. In 1909 company of JJ Elliott amalgamated with Grimshaw Baxter, and the factory moved to Grays Inn Lane, London, in 1911, followed by a further move, in 1917, to larger premises in St Ann’s Road, Tottenham, London. In 1921 the partnership with Grimshaw Baxter was dissolved and Frank Elliott joined a well-known firm of Bell Founders and Clockmakers, Gillett and Johnson Ltd, in Croydon. In 1923, two years later, he took over their clock factory and formed the famous company of F.W. Elliott Ltd. He was joined by his two sons, Leonard and Horace Elliott, who had served their apprenticeships in the trade. The third son, Ronald, joined the company in 1929. Elliott's started to produce clocks for the armed forces when war was declared in 1939, together with test gear and apparatus for the Rolls Royce engines used in the RAF planes. In 1944, Frank Elliott died at the age of 69 and Horace Elliott assumed the role of Managing Director. Whilst Horace controlled sales from a showroom in Hatton Garden. In 1952, Horace Elliott was elected Chairman of the British Horological Institute in the same year as Tony, one of Horace's sons, joined the company after he had completed training as a cabinet maker. Ronald Elliott died suddenly in 1966, at the age of 54, his son Peter continued to manage the company until 1998 when it ceased trading. An item that is now regarded as vintage, sought by horology collector’s worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by a well-known British clock manufacture. Its provenance is well established as the serial numbers on the clock indicate it was made in 1950. Production by F.W Elliott for this design of ships clock ceased in 1959. Clock has a gold color case with a 150 mm white painted dial and Roman numerals. The movement has a balance wheel escapement and a slow-fast timekeeping adjuster to the top of the dial. The back of the clock is stamped “made by F W Elliott Ltd of Croydon” and a serial number 21B/829, an additional number 994 is also stamped on the back casing. Thsi model clock finished production in 1959. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, f w elliott, maritime clock -

Uniting Church Archives - Synod of Victoria

Uniting Church Archives - Synod of VictoriaBook - Handbook, Methodist Department of Christian Education, Methodist Order of Knights Commanders' Handbook, 1957

This book with a foreward by Ivan W Alcorn, Governor-General, and an introduction by W K Hocking was prepared by the General Court of Australasia of the Methodist Order of Knights. It has the following chapters: I. Brief history of the order II. Objects, control and organisation III. How to establish a court IV. Order of meeting for Pages' Court V. Merit badge tests VI. Badge presentation service VII. Service of Dedication for Officers VIII. Bibliography The Methodist Order of Knights was the official youth organisation of the Methodist Church of Australasia. It originated in Hurstville, NSW, on the 4th October 1914 by the then Mr and later Rev Alex Bray. Alex Bray was a Sunday School teacher and spoke to his class of the Knights of the Round Table. In 1917 the Order of Knights was officially recognised by the Sunday School Dept of the NSW Methodist Conference. Courts spread thoroughout Australia. In 1927 the High Court of NSW called for designs for a badge and in 1929 the General Conference of the Methodist Church of Australasia recognised the Order as an approved Organisation. In 1938 the Senior Section was organised into Degrees of Sincerity, Service and Sacrifice; the Junior Section into Pages' Degree with advancement to Esquire. In 1954 the Junior Section was reorganised into two groups: Pages 8 to 11 years and Esquires 12 to 15 years. The Knight's Motto: "Live Pure, Speak True, Right Wrong, Follow Christ the King, else wherefore born?" Courts of the Order: General Conference Department of the Christian Education - General Court - Provincial High Court - District Court - Local Court - Senior Court - Intermediate Court - Junior Court . Regalia: All members of the Intermediate and Senior Courts wore regalia consisting of a cloth shield superimposed by a cross of light and dark blue ribbons, and supported by a cloth collar. Esquire and Degree of Sincerity regalia: White collar and white shield. Degree of Service regalia: Green collar and shield. Degree of Sacrifice: Scarlet collar and shield. District Court regalia: Blue collar and gold shield. High Court regalia: Gold collar and purple sheild. General Court regalia: Purple collar and shield. Officers of the local courts wore their symbols as part of their regalia. MOK 239.1 46 page handbook' The cover has the Methodist Order of Knights symbol, 1957. MOK 239.2 has the W.F.Davies D.R.C. written on the top right of the cover. methodist order of knights, ivan w alcorn, w k hocking -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Melbourne Legacy

Melbourne LegacyDocument, History of Legacy 1953 (H18), 1954

A document summarising events significant to Legacy in the year 1953. The coronation of Queen Elizabeth II was a highlight, with Legatee Stan Savige travelling to London to attend as a representative of Legacy (his account of the event is at 01164). 1,200 children attended a rally at the South Melbourne Town Hall to watch films of the life of the Queen, her visit to Canada and the Coronation. (A copy of the programme of this event is at 01163). It was decided that the Intermediate Legacy Club had degenerated into a club without a distinct purpose. They were encouraged to help the Legatees in the senior Club. For instance in the repairs to widow's houses. There is mention of the country clubs with a new club formed in Benalla. Education of Legatees was seen as something that needed to be addressed and a formal induction process with proper training would be necessary. A two page report was included as attachment 'C', which is stored as 01492. Welfare committee had prepared reports with were attached as 'D' but the whereabouts is not known. Camps and holidays. Country clubs would take city children and work had started at Blamey house to clear land for tent sites and country children could have a holiday in the city. The annual conference was held in Brisbane, a general report was attached as 'J' but the whereabouts is not known. Widows - childless and aged widows were identified in the Brisbane conference as needing more attention and a committee was formed to look into it. A report marked 'G' was mentioned but the whereabouts is not known. Dureau House. It was recognised the premises purchased some years before was not suitable as too much renovation was required and should be sold. The original donor, Mr Goldsmith of the B&G Corporation in New York was approached and he agreed the money could be used directly for the widows and children if provision of a headquarters was not important, but the decision was to be up to Legacy to make. The building was sold to Mr Bernard Evans for £57,000. Contact committee reported that the need for contact outstripped the present membership and new members were needed. The dental committee there were issues with payments by the Repatriation Department. The medical committee had decided that children in all classes would be given a Mantoux test for TB. The notation H18 in red pen shows that it was part of the archive project that was trying to capture the history of Legacy. A report covering the main work of Legacy in 1953.White foolscap paper with black type x 4 pages of the history of Legacy in 1953.Handwritten H18 in red pen.history, annual summary -

Melbourne Tram Museum

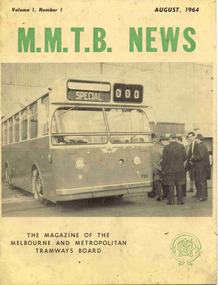

Melbourne Tram MuseumMagazine, K. V. Newmann, MMTB Public Relations Officer, "MMTB News", 1964

Four issues of "MMTB News" - The Magazine of the Melbourne and Metropolitan Tramways Board. Two copies of each issue. 1721.1 - Vol. 1, No. 1 - 16 pages, August 1964, with Bus No. 701 on the front cover. Has articles on; New Buses, Traffic Noise and Trams, Preston Workshops. Cover an cream colour gloss paper, rest of magazine - white gloss paper. 1721.2 - Vol. 1, No. 2 - 16 pages, September 1964, with a photo of a "resilient crossing" on the front cover. Has articles on; MMTB Band, Les Organ - 40 years of service, Tramways Benefit Society, Safety, tram poles, Preston workshops. Cover an cream colour gloss paper, rest of magazine - white gloss paper. Has an obituary for Ron Willingham a member of the band and notes Mr C. Cohen as President and P. Cohen his son is the Secretary. See image i5. 1721.3 - Vol. 1, No. 3 - 16 pages, October 1964, with a photo of part of the training room at Hawthorn depot on the front cover. Has articles on; equipment testing, memories of the cable days, sporting news. Cover an cream colour gloss paper, rest of magazine - white gloss paper. Advised the Clarence Inman constructed the bench mainly in workshop. See image 1721i6 for a handwritten note provided by his son, Kevin Inman. 1721.4 - Vol. 1, No. 4 - 20 pages, November - December 1964, with a colour photo of the new Supervisory control room at Carlton on the front cover. Has articles on; chairman's message, tramway band, Carlton Control - Supervisory Centre, safe electrical working, Christmas celebrations, the old power control centre, a obituary for H. H. Bell, Remembrance day. Printed on gloss white paper.2178.1 has "B706" written in ink on the top of the magazine.trams, tramways, mmtb, carlton control, preston workshops, hawthorn depot, tramway band -

Melbourne Tram Museum

Melbourne Tram MuseumMagazine, Metropolitan Transit Authority (MTA), "Met Lines", 1988

Magazine, published by the Metropolitan Transit Authority of Victoria "Met Lines" (Metlines) - A4, printed on white gloss paper, centre stapled with the MTA logo or symbol. Issued under the name of Kevin Shea as Chairman. Continues from Reg Item 1142 "Met Lines" - printed in an A4 version. Major tram and bus items listed. Tramway names only listed, not railway. .1 - March 1988 - The Pandas car coming! - 20 pages - lists MTA Board, under Minister Jim Kennan; Helen Davison, Jenny Acton, Tony Tuohey, Sybille Kalbitzer, Greg Rodgers, John Usher. Advertising on trams etc, by Australian Posters - contractor, includes a photo of 814 as the Summer in the City tram, Transport Information Centre, launch of St Kilda light rail, photo of test tram 533, Tom Roper, tram 2002. Photo of farewell at Essendon depot. Final W2 - last tram in regular service - 646. .2 - June 1988 - Football theme - 16 pages - Station improvements, Jolimont Decentralisation, advertising the Met (photo for 273), new computer systems, Panamonium - pandas at the Zoo and Z8 painted for the event, new MAN buses - photo of 260. .3 - September 1988 - Uniquely Melbourne theme on the cover, some of the items sold at The Met shop, - 20 - photo of Light Rail vehicle lifting equipment at the workshops with Jack Armstrong and Les Jean, opening of The Met shop, Metrol, kids take a peek at trams (Brunswick depot). .4 - December 1988 - Festival season cover - 20 pages - MAN buses to Elwood, Transport Technology conference, article on the Thornbury Tramway Flyover (the Hump) at Preston Workshops - collisions or accidents on the flyover, tramcar details - submitted by Norm Cross. For next year 1989 - see Reg Item 1184trams, tramways, the met, mta, advertising trams, light rail, st kilda, essendon depot, zoo tram, buses, preston workshops, brunswick depot, the hump, bridges, w2 class, last tram, tram 814, tram 2002, tram 533, tram 2001, tram 8, tram 273, tram 646 -

Federation University Historical Collection

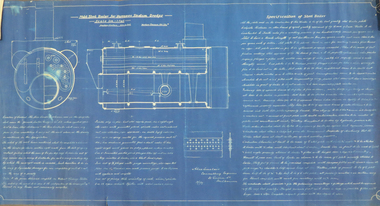

Federation University Historical CollectionPlan, Mild Steel Boiler for Yarrawee Suction Dredge, 16 January 1907

George Milford, a long term staff member of Thompsons Foundry Castlemaine, remembers discussing Alexander Sinclair with this son, Alex Sinclair Jnr. "When Alex Jnr was a boy, his father, a senior design engineer, was sent to Malaya to oversee the erection on site of a suction cutter dredge for Thompsons. This was an adaptation of the idea of a bucket-dredge, where gold is won from alluvial gravels. In the 1915-1920 era, the Thompsons Engineering Department designed a suction-cutter dredge, by which hydraulic suction with a revolving cutter at the end of a long proboscis would collect the alluvial soil and deliver it into the dredge for recovery of the precious metals. Export marketing was then ‘all the go’, and the tin dredges were ordered from Thompsons, using the new cutter design. The dredges were, of course, shipped to Malaya in pieces, ready to be assembled on site. A number of Thompsons employees were selected to travel to Malaya to assemble the dredges. There were fourteen men in the gang. These men sailed on 1st July 1925, their number including Delmenico, McKay and Charles Albert Hauser, an engine driver. C A Hauser died of malaria in Malaya shortly after arrival. Components for a further three of these dredges were in transit or on site when the first suction-cutter dredge was assembled and tested. The designers had failed to take into account the fact that, in the jungle floor in Malaya, many trees grow up, and fall down, in tropical conditions, and become submerged still waterlogged in the floor of the jungle, and in the tin-bearing gravels. The suction-cutter dredge was found to be inefficient in these circumstances, the price of tin had fallen and the Malayan client reneged on the contract. Faced with an outlay of over £4,000 on which no money would be received, the company went bankrupt on 25th August 1925. Alex Sinclair Snr was at that stage in Malaya, and received the news of the bankruptcy by telegram. Upon telegraphing his employers for funds to return home, he received the reply that there were no such funds available. Alex Sinclair Jnr told the story of how his father worked as a labourer in Malaya for two years, while his mother took in washing and ironing during the same period, until together they had assembled enough money to pay for his father’s return Anyone who talks about “the good old days” is talking nonsense!"Large blue printed paper plan outlining the conditions of contract for the making of a steel boiler. The Blueprint includes design drawings and written contract specifying materials, time frame and costs. Signed on front 'Alec Sinclair Consulting Engineer, 31 Queen Street, Melbourne'. Stamped on verso 'Printed by Paterson & Co, Colonial Mutual Chambers, Collins St, Melbourne'. blueprint, designs and plans, yarrawee suction dredge, conditions of contract, thompsons foundry castlemaine, george milford -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1963

The Bocian is a versatile training sailplane that first flew in 1952. The type has been modified in several respects over the course of production by SZD (tailplane and rudder in particular). About 600 have been built; many for export to 27 countries (including Australia). The aerobatic capability and fine performance (best glide ratio of 26) has enabled the Bocian to be used to train competition pilots as well as those of lesser experience. Many world gliding records were set in the 1950s and 1960s in Bocian gliders. The Museum’s example is a type D test flown in Poland on 3 and 4 April 1963. It was imported into Australia in September 1963 by Austerserve Pty Ltd. The first owner was the Alice Springs Gliding Club and the glider had name “Cumulus” painted on the side of the fuselage (since removed). The glider had recorded 726 hours 46 minutes flying time from 2138 launches as at July 1967 when it was transferred to the Darwin Gliding Club. It appears that the glider was damaged in June 1968. The substantial repairs to the fuselage, both wings and tailplane and other minor repairs were completed on 13 October 1968. The glider continued flying with the Darwin Gliding Club until August 1969 at which time the service to that club amounted to 59 hours 7 minutes flying time from 348 flights. Between August 1969 and August 1976 no flights are recorded in the logbook. It is understood that on its last flight at Bachelor, south of Darwin in the Northern Territory (August 1969) it was severely damaged when it crashed after spinning while being auto-tow launched (although this is not expressly mentioned in the logbook). Reg Hancock purchased the damaged glider and rebuilt the port wing and restored it to airworthy condition (September 1976). It was then transferred to Colac, Victoria, and used by the Colac Gliding Group at the Yeo airfield until February 1981, adding another 153 hours from 403 flights to the glider’s record. After airworthy inspection in September 1982 the glider was used by the Geelong Gliding Club until 1983 (logbook details not held). The 20 year survey was then due and the glider fell out of service. In the course of the most recent restoration attempt it was discovered that the glue used in construction had deteriorated and that it was no longer feasible to bring it back to an airworthy condition. Subject to restoration, this exhibit may be representative of the 1950s - 1960s Bocian two seat sailplane typeThis exhibit is a large two seat glider /sailplane of wood and fabric construction. All components are present with the exception of instruments. However, at the time that the aircraft was transferred to the Museum it had been taken apart for major restoration work. As received it is stripped of the top coats of paint and a number of components (including, amongst others, tip fairings, nose cone and cockpit elements) that were removed for facilitating the repair process. The glider, serial number 803, was registered as VH-GNLaustralian gliding, glider, sailplane, bocian, cumulus, alice springs gliding club, darwin gliding club, colac gliding group, geelong gliding club, hancock -

Puffing Billy Railway

Puffing Billy RailwayDH59 - Diesel Hydraulic locomotive (formerly DH 31), 1970

DH31 - DH59 Diesel Hydraulic locomotive Built to 3'6" gauge in 1970 this Diesel Hydraulic locomotive entered service for the Queensland Railways where it remained until withdrawn in 1994. Purchased by the E.T.R.B. in 1995, it was converted to 2'6" gauge in Queensland and transported to Belgrave in 1996 for overhaul. It re-entered service later in 1996, although instead of receiving a V.R. type classification & number and V.R. style livery, it retained its Q.R. number of DH59 and its Q.R. livery minus the Q.R. logo, but has since been repainted the traditional Blue & Gold of V.R. diesel locomotives and reclassified DH31. It has since been returned to DH 59. The DH class was a class of diesel-hydraulic locomotives built by Walkers Limited, Maryborough for Queensland Railways between 1966 and 1974. In 1966 Queensland Railways tested a Walkers Limited built diesel-hydraulic shunting locomotive. This was later purchased and by 1974 the 73 DH class locomotives had taken over shunting duties in most Queensland yards. They were also used on short distance freight services. With the closure of many freight yards and the move to longer trains withdrawals started in the 1980s. Many were sold for further use on Queensland sugar cane railways. Locomotive's Queensland Railways Service History : Locomotive : DH59 Serial No: 646 In Service : 19/05/1970 With drawn from Service : 20/05/1991 LOCOMOTIVE DETAILS DH class No. originally constructed : 74 No. in service : 2 No. stored : Wheel arrangement : Bo-BoDH Roadworthy weight : 40T Maximum axle load : 10T Tractive effort (85%) Length overall: 33' Height overall : 12' 6 1⁄2" Driving wheel diameter : 36" Date of manufacture :1970 Manufacturer :Walkers Place of manufacture : Maryborough, Queensland Locomotive type : Diesel Hydraulic DH Class Type Diesel-Hydraulic Introduced 1966 Number in class 73 Manufacturer Walkers Gauge Narrow (QR, MIM) 900mm (SECV) Axles B-B Length 11.1 m Mass 37 t Engine Caterpillar D355E Transmission Voith L42U2 Power 347 kW / 465 HP Tractive effort 114 / 82 kN Speed 50 / 10 km/hHistoric - Queensland Railways - Diesel Hydraulic locomotive DH59DH59 Diesel Hydraulic locomotive made of steel and metalDH59 Diesel Hydraulic locomotivepuffing billy, diesel-hydraulic locomotive, dh59, dh31, walkers diesel hydraulic, queensland railways -

Puffing Billy Railway

Puffing Billy RailwayDH 5 - Diesel Hydraulic locomotive, 1968

DH5 Diesel Hydraulic locomotive The DH class was a class of diesel-hydraulic locomotives built by Walkers Limited, Maryborough for Queensland Railways between 1966 and 1974. In 1966 Queensland Railways tested a Walkers Limited built diesel-hydraulic shunting locomotive. This was later purchased and by 1974 the 73 DH class locomotives had taken over shunting duties in most Queensland yards. They were also used on short distance freight services. With the closure of many freight yards and the move to longer trains withdrawals started in the 1980s. Many were sold for further use on Queensland sugar cane railways. Locomotive's Queensland Railways Service History : Locomotive : DH5 Serial No: 587 In Service : 27/08/1968 With drawn from Service : 7/07/1992 LOCOMOTIVE DETAILS DH class No. originally constructed : 74 No. in service : 2 No. stored : Wheel arrangement : Bo-BoDH Roadworthy weight : 40T Maximum axle load : 10T Tractive effort (85%) Length overall: 33' Height overall : 12' 6 1⁄2" Driving wheel diameter : 36" Date of manufacture :1970 Manufacturer :Walkers Place of manufacture : Maryborough, Queensland Locomotive type : Diesel Hydraulic DESCRIPTION - B-B DH FORMER CLASS AND NUMBER - 8/1968 Built By - Walkers, Maryborough, Queensland Service History Date built - 1968 Original owner - Queensland Government Railways Original gauge - 1067mm Withdrawn - Next owner - State Electricity Commission of Victoria DH5 8/1968 Sold to SECV as CC2, In service 8-1993 Sold to Mackay Sugar CC02 (Ex DH5). CC02 was purchased by Cooks Construction in 1992 and used on the 900mm Yallourn railway in Victoria. Mackay Sugar purchased in 2001. Title Value Status Preserved - Operational Gauge Narrow 2ft 6in (762mm) Owners Puffing Billy Railway Operators Puffing Billy Railway Manufacturer Walkers Ltd - Maryborough, Queensland Builders number 587 Associated locos Renumbered from CC02 Liveries carried VR Blue & Gold Puffing Billy Service History or Notes Date acquired - 2008 Acquired from - Mackay Sugar Mill ? State when acquired - Operational ? Work done - Regauged, overhauled Restored to service - Current State - Operational Historic - Queensland Railways - Diesel Hydraulic locomotive DH5DH 5 Diesel Hydraulic locomotive made of steel and metalDH 5puffing billy railway, dh5, locomotive, cc02, diesel,, queensland railways, diesel hydraulic locomotive dh5, walkers diesel hydraulic -

Melton City Libraries

Melton City LibrariesPhotograph, Ian and Wendy with Grandma Barrie, c.1943

Jessie May born on 30th November 1883, Jessie, known as Ma Barrie to her grandchildren, was the daughter of schoolteacher, Thomas John Lang and Mary Elizabeth Coates. In 1896 Thomas and Mary Elizabeth moved to Melton. Mr Lang’s previous school was Coliban SS No 1920. Mr Lang was the Head Teacher at Melton until 1917. In 1910 he was a Committee Member Melton Mechanics Institute and Public Library at its establishment. He was a Life Member of the Melton Mechanics Institute Jessie lived in various locations around Central Victoria, particularly Pastoria and Melton. When her father was Head Teacher at Melton State School no 430, she met her future husband, Charles Ernest Barrie. The couple were married at the Methodist Church Melton on the 23rd August in 1906. They lived in the newly built house beside the Chaff Mill on the corner of Station and Brooklyn Road Melton South. Their eldest child was Mary Ena was born on the 7th of October 1907. IN 1909, Ernest Wesley (Bonnie) was born 29th April (Ascot Vale). In 1910 the family moved to a farm in Trundle NSW. The Chaff Mill was sold to Glover Onians – HSK Ward. Later the original mill was burnt and replaced, and in 1977 a fire destroyed it again and it was not rebuilt. In 1911, the family returned to Melton buying the “Darlingsford” farm in May. The weather was too at Trundle for Jessie. Their address was Elizabeth Street Moonee Ponds. William Cecil was born on the 23rd of February 1912 and Charles Edgar was born on 1st June 1913. In 1916 they lived in Moonee Ponds where the children attend Bank Street School, Ascot Vale. The children developed diphtheria Mary and Bon were transferred to Fairfield Hospital. March 1919 the family returned to live at Melton at the time of the outbreak of the Spanish influenza. Mary, Bon, and Edgar returned to Melton School. Following the death of CEB in a car accident in 1931 she was left to bring up her children on her own; the youngest Jim, aged 9 and eldest Mary, aged 24. Jessie left ‘Darlingsford’ in 1946 when her sons had safely returned from WW II. She stayed at Yarram for a time where her married twin daughters lived when more grandchildren were born and spent the remainder of her life living with various family members. SUMMARY - Dr Ian Robinson OAM Born 26th June 1931 Parents – Keith John Robinson of “Creighton” Melton Mary nee Barrie of “Darlingsford” Melton The family lived at “Heatherdale” Toolern Vale. Their 3 children, Ian the first followed by daughters, Ena May and Mary Elizabeth (Beth) Ian and Ena attended Toolern Vale State School. No 946 The family later moved to Columban Ave Strathmore. During 1942 the children stayed their grandmother’s house at “Darlingsford” Melton. They enrolled at Melton State School No 430 on the 13/3/42 after attending State School No 483 Raleigh Street Essendon. They left Melton School on the 31/7/42 returning to Essendon. Ian attended Geelong College as a boarder after completing his schooling he entered University to study Medicine. His early General Practice was in Melbourne. In 1972 he joined the Royal Flying Doctor at Mount Isa, North West Region of Queensland. The region covered an area larger than the British Isles. He was on call 24 hours for emergencies. He spent three weeks away with calls and in the fourth week attended Aboriginal Reserves. Ian took two Queensland Governors and their wives to spend three nights at the Clinic. Sir Colin and Lady Hannah are still their friends. Area Co-ordinator Ian was awarded the Royal Humane Society Medal along with his pilot when they risked their lives landing on flooded land to save a patient. Ian remained a loyal contributor to the Royal Flying Doctor Service until 1997 He met Queen Elizabeth 2nd in Cairns, and also met Prince Phillip and Prince Andrew in Brisbane. Townsville – Locum Beenleigh – General Practice Open 7 Days 198? -2002 Aspects of his work covered the following – Police Work State Commonwealth Medical Officer TEYS COMPANY Q FEVER. Q Fever presents with flu like symptoms. The 1st Test always came back Negative BUT 2nd Test always positive. Ian lectured other Medicos re Q Fever Council Immunization in schools Covered boxing bouts Large Practice In 2002 Ian retired but continued house calls for older patients. Information from Anne to Beth received by Wendy October 2013 Wendy Elizabeth Barrie Jessie May Lang [Barrie] and Ian Keith Robinson standing in front of a carlocal identities -

Federation University Art Collection

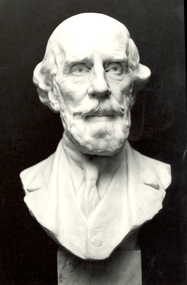

Federation University Art CollectionSculpture - Marble sculpture, 'Professor Alfred Mica Smith' by Paul Montford, 1924

Paul Raphael MONTFORD (1868 - 1938) Paul Montford moved to Australia to carve four buttress groups in granite for the Melbourne Shrine of Remembrance. In 1924 he was teaching at Geelong Technical College. Professor Alfred Mica Smith was a long term lecturer at the Ballarat School of Mines. The sculpture was commissioned by former Students of the Ballarat School of Mines working in Western Australia. One of those former students, William Corbould, remembered his first encounter with the professor fondly:- 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' Alfred Mica Smith was the well-loved Professor of Chemistry and Metallurgy at the Ballarat School of Mines between 1881 and 1922. Upon reaching the age of 78 Mica Smith retired having influenced generations of miners. At the time of his death Ballarat School of Mines Students’ Magazine reported: "In the annals of the School, the year 1922 will be noted chiefly as the last year in which Professor Mica Smith taught here. With his retirement, a memorable epoch closed. The Professor has served the School for 42 years with a service, the length and thoroughness of which are unique. … It is not quite realised in this city how famous the School became throughout the world, nor to what extent the Professor was responsible for its high position in the mining and metallurgical world. … This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Marble bust of Ballarat School of Mines Professor Alfred Mica Smith by Paul Montford. The bust is mounted on a jarrah pedestal made from timber donated by the Millar Timber and Trading Company. The bust was formally presented to the Ballarat School of Mines on Saturday 13 December1924 in front of Alfred Mica Smith and a large gathering. It is signed 'Paul R. Montford, Sc, 1924' at the back.Professor A. Mica Smith, 1924, Presented by His Old Students Associated with Western Australia as a Token of Affectionate Esteemart, artwork, ballarat school of mines, montford, paul montford, alfred mica smith, mica smith, marble, bust, sculpture -

Melbourne Tram Museum

Melbourne Tram MuseumAlbum - Geoff Grant Photos, Geoff Grant, mid 1950s

Photo - see pdf file for further information. Number Brief Description GAG1 51 Sandringham GAG2 50 Sandringham GAG3 50 side Sandringham GAG4 Depot Sandringham_ GAG5 426 Camberwell Depot GAG6 822 St Kilda Rd GAG7 496 St Kilda Rd GAG8 347 Caulfield GAG9 440 Princes Bridge GAG10 190 Camberwell GAG11 190 Camberwell GAG12 Ys Camberwell GAG13 Interior Camberwell Depot GAG14 921 Camberwell GAG15 613 Camberwell Depot GAG16 613 front Camberwell Depot GAG17 887 Bourke St opening_ GAG18 888 Victoria St North Richmond GAG19 888 Victoria Pde GAG20 888 887 Malvern Depot GAG21 888 887 Malvern Depot GAG22 888 Victoria Pde GAG23 1033 North Fitzroy Depot GAG24 957 1033 Bourke St GAG25 1033 Nicholson St East Brunswick GAG26 1001 East Preston Depot GAG27 980 East Preston Depot GAG28 980 Dandenong Rd GAG29 Tower wagons Bourke St at Swanston St GAG30 Tower wagons Nicholson St GAG31 988 tower wagons Nicholson St GAG32 988 tower wagons Bourke St at Russell St GAG33 Albion Tower wagon Clifton Hill GAG34 988 tower wagon Bourke St at Russell St GAG35 988 East Preston Depot GAG36 Cleaner 7 Bourke St GAG37 988 turning from Nicholson St into Victoria Pde GAG38 991 Bourke St GAG39 View down Bourke St from 988 GAG40 988 Nicholson St GAG41 988 Smith St GAG42 988 High St GAG43 988 testing overhead Bourke St GAG44 1003 Nicholson St into Gertrude St GAG45 988 Clifton Hill GAG46 988 Nicholson St GAG47 988 1003 Nicholson St GAG48 988 Bourke St looking west from Elizabeth St GAG49 988 Bourke St looking east from Swanston St GAG50 988 1003 and tower wagons Nicholson St GAG51 988 Clifton Hill GAG52 988 East Preston Depot GAG53 190 Etched saloon door window Yields infomation about VR Tramways, Bourke Street trams and AETA tours. Geoff Grant was a Herald Sun photographer.Assembled album in a black presentation folder of 53 photographs from the Geoff Grant Collection - 27 sleeves All photographs have been scanned and placed on the Museum's G drive. A list of all photographs with details where possible has been compiled. tramways, trams, sandingham, camberwell depot, bourke st, new tramways, tower wagons, tours, victoria parade, east preston, aeta tours -

Victorian Aboriginal Corporation for Languages

Victorian Aboriginal Corporation for LanguagesBook, Native Title Research Unit AIATSIS, Proof and management of native title : summary of proceedings of a workshop : conducted by the Native Titles Research Unit, Australian Institute of Aboriginal and Torres Strait Islander Studies at University House, Canberra 31 January - 1 February 1994, 1994

Introduction - Jim Fingleton - Outlines history and problem aspects to do with the formulation of the Native Title Act 1993 and subsidiary /? consultative bodies (eg National Native Title Tribunal and Regulations; Native Title Implementation Task Force); Note: Talks &? discussion papers annotated separately by author/?title/?workshop title; SESSION GROUP DISCUSSIONS ONLY annotated here; First Session: Claims - Matters raised in discussion - timing; restraining orders; requirement for claim acceptance; researching claims; disputes; representative bodies; native title /? compensation claims; Second Session: Hearings - "Main matters raised in discussion" - 1.gender issue in hearings; 2.subjective /? objective tests of native title; 3.use of maps; 4.practice directions; 5. mediation; 6. what precision is needed to prove ownership; Third Session: Determinations - "Matters raised in discussion" - 1.what is a community; 2.the legal process for proof of communal title(i-iv); Fourth Session: New Management Regimes - Main matters raised in discussion - 1. need for new development models; 2. need for new administrative models; 3. is self-sufficiency a realistic goal; 4. actve/?passive income; 5. direct funding of Indigenous bodies; 6. towards self-government; Fifth Session: New Management Decisions - Main matters raised in discussion - 1. different models for money management; 2. local government laws and native title; 3. restrictions on the enjoyment of native title rights; 4. need for flexibility in investigating native title; Sixth Session: Conclusions and Recommendations - Papers as requested; discussion; Main New Matters raised by panel in discussion - 1. recommendations from the Aboriginal caucus; 2. requirements for an application; 3. issues for funding; 4. role of representative bodies; 5. double dipping; 6. role of AIATSIS; 7. trustees or agents; 8. land management issues; Annexes: annotated separately under author /? title.tablesnative title, land tenure -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Scale and weights, 1860-1900

The subject item was made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broaden the renown of the Avery brand and transform the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix.An item used by grocers and merchants throughout the then British colonies of England to weigh store-bought goods around the mid to late 19th century. This item gives an insight into the daily lives of early colonial settlers and is a significant part of the era’s social history of the time.Balance scale and weights with removable dish, two round weights glued to tray 4oz and 8oz. Scales 'to weigh up to 28lb. Printed in gold on black labels each side "W & T AVERY LTD", "BIRMINGHAM" warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scale and weights, food preparation equipment, w t avery ltd, balance scale, grocers scales, james ford, william & thomas avery, birmingham uk -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Standard avoirdupois weights, Avery Ltd, 1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weights, metal, silver electroplated, 1 x 2lb, 2 x 4lb, 1 x 7lb. (4) all government stamped, made by Avery Ltd.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, imperial weight, imperial standard weights and measures, imperial standard weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Weight Avoirdupois, Avery Ltd, 1940-1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weight, brass, Stamped F27, 2lb.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, brass weight -

Wodonga & District Historical Society Inc

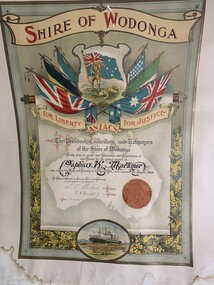

Wodonga & District Historical Society IncCertificate - Captain Kenneth Mortimer, D. W. Paterson Co. Pty. Ltd. Print, 1918

Kenneth Malcolm Mortimer was born in Leneva, Wodonga, Victoria on 9 October 1895. He attended school in Wangaratta before entering the Royal Military College, Duntroon in 1913. Along with the rest of his class, he graduated in June 1915. Mortimer was appointed as a Lieutenant with the 29th Battalion on 1 July 1915. He embarked with Headquarters Staff, 29th Battalion, from Melbourne aboard HMAT Ascanuis (A11) on 10 November 1915. Whilst training in Egypt in February 1916, he was promoted to Captain. He was in command of a company of the 29th Battalion at Fromelles, Armentieres, France in July 1916. and was reported missing, presumed killed in action on 20 July 1916, aged 20 years. Mortimer’s remains were buried along with those of hundreds of others in a mass grave near Pheasant Wood, close to the battlefield. This mass grave was rediscovered in 2008. After extensive research and DNA testing, the remains of Captain Mortimer were finally identified in April 2018. He was buried in the Commonwealth War Graves Commission Cemetery at Fromelles and his grave rededicated on July 19, 2018, 102 years after his death. A memorial tablet was erected to his memory at St Luke’s Church in Wodonga. Honour Certificates WW1 - From 1915 onwards, recruits in many shires and towns in eastern Australia were honoured by local government authorities. A common form of recognition was the award of honour certificates. The first honour certificates were presented in 1915 and 1916 to men who had yet to leave Australia. The designers and publishing companies solicited business directly from councils. Publishers began to print two different types of certificates: honour certificates to thank soldiers who had survived and memorial certificates to commemorate the dead. D.W. Paterson, a Melbourne publishing firm, claimed they had supplied certificates to over 150 cities and shires in Victoria and New South Wales, including the Shire of Wodonga. Paterson also had the widest range of designs The certificate signified that the officials of the community recognised and shared the family's pride and grief. In the earliest designs, the legend "Australia's sons answered the call" appears below the shield. This was replaced with "For Liberty/ ANZACs/ For Justice". After the United States entered the war in April 1917, the design was reworked to include the US flag. Its presence in this certificate dates its publication as late 1917. The certificate was signed by S. T Parker, Shire President and R. H. Murphy, Council Secretary on 4th August 1918. Kenneth Malcolm Mortimer was born in Leneva, Wodonga and enlisted in the AIF after training at Duntroon. He fought and died at the Battle of Fromelles, France which was the first major engagement of the AIF on the Western Front. Along with hundreds of other Australian soldiers his remains were only identified in 2018, more than 100 years after the battle.Coloured certificate presented to the family of Captain K Mortimer by Wodonga Shire Council.29th battalion, mortimer, leneva, fromelles, aif, wodonga shire, honour certificates ww1 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century