Showing 828 items

matching british and american

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Ship's nail in wood, Ca. 1855

This ship's nail in a wood sample was part of the construction of the ship SCHOMBERG. About the SCHOMBERG- James Blaine’s Black Ball Line had commissioned the luxury sailing ship, Schomberg, to be built for its fleet of passenger liners The three-masted wooden ship was launched in 1855, designed by the Aberdeen builders to sail faster than the quick clippers designed by North American Donald McKay. The material used for the diagonal planking was British oak with layers of Scottish larch. The Schomberg’s master Captain ‘Bully’ Forbes commanded the ship on its maiden journey between Liverpool and Melbourne, departing on 6 October 1855 with 430 passengers and 3000 tons of cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. After sailing for 78 days she ran aground on a sand spit at Curdies Inlet near Peterborough, Victoria, on 27 December 1835. At dawn on the next day, the ship’s Chief Officer signalled a passing steamer, SS Queen, for help and all of Schomberg’s passengers were able to disembark safely. The passengers’ baggage and some of the cargo were later collected from the Schomberg. Local merchants Manifold & Bostock bought the wreck and the remaining cargo but did not attempt to salvage the cargo that was still on board. They eventually sold it and after two of the men drowned in the salvage efforts the job was abandoned. In 1975, divers from Flagstaff Hill, including former Director, Peter Ronald, explored the Schomberg wreck site and recovered many artefacts that are now on display at the Museum.The ship's nail in a wood sample is significant for its connection with the Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large and fast clipper ship that sailed on the England-to-Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck. The collection is primarily significant because of the relationship between the objects, as together they can interpret the story of the ship, Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be the fastest and most luxurious of its day.Ship's nail in a wood sample. The object was recovered from the wreck of the SCHOMBERG.flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, ship's nail, ship's wood, wood sample, ship construction -

Kew Historical Society Inc

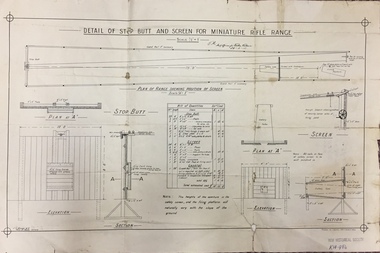

Kew Historical Society IncPlan, JC Brown, Detail of Step Butt and Screen for Miniature Rifle Range, 26 February 1910

On 19 July 1907, The Box Hill Reporter published an article on the Miniature Rifle Range. It stated: "Miniature Rifle Range for Kew. The Kew rifle club has made arrangements for the establishment of a miniature rifle range. The Kew borough council has provided a site in the yard at the rear of the town hall, fronting Brougham street. The site has been inspected by the military authorities, who have approved of the locality selected and the arrangements to be made to render the range absolutely safe. The plans are at present being prepared, and it is expected that the range will be completed within the next two months. The range will be under the direct control of the rifle club, subject to the supervision of a joint committee from the council and the club. The first committee will consist of Crs Wishart (mayor), Kellett, and Hiscock as representing the council, and Captain Argyle and Mr S. Abbott representing the rifle club. The range when completed will be available for the use of cadets, friendly societies, and other miniature rifle clubs in the district. Miniature rifle ranges are now occupying a great deal of attention in Great Britain, on the Continent, and in America. Lord Roberts, writing recently on the subject, remarks- "While I do not for a moment pretend that miniature rifle shooting is, in all respects, as useful as knowing how to shoot on a long range, I am satisfied that men can learn to shoot on miniature ranges, and that unless miniature ranges are very generally made use of, the greatest majority in this country will never learn to shoot at all." It is possible by this means also to divert the at present dangerous enthusiasm of uninstructed youths for the pea rifle into safer and more useful channels."Important early document identifying the specifications for a miniature rifle range in central Kew. Rifle clubs and rifle ranges were an important element in defending Victorians and Australians to outside threats. Single page plan (folded), created and approved in 1910, listing the approved specifications for a miniature rifle range in Brougham Street, Kew.Handwritten signature: J.M. / Staff officer for Works Victoria / 26-2-10rifle clubs - rifle ranges, miniature rifle ranges, rifle clubs -- kew (vic) -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Thomas Lothian, his wife Effie with their family, c. 1932

Thomas Carlyle Lothian (1880-1974) was born on 7 May 1880 at Newcastle-upon-Tyne, England, eldest child of John Inglis Lothian, bookkeeper, and his wife Lillias Charlotte, née Smith. The family arrived in Melbourne in July 1888, John having come to represent the publishing firm of Walter Scott. His father started his own company in c1890. Thomas joined the business in c1897. In 1911 he established the Standard Publishing Co. Pty Ltd to sell the publications of the Caxton Press direct to the public. In 1912 he married Effie Marian Vines, who had worked for several years in his father's office. His father retired the same year and Thomas formed the company of Thomas C. Lothian Pty Ltd to carry on representing numerous well-known British and American publishers. However, he also published in his own right as the Lothian Book Publishing Co. Pty Ltd. In time he handed over his businesses to his two younger sons. His wife Effie pre-deceased him; he died at ‘St Abs’ on 19 April 1974. People in the photo are identified as: Left: daughter Lilian and centre front daughter Jean Back: Son Noel who studied horticulture and became Director of the Adelaide Botanical Gardens for 30 years; son John who managed the Standard Publishing Co. and sons John and Louis who became directors of the publishing firm. Grandson Peter, son of John became a later director.A black and white photograph of a group of 7 people in the garden of a house with veranda with fretwork and balustrade. It appears to be of timber construction. The two older people in front are seated; 4 younger people, a young woman and 3 boys, stand behind them and a young girl stands between them.(mr) thomas lothian, (mr) john lothian, (miss) lilian lothian, (miss) jean lothian, (mr) louis lothian, (mr) peter lothian, st abbs, house names, york street, surrey hills, lothian book publishing -

Melbourne Legacy

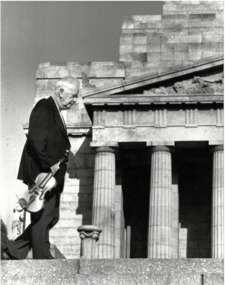

Melbourne LegacyPhotograph, The Changi Violin, 1989

A photo of Jack Geoghegan holding the violin that is part of Melbourne Legacy's collection (see 00080) at The Shrine. The photo appeared in an article in The Age in 1989. One photo also appeared in the President's Highlights report in 1989. The caption of that photo says, 'Pensive thoughts for ex-prisoner of Changi Prison, Jack Geohegan when, as a guest of Melbourne Legacy, he was reunited with a very special possession kept in Legacy's care. Jack, whose signature is one of many, had not seen the violin since his days at Changi.' Background: This violin was played by VX30301 Dvr Roy Arnel, as a member of the Australian Imperial Force Concert Party, in the Changi POW camp, Singapore from 1942-1945. It is claimed that the violin, in its case was thrown over the wall by a Chinese civilian. Roy Arnel, a South African by birth enlisted on 7 June 1940 at Royal Park, Melbourne and served with 2 AASC Company as a driver. He was captured by the Japanese Imperial Army at the fall of Singapore in February 1942. There was more than one concert party in Changi as indicated on the rear of the violin. The details of the Dutch, British and American Concert Parties scratched in to the varnish. There are some well-known names scratched into the violin including: The English author and cartoonist, Ronald Searle; Australian entertainer, Frank Rich; and Australian Author, Russell Braddon. Mr Arnel died in 1982 and the violin was presented to Melbourne Legacy for preservation, safe keeping and display by his widow Mrs Florence Arnel in 1983.A record of a poignant reunion, Jack Geoghegan knew the violin while in Changi Prison and posed for photos on the Shrine to tell the story in The Age. Black and white photo x 3 of the Changi Violin at The Shrinechangi violin, pow, jack geohegan -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - AUSTIN COLLECTION: Koch's Pioneer Gold Mine, Long Gully

Koch's Pioneer Quartz Mining and Crushing Company was officially registered on June 30th., 1871 (Government Gazette No. 45, 1871). It operated at Long Gully, the first Manager was Andrew Lewis. Nominal capital was 90,000 pounds in thirty thousand shares of 3 pounds each. The initial partnership in a quartz crushing plant between Henry Koch, Simon Albert and Charles Wallin was dissolved in 1860 with Koch becoming the sole owner. In 1866 the crushing plant consisted of a 50 hp engine and 48 stamping heads capable of crushing 600 tons of quartz per week. By 1902 there were 72 stamps and this was by far the largest crushing plant in the area, serving many quartz mines. Henry Koch (1800-1889) was a German sailor who signed off when his ship reached Melbourne in 1851. Having heard of the gold discovery he proceeded to Bendigo where he was initially employed in puddling in the Myers Flat area. He was soon employed and then made partner in a quartz crushing plant that he became sole owner of in 1860. He was also landlord at the British and American Hotel and the Silver Mines Hotel. HE also started the Perseverance United gold claim. He married Anna Maria Theresia Heinz in 1857. In 1872 he sold the crushing plant for 75,000 pounds and took his family back to Germany. He resumed his trade as a ship builder although he maintained many Bendigo mining interests.Two sepia coloured images on paper, possibly taken from book. Top image: Koch's 'Pioneer' Quartz Crushing Works - Long Gully, printed under image. Image shows mining dam in foreground, large two storey mine building in middle background, two mine chimney on right hand side. Bottom image; interior of crushing battery. Printed on bottom ' Quartz Crushing Batteries & etc. Koch's Pioneer'. gold mining, koch's pioneer crushing battery, long gully, perseverance g.m. co., henry koch -

Supreme Court of Victoria Library

Supreme Court of Victoria LibraryPortrait, Sir Edmund Herring, 1963

Sir Edmund Herring had a military career before becoming the Chief Justice of Victoria in 1944. Sir Edmund served as an artillery officer with the British Army in World War One and was awarded the Military Cross. While he returned to the Law between the wars, becoming King's Counsel in 1936, he continued his military associations through Australian Militia Forces, rising to colonel by the start of the Second World War. At the outset of WWII Herring was appointed as Commander of the Royal Artillery for the Australian Sixth Division. Herring saw service in North Africa and Greece and was in charge of Australian Northern forces in 1942, afterwards working with General Blamey in Papua New Guinea. Sir Edmund was appointed Chief Justice, straight from his army command in 1944. As Chief Justice he quickly established the Law Reform Committee and after the war oversaw the extension of the Supreme Court buildings, with the creation of new Courts. He was considered an able administrator, but his refusal to appoint Joan Rosanove a Queen’s Counsel throughout the 1950s, did not sit well with many legal practitioners. After his retirement from the Bench, he continued in his many public activities, including trustee of the Shrine of Remembrance and the Australian War Memorial and a member of the Melbourne Grammar School Council, as well as Lieutenant Governor of the State of Victoria, a position he held from 1945 to 1972. Herring was also an outspoken social critic; between the wars he had been a member of the White Guard, who were a far right group acting against communism. During the Cold War period of the 1950s, Herring spoke out in favour of the British Empire and the American alliance. The portrait of Sir Edmund Herring is the second one that Sir William Dargie (1912-2003), completed of Sir Edmund; his first effort in 1944/45 won the Archibald prize. Dargie won the Archibald prize a record eight times. His fame as a portrait painter was not without controversy, as he was considered ‘safe’ and the favourite of conservative sitters, particularly as many of his Archibald winners were of ‘Captains of Industry’. While no Archibald prize was awarded for this portrait, it is an interesting counterpoint to Dargie’s 1944/45 portrait. The portrait of Sir Edmund Herring is significant because of whom it portrays and the artist William Dargie who painted it.Portait in oils of Sir Edmund Herring. This is a half portrait of Sir Edmund in his red judicial robes. Gold leaf frame, with plaque.Plaque reads "The Honourable Sir Edmund Francis Herring, KCMG, KBE, DSO, MC, ED. Chief Justice of the Supreme Court 1944-1964"edmund herring, william dargie -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Tatting craft book, Paragon Art Needlecraft Pty Ltd, Tatting Designs, circa 1940's

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". It looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. Paragon knitting, crochet and tatting books have been distributed throughout Australia since the 1930's, originally by "Paragon Art Needlework Pty Ltd" of Sydney, N.S.W. From 1946 these books were designed and printed in Australia from patterns provided by British and Australian thread companies. Consequently these patterns may also appear in similar British and American publications. Paragon Book No. 104 is an instruction book designed for the "beginner" whilst Paragon book No. 105 is designed for the more experienced tatter. The layout of these books was typical of the 1940s period when paper was in short supply. Most of the pattern books were approximately 18 cms wide by 24 cms high and some were smaller at about 13cm by 21 cms. The type used was small (about four lines of text per centimetre) which was difficult to read. This item is an excellent example of a needle work pattern book available to women in the 1940's in Australia.A soft covered, 16 page instruction book titled "Tatting Designs". It has black and white photographs and detailed patterns for tatted doilies, a tray mat, a chairback and arm rests, a cheval set, a luncheon set, collars and edgings for an underskirt, gloves and handkerchief. It is published by Paragon Art Needlecraft of Sydney.Front cover - "Paragon's No 105" "PRICE 1/3" "Tatting Designs" "Household Linens * Personal Wear" Plus a stylized drawing of a deerflagstaff hill maritime museum and village, great ocean road, warrnambool, shipwreck coast, tatting book, tatting patterns, craft, handiwork, handcraft, needlework, shuttle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Tatting craft book, Paragon Art Needlecraft Pty Ltd, Learn to Tat, circa 1940's

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". It looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. Paragon knitting, crochet and tatting books have been distributed throughout Australia since the 1930's, originally by "Paragon Art Needlework Pty Ltd" of Sydney, N.S.W. From 1946 these books were designed and printed in Australia from patterns provided by British and Australian thread companies. Consequently these patterns may also appear in similar British and American publications. Paragon Book No. 104 is an instruction book designed for the "beginner" whilst Paragon book No. 105 is designed for the more experienced tatter. The layout of these books was typical of the 1940s period when paper was in short supply. Most of the pattern books were approximately 18 cms wide by 24 cms high and some were smaller at about 13cm by 21 cms. The type used was small (about four lines of text per centimetre) which was difficult to read.This item is an excellent example of a needle work pattern book available to women in the 1940's in Australia.A soft covered 16 page instruction book with black and white photographs and detailed instructions explaining how to tat and eight tatting projects including how to make a collar and handkerchief edgings, published by Paragon Art Needlecraft of Sydney.Front cover - "PARAGON BOOK NO. 104" "PRICE 1/3" "Learn to/ TAT' Back Cover - "36/D5 E/A DO2" - handwritten in pencil flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, tatting, tatting pattern book, tatting instructions, handicraft, needlework, shuttle, tatting shuttle, paragon needlecraft, paragon craft book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1878

This crucible was raised from the wreck of the LOCH ARD. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All bear markings to indicate their manufacture by the Morgan brothers of Battersea, trading as the Patent Plumbago Crucible Co. A crucible is a container used for purifying and melting metals so that they can be cast in a mould to a predetermined shape and use. They must withstand extremely high temperatures, abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles in mid-Victorian Britain, a significant technological advance at a time of great activity in foundries and expansion of demand for refined metals. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm’s manufacturing rights and began producing their own graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India, and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the LOCH ARD, suggest they may have been part of a sample shipment intended for similar promotion in the Australian colonies ― at Melbourne’s International Exhibition to be held in 1880. The summary of cargo manifest, by Don Charlwood in ‘Wrecks and Reputations’ does not mention any crucibles, implying that they were not a large consignment of uniform items. A newspaper account of an 1864 tour of the Morgan brothers’ ‘Black Potteries’ at Battersea indicates: “All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilogrammes; a No. 3, three kilogrammes, and so on.” These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six are of the same size from a visual appraisal.The shipwreck of the LOCH ARD is of State significance ― Victorian Heritage Register S417A large crucible, or fluxing pot, for heating and pouring molten metal. It was recovered from the wreck of the LOCH ARD. The clay fired vessel rises from circular flat base to a larger rim with pouring lip. It is stained a rust colour and bears some sedimentary accretion. Half of its loose fitting lid with central knob has also survived. Markings on the artefact indicate it is a Morgan’s crucible, made with graphite to prevent cracking in the furnace and provide a smooth (non-adhesive) inner surface. On base: “…RGAN’S PATENT CRUCIBLE”. On rim: “MORGAN’S PATENT P…” Below top edge "BAK"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, graphite crucible, plumbago crucible, morgans crucible company, loch ard, fluxing pot, crucible -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1878

This crucible was raised from the wreck of the LOCH ARD. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All bear markings to indicate their manufacture by the Morgan brothers of Battersea, trading as the Patent Plumbago Crucible Co. A crucible is a container used for purifying and melting metals so that they can be cast in a mould to a predetermined shape and use. They must withstand extremely high temperatures, abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles in mid-Victorian Britain, a significant technological advance at a time of great activity and expansion in foundries and demand for refined metals. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm’s manufacturing rights and began producing their own graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India, and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the LOCH ARD, suggest they may have been part of a sample shipment intended for similar promotion in the Australian colonies ― at Melbourne’s International Exhibition to be held in 1880. A summary of the LOCH ARD cargo manifest, by Don Charlwood in ‘Wrecks and Reputations’ does not mention any crucibles, implying that they were not part of a larger consignment of uniform items. A newspaper account of an 1864 tour of the Morgan brothers’ ‘Black Potteries’ at Battersea indicates: “All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilogrammes; a No. 3, three kilogrammes, and so on.” These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six are of the same size from a visual appraisal. The shipwreck of the LOCH ARD is of State significance ― Victorian Heritage Register S417A No. 6 size Morgan’s graphite crucible (i.e. 6kgs capacity). The crucible rises in a slight curve from a smaller flat base up to a wider top with a (chipped) pouring lip. It was recovered from the wreck of the LOCH ARD. The artefact is largely accretion free despite its long period of submersion at the wreck site. It has a number of visible maker’s markings which identify the manufacturer and the smelting capacity of the pot. The graphite crucible is in fair and stable condition. The number “6” which is framed in a square. The letters “THE PATENT PLUMBAGO CRUCIBLE COMPANY” and “BATTERSEA WORKS COMPANY”. Below rim "... GNS"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, graphite crucible, plumbago crucible, morgan's crucible company, loch ard, crucible, fluxing pot -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Baby Feeding Bottle, Allen & Handbury's, 1891-1920

Allen & Hanburys was founded in 1715 in Old Plough Court, Lombard Street, London, by Silvanus Bevan, a Welshman, apothecary, and a Quaker. Bevan and his brother, Timothy, who became his partner and later succeeded him, were known for their just dealings and the integrity and quality of their drugs. The company grew into a respected pharmaceutical center and had established a strong reputation with American doctors by the late 18th century. William Allen, FRS, also a Quaker, and well-known scientist, joined the firm in 1792 and rose quickly to become the dominant personality. His second wife was a member of the Hanbury family who had produced several learned scientists. On Allen's death, the Hanbury family assumed control of the company. The growth of the company was continuous, but it was in the second part of the 19th century that developments on a large scale took place. Factories were built at Ware, Hertfordshire, and Bethnal Green in East London. The factory at Ware specialised in infants' foods, dietetic products, medicated pastilles, malt preparations as well as galenical preparations, beginning production in 1892. The brands included Allenburys Nº1 and Nº2 foods (essentially milk foods for babies up to six months), and Allenburys Nº 3 (malted farinaceous food, six months and older). Allenburys Rusks was a suitable first solid food for infants. Allenburys claimed to be pioneers in Great Britain in the production of pastilles, and thus the Ware factory also produced Allenburys Glycerine and Black Currant Pastilles, amongst another 80 different kinds of medicated and crystallised pastilles. Allen and Hanburys were one of the first manufacturers of cod liver oil in Great Britain, and owned factories in the Lofoten Islands (Norway) as well as at Hull and Aberdeen taking cod directly from the North Sea. The Bethnal Green factory carried much of the administrative and scientific side of the business, which included research, analytical control, chemistry, pharmacy, and pharmacology. In this plant, galenical preparations, pills, tablets, capsules, and other classes of pharmaceutical and medical goods were prepared. The company had overseas branches in Lindsay, Ontario, Durban, India, Shanghai, Australia, and Buenos Aires, and agencies in many other countries. The company address was for many years at 37 Lombard Street, London EC. Allen and Hanburys Ltd were absorbed by Glaxo Laboratories in 1958 under the name Glaxo Smith Kline, the company, used the Allen and Hanburys name for the specialist respiratory division until it was phased out in 2013.An early baby feeding bottle was made by the Allen & Hanburys company between 1891 to around 1920. The item is significant as it was used to feed babies the new manufactured baby milk formula's made by Allen & Hanburys that were gaining in popularity towards the end of the Victorian era.Baby feeding bottle clear glass curved with flat bottom and measuring scale, teat opening at one end and filling hole without stopper at the other end.Allenburys Feeder AD 1715warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, baby feeding bottle, bottle, domestic object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Block (sailing), Burrows, Ship Candler, c. 1869

The Lightning was an American-built sailing ship and it is believed the rope block was part of the ship’s rigging or included as cargo. The plaque on the block mentions that the item was, “as supplied by Burrows Ship Chandlers” in 1869. The plaque could also mean that the rope block was supplied by the firm Burrows, Ship Chandler and Shipping Stock, as a replacement block for the Lightning. The American vessel named “Lightning” was a 3-masted, fully rigged extreme clipper ship. She was commissioned by James Baines, of the Black Ball Line in Liverpool, England, during the time of the Australian Gold Rush for the trade of passengers and cargo between England and Australia. Her load listed on early consignments included livestock and animals, including rabbits sent to Thomas Austin of Barwon Park, Winchelsea, Victoria, where the challenging association between Australia's agriculture and the imported rabbits started. The Lightning was built in 1854 by shipbuilder Donald McKay, in East Boston, USA. She was described as spacious and comfortable and regarded as one of the smartest ships of the time. The vessel set many speed records for her voyages and became one of the most famous of racing clippers and one of the fastest ever launched. In 1854, with Captain 'Bully' Forbes and Mate 'Bully' Bragg, Lightning made the return trip from Melbourne to Liverpool in only 64 days, 3 hours and 10 minutes; a record. Captain Enright became the new Master of LIGHTNING soon after this record was established and was regarded as one of the finest mariners in the Australian trade. One of Captain Enright's innovations was to publish a ship's paper called "The Lightning Gazette". What is of additional historic interest is that captain "Bully Forbes" had left the Lightning to captain the ill-fated Schomberg. In 1857, for a very brief time under Capt. Byrne the Lightning was used as a troopship, taking British officers and soldiers, stores and ammunition, to fight in India. In 1859 she then returned to her normal route between Liverpool and Melbourne, apart from 1867 when she made a special trip between Melbourne and Port Chalmers in New Zealand. In 1869 the Lightning was sold to Thomas Harrison of Liverpool, and continued to sail for the Black Ball Line. Master of Lightning, Captain Henry Jones, sailed her to Geelong in October 1869, and whilst docked, he had her loaded with a cargo of wool, copper, wire, tallow and other goods. At about 1 am on 31st October 1869, whilst still docked and fully laden, a fire was noticed on the vessel. Efforts to extinguish the fire were unsuccessful, so she was towed to the "Lightning Shoals" in Corio Bay, where she eventually sank, losing all cargo but no lives. The Lightning is listed on the Victorian Heritage Register (Ref S 415). The vessel is historically significant for being one of the fastest wooden ships ever built. it was notable as the first clipper built in the USA for British owners and as a shipping disaster in Geelong's history. The Lightning spent its whole career carrying cargo and immigrants from England to Australia. Its documented voyages give us a snapshot into shipping history, not only of Australia in the mid-19th century but how the world's commercial transport functioned o promote trade and emigration during this time.Large ship's block, wood, with two wooden sheaves and fibre straps, eye and thimble. The metal plaque attached to the block has an inscription. The block was used on the ship "Lightning".Plaque inscription: "BLOCK OFF THE LIGHTNING / AS SUPPLIED BY / BURROWS SHIPS CHANDLERS / & SHIPPING STOCK CORIO BAY / 1863" (or 1869)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sailing ship lightning, extreme clipper ship, american clipper ship, record breaking clipper ship, james baines, black ball line, donald mckay shipbuilder, captain ‘bully’ forbes, australian immigration, liverpool to melbourne migration, captain enright, captain byrne, captain henry jones, corio bay geelong, lightning shoals geelong, rabbits introduced to australia, burrows and bascombe, burrows, ship chandler, corio bay, burrow's ship chandlers and shipping stock, -

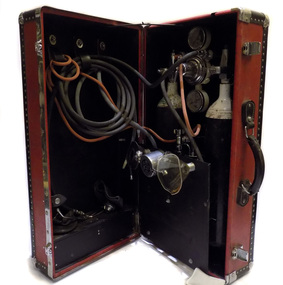

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Resuscitator Unit, c. 1960

Mechanical resuscitation devices, such as the Pulmotor and Lungmotor, were popular in the early part of the twentieth century. Their use waned in the 1920s as significant bodies like the British Medical Research Council and American Red Cross refused to endorse them. The most popular of the resuscitators to emerge in the 1930s was the E&J (Ericson and Johnson) resuscitator. The device was soon widely available, vigorously promoted with support from many medical practitioners. They were soon to be found in hospitals, emergency services like the ambulance and fire brigade, and voluntary life-saving organisations. In Australia, Norman James, director of anaesthesia at the Royal Melbourne Hospital, developed an interest in equipment for ambulances and the resuscitation of drowning victims. Little in the way of practical, portable equipment was available to either the ambulances or the voluntary life-saving organisations, such as Surf Life Saving Australia (SLSA); American resuscitators, like the E&J, were expensive and bulky to import. James designed a simple portable resuscitation device for local use after being approached by Jack Conabere, secretary of the Elwood Life Saving Club (ELSC). The resulting Royal Melbourne Hospital resuscitator, or the R.M. resuscitator as it was marketed, was a simpler, manual version of those available overseas. It was gas driven with a plunger, marked “Press”, and a safety valve. The small working unit attached directly to the facemask. Once the patient was positioned facedown and the airway cleared of debris, the mask was placed firmly over the face. The plunger allowed gas to flow and lung inflation; releasing the plunger allowed expiration. This simple resuscitator was marketed by Commonwealth Industrial Gases (CIG) and became very popular in Australia with volunteer and professional rescue organisations. It represents one of the many innovations in resuscitation equipment that resulted from cooperation between volunteer life savers and medical practitioners. Norman James worked closely with Jack Conabere and the Government Pathologist to develop the equipment. ELSC was the first life saving club to use the resuscitator on the beach. While conducting an early training exercise on 23 December 1951, they used it to successfully resuscitate a man who had drowned after capsizing his home made yacht. The R.M. resuscitator was also used in more inventive ways. At Fairfield Hospital in Melbourne, a group of physiotherapists and doctors did some innovative work with polio patients, teaching them glossopharyngeal (or “frog”) breathing, as a means of becoming less dependent on ventilators. In 1981, the Australian Standards Association stated that the RM head failed to meet its revised standards and it was withdrawn from the market. Red leather suitcase with black leather trim with metal studs. There are clip locks for locking the suitcase in the closed position. The suitcase contains equipment for oxygen resuscitation. There is a space allocated for two oxygen cylinders, however there are no cylinders present.Embossed into metal plaque: The C.I.G. / Oxy-viva / PORTABLE UNIVERSAL OXYGEN RESUSCITATORresuscitation, portable, surf life saving australia, royal melbourne hospital, rm resuscitator -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Platform Scales

Large platform scales such as these ones made by W. & T. Avery were used for weighing goods for trading and passengers' luggage. They would be used in places such as railway stations, shipping ports, customs offices and ticketing offices. Often fees would be charged to customers according to the weight of their goods and luggage. Items would be placed onto the large horizontal platform then weights would be added to the weighing bar until the bar leveled to being horizontal. The weights would be added together and the total of the weights would be used for the final figure. These scales were made in Birmingham, England, by the British company, W and T Avery. The company had its origins in the early 1700s but only became known as W and T Avery when the brothers William and Thomas Avery inherited the scale-making business from a relative, Joseph Balden, on his death in 1813. By 1885 they had three factories and In 1895, the company acquired James Watt & Co and two years later had moved to the 25-acre Soho Foundry site in Smethwick, Birmingham where James Watt had manufactured steam engines. When the last Avery family member died in 1918, the company employed over 3,000 people and had businesses all over the world. Following the highly successful introduction of the first digital retail scale in 1971, the company was taken over by the GEC Group in 1979. The business was subsequently acquired by the American company, Weigh-Tronix, in 2000 which had already acquired a competitor, Salter. The Avery name continues today in the company known as Avery Weigh-Tronix.An item that was used at the turn of the century as train platform scales or for weighing agricultural products. Made by a company that pioneered weighing equipment with offices all over the world. With many examples of this scale in museums throughout the world. Platform scales with wheels. Large cast iron, scales painted black, weight capacity to 7 CWT (hundred weight). Weight beam has markers "0. 5. 10. 15. 20. 25". Platform scale loose weight type with relieving handle; cast iron construction, fluted columns with integral weight stand, the two wheels are fitted to base at front of platform; there is a graduated steelyard 0-14bs with pear-shaped poise. Weight carrier is missing.Pressed into cast iron arm on scale, one side "W. & T. AVERY", opposite side "BIRMINGHAM", and into the platform "TO WEIGH 7 CWT, W. & T. AVERY, MAKERS, LONDON & BIRMINGHAM" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, measuring scales, weighing scales, weighing instrument, fees for goods, fees for luggage, ticket office -

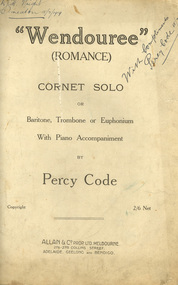

Federation University Historical Collection

Federation University Historical CollectionBooklet - Sheet Music, Allan & Company Pty Ltd, "Wendouree", Romance by Percy Code, 1919

This music was used by Frank Wright who had been tutored by Percy Code. Frank Wright won the Australian Open Cornet Championship using this music, and won the gold medal for the highest mark in the British Colonies. Percy Code was born in Melbourne on 03 July 1888. He started learning the violin and piano at the age of eight. Three years later his father, Edward, started tutoring him on the cornet. His first competition was in October 1902 in Ballarat's South Street Competitions. Percy Code was Musical Director of Ballarat City Brass Band from 1913 until 1921. He was Frank Wright's teacher. Code apparently lived in a large house just west of where St Peter's church (Ballarat) now stands. Percy Code toured the world as principal cornet with the 'Besses o' th' Barn Band.' He returned to Australia in 1912. Frank Wright at one stage rode his pushbike from Smeaton to Ballarat for lessons. Leaving Australia for America in March 1921 Percy Code obtained an appointment as trumpet soloist for the 70 piece San Francisco Symphony Orchestra. He returned home two years later and became bandmaster to the Prahran City Band in 1925. From 1938, as part of Australia's Sesqui Centenary celebrations, Percy Code conducted the Sydney Symphony Orchestra for the ABC orchestral concerts in Sydney Town Hall. His career with the ABC came to an end in late 1951 due to poor health. Percy Code died on 17 October 1953. From 'Legend in Brass' with additions from Bob Pattie of the Ballarat Brass Band.11071.1 Four cream pages containing handwritten title page in front, two sheet music pages inside and blank back cover. 11071.2 Eight cream pages containing front page typed title with handwritten text at top, Six pages of sheet music cream pages, with parts for piano and cornet, with black printed notes. A photograph of the composer Mr Percy Code is glued into the first page at the top left hand corner. The back cover page has advertisements for four music albums from Allan & Co. Prop. Ltd..1) Front page handwritten in blue pen and pencil. Hand written notations in pencil for cornet throughout sheet music pages. Frank Wright Smeaton 15 July 1919 in top right hand corner; Champion Bb cornet solo South Street 1919 in top left hand corner. Under title on front page: Handwritten notes in pencil giving results of competition and judge's comments. 2) Frank H. Wright Smeaton 15/7/1919 handwritten in top left hand corner. "With Compliments Percy Code 15/7/1919 written diagonally in blue pen in at right hand top.cornet, frank wright, allan & co., allans music, ballarat, south street, percy code, code, wright, sheet music, "wendouree", (romance), wendouree, romance, wendouree -

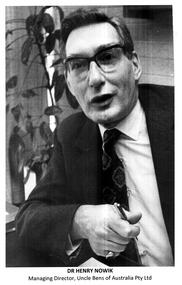

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMixed media - Dr Henry Nowik and Uncle Bens at Wodonga

Dr Henry Nowik played a critical role in the development of industry in Wodonga, through his management and leadership of Uncle Bens Wodonga from 1965 until 1979. Born in Poznan, Poland in 1917, Henry was studying medicine in Paris when World War II broke out and he enlisted in the Royal Air Force, serving with distinction as a Bomber Pilot. He was imprisoned in Russia when his plane ditched, escaped through Kazakhstan and was eventually evacuated to London where he was appointed RAF Aide-de-Camp to General Charles de Gaulle. He was later awarded the French Croix de Guerre. After the war Dr Nowik received a PhD in Political Science and Law from American Beirut University before moving to London to teach at the London School of Economics. He then moved into industry occupying a number of senior positions in marketing and market research. In 1964, Dr Nowik, then Market Research Manager for Pedigree Petfoods, the British arm of Mars Inc., came to Australia to research the prospects for establishing a petfood business. Dr Nowik was a passionate believer in the need for decentralisation of Australian industry. In 1965 Uncle Bens of Australia began building their first Australian factory in Wodonga, Victoria, from humble beginnings in a small house in Hovell Street. It became fully operational in 1967. Dr Nowik became the Marketing and Sales Director and in 1970 the Managing Director. Dr Nowik's work as a member of the Albury-Wodonga Consultative Committee was recognized in 1975 with the Order of the British Empire and in 1977 he was appointed Chairman of the Commonwealth Government's Decentralisation Advisory Board. He participated in a number of trade missions to Malaysia, China and Japan and was a Member of the Executive Committee of the Trade Development Council and the Victorian Promotion Committee. These contributions were recognised in 1982 when he was made an Officer of the Order of Australia. In 1979, Dr Nowik left Wodonga and moved to the United States to become Vice-President, Marketing for Mars, becoming Global Product Group President in 1980. Following his retirement in 1985 he continued to act as Senior Advisor to a number of Mars' businesses. Albury-Wodonga retained a special place in Dr Nowik's heart and he kept a close interest in Charles Sturt University, sharing his time, experience and expertise with staff and students. The University made him an honorary Doctor of Letters in 1993 when the Henry Nowik Lecture Theatre officially opened at the University's Albury campus. Later the City of Wodonga named a park in his honour. Dr Nowik and his wife returned to Australia in 2004, first living in Brisbane then moving to Maleny in Queensland. Henry Nowik died on 12th March 2015 aged 98. These items are significant because they demonstrate the contribution made to the Wodonga community and the Australian economy by Dr Henry Nowik AO OBE.A collection of items briefly documenting the contribution of Dr Henry Nowik to Wodonga, Victoria. Included are photos of Dr Nowik, newspaper items, a photo of the first office of Uncle Bens in Wodonga and a farewell card from Dr Nowik.dr henry nowik, uncle bens wodonga -

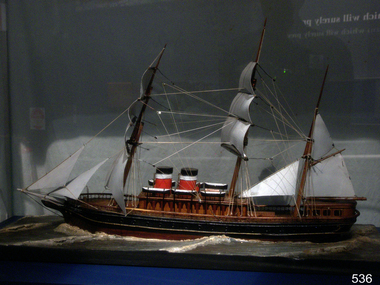

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Joseph Conrad, 20th century

The ship model of the Joseph Conrad represents the craft of ship model making, which has been enjoyed by many people over the years. Although the model is made from modern materials, it shows the elements of a sailing ship of a bygone era. About the sailing ship JOSEPH CONRAD: - The vessel Joseph Conrad began as the Danish iron-hulled sailing ship Georg Stage, launched in 1882. It was used as a training ship for Danish sailors. In 1905, while docked in Copenhagen, the ship was rammed by a larger ship, and 22 boys were killed while sleeping in the hull. The ship was later raised and on guard during World War I. Alan Villiers was an Australian author of seafaring books as well as a sailor. He bought the wooden sailing ship George Stage and renamed it Joseph Conrad in honour of the renowned Polish-born maritime author and once the captain of the barque Otago. In 1934 Villers sailed the ship on a two-year voyage around the world. In 1936, it was sold to an American, who later donated it for use again as a training ship. After World War II the ship was no longer used, and in 1947 it was transferred to the Mystic Seaport Museum for training use again as well as an exhibit. JOSEPH CONRAD (1857-1927): - Joseph Conrad was Polish-born and became a British subject in 1886. He was a renowned marine fiction writer and also, for a short time, a mariner and Captain. As a boy of 13 years old, Joseph Conrad desired to be a sailor. At 19, he joined the British merchant marines, working in several roles. He eventually qualified as a captain but only served in this role once, from 1888-89, when he commanded the barque Otago sailing from Sydney to Mauritius. In 1889 he also began writing his first novel, Almayer’s Folly. He retired from life as a mariner in 1894, aged 36. Conrad’s visits to Australia from 1878 to 1982, and his affection for Australia, were later commemorated by a plaque in Circular Quay, Sydney. Conrad continued as an author. It is said that many of the characters in his books were inspired by his maritime experiences and the people he had met. By the end of his life, he had completed many stories and essays, and 19 novels, plus one incomplete novel titled ‘Suspense’ that was finished and published posthumously. Shortly before he passed away, in 1924, Conrad was offered a Knighthood by Prime Minister Ramsay MacDonald for his work but declined the offer. The ship model represents the design of sailing ships built in the 1880s and can be used as a reference in understanding the construction of the ships of the Victorian era. The model is important for its connection to the vessel Joseph Conrad which was used as a training ship for seafarers, and even now is used to teach maritime skills, as well as an exhibit, in the maritime museum, Mystic Seaport. The model's name is significant for its association of its name with the famed early 20th-century maritime author, Joseph Conrad.Ship model; A three-masted sailing ship named the Joseph Conrad, with cabins on deck, lifeboats, a ladder on the side and a figurehead on the bow. The hull is black at the top and red below. The ship's name is painted on both sides of the bow. JOSEPH CONRADflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, joseph conrad, captain joseph conrad, maritime author, marine author, nautical author, sailor, seafarer, ship model, two-masted ship, iron hull, sailing ship, georg stage, 1882 ship, danish ship, training ship, boys killed, alan villiers, ship joseph conrad, mystic seaport, museum ship, otago -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined