Showing 226 items matching "cast iron work"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plough, Syracuse Chilled Plow Co, 1876-1900

The Syracuse Chilled Plough Company was created in 1876 and specialised in the manufacture of agricultural ploughs. Harry Wiard invented the chilling process in plough manufacture. The company was originally founded as the Robinson Chilled Plough Company in 1876 and changed its name 3 years later. At its peak, in the early 20th century. The company made more than 100,000 horse-drawn ploughs and road scrapers of various designs that were sold from the Syracuse plant each year and exported around the world. The company slogan of the day was, “The sun never sets on a Syracuse plough." Eventually, other farming implements were added to the line. The company employed more than 300 people in its local plant, which covered a square block on the cities Near West Side. In 1910-11, Deere and Company began expanding its holdings, and with the success of the Syracuse Chilled Plough Company, Deere sought to acquire the company. The management of the Syracuse operation after John Deere took over remained in the hands of Wiard and Chase, and the manufacturing operations were left in Syracuse. The only change from previous Syracuse operations was the selling of the companies products through Deere retail outlets instead of directly to the trade. The factory in Syracuse continued to produce ploughs until 1955. The subject item in the Flagstaff collection is an early model Syracuse Chilled plough with a wooden beam frame it is very much lighter in weight and was adapted to work sandy or light loamy soil. This plough has a sloping landside, which tends to keep the clods and dirt from falling into the furrow, making the ploughman's work much more comfortable and easy. This design was made in eight sizes for both right and left-handed ploughing and became very popular in the far West and South of the USA. Note: The definition of a chill plough means : a plough having the share and mould-board of chilled semi steel or cast iron.The subject item is believed to be a very early plough given its wooden beam frame and was made before 1900 probably around 1880. This makes it a significant example of the types of plough that early settlers were using in Victoria. There would not be very many of this type of vintage plough left with a wooden beam and frame, making it today a desirable collector's item. Syracuse Wood Beam Chilled single furrow plough metal wheel in front. Syracuse Chiller Co Syracuse & 50 L stamped on ploughshare.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plough, syracuse chiller co, chiller plourh, farm equipment, furrow -

Flagstaff Hill Maritime Museum and Village

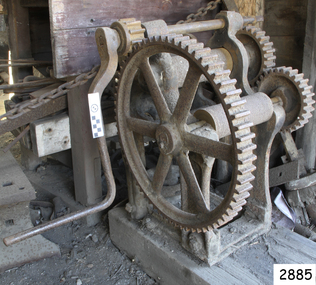

Flagstaff Hill Maritime Museum and VillageTyre Bender, 1884

A tyre bender is used to bend and shape metal rims for wooden wagon wheels. This tyre bender’s model first appeared in the Day Bros catalogue in 1884 as the “Giant” model. The catalogue of 1883 only showed a lighter duty model called the “Lion”. It can be assumed that this later “Giant” model was a heavy duty improvement over the 1883 "Lion" and other smaller models which were still being advertised for sale in 1884. The Day Bros foundry, makers of this tyre bender, was operating as the manufacture of wheel right and blacksmith tools and general machinery in the 19th century in the USA and successfully exported their goods all over the world. Wagon tyre benders would have been very common circa 1850-1920, so there were probably many makers over the years. Early on, it would have become clear to the blacksmiths about which designs worked best so, eventually, the various makers would have made similar products to each other. This tyre bender was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The tyre bender is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The machine or tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Steel tyre bender mounted on timber base, used for wagon wheel steel rims. Made from cast iron and steel, double geared with four cogs to unite the upper and lower steel rollers. There are adjustable guide collars to keep the iron in line while it is being bent. It can also be used with two cranks for heavy duty work utilising the use to two operators. It is the Giant model, made in 1884 by Day Bros. of Philadelphia. This tyre bender once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria. “DAY BROS. PHILAP. PA” cast into the side of machineflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, machinery, wagon wheel, wheelwrights, blacksmith, steel rim wheels, tyre bender, tire bender, the giant tyre bender, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, wagon tyre bender, day bros. philadelphia pennsylvania, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Window weights, Circa 1890

Dutton and Wiggs operated a brass and iron foundry known as the Warrnambool Brass and iron Foundry situated in Timor St. Mr Dutton was a mechanical engineer and Mr C Wiggs was an experienced foundry worker. They were innovative in their work and also manufactured a large number of everyday items such as verandah posts, brackets and milk aerators.The significance lies in the fact that the items were manufactured in Warrnambool by a well- established local business. Two solid cast iron rods of cylindrical shape with one flattened edge with name imprinted. Hollowed out section on one end. S. Wiggs W,bool. One has the number 7 and the other 5 cast into the metal. warrnambool, wiggs, dutton & wiggs, window weights -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Charcoal, c1850 - 1920

This iron was used by women, in their domestic role, to press the clothes from the mid 19th century. Coal embers were put inside, heating the base of the iron, to press the family's clothes and linen. Small bellows were used to fire up the embers to keep the iron hot. In the Kiewa Valley the embers would have been from the local hard wood growing on the farms.Ron White worked for the SEC on the Kiewa Hydro Electric Scheme. The iron belonged to his mother. Ron remembers being a boy of approximately 8 years of age, watching his mother do her ironing with this charcoal iron in the c1920s.This iron is made of cast iron. It has a hinged lid so that coal embers can be put inside for heat. The lid has a curved funnel. Bellows are used to blow air into the iron and keep the coals burning. It has a wooden handle and a lever (also with a wooden handle) to open the lid. There is a 2 and a half centimetre hole at the back of the iron to check the coals. The hole has a swivel cover.There is an embossed "S" on the swivel cover.iron, laudry, household, charcoal, antique, domestic, pressing clothes -

Eltham District Historical Society Inc

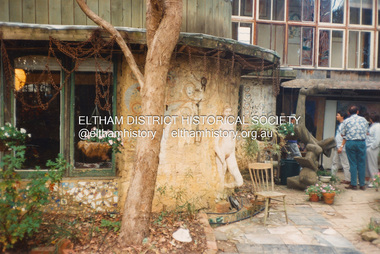

Eltham District Historical Society IncPhotograph, Fay Bridge, Clifton Pugh's Artists' Colony, Dunmoochin, Barreenong Road, Cottles Bridge, c.1995

Visit to Dunmoochin prior to Clifton Pugh's home being destroyed by fire in 2002. Following military service in the second world war, Clifton Pugh studied under artist Sir William Dargie at the National Gallery School in Melbourne as well as Justus Jorgensen, founder of Montsalvat. For a while he lived on the dole but also worked packing eggs for the Belot family saving sufficient to purchase six acres (2.4 ha) of land at Barreenong Road, Cottles Bridge. He accumulated more land and persuaded several other artists and friends to buy land nearby, resulting in a property of approximately 200 acres, stablishing it as one of the first artistic communes in Australia alongside Montsalvat in Eltham. It was around 1951 that Pugh felt he had '"done moochin' around" and so the name of the property evolved. He bought timber from Alistair Knox to build his house on the crest of a hill. Inspired by local goldminer's huts, it was a one room wattle-and-daub structure with dirt floor. Over the years it expanded with thick adobe walls made from local clay, high ceilings and stone floors. All materials other than the local earth were sourced from second hand materials, most found at wreckers' yards. Artists from across the nation were drawn to Dunmoochin, with several setting up houses and shacks on the property, maintaining their independence but sharing their artistic zeal. Artists who worked or resided at Dunmoochin included Mirka Mora, John Perceval, Albert Tucker, Fred Williams, Charles Blackman, Arthur Boyd and John Olsen. In 2002, Pugh's house along with its treasure trove of art and a library of some 20,000 books was destroyed by fire. Traces of Pugh's home remain with the presence of the Victorian doorframe archway with leadlight of intricate design, procured from a demolished Melbourne mansion; and two bronze life-sized female statues created by Pugh and cast by Matcham Skipper. In place of Pugh's house rose two double-storey mud-brick artists' studios topped with corrugated iron rooves curved like the wings of a bird with accommodation for seven. The original studios, gallery and other buildings survived the fire.fay bridge collection, 1995, barreenong road, cottles bridge, dunmoochin -

Eltham District Historical Society Inc

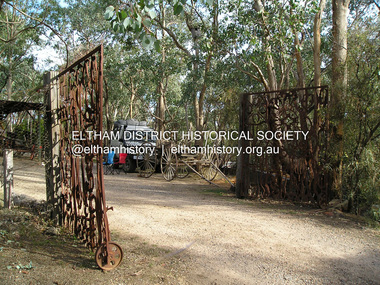

Eltham District Historical Society IncPhotograph, Fay Bridge, Clifton Pugh's Artists' Colony, Dunmoochin, Barreenong Road, Cottles Bridge, 14 May 2016

Following military service in the second world war, Clifton Pugh studied under artist Sir William Dargie at the National Gallery School in Melbourne as well as Justus Jorgensen, founder of Montsalvat. For a while he lived on the dole but also worked packing eggs for the Belot family saving sufficient to purchase six acres (2.4 ha) of land at Barreenong Road, Cottles Bridge. He accumulated more land and persuaded several other artists and friends to buy land nearby, resulting in a property of approximately 200 acres, stablishing it as one of the first artistic communes in Australia alongside Montsalvat in Eltham. It was around 1951 that Pugh felt he had '"done moochin' around" and so the name of the property evolved. He bought timber from Alistair Knox to build his house on the crest of a hill. Inspired by local goldminer's huts, it was a one room wattle-and-daub structure with dirt floor. Over the years it expanded with thick adobe walls made from local clay, high ceilings and stone floors. All materials other than the local earth were sourced from second hand materials, most found at wreckers' yards. Artists from across the nation were drawn to Dunmoochin, with several setting up houses and shacks on the property, maintaining their independence but sharing their artistic zeal. Artists who worked or resided at Dunmoochin included Mirka Mora, John Perceval, Albert Tucker, Fred Williams, Charles Blackman, Arthur Boyd and John Olsen. In 2002, Pugh's house along with its treasure trove of art and a library of some 20,000 books was destroyed by fire. Traces of Pugh's home remain with the presence of the Victorian doorframe archway with leadlight of intricate design, procured from a demolished Melbourne mansion; and two bronze life-sized female statues created by Pugh and cast by Matcham Skipper. In place of Pugh's house rose two double-storey mud-brick artists' studios topped with corrugated iron rooves curved like the wings of a bird with accommodation for seven. The original studios, gallery and other buildings survived the fire.fay bridge collection, 2016-05-14, art gallery, barreenong road, clifton pugh, cottles bridge, dunmoochin, maurice hurry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Greensborough Historical Society

Greensborough Historical SocietyTool - Shoe last, Cast iron shoe last, 1920c

Used in shoe repair as a work stand, shoe lasts come in various sized depending on the shoe size.Cast iron triple shoe lastshoe lasts, bootmaking tools -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Crane, n.d

Port of Portland Authority Believed to be one of the items transferred to City of Portland from Port of Portland Authority late in 1997. There is no apparent evidence that this item has formally come under the responsibility of Glenelg Shire Council, although through practice, and community expectation, Glenelg Shire Council has assumed responsibility for its care and maintenance. Efforts to identify its status are continuing.Maritime jetty crane consisting of cast iron gears and housing, struts, supports, pulleys and timber masts. The metal work has been coated in gren paint, the timber mast in white paint.jetty cranes, crane, portland harbour, cargo -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTool Spring Set, circa early 1900s

This is part of a crosscut saw raker/jointer/guage set used to bend the tip of each cutter tooth for cross cut logging saws. The logging saws used in the early 1900's for the clearing of forests required constant sharpening of their "cutting teeth". The logging of forested areas during these times was very much a "hands on" method of either one or two men by the use of saw or hand axe. This item was used by the surveyors commissioned by The S.E.C. Victoria Kiewa Hydro Electricity Scheme project mapping the relevant Alpine region. Chain saws, chain and ball(clearing) and bulldozing methods came in the mid 1900's.This particular saw sharpening method was used by surveyors laying down boundaries for the S.E.C. Victoria Hydro Electricity Scheme (1920's). This item was given to a local Kiewa Valley lad who accompanied the initial surveyors. The lad was responsible for the tendering and feeding of the surveyors "pack horses". Surveys work during this period and in these dense mountainous terrain of the Victorian Alps was both exhausting and hazardous. Overnight accommodation at various log cabins was not always possible and swag/tent alternative was the "fall back".This cast iron Spring Setting tool has a main body of angle iron contours with one end tappered into a flat circular extension with a slit (3/32" wide) running from the top to nearly the centre(15mm). This slit is to allow the bending of each "cutter tooth" of the cross cut saw. The "bottom of this slit has a semi circular ending. Protruding from one side of the bar body, and close to the "slit" is a tounge like extension (wedge) to fasten the spring set tool into a tree stump. See KVHS 0090 (A) for its Raker/Jointer saw sharpening guage set partner. Also see KVHS 0090 (C) for the associated wrench. On one side of the bar "DISSTON U.S.A."hand tool, saw, sharpening method, tree felling -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand, circa 1867 to circa 1871

This is size one of three sizes (Mrs Potts) irons available in the late 1800s and early 1900s which were used for (press) ironing clothes etc. using wood or coal based heaters. The majority of these irons would have been placed on top of wood or coal fuelled stoves. They survived longer in isolated outback regions where electricity had not been connected. The weight of these irons was intentionally heavy so as to press the clothes etc. neatly. These irons were used in an era where stiff collars and creases in particular types of clothing was essentially a social requirementHistorically these irons fulfilled a particular function that was the norm in isolated or semi isolated country locations. Cities and larger towns had professional laundry and pressing shops. In smaller towns and homesteads, wives and relatives would use these heavy irons and required strong arms. In middle and higher levels of society these irons would be used by maids or nannies. Their use was a necessity to conform to the social requirements of acceptable appearances that all clothing worn had been "pressed" clean. In the Kiewa Valley the majority of these irons would have been used by mothers or relatives. Men would hardly have used these irons as society labelled this type of activity as "women's work"This double pointed, heavy and solid cast iron, is a Mrs Potts No. 1 type. It does not have a handle. It was used to iron clothes. Open cavity on top for handle (not included) see KVHS 0369 for No. 3 ironMrs Potts No. 1house hold, ironing, domestic, pressing, clothes appliance -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand, 1867 to 1871

This is size one of three sizes (Mrs Potts) irons available in the late 1800s and early 1900s which were used for (press) ironing clothes etc. using wood or coal based heaters. The majority of these irons would have been placed on top of wood or coal fuelled stoves. They survived longer in isolated outback regions where electricity had not been connected. The weight of these irons was intentionally heavy so as to press the clothes etc. neatly. These irons were used in an era where stiff collars and creases in particular types of clothing was essentially a social requirementHistorically these irons fulfilled a particular function that was the norm in isolated or semi isolated country locations i.e., ironed clothes and linen.The iron was heated by using locally acquired wood in a cast iron stove or "pot Belly". It would be placed on top of the stove but not directly in the flames. Cities and larger towns had professional laundry and pressing shops. In smaller towns and homesteads, wives and relatives would use these heavy irons which required strong arms. In middle and higher levels of society these irons would be used by maids or nannies. Their use was a necessity, to conform to the social requirements of acceptable appearances in that all clothing worn had been "pressed" clean. In the Kiewa Valley the majority of these irons would have been used by mothers or relatives. Men would hardly have used these irons as society labelled this type of activity as "women's work"This double pointed, heavy and solid cast iron, is a Mrs Potts No.3 type. It does not have a handle. It was used to iron clothes. Open cavity on top for handle (not included) Note: one end is pointed up to allow the natural weight of the iron to increase the pressure at any of the "hard to press" spots or emphasizing required creases. see KVHS 0368 for No. 1 ironMrs Potts No. 3house hold, ironing, domestic, pressing, clothes appliance -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - G.S. Mackay company seal, Late 19th century

George Sutherland Mackay came to Warrnambool in 1891 and in 1893 joined his practice with that of James Fletcher and the firm became known as Mackay and Fletcher later changed to Mackay and Taylor. G S Mackay served for a long time on the Warrnambool City Council including 4 terms as Mayor. He was also an active member of the Presbyterian Church and worked to establish the Warrnambool Agricultural High School. He built the offices which still stand at 131 Kepler Street. He died in 1926. The firm celebrated its centenary in 1993.A commonly used office item which is well linked to both a long established business in Warrnambool and G. S. Mackay who contributed greatly to the community of Warrnambool and district. Cast iron painted black with rounded rectangular base. Circular seal and shaped handle which moves down 45 degrees. Trimmed with worn gold paint. Excelsior in gold on the front. The oval seal reads G. S. Mackay Warrnambool solicitor.warrnambool, g s mackay, mackay & taylor, mackay solicitor, company seal -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Newcombe timber company Seal, Mid to Late 19th century

Newcombe and Co traded as timber merchants And iron mongers in Koroit Street in the later part of the 19th century and early 20th century. It was destroyed by fire in March 1918.A commonly used office item which is well linked to a long established business in Warrnambool.Cast iron rectangular base with arch form leading to handle. Painted black and decorated with gold scroll work. Orange line around rectangular base. The seal is operated by pushing down the handle which stamps on paper which would be placed between the circular stamp and the base plate.warrnambool, company seal, embossing seal, newcombe timber company, koroit street -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1867

Langlands Company History: Langlands foundry was Melbourne's first foundry and iron shipbuilder established in 1842, only 8 years after the founding of the Victorian colony by two Scottish immigrants, Robert Langlands and Thomas Fulton, who had formed a partnership before emigrating (1813–1859). The business was known as the 'Langlands Foundry Co'. Henry Langlands (1794-1863), left Scotland in 1846 with his wife Christian, née Thoms, and five surviving children to join his brother Robert. By the time he arrived in early January of 1847 the partnership of Robert Langlands and Fulton had dissolved as Fulton had gone off to establish his own works. It was at this time that the two brothers took over ownership of Langlands foundry. Several years later Robert retired and Henry became sole the proprietor. The foundry was originally located on Flinders Lane between King and Spencer streets. Their sole machine tool, when they commenced as a business, was a small slide rest lathe turned by foot. In about 1865 they moved to the south side of the Yarra River, to the Yarra bank near the Spencer Street Bridge and then in about 1886 they moved to Grant Street, South Melbourne. The works employed as many as 350 workers manufacturing a wide range of marine, mining, civil engineering, railway and general manufacturing components including engines and boilers. The foundry prospered despite high wages and the lack of raw materials. It became known for high-quality products that competed successfully with any imported articles. By the time Henry retired, the foundry was one of the largest employers in Victoria and was responsible for casting the first bell and lamp-posts in the colony. The business was carried on by his sons after Henry's death. The company was responsible for fabricating the boiler for the first railway locomotive to operate in Australia, built-in 1854 by Robertson, Martin & Smith for the Melbourne and Hobson's Bay Railway Company. Also in the 1860s, they commenced manufacture of cast iron pipes for the Board of Works, which was then laying the first reticulated water supply system in Melbourne. Langlands was well known for its gold mining equipment, being the first company in Victoria to take up the manufacture of mining machinery, and it played an important role in equipping Victoria's and Australia's first mineral boom in the 1850s and 1860s. Langlands Foundry was an incubator for several engineers including Herbert Austin (1866–1941) who worked as a fitter at Langlands and went on to work on the Wolesely Shearing machine. He also founded the Austin Motor Company in 1905. Around the 1890s Langlands Foundry Co. declined and was bought up by the Austral Otis Co. in about 1893. History for Grimoldi: John Baptist Grimoldi was born in London UK. His Father was Domeneck Grimoldi, who was born in Amsterdam with an Italian Father and Dutch mother. Domeneck was also a scientific instrument maker. John B Grimoldi had served his apprenticeship to his older brother Henry Grimoldi in Brooke Street, Holburn, London and had emigrated from England to Australia to start his own meteorological and scientific instrument makers business at 81 Queens St Melbourne. He operated his business in 1862 until 1883 when it was brought by William Samuel and Charles Frederick, also well known scientific instrument makers who had emigrated to Melbourne in 1875. John Grimoldi became successful and made a number of high quality measuring instruments for the Meteorological Observatory in Melbourne. The barometer was installed at Warrnambool's old jetty and then the Breakwater as part of the Victorian Government's insistence that barometers be placed at all major Victorian ports. This coastal barometer is representative of barometers that were installed through this government scheme that began in 1866. The collecting of meteorological data was an important aspect of the Melbourne Observatory's work from its inception. Just as astronomy had an important practical role to play in navigation, timekeeping and surveying, so the meteorological service provided up to date weather information and forecasts that were essential for shipping and agriculture. As a result, instruments made by the early instrument makers of Australia was of significant importance to the development and safe trading of companies operating during the Victorian colonies early days. The provenance of this artefact is well documented and demonstrates, in particular, the importance of the barometer to the local fishermen and mariners of Warrnambool. This barometer is historically significant for its association with Langlands’ Foundry which pioneered technology in the developing colony by establishing the first ironworks in Melbourne founded in 1842. Also, it is significant for its connection to John B Grimoldi who made the barometer and thermometer housed in the cast iron case. Grimoldi, a successful meteorological and scientific instrument maker, arrived in the colony from England and established his business in 1862 becoming an instrument maker to the Melbourne Observatory. Additional significance is its completeness and for its rarity, as it is believed to be one of only two extant barometers of this type and in 1986 it was moved to Flagstaff Hill Maritime Village as part of its museum collection. Coast Barometer No. 8 is a tall, red painted cast iron pillar containing a vertical combined barometer and thermometer. Half way down in the cast iron framed glass door is a keyhole. Inside is a wooden case containing a mercury barometer at the top with a thermometer attached underneath, each with a separate glass window and a silver coloured metal backing plate. Just below the barometer, on the right-hand side, is a brass disc with a hole for a gauge key in the centre. The barometer has a silvered tin backing plate with a scale, in inches, of "27 to 31" on the right side and includes a Vernier with finer markings, which is set by turning the gauge key. The thermometer has a silvered tin backing plate with a scale on the left side of "30 to 140". Each of the scales has markings showing the units between the numbers.Inscription at the top front of the pillar reads "COAST BAROMETER" Inscribed on the bottom of the pillar is "No 8". and "LANGLANDS BROS & CO ENGINEERS MELBOURNE " The barometer backing plate is inscribed "COAST BAROMETER NO. 8, VICTORIA" and printed on the left of the scale, has "J GRIMOLDI" on the top and left of the scale, inscribed "Maker, MELBOURNE". There is an inscription on the bottom right-hand side of the thermometer scale, just above the 30 mark "FREEZING" Etched into the timber inside the case are the Roman numerals "VIII" (the number 8)flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, warrnambool breakwater, coast barometer, coastal barometer, barometer, weather warning, ports and harbours, fishery barometer, sea coast barometer, austral otis co, coast barometer no. 8, henry grimoldi, henry langlands, john baptist grimoldi, langlands foundry co, meteorological instrument maker, robert langlands, scientific instrument maker, thermometer, thomas fulton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Childs high chair, 1890 - 1900

It appears that the earliest form of child's high chair is attributed to Jonathan Jacobs (1845-1919) a cabinet maker of Browningsville, Pennsylvania USA around the mid to late 19th century. However, children’s chairs from the 18th century and earlier were being used and are in many museum collections around the world that show woodworkers were adapting chair designs for younger users in Europe and America at this time.An early children's wooden high chair probably made in America around 1890-1900. Many American manufactures made this type of wooden high chair called an “Eastlake” style and many did not mark their work so it is difficult to determine the subject items exact provenance. A significant item giving a snapshot into the evolution of children's furniture and domestic life during the late Victorian era.Convertible pressed back Victorian era high chair with convertible frame, cast iron wheels, Carved picture of a child to back of seatflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, high chair, potty chair, baby furniture, kitchen furniture -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeIron, Flat, 1800 (estimated); 19th. century

From the 17th century, sadirons or sad irons (from an old word meaning solid) began to be used. They were thick slabs of cast iron, delta - shaped and with a handle, heated in a fire. These were also called flat irons. Another solution was to employ a cluster of solid irons that were heated from the single source: as the iron currently in use cools down, it could be quickly replaced by another one that is hot. Source: www.wikipedia.orgLocal social history, domestic itemBlack cast iron with handleon top plate but not decipherabledomestic, iron, work, womens, laundry -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Black and White, Photographs of Ballarat Buildings by Geoff Biddington, 1967, 1967

Geoff Biddington took numerous photos around Ballarat and District. He was an active member of the Ballarat Branch of the National Trust. 48 black and white photographs of Ballarat buildings. 1. National Bank, Buninyong 2. Gas Light Standard, Geelong Road, Mount Clear 3. Water Hydrant 4. Former Police Station, Camp Street 5. Cast Iron Drinking Fountain, Eureka Stockade 6. Buninyong Gold Discovery Monument 7. Ballarat Old Cemetery Gates 8. Ballarat East Post office 9. Carriers Arms, Doveton Street North 10. North Star Hotel, Lydiard Street North 11.Lake View Hotel 12. Former Ballarat Gaol, Gate Two 13. Beaufort House 14. Smythesdale Post Office 15. Ballan Timber Building 16. National Mutual Building, Sturt Street 17. Craig's Hotel Doors 18. Her Majesty's Theatre Stage 19 & 20. Ballarat Botanical Gardens Statuary House 21 & 22. Stonemason at work 23. Methodist Church School (1867) Humffray Street 24 & 25. Methodist Church, Brown Hill 26. Queen St Statue,Sturt Street 27-29. Sturt Street Fountain 30. Moore Statue, Sturt Street 31. Hede Statue, Sturt Street 32. George V Statue (Victor Greenhalgh), Sturt Street 33-35. Peter Lalor Statue, Sturt Street 36. Art Deco Statue, Sturt Street 37. Beaufort Bandstand 38. Ranger Barracks, Curtis Street, Ballarat 39. Smeaton Mill and Bridge 40. Hepburn Graveyard, Smeaton 41-45 - Ballarat Tram Ride (possibly last) 46-48. Taking up the Ballarat Tram Tracks, 1967 .49. Melbourne House, Sebastopolgeoff biddington, biddington, buninyong, mount clear, police, gold, cemetery, hotels, ballarat gaol, beaufort house, smythesdale, ballan, theatre, statue, statues, statuary, peter lalor, ranger barracks, smeaton mill, smeaton bridge, hepburn, tram, sebastopol, craig's, her majesty's theatre, smeaton, hepburn graveyard, gold monument, queen victoria statue, ballarat, foodland, ballarat, ballarat buildings, former eagle hotel, former ballarat police station, gold discovery, craig's hotel, buninyong gold discovery obelisk -

Federation University Historical Collection

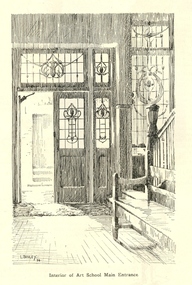

Federation University Historical CollectionArtwork, other - Artwork, Artwork from the Ballarat School of Mines Students' Magazine, 1934, 1934

Sir Alexander Peacock opened the Ballarat Technical Art School in July 1915. It cost 10,000 pounds and was constructed by the Public Works Department from plans drawn by the then Art School Principal, Herbert H. Smith. The building contractors were Messrs Gower and Eddards. According to the SMB Annual Report of 1914 'the internal upholstering and fittings have all been carried out in Australian timbers, with Queensland maple largely used throughout.' Before this building was constructed art and craft classes were held in various buildings around Ballarat. The building could be described as federation-art deco in style. It features sandstone insertion with sandstone string coursing. The base of the building is rusticated sandstone. The relief stone panel on the front with the words "Technical Art School" features stone pilaster brackets and corbels. In the centre front can be seen rectangular sandstone pediment with decorative stonework incorporating the date of construction. The windows in the lower floor feature five supporting keystones whereas the upper windows have sandstone lintels. The building also features decorative cast iron downpipes. The entrance on the northern side has attractive leadlight glazing in an art deco style. Above the door a miner's lamp and pick are featured in the design. The building is functional in design with large metal windows in the south wall to ensure good light into the studios. The northern wall has standard double hung windows. The interior of the building features a carved wooden staircase and cast iron ceiling vents. The rear drawing studios can be made into one large studio by opening panelled timber doors. This opening features classical plaster pilasters with a pediment above. This building is now the Gribble Building on the Federation University Australia SMB Campus.Artwork by students of the Ballarat Technical Art School from the 1934 Ballarat School of Mines Students' Magazine .1) Stairs to the Ballarat Junior Technical School from Grant Street .2) Caricatures by Nornie Gude .3) work by Colin S. Hunt .4) A girl and a rooster by Gilda Gude .5) Self Portrait .6) Main entrance to the Ballarat Technical Art School by Lorna Bailey .7) Artwork from the magazineballarat technical art school, gribble building, gribble, stained glass, white flat, hopwood, bailey, gude, ballarat junior technical school, visual arts -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Boiling Copper, Newberry & Walker, Boiling Tub, Circa1900

Francis John Newberry founded the Victoria Foundry and Enameling Works in 1890 with a workmate from the Humbles iron foundry in Lupton Street Geelong where he worked. Newberry & Walker Foundry & Enameling Works was built adjoining a cottage that was to be the home of the Newberry family during the ensuing years. Although Walker soon relocated to New Zealand, the Newberry and Walker foundry had become a local success. The foundry produced numerous cast iron products such as washing copper frames, and friezes, balustrades and verandah columns. Verandah posts are to be found in declining numbers, but the Newberry and Walker mark can sometimes be seen on the few which remain. A certain number of iron culvert posts were also made; some of them were still in place on the road to Cressy as late as 1961. Perhaps half the iron friezes on Geelong West verandahs came from the local firm’s foundry. A significant item made in Geelong giving a snapshot into the early beginnings of Victoria's industrial manufacturing of products that helped to replace previously imported items from England or America.Copper boiling tub, cast iron frame copper bowl inside of 14 gallon capacity Newberry & Walkerflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, cast iron, newberry & walker, washing copper frame, laundry, dairy, butchering -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'G' Clamp, early 20thC

A C-clamp or G- clamp is a type of clamp device typically used to hold a wood or metal work-piece, and often used in, but are not limited to, carpentry and welding. These clamps are called "C" clamps because of their C shaped frame, but are otherwise often called G-clamps or G-cramps because including the screw part they are shaped like an uppercase letter G. The fixed end is not adjustable so size is not variable. G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "G" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame When used some other object or objects will be contained between the top and bottom flat edges. A steel 'G' Clamp tools, g clamp, screws, steel, clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabin, bentleigh, cheltenham -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, sad iron, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire. The family of Miss M Curtis were early settlers in Moorabbin Shire. Sad-iron, domestic, flat, cast iron, Silvester's Patent, No 6, Salter, England, c. 1890-1900s A sad iron made from cast iron was heated over a fire or on a stove and used for pressing clothing and table wareSILVESTER'S/ PATENT/ SALTERS / No 6 with the pretzel & a arrow going through the centresad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, flat iron with trivet stand, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin Shire. A) A heavy cast iron, flat iron with B) horseshoe shaped trivet stand c1880 The trivet can be attached to a table by an adjustable clamp.A) 5 on tip of ironsad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, sad iron with lifter, c1900

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and using the lifter the cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire. The Curtis family were early settlers in Moorabbin ShireA) This heavy sad iron, made from cast iron, was heated over a fire or on a stove and used for pressing clothing and haberdashery. B) The separate tapered handle was used to lift the hot iron from the fire and when a "Potts" Handle was attached the ironing commenced. sad iron, kitchen equipment, fireplaces, stoves, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, sad iron with Mrs Potts handle, c1900

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. Mrs Florence Potts invented in 1871 a detachable handle made from walnut wood with a metal latch to release the handle. These wooden handles prevented burned hands and were sold to grateful women all over the world. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.Mrs Florence Potts invented this type of detachable walnut wood handle with a meta release latch for sad irons in 1871 and it sold widely throughout the world to grateful women including those in Moorabbin Shire. The family of Ms May Curtis were early settlers in Moorabbin ShireA) A sad iron, made of cast iron , has a special handle invented in 1871 by Mrs Florence Potts of Iowa, USA. B) The detachable handle made of walnut wood to prevent burned hands, was attached to the iron by a metal latch.A) UNITED/ N0 / 50 / AUSTRALIApotts florence, iowa usa, melbourne, moorabbin, sad irons, kitchen equipmentn fireplaces, walnut wood, sewing, laundry, table ware, linen, pioneers, early settlers, washing days, craftwork