Showing 23323 items

matching ? madely

-

Bendigo Military Museum

Bendigo Military MuseumArtwork, other - LAMP - TRENCH ART, Post WW2

Possibly made by the donor.This object is an example of trench art. .1 The lamp base consists of a chrome plated deactivated mortar bomb attached to a turned brown wooden base. A globe and switch socket are attached to the tip of the bomb. An electrical cord with power plug is threaded through the base of the bomb. .2 The lampshade is made of stiffened brown paper laced to a wire frame with dark brown cord. Handpainted coloured flowers decorate the outer surface of the shade. The shade is attached to the globe via a wire clamp.On the base of the mortar bomb: ' ?LB, IM, MF, 1940'ornaments, lighting - electrical, trench art, souvenir -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Bendigo Military Museum

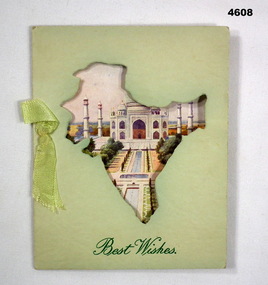

Bendigo Military MuseumCard - CARD, CHRISTMAS, Raphael Tuck & Sons Ltd London, c 1939-45

Refer to Cat 4575P for details.This card is made in two pieces. The outer is made of cardboard. The inner is made of stout paper. They are folded in the centre. The two pieces are bound on the fold with a piece of light green ribbon. In the outer card is a cutout in the shape of the Indian sub continent. This opening reveals a print of the Taj Mahal.Inside the card are the word: - "To Dorrie, with the best of Good Wishes for Christmas and the coming year. Love from Doug 1940"christmas, ww2, india -

National Wool Museum

National Wool MuseumTextile - Blanket, Onkaparinga Woollen Mill Company, 1960s

Collector says: I adore these bright blankets with their labels depicting summer times. For most blanketeers, the Laconia Mexicana is a bit of a holy grail - for the label just as much as the blanket. Laconia made the Mexicana in 1964 and I suspect the Waverley and Onkaparinga came afterwards.Collector says: "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from.Queen sized checked blanket, red, blue, orange, yellow. An Onkaparinga 100% pure wool production. In emblem: Made in Australia. Name tag sewn below label: R M. Shiltonwool, blanket, blanket fever, onkapringa -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Haeusler Collection Australian Made Telescope with Booklet c. late 1800s to early 1900s, The Union Mfg, & Agency Co

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This telescope belonged to Louis Haeusler (b.1878) and is one of the many objects in the Haeusler Collection that represent home and social life in early twentieth century Wodonga. It was manufactured by The Union Mfg [manufacturing], & Agency Co. in Melbourne. This item has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Australian made telescope covered with a faux shagreen paper. Extends to three and a half feet long, with a five to ten mile sight range. On front of paper booklet: "TELESCOPE TALK/SOMETHING TO LOOK THROUGH/The Union Mfg, & Agency Co./299 ELIZABETH STREET,/MELBOURNE"telescope, recreation, family, haeusler collection, haeusler, wodonga -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Ornament, ca. 19th century

This fine white unglazed porcelain figurine is one of six donated together, and one of a pair of two children carrying baskets on thei. The bisque material was easy to carve and allowed fine detail. Figurine ornaments were popular for table decorations between the mid-18th to early 19th centuries. This ornament was made in Germany, and German manufacturers began to use bisque material to make realistic faces for dolls in the 1850s.The set of six bisque figurines is representative of popular table decorations during the 19th and early 20th centuries.Fine unglazed white porcelain ornament, carved to represent a girl holding a basket on her back. One of a pair, the other being a boy holding a basket on his back. The hollow basket is a vase. It was made in Germany. "1084" "105" "GERMANY"flagstaff hill, warrnambool, maritime museum, bisque, china ornament, white china ornament, german, porcelain, unglazed porcelain, 19th century, 18th century, european ornament, pottery, unglazed pottery, domestic ornament, decoration, table decoration, germany, girl with basket, vase -

National Wool Museum

National Wool MuseumTextile - Red Cross Quilt, 1930-1949

This quilt was purchased from an op shop in Clifton Hill, Vic. by Lois Densham, a quilter and former member of the Running Stitch group who has an interest in historic Australian quilts. The quilt has been displayed in NSW, where it was part of an exhibition of Historic Australian Quilts curated by Annette Gero and held at Old Government House, Paramatta between 5 June and 22 August 2000. Initially purchased in Clifton Hill, it originally came from a source in Highton, Geelong. It is a double bed sized quilt in the classic 'crazy' style with extensive use of herringbone and feather stitching.The pieced style of the quilt, made from squares of patchwork is similar to the style of quilts made by members of the Country Women's Association (CWA). The women sometimes made a quilt as a group activity and Lois suggested that the quilt may have been made by this group.Quilt, rectangular. Made with crazy patchwork in twelve large blocks. The blocks at each corner are fairly regular, whereas the others are full of random pieces. The patches are oversewn with hand embroidered feather stitch in different colours. In the centre there is a block with a maroon cross. Many of the pieces have central 'sprigs' of green embroidery in bullion stitch. The quilt is backed with a blue and green striped fabric.quilting patchwork, running stitch group national trust of australia (nsw), running stitch collection, densham, ms lois, geelong, quilting, patchwork, cwa -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Equipment - Lead balls, Lead Shot Balls

Lead shot used for guns. No information is available on the origin of these lead balls.These balls are of antiquarian interest only and may be useful for displayThese 13 balls are made of lead but their purpose is unclear. They are all pitted and are obviously home made. They are in a small Havelock Tobacco tin, much rusted but originally painted green.Tin – ‘Havelock Flake Cut Tobacco’lead balls, warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Bung, cask Sheldrick's Brewery, 19th century

This cask bung came from the brewery of Sheldrick and Co. The New Brewery (Warrnambool), founded by Walter Sheldrick and Thomas Price as partners in a company, was situated at the corner of Timor and Fairy Streets. It was known as Sheldrick and Co. and operated from 1868 to 1922 with John McGee and Company running the business after 1894. In 1922 the business was sold to Ballarat, Melbourne Co-operative and Carlton and United Breweries. The casks, used for wine and spirits, were in 1892 cleaned by steam and a lifting device was used to transport the casks from the cellars to the delivery wagons. This is a most significant item as one with a clear provenance and used in the brewery business of Sheldrick and Co., a major industry in Warrnambool in the 19th and early 20th centuries. It is an example of the equipment use in the brewery business more than a 100 years ago. This is circular cask bung or stopper with the outer shell made of brass and the stopper insert made of cork. There is a screw thread on the metal. Both the brass and the cork are slightly worn.Inscribed on the metal:‘Sheldrick & Co. Warrnambool’sheldrick and co., sheldrick’s brewery -

Bendigo Military Museum

Bendigo Military MuseumWeapon - CARTRIDGE, WW2

Item souveniered by Billy Bird No VX113169 2/14 Batt AIF. Refer Cat No 1601 for service details..1) Shell approx 20mm Dia. Made of steel. Flat nose inert one copper driving band .2) Shell case rimless, made of brass.arms ammunition, metalcraft, cartridge -

Frankston RSL Sub Branch

Frankston RSL Sub BranchKnives, Butter (set of 3)

This is a set of 3 trench art butter knives. The handles are made of chrome plated spent bullet cartridges (0.303 inch) and the blades are made from chromed steel. On the base of the cartridge is the marking 'MG 1941 V11'ww2, trench art, butter knives -

Orbost & District Historical Society

Orbost & District Historical Societytable cloth, first half 20th century

This item is an example of a handcrafted item and reflects the needlework skills of women in the early to mid 20th century. Embroidery was an affordable way to personalise and add aesthetic value to domestic linen and examples of embroidered and crocheted pieces could be found in most Australian homes, A hand made rectangular shaped white table cloth made of fine linen. it has lace insertions which are flower shaped. The flower stems and leaves are embroidered.table-linen handcraft needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBracket

A Frame Bearing bracket. Made from pressed steel. Made by Standard Pressed Steel Co Jenkintown USA. Height 600mm width 400mm Circa 1960flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBracket

A Frame Bearing bracket. Made from pressed steel. Made by Standard Pressed Steel Co Jenkintown USA. Height 600mm width 400mm Circa 1960flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBracket

A Frame Bearing bracket. Made from pressed steel. Made by Standard Pressed Steel Co Jenkintown USA. Height 600mm width 400mm Circa 1960flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Box spanner

Blacksmith made box spanner with octagonal collar, attached to long iron handle with rounded end. Made from bar stock with collar extension piece added on1 1/2 box, spanner, blacksmith, blacksmithing, smithing, tool, tools, churchill island, farm -

Churchill Island Heritage Farm

Churchill Island Heritage FarmFurniture - Armchair, 19th century

Large wooden rockingchair. Woven wicker back and arms. Rattan seat. Legs made of carved wood with insets of slats, circular patterns. Probably made by Rocke. churchill island, rocking chair, rocke -

Donald History and Natural History Group operating the Donald Court House Museum

Donald History and Natural History Group operating the Donald Court House MuseumMedicine Patches

Yellow box made of cardboard with white and green decoration on lefrt side of front, with picture of a Buddha. Lapelled "Antiphlogistic Analgesic STRONG MAITREE - PAS. Made in Japan."medicine patches, georgie ah ling, yellow box -

Jewish Museum of Australia

Jewish Museum of AustraliaKippah, 1991

A kippah, also called a yarmulke or skull cap, is a head cover worn by religious Jewish men for many reasons, one being that it is a sign of one's respect for God.This crochet kippah was made in Melbourne, Australia. This kippah is made of cotton. It is navy blue and decorated with decorative bands, mauve rose buds, blue leaves and yellow flowers. -

Anglesea and District Historical Society

Anglesea and District Historical SocietyTeapot, Before 1900

Made circa 1890-1900. Large electroplated Britttania metal teapot with hinged lid. Panelled etching on body and lid. Made in Sheffield by Thomas Otley & Sons.Trade Mark: Thomas Otley & Son Sheffield / EP BM TOS / S / Thomas Otley & Sons (Electroplated Brittania Metal). 0263 - 4 - 55teapot, electroplated brittania metal -

Whitehorse Historical Society Inc.

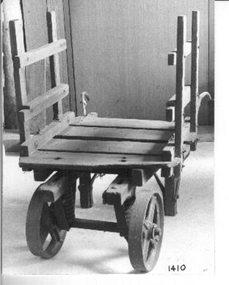

Whitehorse Historical Society Inc.Functional object - Barrow

Hand Barrow. Appears to be handmade and it was used to transport products around the pottery.The wheels are made of cast iron; it has a steel frame with springs and the sides are made of wood.ceramics, terracotta -

Queen Victoria Women's Centre

Queen Victoria Women's CentreRe-purposed Quilt, The Century Bedspread, c.1975

Patsy Coverdale wrote on about the artwork which is found with the bedspread "This trousseau bedspread commemorates a century of our daily living, of four generations, a bedcover where many loves and lives have begun and ended. Once immaculate, its years of service, of blood, sweat and tears, have seen so many building washes that today's embroideries would shrink from. I rescued it, patched its tears and wears with needlework from ancestors and aunties to celebrate the International year of Women in 1975. It symbols include the IYW to the left, women's work and its rhythms and cycles, a pearl button for our pleasure centre. The male phallic symbol illustrates the organ's early development and its natural power with the energy of relativity behind it all."A quilt made for the centenary of the Hospital made for the International year of women 1975. Re-purposed from a quilt used at the hospital. Given to QVWC in 1997 for the grand opening. textile art, centenaries, hospitals -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionPlaque - Presentation Plaque, 2 Royal Australian Regiment

Shield shaped plaque made from a black coloured wood. Located centrally is a unit symbol made from golden line to the Royal Australian Regiment badge. rar, infantry, hat badge, plaque -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Manicure Set, c1910

This item is from a collection donated by descendants of John Francis Turner of Wodonga. Mr. Turner was born on 6 June 1885. He completed all of his schooling at Scotts Boarding School in Albury, New South Wales. On leaving school, he was employed at Dalgety’s, Albury as an auctioneer. In 1924 John was promoted to Manager of the Wodonga Branch of Dalgety’s. On 15/03/1900 he married Beatrice Neal (born 7/12/1887 and died 7/2/1953) from Collingwood, Victoria. They had 4 daughters – Francis (Nancy), Heather, Jessie and Mary. In 1920, the family moved From Albury to Wodonga, purchasing their family home “Locherbie” at 169 High Street, Wodonga. "Locherbie" still stands in Wodonga in 2022. The collection contains items used by the Turner family during their life in Wodonga.This item comes from a collection used by a prominent citizen of Wodonga. A 5 piece manicure set in a cylindrical container. Individuals items are made of steel, electro plated silver with tortoise shell handles. The case is also made of tortoiseshell.On side of tweezers; "EPNS A1" On file "ENGLISH STEEL MAKE"personal items, manicure implements -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Colour print, The Harvest of Oats is Finished at the Burnley School of Horticulture and Primary Agriculture, 1935-1990

Photograph made by A.P. Winzenried for, "Green Grows Our Gardern," p73Colour photograph. Copy of newspaper article, made by A.P. Winzenried. Caption reads, "The harvest of oats is finished at the Burnley School of Horticulture and Agriculture, but these cheery girl harvesters will not be able to stack the crop until the weather improves. There are about 20 girl students at Burnley this year learning chiefly horticulture, but they are taught to grow and reap crops for fodder as well." 9 female students standing in a line holding forks in a paddock.Handwritten underneath, "Barbara Betty Herald Dec 1st/45."a.p. winzenried, green grows our garden, harvest, oats, burnley school of horticulture and agriculture, female students at burnley, barbara betty, students working outside, forks -

Falls Creek Historical Society

Falls Creek Historical SocietyClothing - Wool Shirt, Camp at Gap Saddle, 1947

MEYER COLLECTION - FALLS CREEK PHOTOS In 1947 a determined group of like-minded State Electricity Commission (SEC) staff including Ray Meyer, the chief surveyor of the Kiewa Hydro-Electric Scheme, had a common interest that revolved around the skiing potential of the snow-covered high plains which included what is now the resort of Falls Creek. The six SEC employees, Toni St Elmo, Ray Meyer, Jack Minogue, Lloyd Dunn, Adrian Ruffenacht and Dave Gibson (together with their families) banded together to secretly build a 'hut' that was the first ski lodge at Falls Creek. Using a road built in 1930s to gain access to Falls Creek, their hut project was carried out in secret as efforts by other skiers were blocked by H.H.C. Williams – the engineer in charge of the Hydro Scheme. In 1946 Ray Meyer made a trip to the Lands Office in Melbourne. He came away with a 99-year lease on three acres that was ideally suited for a hut designed by Lloyd Dunn. Adrian Ruffenacht (Design Engineer for the KHS) had suggested where the group should build because of easy access to a spring for water. Much of the building material required was scavenged from derelict huts on the high plains. Due to the need for secrecy, the determined group worked on the hut in the evenings and weekends to avoid detection. During the building period the group had met at Echidna Rock (now known as Eagle Rock) where Skippy St Elmo announced, "This is my favourite ‘Skyline’.” And so the first lodge in the area at Falls Creek Ski Resort came into existence. With the development of the International Poma in the 1970s, the Skyline Lodge, which was sited between the ski-lift’s pole one and pole two, was demolished. However, the legacy of Ray Meyer, Toni St Elmo, Jack Minogue, Lloyd Dunn, Adrian Ruffenacht and Dave Gibson and Skyline lives on in the vibrant atmosphere of Falls Creek Resort. The MEYER COLLECTION documents developments on the Kiewa Hydro Scheme and their life at Falls Creek from the mid 1930s to 1960s.These images are significant because they depict aspects of the life of a pioneering family of Falls Creek and the founders of "Skyline", the first lodge at Falls Creek.A blue and brown checked shirt made of woollen fabric. It has a buttoned down collar and front closing. Meyer Family records suggest that it could have been handmade by Rel Gibbs who hand made woollen shirts and embroidering Skyline badges.falls creek, building skyline, skyline founders, toni st elmo, adrian ruffenacht, jack minogue, ray meyer, lloyd dunn, david gibson -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Digital image, 18/05/1956 12:00:00 AM

Yields information about the appearance of No. 25 promoting Made in Australia week during 1956.Digital image from the Wal Jack Ballarat Album of a photograph of No. 25 at the Victoria St terminus, carrying banners for Made in Australia Week. Tram has a sheet with an Australian flag painted onto it, with holes made for the lights on the front of the tram, and three panels that have been fixed to the side of the tram. Tram has the destination of Gardens via Sturt St West. Photo by Wal Jack 18-5-1956 - see also Reg Item 5347. See image i2 for rear of photograph. See image i3 for hi res scan of print. See image i4 for hi res scan of negativeOn rear of photograph in ink "SEC, Ballarat No.25 done up with calico posters "Made in Australia" week, Victoria St terminus 18/5/56" and in top right hand corner, Wal Jack stamp with "T237" written in.trams, tramways, victoria st, advertisements, made in australia week, tram 25 -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Camera, c1940

Superfex Camera - made of plastic with a Fexar Spec Optic made by Fritz Kaftanski. Originally made in Prague in Czechosovakia from 1938 - 1942. This camera was made in Lyon, France in 1942 after Company moved from Prague. This is shown on the lower right front of the camera. The back is removable using the two clips on each side. Provisions made for two spools - one blank, the other for the 127 film role. Shutter button on top front of camera. M & B lever for exposure settings is on the side. A carrying cord is fitted.Superfex - Fexar spec Optic - Francephotography, cameras -

Disability Sport & Recreation Victoria

Disability Sport & Recreation VictoriaKeyring, Union Jack keyring, unknown

Unclear when this likely souvenir would have been made, or the circumstances in which it wasacquired.Round metal and enamel keyringFront contains a Union Jack design, with gold coloured lines in between the various flag sections. Back contains the text: MADE IN ENGLAND, and a stylised 'B' - likely the makers' mark - and the copyright symbol. -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Shoehorn

This shoehorn is a typical household item which has been used since the Middle Ages to assist in manipulating shoes onto the feet. They are made from a variety of materials with horn being a popular and common material and being readily available in many cases are simply honed down to a smooth shape. The age of this particular one is unknown. A common item made from natural material which would have historical and social interest and significance.Made from a cow's horn, this is fawn to grey in colour with the narrow end more of a striped nature with the bottom section, a plain grey them cream. It remains a horn shape and has been filed to suit its purpose, that of a shoe horn.warrnambool, history of warrnambool, shoe horn