Showing 192 items

matching crank

-

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of four Black & White Photograph/s, Sutcliffe Pty Ltd, late 1920's

Set of four Photographs, Black and White, of the MMTB Tourist Bus late 1920's. .1 - Side on view of the MMTB Tourist bus showing the lettering and logo. .2 - Front on view showing the radiator, head lights and other details including the crank handle. .3 - Interior view looking along the bus from the front. Shows the curtains and the extensively upholstered seats. .4 - ditto showing the woven cane seats. Photos Print and photograph by Sutcliffe of Cromwell buildings 366a Bourke St. Melbourne.In ink on the rear: All "M&MTB Tourist bus late 1920's" and the photographers stamp, with .3 and .4 adding "Interior" KSK print number SA957 to 960trams, tramways, mmtb, tourist bus, buses, interiors -

The Beechworth Burke Museum

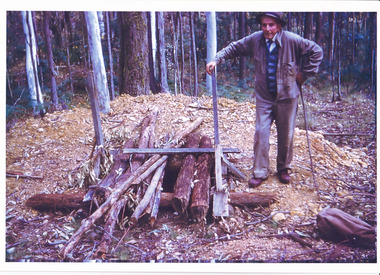

The Beechworth Burke MuseumPhotograph

The date this photograph was taken is unknown. Estimated date 1960-70s. The gentleman in the photograph and location the photograph was taken are also unknown. Perhaps in the Beechworth or Stanley area. The photo is associated to another record, 6856 as it has the same elderly gentlemen in the image. He is able to be identified through wearing the same clothes and distinctive hat in both photographs. The photograph is associated to mining as the gentleman is standing next to a small mine site where perhaps a windless or whip was mounted over the entrance of the shaft. The windless was a structure mounted over the shaft, fitted with a hand-cranked winch, which was usually constructed from wood that would have been found in the surrounding area. Colour rectangular photograph printed on glossy photographic paper.Obverse: Reverse: 6856/ mining, windlass, whip, empty record -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hand operated seed broadcaster

Seed broadcaster were used to distribute seed across a small area or to fill in patches where seeding has been missed. This method does not ensure a uniform distribution of seeds unless the person using the machine walks at a very measured pace. It also requires a lot of time and manual labour if used in larger areas. It was most used for planting cover crops, grains, grasses and similar plants that do not need to be in neat rows. The hand-crank broadcast seed spreader was invented in 1868 by Samuel S. Speicher (aka. Spyker) in Indiana, USA. By 1955 new developments included the invention of a seed broadcaster on wheels and these smaller spreaders started to disappear.This item is representative of agricultural machinery used on a local, national and international level in the late 19th and early 20th century.A metal hand seed broadcaster. A hopper at the top was the receptacle for seed. The wheel with a handle on the side when turned drives the cogs attached to an axle. This action rotates the attached spindle with blades to propel seed out the front of the broadcaster. The broadcaster would have had a shoulder strap and a bag of seed would have been added to the hopper and secured with twine through the holes around the top.agricultural tools, farm machinery -

Federation University Historical Collection

Federation University Historical CollectionBook, Ballarat School of Mines Apprentices' Handbook, 1953, 1953

Apprentices' Handbook, Issued with the compliments of The Council and Staff of The Ballarat School of Mines and Industries. It contains a foreword from the Principal to apprentices. It states how they are taking the first step towards becoming a first class craftsman in their chosen field. The course is set down by the Victorian Apprenticeship Commission and consists of the practical experience obtained while on the job together with the subjects studied at this school. Page 26 gives the date the book was produced. From the diary of a service man dated January 25, 1913:- "Been filing crank pins all day. Hard to get a good job if they are much out of round, but it is the only practical way at present." That is 40 years ago and contrasts with today. (1953)Sixty-two page handbook with illustrations. .1: E J Tippett in blue ink on inside of front cover. Printer's name and emblem on last page. "John Fraser & Son Printers - Albert Street, Ballarat"ballarat school of mines, trades, apprenticeship, apprentice, electrical mechanics, motor mechanics, turning and fitting, plumbing and gasfitting, blacksmithing, printing, useful tables, mechanical and electrical unit equivalents, power consumption of electrical appliances, horse power to drive machinery, breakdown troubles of cars, pre-war post-war, table of chemical elements, screw gauges, welding tips -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionEquipment - Equipment - Divers air pump, 1900-1930

Port of Portland CollectionFront: C. E. Heinke/ Submarine Engineer 103 GI Portland St London (brass plate on side of pump)port of portland archives -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 6 Black & White Photograph/s, Sutcliffe Pty Ltd, c1940

Series of 6 black and white photographs of work in the Nicholson St bus workshops of staff at work. Possibly c1940. .1 - three workers, possibly apprentices working on engine blocks with a supervisor/manager in a suit looking on. .2 - with a crank shaft and other equipment. .3 - motor on a stand with piston rods in the background. .4 - possibly the or "testing" room with a fluid being tested? .5 - An engine part (end block) on a "Central Garage" trolley. .6 - Battery room. All stamped "Sutcliffe Pty Ltd of 94 Elizabeth St Melbourne" with a sequence number on rear.trams, tramways, buses, nicholson st, workshops -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPocket Phonograph, Palliard Cie (St Croix), Circa 1926

This mikiphone has an approximate manufacture date of circa 1926. It is stamped in the interior with the maker’s mark of Palliard Cie (St Croix), who partnered with the patent owners, Nicolas and Etienne Vadasz for the large scale production of the mikiphones. A Mikiphone – or Pocket Phonograph is one of the earliest versions of a portable music player. The Mikiphone was small enough to fit into a pocket for portability, and once unpacked had the ability to play 10” records. Power was supplied to the unit by a small hand crank, and sound was amplified by a small resonator. It is estimated that 100,000 to 180,000 of the units were made between 1924 and 1927. Luxury editions were also available with either a gold or silver casing. Le Corbusier is quoted as saying he could ‘see in the Mikiphone the essence of Esprit Nouveau’. The pocket gramophone is significant for historical and social reasons. It is primarily an enabler of leisure activities due to its portability and size. The design of the object is also significant as it showcases design advancements in the early part of the 20th century. The Swiss made "Mikiphone", the smallest talking machine ever placed on the market folded up to the size of a large pocket watch or small cheese case. Production stopped in 1927. A total of 180,000 were made. A few were made in a luxury version with gold or silver case for a "Pretentious clientele".Inside on dial: Mikiphone / Pocket Phonograph / Swiss made / System Vadasz. Outside: Pocket Phonograph / Mikiphone / System Vadosz / Patented in all countries.pocket phonograph, mikiphone, gramophone, pocket, music player, swiss made, switzerland -

Federation University Historical Collection

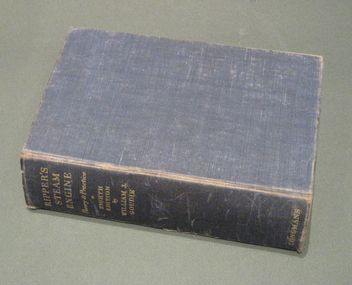

Federation University Historical CollectionBook, William J. Goudie, Ripper's Steam Engine Theory and Practice, 1932

Formerly part of the Ballarat School of Mines libraryA blue book with the title printed in gold on the spine, and the publisher "Longmans" printed in gold at the base of the spine. It has 503 illustrations throughout. It has two loose pages of plates in a sleeve inside the back cover and some pull out plates throughout. 841 pagesIt is stamped with The School of Mines Ballarat near the front and back pages, as well as some throughout the book.steam engine, properties of steam, flywheels, condensers, thermodynamic principles, energy diagrams, engine cycles and efficiencies, brake horse-power, steam in the cylinder, multiple expansion engines, valve gears, governors, crank, corliss and drop-valve engines, steam turbines, turbine performance, steam -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Late 19th to early 20th century

A butter churn is a device used to convert cream into butter. This is done through a mechanical process, frequently via a pole inserted through the lid of the churn, or via a crank used to turn a rotating device inside the churn. The use of butter is mentioned in biblical works and the earliest butter churn vessels belonging to Beersheba culture in Israel were found in Bir Abu Matar going back to Chalcolithic period between 6500–5500 BC. The butter churn in Europe may have existed as early as the 6th century AD, In the European tradition, the butter churn was primarily a device used by women, and the churning of butter was an essential responsibility along with other household chores. In earlier traditions of butter making, nomadic cultures placed milk in skin bags and produced butter either by shaking the bag manually, or possibly by attaching the bag to a pack animal, and producing butter simply through the movement of the animal. An item used to make butter in a domestic situation by turning a handle until the cream inside has turned to butter.Butter churn, wooden, lid pieces screwed or nailed together. Brass bearing on side with iron turning handle.Handle marked 28204 no other marks to indicate manufacturer or date of productionflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, churn, butter churn, wooden churn, butter making, food, dairy, kitchen utensil -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, early 20th century

Sewing machine, portable, hand operated, with Premier logo. Has folding crank handle, body painted black with floral design, wooden base and separate wooden cover with lock. Base has compartment with accessories, covered by curved ended, sliding wooden panel. Decorative linework on side, carvings on each corner. Wooden handle on cover is carved in rings, folds down. Below handle is decorative inlaid pattern. Serial number on plate at back of machine. Accessories include 13 attachments, key (broken), screwdriver, sewing machine needle, razor blades (2) and buttons. Attached to inside of case is a square of paper with a number on it. Instruction book for Singer Sewing Machines is included. Also with machine are white tailor's chalk and a cut out, fabric pocket with tissue paper pattern pinned to it.Serial number "579200" is stamped into plate at back of machine. Brand on transfer on front of machine is "Premier". Paper inside case has hand written number "334A". Instruction book "Instructions for using Singer Sewing Machines No. 66 - Oscillating hook for family use" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile -

Anglesea and District Historical Society

Anglesea and District Historical SocietyButter Worker, E. Cherry & Sons, Pre 1912

Wooden with cast iron gearing components and round butter worker is hand operated. The rotary butter worker has a round tray carved from wood. Protruding upwards from the centre of the tray is a column with arched top. The column has a small square outlet on one side near the base that provides for excess buttermilk to be drained away. Around the circumference of the butter worker protruding outwards from the sides is a thick cast-iron track. The wooden paddle has a unique curved shape that has a wave appearance. It has a slight arch which forces the butter to remain in the tray and to direct any excess buttermilk to the centre. Through the wooden paddle is an iron rod connected to a crank handle. By turning the handle the rod rotates a gear system that leads the table to rotate on the metal track.Side: CHERRY'S PATENT NO. 1 GISBORNE VICTORIA 4407 Etched into upper arm of wooden frame.cherry's patent, bubb family, evans family -

Whitehorse Historical Society Inc.

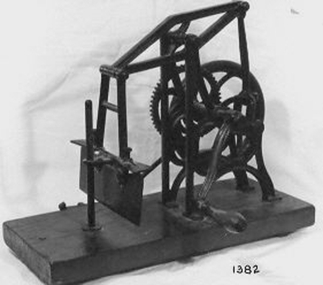

Whitehorse Historical Society Inc.Machine - Household Chopping Machine, Mechanical Chopper, c1886

Used in kitchen to cut carrots, cheese slices, onions. boiled eggs, etc.Painted black guillotine on a wooden stand. An iron pole keeps the guillotine in vertical position at one end of the block. Driven by two wheels when a handle is turned. A tilting beam moves the guillotine up and down to cut vegetables, etc. Blade 18cm long by 6.5cm wide. Metal plate missing under blade. A rotatable drum to contain the food to be chopped, which is rotated by a cog at the base (also missing) turns the container. The upright holding chopper blade e is a modification made because of the missing container.|The following description is from Ken Turner Booklet referred to under 'Reference'. ----|The Starrett food chopper would certainly have to be considered one of the more interesting inventions, which incidentally is now considered the ultimate in kitchen collectables. Laroy Starrett in later years' told of how the design of his food chopper was inspired by the action of the walking beam engine used on the Mississippi steam boats. When the crank handle of the chopper is turned, this sets in motion a mechanism which is just fascinating to watch. The crank activates a flywheel which in turn, by a series of cogs and levers, simultaneously rotates a food holding container and raises and lowers within the rotating container, a guillotine like 'chopping blade - the action does not only look like that of a beam steam engine, it even in a way sounds like one, although somewhat noisier. Starrett produced seven different models of these choppers, ranging in size appropriate for domestic use to heavy duty models for butchers, restaurants and for hotel use. The small model was capable of chopping 3lbs in three minutes, and the largest had a capacity for chopping something like 100 lbs in an hour. The mechanical chopper, which became affectionately known as the 'hasher', was the first of some one hundred of Starrett's inventions, and these include a washing machine patented in 1865 which had a similar action to his food chopper, a food press patented in 1873, and a device for lacing shoes he patented in 1886.domestic items, food preparation -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MARKS COLLECTION: HERCULES AND ENERGETIC GOLDMINING CO. SPECIFICATIONS

Handwritten document (15 pages) with two page blue document appended at back. On front of handwritten document : specifications for machinery and ironwork engineer and ironfounder for building plant for the Hercules & Energetic Goldmining Comp., Sandhurst. The contractor is to supply and deliver on the claim of the above Company the following machinery &c - and to get proper receipts for same from the Contractor for the erection of plant. Areas in specifications include: repairs to engine and boiler set-up & c., safety valve, whistle, cylinder, stop valve, piston, eccentric, crank shaft, feed pump & eccentric, flywheel very extensive descriptions of all areas, some with diagrams. Appended to back of document Ironfounders general conditions of contract work required in the making and delivery on the claim machinery &c for a winding plant for the Hercules & |Energetic Co., Drawings prepared by Wm Middleton, Engineer, Sandhurst. Agreement entered into this twelfth day of October, 1878, by and between Messrs Mitchell & Osborne and Hercules and Energetic GMC. Signed by Mitchell & Osborne, per ? Dobson., Wm Middleton ?.bendigo, mining, hercules & energetic mine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

The Beechworth Burke Museum

The Beechworth Burke MuseumPostcard, George Symons, c.1990

The photograph printed on this postcard comes from the collection of the Mitchell Library in Sydney. It is sepia in tone and depicts seven men standing and sitting around a mine shaft in the Beechworth region. The photograph has been dated to approximately 1872. This period in history post-dates the Victorian gold rushes which occurred 1852-1853 in Ballarat, Bendigo and Beechworth. During this period, in the 1870s, the surface alluvial gold had been discovered and removed from location. Therefore, in order to reach the deeper and less accessible alluvial gold, diggers began to dig shafts into the earth. These shafts sunk below the ground level by 20 to 30 feet and required timber structures around the entrance and winches to bring the paydirt to the top. The top of this wooden structure is visible behind the man standing in the upper right of the image. This type of mining was highly dangerous as mines often caved in which injured the minors and often resulted in death. Thus, following this period, in the early 1900s, miners opted instead for hydrolic slucing which cut away the earth without the devastating consequences of a mine cave in. This particular group of miners appear to have been unable to afford a horse (then worth around 50 pounds) which were generally used at mines like this to help pull buckets attached to ropes up and down the mine. Instead, this group brought the buckets up and down by windlass. The windlass was a wooden structure mounted over the mining shaft and fitted with a hand-cranked winch which enabled the bucket attached to the rope to be brought up and down.Gold was first discovered in Beechworth in Spring and Reid's Creek in the summer of 1852-1853. At its popularity, this region had approximately 8000 people on the gold fields searching for gold on the banks of these creeks. These periods did not require the use of heavy machinery or the digging of deep mining shafts like the one depicted in this image. Therefore, this image has important connotations for the technologies associated with mining during the approximated 1870s when gold was harder to access. This is a later period in gold history which does not fit into the "gold rush" period. Instead, it occurred after the surface gold had disappeared and therefore, is essential for researchers who are investigating the mining techniques and structures used to reach the alluvial gold which was located deeper under ground in the 1870s. This period predates the use of big heavy machinery used to mine in the 1900s which include dredges. Images such as this one can also impart essential information as to the wardrobe and fashion of men during this period. It also imparts knowledge about the landscape of Beechworth which is useful for people researching the environment and impact of gold mining in the north-east region of Victoria. In addition, since this image is a postcard reproduction of an early Australian image which may date to approximately 1990 it can impart knowledge as to the interests of people during this time period when there may have been an increase into Australian history.A sepia tone facsimile of an early Australian photograph (circa 1872) printed as a postcard.Obverse: BEECHWORTH / Victoria, Australia / Reverse: GM 2 3275 / CORRESPONDENCE / AUSTRALIAN / YESTERYEAR / CARDS / ADDRESS / Published by George Symons (057) 65 3240 / THE MINEHEAD C. 1872 / The easily gleaned gold of the early fields did / not last very long. In order to reach less / accessible alluvial gold diggers began sinking shafts as much as twenty to thirty feet down / and the mines required timbering and winches / to bring the paydirt to the top. / This syndicate has been unable to afford the / luxury of a horse (about 50 pounds) and so everything / must go up and down by windlass and rawhide / bucket. / Photo: Mitchell Library, Sydney / A sepia tone facsimile of / an early Australian photographmining album, gold mine, beechworth, burke museum, mine shaft, postcard, australian yesteryear cards, george symons, the minehead, gold fields, alluvial gold, early australia, c.1872, 1872, gold diggers, north east victoria -

Puffing Billy Railway

Puffing Billy RailwayHeinrici Hot Air Motor, 1900s

Louis Heinrici, Germany, circa 1900 a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici hot air engines are of the valveless, closed cycle type, generally called Stirling cycle engines, after Robert Stirling, the Scottish Presbyterian minister who pioneered their development in the early 1800's. They operate by alternately heating and cooling a quantity of air, called the working fluid, contained in the engine's internal spaces. Heat is applied externally and passes through the cylinder wall, heating the working fluid, which is then expanded against a piston to do mechanical work. After heating and expanding, the working fluid is moved to a cool space where it cools and contracts before being returned to the hot space for the cycle to repeat. It has a displacer (just a loose piston), below and in the same cylinder as the power piston to which it is connected via cranks and linkages so as to lead by 90degrees of crankshaft angle. The displacer space and the piston space are connected by the annular gap around the loose fitting displacer so that the working fluid moves between these spaces and changes volume by the appropriate ratio as the engine rotates. Because they have no valves and experience no sudden pressure changes, Stirling engines are noted for quietness and reliability. Heinricis use air at atmospheric pressure for their working fluid, but for higher specific output (power for size) and better efficiency, modern Stirling cycle engines use pressurised gas- air, nitrogen, helium or hydrogen.Historic - Hot Air Engine - MotorHot Air Motor made of Steel with two drive wheels. a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici Motorheinrici hot air motor, puffing billy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine and case, Joseph Wertheim, late 19th century

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Sewing machine, Wertheim brand “ Syst 182” hand crank operated machine with folding handle, timber case and carry handle. Metal machine is painted black, with remnants of gold, red and green scrolls and floral decoration. Machine has base with inlaid measuring rule across front and 2 holes drilled through the base (perhaps for mounting machine to a bench). Machine tilts open, hinged on one side, after thumb screw is unwound, revealing machine’s workings and serial number. Base has a fitted round, concave, silver metal pin holder with lid that hinges open, and symbol pressed into lid; several pins are inside. Body of machine has brand name transfer across front and oval metal trademark disc on front. Metal sliding covers over footplates have stamped lettering. Timber machine case or cover includes an accessory box with sliding cover and metal hook and eye latch, and inside the box are 23 metal sewing attachments, a disc and a stick of black crayon with maker’s trademark on it paper cover. Workings of machine have seized up. The crayon wrapper has printed on it “For the wonderful Wertheim new family machine made in Germany ‘Syst. 182’”, and the maker’s symbol with “Trademark” beside it. Made for Hugo Wertheim.“WERTHEIM” transfer across front and back of machine body. Cover of pin holder has symbol ‘Wings above a shield’. Maker’s trademark on gold oval disc, “WERTHEIM / FRANCFURT” and picture of a dwarf with a hammer. Left footplate has script “Syst 182”, right footplate has stamp in oval shape “MANUFACTURED IN - - /SPECIALLY FOR / HUGO WERTHEIM” Serial Number “7501”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand crank sewing machine, hugo wertheim, wertheim, clothing manufacturer, sewing, syst 182 -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Commonwealth Engineering Standards Association, Set of 5 Australian Standards, 1925 & 1940

Australian standards for rolling stock issued by the Australian Commonwealth Engineering Standards Association.Gives details of the 1920s standards in Australia for railway rolling stock.1 - Book - 20 pages + light grey cover, side stapled, issued by the Australian Commonwealth Engineering Standards Association tentative standard E2 to E5 - for Railway Rolling stock material, laminated volute and helical springs and spring steel, dated Dec. 1925. .2 - Book - 40 pages + light grey cover, side stapled, issued by the Australian Commonwealth Engineering Standards Association tentative standard E16 to E21 - for Railway Rolling stock material, steel blooms for railway forgings, axles, locomotive crank axles, wagon and engine tender axles - dated Dec. 1927. .3 - Book - 24 pages + light grey cover, side stapled, issued by the Australian Commonwealth Engineering Standards Association tentative standard E8 to E12 for Railway Rolling stock material - copper plates, rods, tubes and pipes and brass tubes. Dated Dec. 1925 .4 - Book - 20 pages + light grey cover, side stapled, issued by the Australian Commonwealth Engineering Standards Association tentative standard E6 and E7 - railway rolling stock material - steel plates, angles and rivets for locomotives; steel castings. Dated December 1925. .5 - Book - 12 pages + grey covers, centre stapled issued by Standards Association of Australia, standards H13 and H14 - Bronze (Gun Metal) ingots and castings for General engineering purposes Dated 1940..trams, tramways, standards, rolling stock, axles -

Flagstaff Hill Maritime Museum and Village

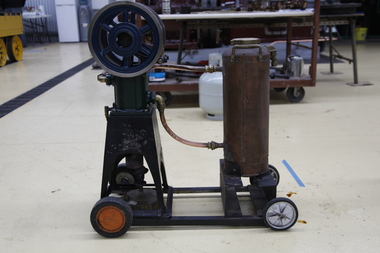

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Falkiner Electric Road Train in front of George Leighton's Wodonga Store and Bakery Wodonga 1914

This image of the Ralph Falkiner’s Mueller Petrol-Electric Road Train was taken in Wodonga in February 1914. Imported from Germany by Mr Ralph S Falkiner in late 1913, the train’s inventor, Major W A Mueller with two assistants, came to Melbourne to assemble then commission the train. The train cost Mr Falkiner about £13,000 plus £4,591 import duties. The Falkiner family were sheep breeders in the Western Riverina and he hoped to use the road train primarily to convey wool to the railways for despatch to Sydney. The train was 216 feet long, weighed 43.5 tons with a top speed loaded of 6-8m/h and petrol consumption up to two gallons per mile. Its first Australian journey was to haul 50 tons of cargo to Edmondson & Co at Wagga Wagga, 277 miles away. The journey from Melbourne was plagued with problems including broken cylinders and crank shaft and overheating as it was not designed for Australian climatic conditions. Three months after leaving Melbourne it arrived in Wodonga. A series of problems between Springhurst and Wodonga, including broken cylinders and valves caused an eight day delay. Some of the cargo was off-loaded in Albury, then after repairs the train continued on to Wagga where it arrived in May 1914. After unloading there, the road train was taken to Mr Falkiner's Groongal Station, near Hay and subsequently made several long trips into drought-stricken areas or the Western Riverina. Eventually the dream collapsed when the engines gave out after the train bogged in the sticky black soil of the Hay plain with 251 bales of wool on board. The train was finally railed back to Melbourne and stored but destroyed when the warehouse burnt down. In this photo, the road train is drawn up outside the Wodonga Stores and Bakery owned and operated by George Leighton. Mr Leighton began his business opposite the Terminus Hotel in Sydney Street, Wodonga in 1885. His business included a general store, stocking groceries, ironmongery, drapery, crockeryware, boots and shoes as well as a bakery. He was very actively involved in the community and served on the Wodonga Council for 18 years including three terms as Wodonga Shire President in 1901 – 02, 1910-11 and 1913-14. He was also Chairman of the Wodonga Waterworks Trust for several terms. Mr. Leighton also took a prominent part in the movement to establish a Public Library in Wodonga. His other involvements including being a Founder of the Wodonga Lodge of Freemasons, Honorary Treasurer of the Wodonga Bulldogs Football Club and Secretary of the Wodonga Racing Club. Mr Leighton passed away in Wodonga in 1916.This image is significant because it records a rare event in Wodonga and an experiment in Australian road transport.Black and white images of the Falkiner Road Train in Wodonga and on its first journey from Melbourne to Wagga, NSW It is taken in front of the Wodonga Stores and Bakery operated by George Leighton in Sydney Street, Wodonga.falkiner electric train, early road transport, high street wodonga, george leighton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Desk Pencil Sharpener, Mid 1900's

Cylindrical (planetary) sharpeners: These mechanisms are also called planetary sharpeners, in reference to their use of planetary gears. A larger, stationary planetary sharpener can be mounted on a desk or wall and powered by a hand crank. Typically, the pencil is inserted into the sharpener with one hand, and the crank is turned with the other. This rotates a set of helical cylindrical cutters in the mechanism, set at an acute angle to each other. The multiple cutting edges quickly sharpen the pencil, with a more precise finish than a single-blade device. Some cylindrical sharpeners have only one helical cutter cylinder, but most have two cylinders or more. https://en.wikipedia.org/wiki/Pencil_sharpener This mechanical pencil sharpener once belonged to Dr. Angus. It was one of his personal belongings and would have been used in his office. The mechanical pencil sharpener has provision for attaching it to a flat surface such as a desk. The user would insert the pencil into the hole in the front of the sharpener, wind the handle around several times until the pencil is the desired sharpness then remove the pencil. The plastic compartment is clear so that the user can see when it needs emptying, slide down the metal braces on the side of it, remove and empty the compartment and fit it back onto the stand. The sharpener was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served with the Australian Department of Defence as a Surgeon Captain during WWII 1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Pencil sharpener, mechanical, part of the W.R. Angus Collection. Metal stand and frame, plastic compartment to hold the shavings. Rotating plastic handle. Metal front on compartment has a re-inforced hole for inserting pencil. Plastic oompartment has sliding metal bracket on each side to allow its removal. Base has two holes for mounting on flat surface. Mid 1900's. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, pencil sharpener, mechanical pencil sharpener, office equipment, office stationery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Dioptric Apparatus, mid 19th century

Before the introduction of electricity, lighthouses had a clockwork mechanism that caused the lens to rotate with a light source inside that was either powered by Kerosene or Colza oil. The mechanism consisted of a large weight attached by a cable through the centre of the lighthouse to the top where the cable wrapped around a barrel, drum or wheels that controlled the speed of the lights rotation by a clockwork mechanism. The keeper would crank the clockwork mechanism, which would lift the weight ready for the next cycle similar to an old grandfather clock mechanism. Once the weight lifted to its apex at the bottom of the first landing, the keeper would let it fall, which would pull on the cable, which would, in turn, operate a series of gears activating the rotation of the Fresnel optical lens, which would then rotate to create the lighthouse’s unique light speed of rotation characteristic. Creating a specific characteristic required a way to regulate the speed of the rotation, and was important as sailors could identify a particular light by its speed and time between flashes. The weight had to fall at a certain rate to create the proper rotation speed of the lens and a regulator within the mechanism accomplished this. History: From 1851, Chance Brothers became a major lighthouse engineering company, producing optical components, machinery, and other equipment for lighthouses around the world. James Timmins Chance pioneered placing lighthouse lamps inside a cage surrounded by Fresnel lenses to increase the available light output these cages, are known as optics and they revolutionised lighthouse design. Another important innovation from Chance Brothers was the introduction of rotating optics, allowing adjacent lighthouses to be distinguished from each other by the number of times per revolution the light flashes. The noted English physicist and engineer, John Hopkins invented this system while employed at Chance Brothers. Chance Brothers and Company was a glass works and originally based in Spon Lane, Smethwick, West Midlands England. The company became a leading glass manufacturer and a pioneer of British glass making technology. The Chance family originated in Bromsgrove as farmers and craftsmen before setting up a business in Smethwick near Birmingham in 1824. They took advantage of the skilled workers, canals and many other industrial advances taking place in the West Midlands at the time. Robert Lucas Chance (1782–1865), known as 'Lucas', bought the British Crown Glass Company's works in Spon Lane in 1824. The company specialised in making crown window glass, the company ran into difficulty and its survival was guaranteed in 1832 by investment from Chance's brother, William (1788 – 1856). William owned an iron factoring business in Great Charles Street, Birmingham. After a previous partnership that Lucas had dissolved in 1836, Lucas and William Chance became partners in the business which was renamed, Chance Brothers and Company. Chance Brothers invented many innovative processes and became known as the greatest glass manufacturer in Britain. In 1848 under the supervision of Georges Bontemps, a French glass maker from Choosy-le-Roi, a new plant was set up to manufacture crown and flint glass for lighthouse optics, telescopes and cameras. Bontemps agreed to share his processes that up to then had been secret with the Chance Brothers and stayed in England to collaborate with them for six years. In 1900 a baronetcy was created for James Timmins Chance (1814–1902), a grandson of William Chance, who had started the family business in 1771 with his brother Robert. Roberts grandson, James became head of Chance Brothers until his retirement in 1889 when the company became a public company and its name changed to Chance Brothers & Co. Ltd. Additional information: Lighthouses are equipped with unique light characteristic or flashing pattern that sailors can use to identify specific lighthouses during the night. Lighthouses can achieve distinctive light characteristics in a few different ways. A lighthouse can flash, which is when brief periods of light interrupt longer moments of darkness. The light can occult, which is when brief periods of darkness interrupt longer moments of light. The light can be fixed, which is when the light never goes dark. A lighthouse can use a combination of flashing, oscillating, or being fixed in a variety of combinations and intervals to create individual light characteristics. It is a common misconception that a lighthouse's light source changes the intensity to create a light characteristic. The light source remains constant and the rotating Fresnel lens creates the various changes in appearance. Some Fresnel lenses have "bulls-eye" panels create beams of light that, when rotated between the light and the observer, make the light appear to flash. Conversely, some lenses have metal panels that, when rotated between the light and the observer, make the light appear to go dark. This Dioptric clockwork apparatus used to turn a lighthouse optical lens is very significant as it is integral to a lighthouses operation, we can also look at the social aspect of lighthouses as being traditionally rich with symbolism and conceptual meanings. Lighthouses illustrate social concepts such as danger, risk, adversity, challenge and vigilance but they also offers guidance, salvation and safety. The glowing lamp reminds sailors that security and home are well within reach, they also symbolize the way forward and help in navigating our way through rough waters not just on the oceans of the world but in our personal lives be it financial, personal, business or spiritual in nature. Nothing else speaks of safety and security in the face of adversity and challenge quite the way a lighthouse does. Revolving dioptric clockwork apparatus used to turn a Fresnel optical lighthouse lens. A cylindrical cast metal pillar and cabinet painted green with 3 glass doors enclosing the top section. Inside the pillar/cabinet is a large clockwork mechanism used to turn and regulate a lighthouse light by means of weights and a chain attached to same. One door has the name "Adams Mare" in metallic dots similar to "Braille" to the inside edge of door frame.shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff hill, maritime-museum, shipwreck-coast, warrnambool, flagstaff-hill-maritime-village, revolving dioptric mechanism, dioptric mechanism for lighthouse, lighthouse clockwork timing mechanism, acetylene lighthouse light mechanism, 19th century lighthouse mechanism, kerosene light, fresnel lenses, colza oil, chance brothers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, John Harper & Co, Early - Mid 20th Century