Showing 372 items

matching water glass

-

Ringwood and District Historical Society

Ringwood and District Historical SocietyLetter, Property for sale - Ringwood Shop and Dwelling Estate, Ringwood, Victoria - circa 1925

ID 5225 note: Further information relating to allotments marked on the hand-drawn plan are included in ID 5224 - Ringwood Station Estate.Typewritten letter from A.V. Greenwood with hand drawn plan of Ringwood Shop and Dwelling Estate, detailed description of property for sale, and top and side elevation views of house. (7 pages)(Transcript of first page - to unknown recipient) Phone 988 Central, 331 Canty Greenwood Pty. Ltd. 5 Flinders Street Melbourne. Dear Sir, 1. Attached please find drawings of my house at Ringwood. 2. It is for sale at £4,865 or to let at £5 per week to an approved tenant. 3. I sold it to Mr. De Garis and vacated it, but it is now back on my hands. 4. I leased another place instead of living in my own. I may be able to cancel same; in the meantime, however, I propose to sell or let my own. The painters are now going through the place; re-varnishing, re-oiling and re-polishing so that in about five days it will look "spick and span". 5. The house was specially built under my own supervision. 6. It is very suitable for a high class Guest House, Doctor's residence, Hospital or Convalescent Home. If you know of anyone whom it might suit, please communicate with them. DESCRIPTION 7. It stands on 305 feet of land facing Greenwood Avenue. It is cement, roughcast and hardwood, well oiled, and is now being redone so that the house is as good as new; red tile roof; verandahs three sides; two sleep-outs; five bedrooms; large dining room; very large music room with nooks, upstairs lounge, study; sewing room; built-in wardrobes and cupboards throughout; handsome kitchen with handsome pantry cupboard with drawers and glass front; one bath room; one shower room; wash house with patent copper and laundry. Every modern convenience, hot water system (through copper pipes with large copper cylinder) electric lights everywhere, outside and in, Yan Yean water laid on everwhere throughout house and gardens. Floors throughout are the very best, close set, stained and polished; dainty lead light windows etc. 8. There is a big garage, with tiled roof and two rooms with all conveniences for a married couple. Property is well drained with a system of its own. The house stands upon the top of a hill close to Railway Station, say 500 feet from the Footbridge. 9. The garden has expansive shrubs; sheds; fernery; tennis court. 10. A handsome piece of furniture goes with the house; a combination pantry and storeroom for groceries, milk, bread etc., consisting of drawers, glass and wire doors, as mentioned above. 11. It is within easy distance of Melbourne as it is only two minutes from Ringwood Station, which is a frequent electric train service bringing it within 39 minutes of the City. It is thought better by some to go further out into the country atmosphere and walk a short distance at the end than to go by train 20 minutes then walk 15 to 20 minutes. 12. The price quoted of £4,865 is made up as follows - 305 feet of land @ £5 ... £1,515 Garage and dwelling ... £300 House hot water system, American cupboard ... £2,600 Water, fencing, sheds & drain ... £250 For the lot ... £4,865 Should you require copies of the enclosed drawings I shall be pleased to supply same. 13. Mr. J.B. McAlpin is the local agent, Phone Ring. 7 (after hours Ring. 44) or you may phone me Central 988. 14. The house is south of the line, facing Greenwood Avenue and immediately at the back of Ringwood House, which is also my property. Yours sincerely, A.V. Greenwood (illegible) ..... (Transcript of second page) RINGWOOD SHOP AND DWELLING ESTATE See these letters on plan attached (H.) Ringwood House and Shops on 100 by 150 feet of land fronting Bedford Road 100 feet @ £10 per foot - £1,000 House and shops - £2,400 ... £3,400 Ringwood House consists of Boarding House, (Phone 101) and two shops, mainly brick; 9 inch walls. Will carry another story. Has music room, dining room, entrance halls, 10 bedrooms, large verandahs, all conveniences, hot and cold water, and stands on what will become a most valuable business corner. (F.)(G.) Mr. Greenwood's house, garage and sheds, stands on 307 feet of land fronting Greenwood Avenue. See detailed description attached ... £4,865 (J.) Cottage on Block 81 in William Street ... £750 (K.) Cottage in Pitt Street ... £650 (Total) £9,665 ..... (Description of third page - Subdivision Plan) Drawn by Edyth Greenwood, phone 988 Central. Subdivision includes Station Street, Pitt Street, Bedford Road, Wantirna Road, James Street, William Street (later Kendall Street), Greenwood Avenue, Ellison Street, and Haig Street. Circles denote blocks for sale. Squares denote house properties for sale. Other features marked include location of businesses along Main Street (Maroondah Highway), cool store, railway station, shop and police station on Bedford Road, church on Station Street, site of schoolmaster's residence and State School, and location of proposed public baths -

Orbost & District Historical Society

Orbost & District Historical Societyglass rolling pin, 1930's

Starting in the 18th century, glassworks in English port towns like Bristol, London, Sunderland, and Newcastle began producing hollow glass rolling pins. They were originally produced for sailors to give to loved ones, particularly young women they were hoping to woo for marriage. Plain, clear glass rolling pins became a common kitchen item in the first half of the 20th century as they were seen to be more easily cleaned that wooden ones.This item is an example of a once commonly used kitchen item.A moulded clear glass cylinder rolling pin with glass handles at each end. It is hollow and can be filled with cold or warm water to better roll a preferred food. There is no stopper at one end. It is marked with M at one end (probably indicating size).one one end - Mdomestic kitchen glass rolling-pin, -

Orbost & District Historical Society

Orbost & District Historical Societysoda syphon, first half 20th century

Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. Phillips & Stone operated in Orbost and Bairnsdale. This bottle is an example of a product manufacture by a local industry no longer existingA clear glass soda syphon bottle with a red pump on the top."Soda Water Phillips & Stone Bairnsdale P S ORBOST (trademark) 30 Fl OZ"phillips&stone syphon bottle -

Orbost & District Historical Society

Orbost & District Historical Societysoda syphon bottle, first half 20th century

... -bottle Drosseau D.DROSSOU, ORBOST Soda Water A clear glass soda ...Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass soda syphon bottle. It has a red syphon pump.D.DROSSOU, ORBOST Soda Watersyphon-bottle drosseau -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageThermometer, Early 20th Century

A Storm Glass and Thermometer such as this one would be used in predicting or forecasting the weather. Farmers used predictions they read from their Storm Glass to prepare for stormy weather or for choosing a good time for planting or harvesting their crops. This could mean to them the difference between a good year and a year without income. This design has been in use since the early 1800’s. According to Admiral Fitzroy (who studied the storm glass and wrote instructions on its use) the liquid in the glass changes composition and appearance according to the direction of the air moving around it. He advised the user to disturb the contents once or twice a year by tipping it upside down and shaking it gently. Item is a good example of a barometer/thermometer that would have been in most homes and farms from the late 19th century and early 20th century. This item would have been massed produced at the time therefore easily available and quite cheap to purchase making this particular item not very significant as not associated with a historic person or property or with a known manufacturer or date.Storm Glass and Thermometer, commonly called a 'Cottage Barometer', mounted on a rectangular dark rectangle of wood, top corners rounded. The Storm Glass (or weather glass, or chemical weather glass) is suspended in a long oval shaped hole in the wood on left side, held in place at top and at bottom with 2 metal bands secured by nails. The glass of this gauge is hand blown, sealed at the top with another layer of glass. The watery fluid in the storm glass is opaque brownish colour with dark particles floating in it. (Storm glasses were usually filled with a variation of a mix of camphor, distilled water, ethyl alcohol and silver nitrate.) The alcohol thermometer is mounted on the right side of the wood, bulb resting in a hollow, attached at top and near base by 2 thin metal strips, with clover-leaf shaped ends, nailed into place. Over the bulb is nailed a metal guard with 3 ventilation slits cut into it. On left of thermometer is a scale, stamped into wood, 30 below zero to 130 above zero, in 2 degree intervals. A border of 2 thin parallel lines, with remnants of light coloured paint, is around the block of wood. On the reverse side, a metal plate is nailed to the top with a mounting hole in it. Impressed sideways along edge of barometer is "STORMY" "CHANGE" "FAIR". Across the top of the thermometer is a fleur de leis in the wood, and above this it is stamped "FAHRENHEIT". On right of the thermometer, stamped into the wood, is "BLOOD/HEAT", "SUMR/HEAT", "TEMPE/RATE", "FREEZ/ING". On the back of the wood, at the base, are remnants of a white sticker with "...111.73". Carved into the wood is "HOLLAND / AV". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, barometer, cottage barometer, storm glass, thermometer, chemical weather glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910’s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. Brown, brown glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ nipple-liker bump in the centre. Bottle is straight from base to half height then tapers to a shoulder over the next quarter, than almost straight up to the mouth. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker, ginger beer bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This hand made, green glass bottle is representative of bottle making before mass production and is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. The shine has been worn from three-quarters of the body of the bottle. There are particles adhered to the inside of the bottle. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Water Carafe and Tumbler, 1850 -1900

Carafe believed to be of the mid to late Victorian era and used as a bedside water carafe however the tumbler is possibly not of the same era could be later. These sets were in fashion from the 1700s filled with water and used if the owner required a drink during the night. however the subject item would have been made after 1850 as glass etching started to be used on glass from around this period.The carafe is most likely a vintage example of a Victorian bedside water container and for that is significant. The item was made in England.Bedside water carafe, onion-shaped, with a glass tumbler. The hand-blown set is clear crystal glass with an acid-etched fern decoration on both pieces. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, carafe and tumbler set, blown glass carafe and tumbler, hand made glass, carafe, tumbler, bedside set -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGlue Pot, T & C Clark, Late 19th Century

T. & C. Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enameled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councillor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enameled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enameled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enameled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.An item that was made by a British foundry that was a pioneer and innervated many new processes in the manufacture of enamel ware, producing many items for every day use.Glue pot with inner pot, metal, corroded, both pots have handles."T & C CLARK & Co Ltd, ENGLAND, 55279 RD" and "FIRST QUALITY No. 4/0"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t& c clarke, cast iron, foundry, sanitary ware, ironware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Vanity Jar, 1920s

Skincare cosmetics used for ageing skin have been a priority for over 3000 years, in ancient times masks were used to cleanse and maintain the moisture of the skin. The Egyptians used anti-wrinkle creams made with the essential oil of frankincense which claimed to possess anti-inflammatory properties. Thick creams use on the face were created to preserve moisture on mature skin. And were formulated from resin, wax, oil, grass, and plant juice, In the 1700s, face toners and scented water were popular. Cold cream made with scented oils, spermaceti, and wax mixed with rose water and ambergris was a common toilette preparation. But it was the 20th century when face cosmetics entered their golden era and mass production made cosmetics available to women of all classes. An item used to store face cream from the 1920s when face creams and other cosmetics started to become available to all classes of women and no longer were these types of preparations only available to women of financial means.Clear glass jar with "hobnail" pattern and brass lid used to hold face cream cosmetics.Lid decorated with a relief design of 5 cherub heads and cloudsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, glass jar, cosmetics jar, toilet article -

Flagstaff Hill Maritime Museum and Village

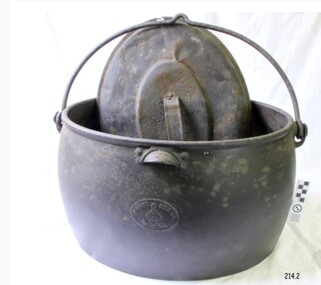

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Rolling Pin, First half of 20th Century

A rolling pin is a simple tool used to flatten dough. The first civilisation known to have used the rolling pin was the Etruscans. Their advanced farming ability, along with a tendency to cultivate many plants and animals never before used as food and turn them into sophisticated recipes, were passed to invading Greeks, Romans, and Western Europeans. Thanks to the Etruscans, these cultures are associated with gourmet cooking. To prepare their inventive foods, the Etruscans also developed a wide range of cooking tools, including the rolling pin. Although written recipes did not exist until the fourth century B.C., the Etruscans documented their love of food and its preparation in murals, on vases, and on the walls of their tombs. Cooking wares are displayed with pride; rolling pins appear to have been used first to thin-roll pasta that was shaped with cutting wheels. They also used rolling pins to make bread (which they called puls) from the large number of grains they grew. Natives of the Americas used more primitive bread-making tools that are favoured and unchanged in many villages. Chefs who try to use genuine methods to preserve recipes are also interested in both materials and tools. Hands are used as "rolling pins" for flattening dough against a surface, but also for tossing soft dough between the cook's two hands until it enlarges and thins by handling and gravity. Tortillas are probably the most familiar bread made this way. Over the centuries, rolling pins have been made of many different materials, including long cylinders of baked clay, smooth branches with the bark removed, and glass bottles. As the development of breads and pastries spread from Southern to Western and Northern Europe, wood from local forests was cut and finished for use as rolling pins. The French perfected the solid hardwood pin with tapered ends to roll pastry that is thick in the middle; its weight makes rolling easier. The French also use marble rolling pins for buttery dough worked on a marble slab. Glass is still popular; in Italy, full wine bottles that have been chilled make ideal rolling pins because they are heavy and cool the dough. Countries known for their ceramics make porcelain rolling pins with beautiful decorations painted on the rolling surface; their hollow centres can be filled with cold water (the same principle as the wine bottle), and cork or plastic stoppers cap the ends. Designs for most rolling pins follow long-established practices, although some unusual styles and materials are made and used. Within the family of wooden rolling pins, long and short versions are made as well as those that are solid cylinders (one-piece rolling pins) instead of the familiar style with handles. Very short pins called mini rolling pins make use of short lengths of wood and are useful for one-handed rolling and popular with children and collectors. Mini pins ranging from 5 to 7 in (12.7-17.8 cm) in length are called texturing tools and are produced to create steam holes and decorations in pastry and pie crusts; crafters also use them to imprint clay for art projects. These mini pins are made of hardwoods (usually maple) or plastic. Wood handles are supplied for both wood and plastic tools, however. Blown glass rolling pins are made with straight walls and are solid or hollow. Ceramic rolling pins are also produced in hollow form, and glass and ceramic models can be filled with water and plugged with stoppers. Tapered glass rolling pins with stoppers were made for many centuries when salt imports and exports were prohibited or heavily taxed. The rolling pin containers disguised the true contents. The straight-sided cylinder is a more recent development, although tapered glass pins are still common craft projects made by cutting two wine bottles in half and sealing the two ends together so that the necks serve as handles at each end.Tiny rolling pins are also twisted into shape using formed wire. The pins will not flatten and smooth pastry, and the handles do not turn. The metal pins are popular as kitchen decorations and also to hang pots, pans, and potholders. https://www.encyclopedia.com/sports-and-everyday-life/food-and-drink/food-and-cooking/rolling-pinThe use of the rolling pin to make thin pastry or pasta.Wooden rolling pin with some damage on cylinder section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rolling pin, cooking, pastry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

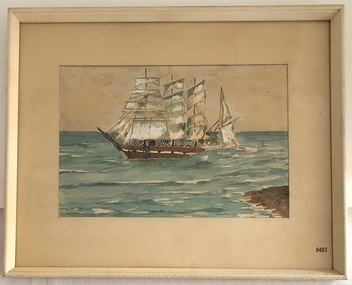

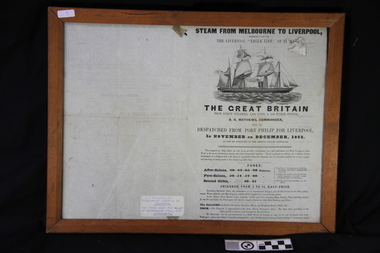

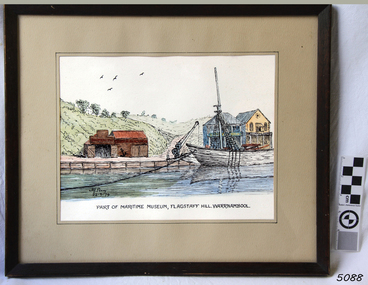

Flagstaff Hill Maritime Museum and VillagePainting - Watercolour painting, Early 20th century

FALLS of HALLADALE - History The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She had a sturdy construction, built to carry maximum cargo and maintain full sail in heavy gales. She was one of the last of the ‘windjammers’ that sailed the Trade Route and one of the first vessels to include fore and aft lifting bridges, which kept the crew safe and dry in as they moved around the decks in stormy conditions. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles, 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items (a list of items held at Flagstaff Hill Maritime Village is included below). The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not to technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire.The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Watercolour painting behind glass, framed in the Art Deco style - stippled cream painted wood. There are some age marks under the glass. The painting depicts the Falls of Halladale with its stern under water. The back of the painting contains facts about the shipwreck handwritten in a similar style to the artist’s signature. The artist’s signature is not clear enough to identify. Inscription on the back: Pasted on typed text: Peterborough Handwriting: Falls of Halladale 2085 tons 4 masted iron barque wrecked Saturday November 14th 1908 Captain Thomson crew of 28 !st mate F Pearson 2nd mate T Griffinflagstaff hill, warrnambool, flagstaff hill maritime museum & village, maritime museum, maritime village, shipwreck coast, 1908 shipwreck, falls of halladale, peterborough, peterborough shipwreck, great ocean road, captain thomson, 1880s sailing ship, cargo vessel, 1st mate f pearson, 2nd mate t griffin, watercolour painting -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and Forgesoda water syphon

Domestic use soda syphonA heavy glass bottle with a weighted base, fluted sides, an etched label on the side and a metal syphon attachment at the top.W. Whittaker & Sons. W.W & Sons DUNOLLY British Syphon Co. London No. 762/(metal syphon) E. Rowlands. Proprietary Limited British Syphon M.F.G.Co Ltd LONDONbottle, beverage, syphon, glassware, sodawater -

Gippsland Vehicle Collection

Gippsland Vehicle CollectionMaker's Name: Various oil companies (Golden Fleece, Shell, Castrol etc) Maker's Role: Oil & petroleum products et al, c.1950

Common in all service stations for engine oil top-up at pump service area by service station attendant.Before 'self serve' pump operations service station attendants 'serviced' the vehicle on the forecourt whilst filling with petrol, checking oil levels, water etc.Glass wide mouthed bottle with plastic conical spout and capBottle - "FILL TO LINE INDICATED BY ARROW' & "500ml B.T. N.S.W." Spout - Golden Fleece logo with "GOLDEN FLEECE Supreme Motor Oil"oil, oil bottle, golden fleece, motor oil, engine oil -

Federation University Historical Collection

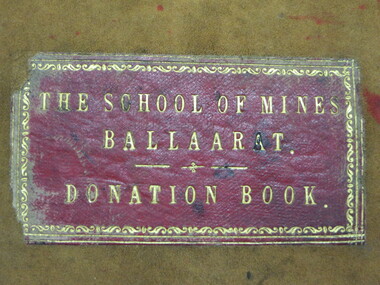

Federation University Historical CollectionBook - Ledger, Ballarat School of Mines Donation Book, 1878 - 1895, 1878-1895