Showing 751 items

matching machine made

-

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Vaporiser, Tecota, Cyprane Ltd, c. 1970

... , London. Trilene was introduced in the 1940s. The machine was made..., London. Trilene was introduced in the 1940s. The machine was made ...Used by mothers during childbirth, the anaesthetic Trilene (trichloroethylene) was inhaled through a face mask [missing] attached to the rubber tubing [missing] and the vaporising chamber. The Trilene was poured into the chamber to be turned into a vapour. The machine was used in the obstetric wards at University College Hospital, London. Trilene was introduced in the 1940s. The machine was made by Cyprane Ltd.Khaki metal multi layered cylinder. Set on top of khaki metal plate with four (4) rubber feet.Stamped in red on top level of vaporiser: Cyprane Ltd •Stamped in red on serial plate: TECOTA MARK 6 / CHARGE WITH TRICHLOROETHYLENE B.P. / CYPRANE LTD. SERIAL No / KEIGHLEY / YORKS. / T1469 •Clear sticker with red printed text stuck on metal plate: PAT No 646680 / PATENTS PENDINGtrichlorethylene vaporiser, tecota mark 6 -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumClothing - bodice, Elfriede Girschik, Helga's Bodice, 1942

... sewing machine it was made on came with her into the Camps....). The singer sewing machine it was made on came with her into the Camps ...Bodice of a blue linen dress made by Elfriede Girschik for her daughter, Helga, in Camp 3. c1942 (early). The singer sewing machine it was made on came with her into the Camps.Blue linen bodice which has been part of a dress. The bodice has sleeves gathered at the top and slots for elastic (not there) at the lower edge. 6 handmade buttonholes down the opening at the back with 6 small buttons. Hand embroidery on the front, 2 ladybirds, sprays of yellow, blue, pink and orange flowers. The bodice has been separated from the bottom of the dress and hemmed up to make into a top.bodice, embroidery, camp 3, tatura, ww2 camp 3, internment camp handwork, helga griffin, helga girschik -

Flagstaff Hill Maritime Museum and Village

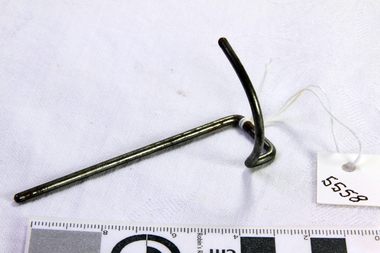

Flagstaff Hill Maritime Museum and VillageAccessory - Hook, ca. 1891

... arc. Thais sewing machine part was made for a Wertheim sewing... arc. Thais sewing machine part was made for a Wertheim sewing ...This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Hook; thin metal rod bent at one end into a curved upward arc. Thais sewing machine part was made for a Wertheim sewing machine by Joseph Wertheim, Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, domestic machines, dressmaking, home industry, fashion -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing machine, Wilcox & Gibbs, c1870

... with its wooden carry case. The machine was made in America.... The machine was made in America c1870 but it has the ornate hand crank.... The machine was made in America in the late 1860's but it has ...Willcox and Gibbs: Serial No. 158679. The Willcox & Gibbs Sewing Machine Company was founded in 1857 by James E. A. Gibbs and James Willcox and opened its London Office in 1859 at 135 Regent Street . By 1871 the Company's Chief Office for Europe was at 150 Cheapside, London, this office was later moved (post 1885) to 94 - 96 Wigmore Street, then 37 & 39 Moorgate Street (by 1891 to post 1907) and later 20 Fore Street, London . Right from the initial production the manufacturing of the Company's single thread, chain stitch machine was undertaken by Brown & Sharpe, Rhode Island and this continued up until 1948. A special hand crank mechanism was produced in England for the European market, but the general design of the Willcox & Gibbs remained essentially the same throughout its production. The only major improvement was in 1875 when the glass tension discs were replaced with an automatic tension device which ensured the machine could not get out of adjustment. In addition to the domestic hand and treadle machines the company produced a wide range of industrial models. The Company finally closed in 1973. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America in the late 1860's but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The cloth plate has various American patent dates, four dating between 1857 & 1860 relating to J. E. A. Gibbs, three dating between 1860 & 1864 relating to Chas H. Willcox (son of James Willcox), the machine was also licensed under five other patents including the infamous Elias Howe patent of 1846. There are only two English patents one for J. E. A Gibbs and the other for James Willcox. In 1887 a W & G Sewing Machine sold in England for 6 pounds , with its box and bits, at a time when the average wage was less than 10/- shillings per week. The early settlers of Moorabbin Shire had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. The women were skilled dressmakers and craft workers.Willcox and Gibbs: Serial No. 158679. A single thread, chain stitch Sewing Machine with a special hand crank mechanism produced in England for the European market, and the glass tension discs which were used on domestic models until 1875. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America c1870 but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The Willcox & Gibbs badge is located on the rear of the base castingsewing machines, early settlers, pioneers, moorabbin, brighton, gibbs james, willcox james, willcox henry, new york, america, dressmaking, mateial, machine makers, wrought iron work, telford england -

Tennis Australia

Tennis AustraliaRacquet, Circa 1925

... with Narragansett Machine Company, made up of a squares and triangles design.... The symbol associated with Narragansett Machine Company, made up ...A wooden racquet with a concave throat. Inscription along the throat on reverse: LAWFORD. The symbol associated with Narragansett Machine Company, made up of a squares and triangles design, features below on the stem. Inscription along the throat on the obverse: MARATHON. The Marathon racquet was a in-house brand-name for all Montgomery Ward sporting goods. The 'Lawford' is obviously the model name. Materials: Wood, Gut, Metal, Lacquer, Glue, Leather, String, Plastic, Clothtennis -

National Wool Museum

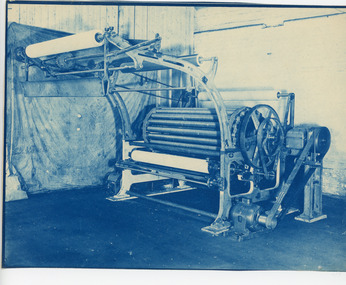

National Wool MuseumPhotograph, Q-VEE Machine, 29/06/1937

... the fabric soft and fluffy. The photographed machine was made by J... machine was made by J. Stone & Co, a British marine and railway ...Photographs were most likely used for promotional purposes. The Q-VEE machine is a scouring machine. When fabric is removed from the loom it is often stiff, rough or uneven. Scouring removes the oils and dirt picked up from manufacture, leaving the fabric soft and fluffy. The photographed machine was made by J. Stone & Co, a British marine and railway engineering company based in Deptford in south east London.Four black and white, blue tinged photos of a Scouring Machine from different angles. Black writing on the rear, typed with a typewriter and stamped with the company stamp.8051.1 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 849 8051.2 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 856 8051.3 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 851 8051.4 - front on machine - FIY Chain Gear J.Stone & Co Ltd London rear - P.I.V. Dial Control Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 853textile machinery, wool manufacture, wool, scouring -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine - Singer

... . Treadle machines were made into the 1950s but they were most.... Treadle machines were made into the 1950s but they were most ...Singer began to market its machines internationally in 1855. They began mass-producing domestic electric machines in 1910. Treadle machines were powered mechanically by a foot pedal that is pushed back and forth by the operator's foot. There were also machines belt powered, hand powered and eventually electric powered. Treadle machines were made into the 1950s but they were most common during the late Victorian years (up to 1901). This machine is c1894.This machine was owned and used by a resident of the Kiewa Valley. It was used for domestic sewing such as for making clothes for the family, making toys for eg. a fete and making useful items eg. a bag for school readersSinger Fiddle Base treadle sewing machine with decoration of flowers. Straight stitch. No stand. A little rusty.Top: 'the Singer Manufacturing'. Front: 'Singer' and the Metal Plaque 'The Singer MFC Cony'singer manufacturing co., clothes, sewing, domestic -

National Wool Museum

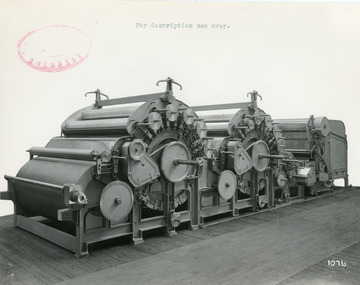

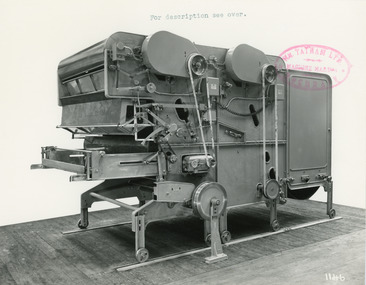

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

... collectively as the carding engine. The photographed machine was made... machine was made by William Tatham Ltd, a textile engineering ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

Camp Eureka Working Collective

Camp Eureka Working Collectivescarf

... Brown and yellow square rayon machine edged scarf made... machine edged scarf made for the 1952 Youth Carnival for Peace ...The scarf was worn by Eileen Capocchi, a member of the Eureka Youth League Choir who sang at the Youth Carnival for Peace and Friendship and donated the item. The planned event had been targeted by Prime Minister Menzies as a Communist Party activity. The Commonwealth Government pressured local Sydney Councils to deny the organisers a venue. These attempts failed. The event combined sporting, athletic and musical events at a football stadium. In later years it was the subject of two documentary films. The scarf is of historic and social significance because of its association with the Peace Carnival for Peace and Friendship of 1952 and the Eureka Youth League. The scarves were worn by all participants and by Eureka Youth League members in subsequent years. The scarf records some of the musical and sporting events organised by the Eureka Youth League in most major Australian cities.Brown and yellow square rayon machine edged scarf made for the 1952 Youth Carnival for Peace and Friendship in Sydney. Central portion shows a peace dove, pink heath, flannel flower and wattle. Perimeter shows a saxophonist, ballet dancer, high jumper, hurdler, cyclist and volleyball net. "Youth Carnival for Peace and Friendship" white script on 3cm brown banner repeated 4 times around perimeter.eileen capocchi, eureka youth league choir, youth carnival for peace and friendship, eureka youth league, 1952 -

Tatura Irrigation & Wartime Camps Museum

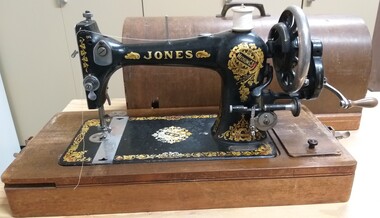

Tatura Irrigation & Wartime Camps MuseumDomestic object - Sewing Machine, Jones Sewing Machine

... and brown wooden knob. To keep accessories in. Machine is made from... and brown wooden knob. To keep accessories in. Machine is made from ...This Jones sewing machine was one of the few sewing machines that accompanied the Germans who were deported from Palestine in 1941 to Australia where they were interned at Tatura. The machine was owned by Nelly Wied (nee Glenk). See notes in Item receipt form.Lid is plywood constructed with domed top. Brown handle on top and a clip each end to fasten to machine base. Machine is on a wooden base with clips on each end to fasten to lid. Right hand side of machine has a rectangular hole with wooden lid and brown wooden knob. To keep accessories in. Machine is made from metal, painted black and has fancy gold patterns on front right, "Jones" in gold and gold design around the metal base. It has a silver turning wheelJONESjones sewing machine, palestine germans, german templers, palestine internees, templer internees, nelly wied, nelly glenk, helmut glenk, tatura internment camps -

National Wool Museum

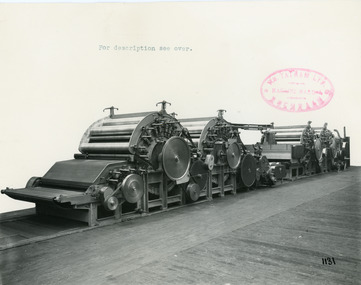

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

... other.The photographed machine was made by William Tatham Ltd... that they are parallel with each other.The photographed machine was made ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

... and Finisher Card Sections. The photographed machine was made... machine was made by William Tatham Ltd, a textile engineering ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

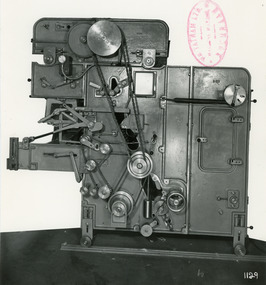

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

... . An Automatic Feeding Machine automatically and sequentially supplies..., The photographed machine was made by William Tatham Ltd, a textile ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyAddressograph Machine

... Metal plate attached to front of machine which reads "Class... through the machine onto pay envelopes.See also: KVHS 1046, KVHS ...This metal plate machine used plates that contained names, addresses and classifications of each State Electricity Commission of Victoria employee working on the Kiewa Hydro Electric Scheme. The plates were put through the machine onto pay envelopes.See also: KVHS 1046, KVHS 1233The S.E.C.V. employed many people on the Kiewa Hydro Electric Scheme and used the latest technology of the time to pay each of them including providing each one with a pay slip. Metal table with the addressograph machine set into the middle section. The electric machine is belt driven and controlled by three 52 cm long metal pedals. The operator uses 5 stops, 2 knobs and 1 winder while sitting at the machine. There are 5 extra metal parts (or pieces) which belong to this machine. Ref. KVHS 1046 - Ink Rolls - Labelling Cartridges for Addressograph MachineMetal plate attached to front of machine which reads "Class 22000 Serial No. B-01547. Addressograph regd. Addressing machine. Patents Pending Made in England Addressograph Multigraph Limited London.addressograph machine. state electricity commission of victoria. kiewa hydro electric scheme. payroll. office work. -

National Wool Museum

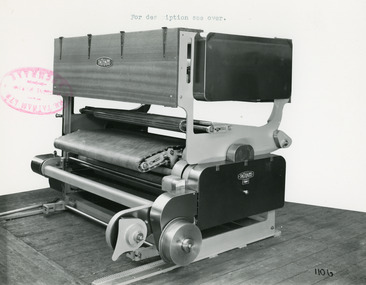

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

... into a sliver. The photographed machine was made by William Tatham Ltd... section into a sliver. The photographed machine was made ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

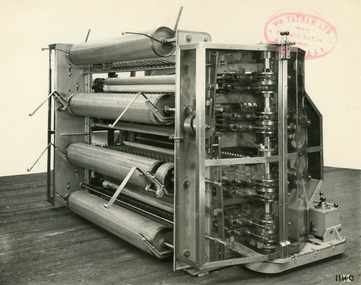

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

... weighing and feeding of wool. The photographed machine was made.... The photographed machine was made by William Tatham Ltd, a textile ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

Kew Historical Society Inc

Kew Historical Society IncClothing - Camisole, 1900s

... White muslin camisole with fabric made by machine joined... fashion night wear White muslin camisole with fabric made ...The Fashion & Design collection of Kew Historical Society includes examples of women’s, men’s, children’s and infants' clothing from the 18th, 19th and 20th centuries. While the collection includes some examples of international fashion, most items were handmade or purchased in Melbourne. White muslin camisole with fabric made by machine joined tape lace. Sleeves have three layers tape lace between three pieces of muslin. Edges are of a layer of scalloped tape lace joined to sleeves by a ribbon insert tape lace.fashion and textiles collection - kew historical society, lace, women's clothing, australian fashion, night wear -

Mont De Lancey

Mont De LanceyFunctional object - Bottles, Unknown

... machine made with embossing.(This bottle is missing, 13.10.2022). ... machine made with embossing.(This bottle is missing, 13.10.2022 ...These bottles were common in the late 1800's and 1900's. Bottle Nos 1 and 2 were made by Angus & Co, a Sydney company producing ink and gums (glue and clag) from about 1880 to 1920. Their products were sold in stoneware and glass containers in varying sizes. 1. Small pottery bottle referred to as a "Penny Ink" bottle, made by Angus & Co. The small bottle got its name because of the price of 1d. = 1 penny. This bottle is missing. Nos. 3 and 4 The two tall thin Erven Lucas bottles with handles at the top were usually referred to as "Dutch Gins". In fact they actually contained "'Seltzer Spa water' or a form of Quinine Tonic, both supposed to be health drinks. These types of bottles first arrived in Australia with the Gold-seekers from Europe. Early samples are somewhat crudely made. The potter would have formed the bottle with a young apprentice applying the handle, name stamp and the glaze prior to being fired in the kiln. There is evidence of fingerprints from these processes on both samples.A collection of five handmade rare stoneware bottles with a salt glaze: 1. Small pottery bottle referred to as a "Penny Ink" bottle, made by Angus & Co. The small bottle got its name because of the price of 1d. = 1 penny. This is missing. 2. Medium glazed brown pottery bottle with a pouring spout (Angus & Co Ink Commercial). 3. Medium glazed brown pottery bottle with a pouring spout (Bourne Denby). 4. Large glazed brown pottery bottle with a pouring spout (Bourne Denby). Sample is from England probably sold for 2/- or 2/6d. Two shillings or two shillings & sixpence. 5. and 6. Two tall thin brown pottery bottles, one with a broken cork stopper and one without a stopper with Erven Lucas Bols - Het Lootsje Amsterdam stamped at the top of both. They were usually referred to as "Dutch Gins". 6. Green/black bottle is a traditional Dutch Gin with tapering sides, which made it easy to remove from the mold after being blown by hand and the cork top was applied by an apprentice. This sample dates from approximately 1900. Earlier samples are very crude with later samples being machine made with embossing.(This bottle is missing, 13.10.2022). 2. 'Angus & Co Ink Commercial' 3 and 4. 'Bourne Denby' stamped inside an oval lined shape. 5. and 6.Erven Lucas Bols - Het Lootsje Amsterdambeverage bottles, bottles, storage containers, stoneware bottles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine and case, Joseph Wertheim, late 19th century

... machine made in Germany ‘Syst. 182’”, and the maker’s symbol... machine made in Germany ‘Syst. 182’”, and the maker’s symbol ...Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Sewing machine, Wertheim brand “ Syst 182” hand crank operated machine with folding handle, timber case and carry handle. Metal machine is painted black, with remnants of gold, red and green scrolls and floral decoration. Machine has base with inlaid measuring rule across front and 2 holes drilled through the base (perhaps for mounting machine to a bench). Machine tilts open, hinged on one side, after thumb screw is unwound, revealing machine’s workings and serial number. Base has a fitted round, concave, silver metal pin holder with lid that hinges open, and symbol pressed into lid; several pins are inside. Body of machine has brand name transfer across front and oval metal trademark disc on front. Metal sliding covers over footplates have stamped lettering. Timber machine case or cover includes an accessory box with sliding cover and metal hook and eye latch, and inside the box are 23 metal sewing attachments, a disc and a stick of black crayon with maker’s trademark on it paper cover. Workings of machine have seized up. The crayon wrapper has printed on it “For the wonderful Wertheim new family machine made in Germany ‘Syst. 182’”, and the maker’s symbol with “Trademark” beside it. Made for Hugo Wertheim.“WERTHEIM” transfer across front and back of machine body. Cover of pin holder has symbol ‘Wings above a shield’. Maker’s trademark on gold oval disc, “WERTHEIM / FRANCFURT” and picture of a dwarf with a hammer. Left footplate has script “Syst 182”, right footplate has stamp in oval shape “MANUFACTURED IN - - /SPECIALLY FOR / HUGO WERTHEIM” Serial Number “7501”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand crank sewing machine, hugo wertheim, wertheim, clothing manufacturer, sewing, syst 182 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTobacco Picking Apron

... machines were made. Thick cotton cream apron, hemmed around... machines were made. Thick cotton cream apron, hemmed around ...Tobacco farming began circa 1960 in the Kiewa Valley and consequently became one of its major industries. Many of the Italian families were involved in tobacco farming.Historical: This equipment was used on one of the first tobacco farms in the Kiewa Valley at Mongans Bridge. The picking apron was home-made showing the resourcefulness of farmers living in the Kiewa Valley. Picking machines replaced the picking apron. Provenance: This tobacco farmer came from Italy and was sponsored to visit a tobacco farmer in Myrtleford to learn how to grow tobacco so that he could transfer those skills to his own farm in the Kiewa Valley.The apron was used to gather green leaf before picking machines were made. Thick cotton cream apron, hemmed around the outside. Widest at the waist which has 2 rings each side where string is attached with a knot to tie around the waist. From the ring, material tapers inwards to form a bib. The corners of the bib have rings from which white rope is attached to hang around the neck. Similariy material tapers to the bottom where rings in the corners have rope attached - also to hang around the neck. Half way between the waist and neck, the material is double stitched and overlapped. grubbytobacco. mongans bridge, kiewa valley, parmesan, rossaro . picking apron. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cruet Set, William Hutton & Sons, Circa 1900

... known as British Plate. They sent their machine-made silver... known as British Plate. They sent their machine-made silver ...William Hutton & Sons were manufacturing silversmiths founded in 1800 in Birmingham with company transferring to Sheffield in 1832. William Hutton had established the firm and with the move to Sheffield, they also became platers having licensed the electroplating technique from the firm of Elkington's. This gave them much early success in the field of electroplating. William's son William Carr Hutton continued the business after his father's death using the same business name until 1864 it was then changed to William Hutton & Son when William Carr's son Herbert Hutton joined him. When William Carr died in 1865, the firm name was again changed to William Hutton & Sons when Herbert's brothers (James & Robert) joined the company. They opened a London showroom in Holborn in 1863 which they moved to Farringdon Road, in 1891 operating until 1918. Hutton's had developed a new nickel alloy that was good for plating and in the late 1800s becoming known as British Plate. They sent their machine-made silver flatware from Sheffield to be hallmarked in London. Hutton's went on to acquire Rupert Favell & Co in 1893 and also registered as a limited company as William Hutton & Sons Ltd in 1902. The Hutton's had also bought Creswick & Co and had started to use their crossed arrows trademark. Hutton's became renowned for the quality of their Arts & Crafts silverware items at the turn of the 19th and 20th centuries. In 1930 Hutton's were taken over by James Dixon & Sons. A significant item that was made around the time electroplating was being developed as a means of producing quality utilitarian items in quantity for domestic use that we're able to be purchased by working-class people.Cruet set of silver plated frame with upright handle protruding from tray base. Holds 5 containers of varying shape and size; 3 have metal lids. Inscription is on the base. Some containers have contents in them.On base "WMH&S" and "01548" etc.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cruet set, condiments set, kitchen ware, electroplate, britannia metal, w m hutton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Bolster Sham, Eliza Towns, Late 19th century to early 20th century

... machine and would have made many of her own clothes and household... machine and would have made many of her own clothes and household ...This bolster sham is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes and household linens - adding her own handmade embroidered or crocheted decorative trim. Most beds during the late 19th and early 20th century had a feather, hair or spring mattress covered by a blanket and topped with an under sheet, an upper sheet, several blankets and a bedspread. A flat bolster could be placed either under the pillows or on top of the pillows with a decorative sham. Washing pillows and quilts by hand would have been a very onerous task (involving heating water and handwashing in a tub or using a copper) and so it became the practise of many housewives to cover the pillows and bolsters with an outer slip (or sham) of washable material which could be easily removed and washed when needed. If the bolster was kept under the pillows it wouldn't need to be very decorative but many shams or slips that were "on show" were often highly decorated with embroidery, pintucks, ribbons or lace. This bolster sham is machine made and quite plain with the exception of some pintucking and eyelet lace on each end which suggests that it would mostly be hidden under the top pillows with just the decorative edges on display.This item is an example of the needlework skills of women in the early 20th century - combining machine stitching with hand embroidery to personalise and embellish a practical domestic object. It is also significant as an example of an early 20th century innovation that helped make the working lives of housewives a little bit easier.A long white cotton rectangular bolster sham, machine sewn, with seven ties and two buttons (plus one missing button) to enable it to be folded over lengthwise and closed. It has two pull string ties near each end to enclose a bolster and is finished with a decorative edge of pintucks and handmade eyelet lace and embroidery.flagstaff hill maritime museum and village, eliza towns, sham, bedding, great ocean road, shipwreck coast, warrnambool, household textiles, sewing, bolster sham, housework, pillow sham, charles towns, nhill, haberdashery, needlework, manchester, handmade, household linen -

Orbost & District Historical Society

Orbost & District Historical Societyadding machine, 1964

... machines from US-made parts and later to manufacture the full... machines from US-made parts and later to manufacture the full ...Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manuaIly and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.On front -P3981115 mathematics accounting burroughs adding-machine business calculator -

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumMachine - Adding Machine

... machines from US-made parts and later to manufacture the full...Burroughs Machine Limited, Strathleven, Scotland Made..., initially to assemble machines from US-made parts and later ...Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manually and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.Burroughs Machine Limited, Strathleven, Scotland Made in Great Britainburroughs adding machine, office, calculator, detroit, michigan -

Warrnambool and District Historical Society Inc.

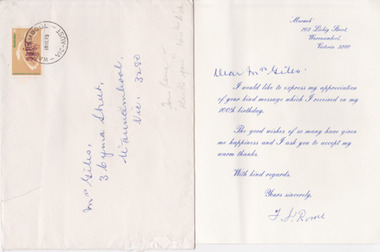

Warrnambool and District Historical Society Inc.Work on paper - Card, Giles, 1973

... and Art Exhibition. With an Edison phonograph machine he made... and Art Exhibition. With an Edison phonograph machine he made ...This thank you card is from Thomas Rome (1873-1974) when he was celebrating his 100th birthday in 1973. Thomas Rome came to Warrnambool from Beechworth to work with John Younger in his Warrnambool store in 1888. He worked there for 17 years before opening his boot and shoe shop at 115 Liebig Street in 1907, retiring in 1962. Thomas Rome is remembered today not only for his long life and prominent Liebig Street business but also because of the sound recordings he made in 1896-7 at the Warrnambool Industrial and Art Exhibition. With an Edison phonograph machine he made sound recordings of local artists and these are regarded as one of the oldest, if not the oldest, surviving sound recordings made in Australia. This card with its envelope is of interest as it reminds us of the long life of a prominent Warrnambool identity of the late 19th century and the first 70 years of the 20th century. The card has T. J. Rome’s signature. Mrs Vera Giles was the recipient of the card a long-serving member of the Warrnambool and District Historical Society and, like Tommy Rome, a person who reached her 100th year and beyond. This is a small piece of white lightweight card folded into two to make a card. Inside is a handwritten and printed message from Tommy Rome on the occasion of his 100th birthday The envelope bears the post mark 18th September 1973 and is addressed to Mrs Giles. Envelope: ‘Mrs Giles, 3 Cyma Street, Warrnambool, Vic. 3280, a seven cent stamp and a handwritten note – ‘Tom Rome, ‘thank you’ 100th b’day’. Card: ‘Murweh’, 203 Liebig Street, Warrnambool 3280 Dear Mrs Giles I would like to express my appreciation of your kind message which I received on my 100th birthday. The good wishes of so many have given me happiness and I ask you to accept my warm thanks, With kind regards, Yours sincerely, T.J.Rome thomas rome, murweh, warrnambool history, vera giles warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Musical Instrument, Edison Phonograph, 1905

... of the machine is made of wood and has a wooden handle attached... of the machine is made of wood and has a wooden handle attached ...The phonograph is a mechanical device for the recording and reproduction of sound and originally used a tinfoil sheet wrapped around a rotating cylinder to produce the sound. It was invented by Thomas Edison of U.S.A. in 1877 and was the model for all phonographs or gramophones made and developed throughout the 20th century. This machine is of particular interest to the Warrnambool and District Historical Society as it is an Edison phonograph and an earlier model of this phonograph was used in Warrnambool late in the 19th century to make an important recording. In 1896 Thomas Rome, an employee in a Warrnambool boot and shoe shop, purchased an Edison phonograph that could both play and record sounds. At the Warrnambool Industrial and Art Exhibition of 1896-7 visitors to the Exhibition paid a fee to listen to music on this phonograph. But Rome also recorded some local Warrnambool people singing and speaking and these recordings survive today. They are regarded as the oldest surviving recordings made in Australia. Thomas Rome later became a shoe shop proprietor in Warrnambool and was a well-known person in the town/city for a great number of years. This is an Edison Gem Phonograph. It has a black-painted wooden base, now detached from the main mechanism. The phonograph is made of metal which is now heavily rusted. It has a cylindrical turntable for playing the Edison cylindrical records and a handle with a wooden knob. The turning mechanism and belt are now broken. The name of the manufacturer and details of the patents are on a metal plate attached to the side of the phonograph. The amplifier mechanism at the top of the machine is missing. The cover of the machine is made of wood and has a wooden handle attached with a piece of metal and two metal screws. There are also two metal screws on the side of the cover. The cover has a slot on the side to allow the turning handle to be accommodated outside of the cover. The cover is much stained and spotted. ‘Edison Gem Phonograph’ thomas edison, history of sound recordings, thomas rome (warrnambool) -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - Satin and machine lace bedspread

... A pink satin and cream machine lace bedspread made from... machine lace bedspread made from alternative 13 to 14cm wide ...A pink satin and cream machine lace bedspread made from alternative 13 to 14cm wide strips in a rectangular pattern with central rectangle set at 45 degrees. Three sides are edged with silk chenille bobbles in pink and cream. The central rectangle and the four corners surrounding the central rectangle have a floral cut work pattern in the silk overlaying the lace which has couched cornelli work.. The third satin rectangle from the outside has a looped and wave pattern in couched cornelli work, missing on one corner.favaloro, bedspread, satin, chenile bobble trim -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... of the drill. In 1891 the first machine-made steel burs were in use... increase in the speed of the drill. In 1891 the first machine-made ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... of the drill. In 1891 the first machine-made steel burs were in use... increase in the speed of the drill. In 1891 the first machine-made ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

... increasingly machine made, which greatly reduced the production time... increasingly machine made, which greatly reduced the production time ...This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied, double collar lip; square upper with flared lower. Neck has seams and shoulder seam from 3-piece mould. Body with horizontal ripples tapers inwards to base. Push-up base with pontil mark and embossed inscription. Tape over wire around mouth. Cork remnants inside mouth. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable