Showing 142 items matching " food manufacturing"

-

Kew Historical Society Inc

Kew Historical Society IncContainer - Doll's House Biscuit tin, Macfarlane Lang, 1930s

James Lang opened a shop and bakery in Gallowgate in 1817. His nephew, John Macfarlane, joined the business and took over when James died. A new bread factory was built at Wesleyan Street in Calton in 1880. The firm decided to move into machine-made biscuit manufacturing and opened the Victoria Biscuit Works on an adjoining site in 1886. Expansion to London followed, with the opening of the Imperial Biscuit Works in Fulham in 1903. In 1925 a new Victoria Biscuit Works with modern equipment was opened in Tollcross. Macfarlane Lang joined with other biscuit manufacturers to form United Biscuits in 1948. United Biscuits has since expanded to become one of Britain's leading food suppliers, and the Tollcross factory remains a major employer in Glasgow's East End at the beginning of the 21st century.Lidded biscuit tine decorated with an image of a doll's house on the lid. The manufacturer Macfarlane lang is inscribed on one Sid eof the box.biscuit tins, biscuit companies, containers -

Beechworth Honey Archive

Beechworth Honey ArchiveHoney Tin

This tin holds 60 pounds of honey. All honey used to be stored and transported in tins, manufactured to industry standards. The tins were eventually replaced by 44 gallon drums, which would hold 300 Kg of honey. Now, plastic food-grade pallecons are used; they hold 1500 Kg.Four gallon honey tin. Metal, rectangular tin. Rusted. Small handle on top. Circular hole in corner on top.four, gallon, honey, tin, beechworth honey -

Beechworth Honey Archive

Beechworth Honey ArchiveHoney Tin

This tin holds 60 pounds of honey. All honey used to be stored and transported in tins, manufactured to industry standards. The tins were eventually replaced by 44 gallon drums, which would hold 300 Kg of honey. Now, plastic food-grade pallecons are used; they hold 1500 Kg.Four gallon honey tin. Metal, rectangular tin. Rusted. Small handle on top. Circular hole in corner on top.four, gallon, honey, tin, beechworth honey -

Brighton Historical Society

Brighton Historical SocietyShoes, circa 1880s - mid 20th century

A pair of shoes worn by a Presentation nun at Star of the Sea Convent, Gardenvale. The history of the shoes is unknown; nuns working in the convent's archive found them stored among convent records, and subsequently donated them to Brighton Historical Society. The Presentation Sisters, a Catholic order originating from Ireland, founded the Star of the Sea Convent in Gardenvale in 1883. Led by Mother Paul Fay and Mother John Byrne, they established a convent and school in a house called Turret Lodge, on the site of the present Star of the Sea College in Martin Street. The order and the school remain active in Brighton today. Foy & Gibson was one of Australia's earliest department store chains. Based in Collingwood, from 1883 until the mid-twentieth century they manufactured and sold a large range of goods, including clothing, manchester, leather goods, soft furnishings, furniture, hardware and food.Pair of black leather women's lace-up shoes with a low heel.Interior label: "COMFORT / FOY & GIBSON PTY LTD / COLLINGWOOD"shoes, nuns, foy & gibson, presentation sisters, star of the sea convent -

Port Fairy Historical Society Museum and Archives

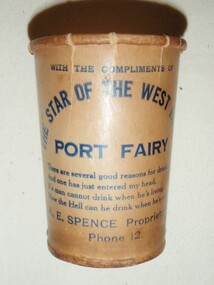

Port Fairy Historical Society Museum and ArchivesContainer - Cup, c. 1930

These paper cups were given to patrons of the The Star of the West Hotel Cnr, Bank and Sackville Streets during the time A.E.Spence was proprietess.waxed paper disposable cup, manufactured for Star of The West Hotel: White waxed paper with coloured letteringWith the compliments of the Star of The West Hotel Port Fairy "There are several good reasons for drinking, and one has just entered my head, if a man cannot drink when he's living, how the hell can he drink when he's dead. A.E.Spence. Proprietress Phone 12local history, domestic items, food & drink consumption, a.e.spence -

Port Fairy Historical Society Museum and Archives

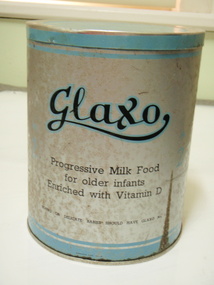

Port Fairy Historical Society Museum and ArchivesContainer - Tin, Glaxo Laboratories, 1930's

Glaxo's Port Fairy Factory was built in 1929 as a milk factory it had a tin shop where the tins were manufactured and the milk was dried and sold as some of the first formula milk for babieslarge tin with printed information "Glaxo" progressive milk food for older infants enriched with Vitamin D Blue bands and silverGlaxo Progressive milk food for older infants enriched with Vitamin D Young or delicate babies should have Glaxo No 1. Table of quantities and directions for useglaxo, factory, princes highway, manufacturer, milk, baby food -

Wodonga & District Historical Society Inc

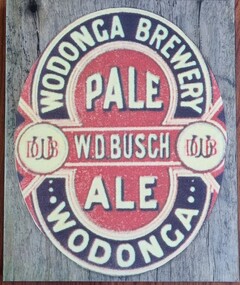

Wodonga & District Historical Society IncPoster - Poster Wodonga Brewery, 1889

The Wodonga Brewery was established in Hume Street (now Church Street) Although relatively short lived the brewery had many changes of ownership. D. Hallahan commenced brewing in 1888. On the Fri 4 Jan 1889 Wodonga and Towong Sentinel announced that the Wodonga Brewery had been taken over by D. Clark of Melbourne. By Fri 27 Sep 1889 the proprietor was advertised as W. D. Busch. However, the Wodonga Brewery was sold at auction on Busch’s behalf on 25 Jan 1890. The entire property was knocked down to Mr Louis Wenkelmann, of Jindera, for £500. The brewery was again sold to Patrick Flanagan in 1891. In 1895 Flanagan rented the brewery to the partnership of J. R. Martin and A. Wilcox. When the partnership was dissolved in January 1896, Patrick Flanagan continued to operate the brewery. In September 1905 the Fresh Food and Frozen Storage Company of Melbourne announced that they had secured the old Brewery Buildings in Hume Street, Wodonga to establish a cream receiving depot. In November 1922 tenders were called for the removal of the Old Brewery buildings.This poster is of local significance as it advertises and early business in Wodonga.A coloured poster advertising Wodonga Brewery printed in black, red and white. It has a wood print background and has been mounted on board to protect it.Around the central name: "WODONGA BREWERY/ WODONGA" In the red section: "PALE / W.D. BUSCH/ALE" On either side inside circle: "WDB"wodonga brewery, w. d. busch, manufacturing industries wodonga -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Ceramic pie Funnel, Thomas M. Nutbrown, c1930

A ceramic pie funnel was a hollow ceramic tool that bakers and home cooks placed in the centre of pies to prevent the contents bubbling over. The hollow core allowed steam to escape during baking leaving the pie crust as light and flaky inside as on the surface. They came in a variety of shapes and sizes. This pie funnel was produced by Thomas M Nutbrown who started manufacturing kitchenware in 1927 from his factory on Walker Street, Blackpool. He registered the company in 1932 and over the following years his company was exporting goods all over the world. His company pioneered many unseen kitchen gadgets and utensils onto the market and had many products patented. The company closed in 1988.This item was typical of kitchenware used widely in the early twentieth century when a broader range of food items were home cooked.A ceramic pie funnel in the shape of an elephant. This is marked “NUTBROWN PIE FUNNEL Made in England” and was made by a company called Thomas M. Nutbrown Ltd of Blackpool. It also has a registered design number which is a little indistinct but is probably No 860928. It dates from the 1930’s and is in very good condition.On side of elephant in black ink "NUTBROWN/ PIE FUNNEL/ Made in England/ Reg. No 860928"domestic appliances, pie funnel, kitchenware early 20th century -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Dazey Churn, 1922

In the early 1900's, E.B. Jones developed a small glass churn for home use. Nathan Dazey purchased Jones' business and relocated it to St. Louis, Missouri as the Dazey Churn and Manufacturing Co. Dazey churns were manufactured up until 1945. Although best known for its butter churns, the company also made can openers, knife sharpeners and other kitchen products. Thes churns were widely used throughout households in rural Australia during the first half of the 20th century.This item was typical of kitchenware used widely in the early twentieth century when households produced more basic food items. A round glass churn with metal lid and mechanism. The handle was turned to rotate the paddle at the base of the mechanism in the jar. The jar holds 2 quarts of milk.The embossed Jar lettering is as follows: DAZEY CHURN No. 20 Patented February 12,1922 DAZEY CHURN & MFG. CO. ST. LOUIS, MO. MADE IN U.S.A.domestic appliances, kitchen appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Meat mincer / Food chopper

The Universal Food Chopper was a common domestic item internationally and throughout Australia. It was manufactured by the Landers, Frary & Clark company ( L.F. &C.). It was first sold in 1897, and proved to be so popular that the company still featured it in their catalogue sixty years later. It was marketed as a device that not only ground meat, but also processed vegetables. The number 2 on the device referred to the size of the grinder, with the 3 model being the largest for heavy-duty use and the 00 model the smallest. This appliance was a common domestic item used throughout AustraliaA cast iron and wood domestic appliance. The food chopper has a large screw on the base which allowed it to be anchored to a table or work bench. Food items were placed in the the cavity at the top and the user wound the handle to force the food through the blade. Different attachments allowed adjustments to the size the food was chopped.On Side 1: Pat. Oct.12, 1897/ Apr. 18, 1899/ Re Sept. 5, 1899 On Side 2 : LF & Co. /New Britain / CONN USA / No 2/ UNIVERSAL FOOD CHOPPERfood chopper, kitchen appliances, food preparation -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - A collection of assorted stoneware and ceramic canisters

Stoneware or pottery canisters were widely used throughout the late 19th and early 20th centuries for storing and preserving a wide range of kitchen food ingredients. Bendigo Pottery was established in 1858 and is Victoria's oldest working pottery. It was founded by George Duncan Guthrie (1828–1910) who abandoned his potter’s wheel in Scotland to join the Australian gold rush. He found a clay deposit perfectly suited for the production of ceramics, so returned to his former profession as a master potter. The population explosion created by the Australian gold rush resulted in an increased demand for all kinds of locally manufactured goods. The Bendigo Pottery became one of regional Victoria’s most important industrial enterprises. By the late 1800s the Pottery was making all kinds of household wares. One of its most popular lines was the mass produced, affordable and functional earthenware such as these canisters.These items are significant on a state and national level due to the importance of Bendigo pottery as a major Victorian manufacturer whose products were widely used in Australian homes.A group of 3 stoneware and ceramic canisters of assorted sizes. The tallest canister bears the Bendigo Pottery makers mark. The flour canister with the lid and the third canister are unmarked. Similar canister were produced by several companies in the early to mid 20th century. They were commonly used for storing flour, salt and other commodities.At bottom of largest canister "BENDIGO POTTERY" above straight linebendigo pottery, earthernware, kitchen utensils -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Rib Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale rib bone with advanced stage of calcification as indicated by brittleness. None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Linton and District Historical Society Inc

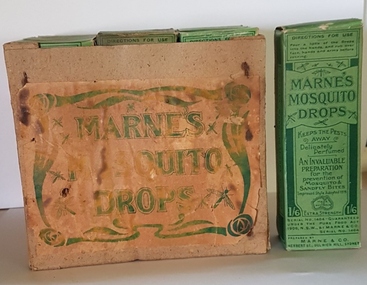

Linton and District Historical Society IncMosquito drops, Marne & Co. Herbert St., Dulwich Hill, Sydney, N.S.W, Marne's Mosquito Drops, 1919

Found in the cellar of the former Barr's drapery shop, Sussex Street, Linton, which at one time had a doctor's consulting room. Bob Albert (who found them) assumed they were something to do with the medical practice. He gave the box of mosquito drops to Joan and Alan Giles. Information in newspaper advertising (found via Trove) shows the drops were marketed in New South Wales, Queensland and South Australia between about 1915 and 1927. The address on the packaging suggests these particular bottles were manufactured after 1918.Twelve green boxes labelled 'Marne's Mosquito Drops', stored in a strong cardboard box bearing a green label, also reading 'Marne's Mosquito Drops'. Information on individual cardboard packaging: "Marne & Co., Herbert St, Dulwich Hill, NSW / Registered under the Pure Food Act 1908 / Improved Formula 1919".marne's mosquito drops, pest control, mosquito drops -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Vertebrae, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Whalebone The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The bone of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as whalebone. Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale bone Vertebrae with advanced stage of calcification as indicated by deep pitting. Off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Jaw Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale jaw bone one side, long & curved with advanced stage of calcification off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Meat Safe known as a "Coolgardie Safe", Early 1900s

The Coolgardie safe was invented in the late 1890s on the Western Australian goldfields. Its invention was credited to a local contractor named Arthur Patrick McCormick. It was a practical system to preserve food prior to modern refrigeration. The wire grid kept the food safe from vermin and allowed breeze to blow through. It was often covered with wet hessian so that as the breeze circulated the water evaporated, creating the same concept as coolant in modern refrigerators and ice boxes. In most respects it was a variation of the bushman’s hessian bag hanging in a tree. In larger towns and cities during this time period large "ice works" could deliver block ice to areas that required a form of refrigeration. These ice blocks where held in early refrigerators to keep perishables cool. In isolated or rural households, the Coolgardie or meat safe was the next best, practical solution for food preservation. This safe was used in the home of the Conway family in Wodonga.This item is very significant to the Wodonga region as it represents the initiative and problem solving skills of the early settlers. It also reflects the primitive conditions in which they lived before the arrival of more modern services such as electricity.Meat safe or Coolgardie safe manufactured in Australia. This safe is made from metal and has been painted in green paint. 2 sides of the safe have a pattern of 6 squares of holes to allow for ventilation and air flow. The holes would also guard against insects and other vermin. There is one shelf inside, dividing it into 2 sections. The safe has a hook attached so that it can be suspended, often from a tree or on a verandah to increase air flow. The safe would often be covered by wet hessian to promote further cooling and preservation of foods such as milk, butter and meat.coolgardie safe, food preservation, pioneers innovation -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Small Butter Churn, E. Cherry & Sons, c1880 - 1920

North east Victoria was a major dairy producing region in the late nineteenth century. The Wodonga Butter Factory Ltd was established in 1892. Many families living in the town or on farms also owned their own cow for family needs and produced their milk and butter. This churn is representative of the equipment they used to process their own dairy products at home. This churn was made by E. Cherry & Sons which was established in Gisborne, Victoria in 1858. Edward Cherry (1830-1910) arrived in Australia from Hertfordshire, England, in 1855. The business manufactured churns and in 1875 opened a larger factory. On his death, the business was taken over by his son and continued to operate until the 1970s.This item has strong links to the history of Wodonga and north east Victoria. It has interpretative potential in the areas of local agricultural history, and the social history of food and farming.A wooden butter churn with metal turning handle and removable lid. The wooden paddle inside is attached to the turning handle which rotates to churn the butter. The model number is T1. It was probably made by E Cherry & Sons of Gisborne although the brand is blurred.On one side in black: "T 1"butter churns, dairying industry, domestic appliances, e. cherry churns -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Teapot, c1927

Belonged to the step-mother of Ray Standfield, husband of donor.The Robur Tea Company issued vouchers/coupons on packets of tea that could be collected and exchanged for the tea-pot when enough coupons had been saved.A round squat silverplated Robur teapot containing a fitted round cup shaped strainer with hinged pull for removal.S475 PERFECT TEA-POT, MANUFACTURED BY ROBUR TEA CO LTD. PATENTED AUS 10373. 14-11-27 NZ59615 U.S AF 816-28 EPNSdomestic items, food & drink consumption -

Mont De Lancey

Mont De LanceyDomestic object - Coffee grinder, Japy Frere's & Co, c 1850 - 1930

Many people used their spice grinders or a mortar and pestle to grind the roasted beans into a powder. Japy Freres & Co were mostly known as watch and clock movement makers, they also manufactured coffee grinders. The company ceased in the 1930s. A square wooden and metal antique hand operated French coffee grinder mill, manufactured by Japy Freres & Co (Beaucourt Paris, France). The grinder has a wooden body and an iron lid and mechanism with a metal turning handle and knob. The metal top is attached by screws. It has a broken brass knob on the pull out wooden drawer below. The moveable lid allows the beans to be poured into the funnel to be ground by the internal mechanism.'Japy Freres & Co B.E. S.C.D.G.' is stamped on a brass plate at the front top of the grinder attached by two screws.coffee grinders, coffee accessories, coffee, food processing equipment, kitchen equipment -

Clunes Museum

Clunes MuseumDomestic object - BOTTLE, EBERHARD & CO., CLUNES

RASPBERRY VINEGAR AND OTHER SOFT DRINKS MADE IN CLUNES BY EBERHARD & CO. CORDIAL MAKERS.FLAVOURED CORDIAL BOTTLE: FLAVOURED RASPBERRY VINEGAR MANUFACTURED BY EBERHARD & CO. CLUNES.FLAVOURED CORDIAL - TRADE MARK FLAVOURED RASPBERRY VINEGAR EBERHARD & CO.local history, food technology, bottling, eberhard & co. -

Hume City Civic Collection

Hume City Civic CollectionContainer - Tin, Sunshine Milk

Powdered milk was sod in cans before plastic packaging was introduced. The Nestle Company manufactured the Sunshine powdered milk in Australia and was made from full cream pasteurised milk which had the water content removed from it this would then allow the tins of powdered milk to be transported without refrigeration. The powdered milk could then be made up by adding water at the recommended quantities as per directions on the labels.A white, and green paper covered rusty tin. The front of the label is printed in black advertising Sunshine full cream milk powder. The back has recipes printed on it.Nestle/SUNSHINE/milk/FULL CREAM MILK POWDER/NET 3LB - AUSTRALIAsocial history, cooking, domestic food and drink, milk products, powdered milk, george evans collection