Showing 456 items

matching metal industry

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Scale, George Salter & Co, Circa 1921

The Hughes’ Family Scale No. 48 is a spring balance scale. It uses the Imperial measurements of ounces and pounds. There are 16 ounces (OZ) in one pound (LB), and each pound equals approximately 454 grams in Metric measurements. Scales have been used to measure and compare items for value for centuries. A weight was placed on one side of a balance and the object was placed on the other. Adjustments were made to either the weight or the object until the balance was horizontal, which meant that each side was the same weight. The Salter family business began in 1760 with spring makers, Richard and William Salter. In the late 18th century, Richard Salter invented the spring scale, where the weight of an object on the tray of the scale causes pressure on a spring in the scale. The pressure caused by gravity was then measured to calculate the weight of an object. Spring scales are still used today along with the more recent and accurate digital scales. The company began manufacturing in West Bromwich, England, in 1770. The firm was taken over by William’s sons, John and George. In 1824, after the death of John, the firm became George Salter & Co. The company produced a wide variety of products, including Britain’s first bathroom scale and the first English typewriter. In 1884 the Salter Trademark of a Staffordshire knot pierced by an arrow was registered. After over 100 years of manufacturing, the company was bought out by Staveley Industries, which was bought by Weigh-Tronix, and then that company was bought by HoMedics Company in 2004.This scale was made by Salter, the company that invented the balance scale, the first British bathroom scale and the first English typewriter. The scale represents the domestic equipment used for measuring in food preparation over 100 years ago. Modern kitchen scales are still using the same principal, along with scales used in business and industry.Scale; a domestic spring balance scale for measuring weight from 0 to 20 pounds. The scale’s grey metal case has a round white dial on the front with black markings, an arrow indicator and a round shallow metal bowl on a pedestal at the top. The scale is raised on a rectangular metal base with outward-sloping sides. An adjustable screw is on the dome top. The scale is marked from 0 to 20 pounds, with each pound marked in 1-ounce increments. The scale is named the Hughes Family Scale No. 48 and was made in Britain by Salter.“HUGHES’ / FAMILY SCALE / No. 48” “BRITISH MADE” “TO WEIGH 20 LBS BY 1 OZ” “SALTER” above logo [knotted rope with an arrow through loops]flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, hughes, salter, british made, family scale, no. 48, spring balance, scale, weighing instrument, weights and measures, weighing machine, kitchen utensil, baking accessory, domestic equipment, cookware, bakeware, kitchen scale, kitchen accessory, food preparation, recipes, cooking, measuring -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Page Numbering Machine, EARLY 1900’S

Antique paging or page numbering machine, also referred to as a paginater. Machine prints six digit numbers consecutively. It was used in the printing industry to number consecutive pages of journals in the early 1900’s. Alex Cowan & Sons Ltd. of Melbourne, Sydney and Adelaide supplied printing equipment to other firms. The parent company, Alexander Cowan & Sons Ltd., manufactured fine paper in Valleyfield, Penicuik, Scotland from 1814-1937. This page numbering machine or paginater is an example of mechanical technology used in the printing industry in the early 1900's.Page numbering machine, also known as a paginater or paging machine. Printing machine with six digits for numbering pages consecutively. Steel frame, wooden treadle plate and bench. Inscription of maker's name on metal plate. Made by Alex Cowan & Sons Ltd.Inscribed on maker's plate, "Alex Cowan & Sons Ltd. / Printers Furnishers / Melbourne, Sydney, Adelaide". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, paging machine, treadle paging machine, printing machine, page numbering machine, paginater, alex cowan and sons ltd, australian printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c. 20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 200 gallons in capacity. Round metal container with rounded base and flat extended lip. flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c.20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 200 gallons in capacity. Round metal container with rounded base and flat extended lip. It was used to heat whale blubber to remove the oil.flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c. 20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 180 gallons in capacity. Round metal container with rounded base and flat extended lip. It was used to heat whale blubber to remove the oil.flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFurniture - Set of Drawers, Matchbox Drawers, n.d

Set of drawers constructed from 46 matchboxes of various brands. Labelled on ends of boxes ' A - Z', plus various other, in black ink. Some boxes not labelled. A number of the drawers contain metal letters for stamps/printing.industry, printing -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Anvil, Bradford and Kendall, n.d

Port of Portland Collection Bradken, originally Bradford and Kendall, began as a steel foundry in Sydney in 1920 and produced BK anvils at its factories in Alexandria and Mascot NSW. Leslie Bradford (General Manager) and Jim Kendall (Chief Mechanical Engineer), two BHP steelworks employees, got lucky at the races one day in 1920 and pledged their £15,000 winnings to start a steel foundry business. The horse they backed, ‘Jack Findlay’ completed a remarkable sequence of five wins during 1919 and 1920. With each win Leslie Bradford, Jim Kendall and a group of friends rolled-over their bets. By January 24, 1920 they had won a small fortune. On April 28 1920, the group used their winnings to establish the Alloy Steel Syndicate and build a steel foundry in Alexandria, Sydney to take advantage of what they saw as an untapped potential for industrial growth. Bradford Kendall Ltd was incorporated on 20th March 1922.Metal blacksmiths anvil. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Blacksmith anvil, 5CWT, iron BK Sydney Australia.Front: 'BK SYDNEY AUST. 5CWT' Back: -port of portland, anvil, blacksmith, industry, bk anvil, bradken, brandford and kendall -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipbuilders model, R W Miller

Original ship - 11,741 gross tons. 589' x 70' x 30' (179.5 x 21.34 x 9.14m). Oil tanker built by Eriksberg Motor Vessels at Gottenburg, Sweden in 1951 for Hjalmar Bjorge of Norway as the Storheim. Purchased November 1964 and renamed R W MILLER. Had a crew of 39 seamen, including the officers. 1973 sold to Independent Shipping Company Pty Ltd of Singapore. Renamed Cherry Victor. Scrapped 1979. Robert Miller traded under the name R W Miller and Company from early 1912. One of Miller's first contracts was to pick up overburden and spoil from the sinking of the Balmain Colliery shaft and dump it at sea. Miller saw the opportunity to sell this material and he ended up getting a sixpence a ton from a local council and other contractors for use as road bases and building foundations. This close association with coal led to Robert W Miller on 15th January 1913 being given the contract for coal distribution from Sydney Harbour Colliery (Balmain mine). So began a long association with coal. Miller built a fleet of lighters that were used to transport blue metal, sand and coal around Sydney Harbour. This introduction into coal transport opened a prospect for him to enter the larger coal shipping transport. During 1917 Miller purchased a vessel, the taking over 1985 by Howard Smith Industries Pty Ltd, Melbourne. Build date 1951-1979. Ship builders model of the tanker R W Miller in a glass case. The body is painted in colours of maroon, green and grey, the deck with detailed fittings and superstructure, an Australian merchant flag flying from the stern, within a mahogany framed glazed display casePlaque at foot of model: M/T R.W. MIILRT/ BUILT GOT. 1951/ OWNERS R.W. MILLER & CO. PTY. LTD/ LENGTH OVERALL 559.04"/ LENGTH BETWEEN P.P 526.06"/ EXTREME BREADTH 70.00"/ MOULDED DEPTH 39.03"/ DEADWEIGHT TONNAGE 18,500/ MACHINERY B & W TYPE A I.H.P 7, 600" on model: "R.W Miller" painted in black -

Seaworks Maritime Museum

Seaworks Maritime MuseumPlaque, Another Hamilton Design

One varnished teak board plaque from the Australian Institute of Navigation with a metal enamelled emblem of AustraliaPresented to Howard Smith Industries P/L in appreciation of your continuing support December 1995 Australian Institute of Navigation Another Hamilton Design the corporate award specialist ph: 026744266 fax: 026744758 -

Glenelg Shire Council Cultural Collection

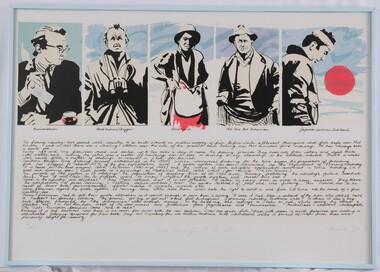

Glenelg Shire Council Cultural CollectionPrint, Angela Gee, Tuna Fishing Pt Lincoln, 1986

UnknownFive portraits of male figures in five square at top of print. Each man is in a different pose, with a blue wash background. Underneath are hand-written inscriptions identifying them as different people involved in the tuna-fising industry. The bottom part of the print is a handwritten short essay on the tuna-fishing industry. Mounted without a matt in a pale blue metal frame with glass glazing.Front: 9/40 (lower left) Tuna Fishing, Pt Lincoln (lower centre) Angela Gee '86 (lower right) (pencil) Back: (no inscriptions) -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionBanner - Banner - Tomorrow's Possibilities, Nov-10

-

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionWeapon - Whaling Harpoons, n.d

Original owner - one of the Henty brothers, bought by Margaret's grandfather, Matthew Edward Mabbitt, lighthouse keeper at a Henty clearing sale about 1900Two matching harpoons with wooden handles. Metal harpoon heads have been re-plated at some stageBack: 'Mcmillan' on back of both harpoon heads - first two letters unclearwhaling, maritime industry, hunting, henty -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Marlin spike, n.d

Used by Peter Carrison, donor's father-in-law, who was a boat builder. Originally used by Henty brothers for wire cable splicing. A marlinspike (/ˈmɑːrlɪnspaɪk/, sometimes spelled marlin spike, marlinespike, or [archaic] marlingspike) is a tool used in marine ropework. Shaped in the form of a polished metal cone tapered to a rounded or flattened point, it is used in such tasks as unlaying rope for splicing, untying knots, drawing marline tight using a marlinspike hitch, and as a toggle joining ropes under tension in a belaying pin splice.Metal spike with timber knob/handle. Circular groove around head of knob, which has a nail inserted in itmarine technology, maritime industry, rope making, rope work -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSign - Sign - Portland Pure Creamery, n.d

Metal sign for Portland Pure Creamerydairy industry, rural, cream, creamery, advertising -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Watches, pocket watch, c1900

A pocket watch is a watch that is made to be carried in a pocket, as opposed to a wristwatch, which is strapped to the wrist.. They were the most common type of watch from their development in the 16th century until wristwatches became popular after World War I The first stem-wind and stem-set pocket watches were sold during the Great Exhibition in London in 1851 and the first owners of these new kinds of watches were Queen Victoria and Prince Albert. Stem-wind, stem-set movements are the most common type of watch-movement found in both vintage and modern pocket watches.In 1857 the American Watch Company in Waltham, Massachusetts introduced the Waltham Model 57, the first to use interchangeable parts which cut the cost of manufacture and repair. Most Model 57 pocket watches were in a coin silver. Watch manufacture was becoming streamlined; the Japy family of Schaffhausen, Switzerland, led the way in this, and soon afterwards the newborn American watch industry developed much new machinery, so that by 1865 the American Watch Company (afterwards known as Waltham) could turn out more than 50,000 reliable watches each year.This silver plated pocket watch with an open glass face has black roman numerals on a white dial , gold hour hands and a blue second hand. The winding stem is at 12 o’clock and has a metal ring for attachment to a chain. Back: of case ; a shield inside 2 circleswatches, brighton, cheltenham, moorabbin, bentleigh, early settlers, pioneers -

Dunkeld Museum Inc.

Dunkeld Museum Inc.Bee Smoker

Many farming families in the district kept bees as a source of honey for home consumption. This item was made for use on the family farm. Most of the equipment used in the local industry was homemade.During the early to mid 20th century bee keeping was a significant rural industry in Dunkeld and surrounding districts. It is believed that there were nearly twenty apiarists operating in the area. Honey in large quantities was railed to Melbourne for sale.Homemade bee smoker consisting of a copper cylindrical firebox and rectangular bellows constructed of wood and leather. Components are assembled with rivets, scrap wire, sheet metal, nuts and bolts and nails. -

Dunkeld Museum Inc.

Dunkeld Museum Inc.Shearers Oil Can, Untitled, Shearer's Oil can, 1920's

Small copper oil can used in the shearing industry to oil combs and cutters.This item is made of copper as opposed to regular ones which were manufactured from tin plate.Copper cone shaped oil can. Soldered metal base. Brass screw top with pourer attachedNoneshearing, oil can, combs and cutters -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Saddler's tools, n.d

2 saddler's tools, curved metal rod, 6-sided small spiked wheel at end, teardrop shaped handle. Wheels slightly different size. a) smaller, has '14' on rod near handle b) larger, has '10' on rod near handletool, saddler, leatherwork, trade, industry -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Memo Slate - Peter F. Cram Chemist, Casterton, c. 1958

Peter Francis Cram was a pharmacist based in Casterton. In the 1966 Victorian government gazette he is listed as being at 83 Henty Street and having registered on 20 April 1955.Memo slate advertising Peter F. Cram, Chemist, Henty St., Casterton. Yellow plastic, red lettering, 1958 calendar on back. Slide-out white plastic slate, held between front and back by round metal stud.casterton, local business, industry, pharmacy, chemist -

Halls Gap & Grampians Historical Society

Halls Gap & Grampians Historical SocietyPhotograph - B/W

This is a photo of Smith's Mill after it was destroyed by fire. The mill operated in an area close to Wartook.The photo shows a large amount of debris, including a large metal tank on its side and large fly -wheels/gears. A charred post stands among the debris on the left.timber industries, sawmilling -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomAmplifier Audio Frequency AM-1780/VRC, 1980's

Solid metal radio harness control box with 10 cable sockets around sides and various control switches and line connections on faceSerial No 33765radio equipment, 1780 box -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Time Capsule Ceremony, 10 November 1985, 10/11/1985

On Sunday, 10 November 1985 a time capsule was lowered into a monument installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria’s 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society’s 20th anniversary. The main feature of this monument is a ‘tyring disc’, a blacksmith’s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden-spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red-hot iron hoop, previously forged to the correct size, was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel. [from EDHS Newsletter No. 45, November 1985:] TIME CAPSULE CEREMONY: Our 150th Anniversary Monument is now under construction in the gardens in front of the Eltham Community Centre. Further details of the project are given under a separate heading below and this item deals with the proposed ceremony. We propose to formally lower the time capsule into its container underneath the monument as part of the Eltham Community Festival. All members are invited to attend the ceremony at 2.00 p.m. on Sunday, 10th November. Come earlier with a picnic lunch if you like. Local people and firms who have contributed money or services for the monument will also be invited. As part of the Festival programme the public are welcome to attend. This is one of the most significant projects the Society has undertaken and members' participation in its finalization would be most gratifying to the organizing committee. 150TH ANNIVERSARY PROJECTS: We have concentrated our efforts on finishing the monument and time capsule project within the 150th year and have found it necessary to abandon the historical tour project. We have applied to the State 150th Committee to transfer the funds allocated for the tour to construction of the monument. The historical tour project will be continued at a later date and photos of historic houses in the area, taken by Doug Orford, will be available for use in an associated display. At the time of writing, the monument construction is on schedule for the ceremony on 10th November. The concrete base has been completed and the main feature of the monument, which is an old tyring plate or disc, will be lifted into place in the next week. The final ceremony will involve lowering the sealed time capsule into place, bolting down its container lid and then concreting over the lid. The capsule will contain mainly items relating to present day Eltham and its people and is to be opened in the year 2035, a video film made by Joh Ebeli and also details of families and organizations who have contributed to construction of the monument. It is proposed to place the items in the capsule on 5th November and any items members think could be included may be submitted up to that date. The Society has received an excellent response from local people, firms and organizations by way of assistance with this project. Graham Beyer, who originated the project, has arranged many of the donations. He and his firm, Package Handling Equipment, have donated the time capsule itself and have carried out fabrication of sections of the monument. The design of the monument was adapted by Graham Beyer from drawings by Joh Ebeli. Charmac Industries has donated the container for the time capsule and a cast gun metal name plate for the monument. BMG Concrete has donated concrete for the base which was constructed by Caridi Construction Company. Northbourne Garden Supplies has donated materials for the paving around the monument. Robert Becker from Eltham Apex directed construction of the paving by Society members. Terry Hutchinson has agreed to donate the use of his crane to lift the tyring disc into place. Financial contributions have been made by the Eltham Chamber of Commerce and the Rotary Club of Eltham. We are grateful to all who have helped, and members' support for firms who have donated their services would be an appropriate recognition. It is planned to print "Time Capsule Certificates" which can be held by organizations or passed on to descendants by individuals. The certificates will indicate an interest in the contents of the capsule when it is opened in fifty years. Certificates will be distributed to Society members and those who have contributed to the project.Nine colour photographsactivities, 1985, time capsule, eltham, eltham festival -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Time Capsule Ceremony, 10 November 1985, 10/11/1985

On Sunday, 10 November 1985 a time capsule was lowered into a monument installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria’s 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society’s 20th anniversary. The main feature of this monument is a ‘tyring disc’, a blacksmith’s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden-spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red-hot iron hoop, previously forged to the correct size, was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel. [from EDHS Newsletter No. 45, November 1985:] TIME CAPSULE CEREMONY: Our 150th Anniversary Monument is now under construction in the gardens in front of the Eltham Community Centre. Further details of the project are given under a separate heading below and this item deals with the proposed ceremony. We propose to formally lower the time capsule into its container underneath the monument as part of the Eltham Community Festival. All members are invited to attend the ceremony at 2.00 p.m. on Sunday, 10th November. Come earlier with a picnic lunch if you like. Local people and firms who have contributed money or services for the monument will also be invited. As part of the Festival programme the public are welcome to attend. This is one of the most significant projects the Society has undertaken and members' participation in its finalization would be most gratifying to the organizing committee. 150TH ANNIVERSARY PROJECTS: We have concentrated our efforts on finishing the monument and time capsule project within the 150th year and have found it necessary to abandon the historical tour project. We have applied to the State 150th Committee to transfer the funds allocated for the tour to construction of the monument. The historical tour project will be continued at a later date and photos of historic houses in the area, taken by Doug Orford, will be available for use in an associated display. At the time of writing, the monument construction is on schedule for the ceremony on 10th November. The concrete base has been completed and the main feature of the monument, which is an old tyring plate or disc, will be lifted into place in the next week. The final ceremony will involve lowering the sealed time capsule into place, bolting down its container lid and then concreting over the lid. The capsule will contain mainly items relating to present day Eltham and its people and is to be opened in the year 2035, a video film made by Joh Ebeli and also details of families and organizations who have contributed to construction of the monument. It is proposed to place the items in the capsule on 5th November and any items members think could be included may be submitted up to that date. The Society has received an excellent response from local people, firms and organizations by way of assistance with this project. Graham Beyer, who originated the project, has arranged many of the donations. He and his firm, Package Handling Equipment, have donated the time capsule itself and have carried out fabrication of sections of the monument. The design of the monument was adapted by Graham Beyer from drawings by Joh Ebeli. Charmac Industries has donated the container for the time capsule and a cast gun metal name plate for the monument. BMG Concrete has donated concrete for the base which was constructed by Caridi Construction Company. Northbourne Garden Supplies has donated materials for the paving around the monument. Robert Becker from Eltham Apex directed construction of the paving by Society members. Terry Hutchinson has agreed to donate the use of his crane to lift the tyring disc into place. Financial contributions have been made by the Eltham Chamber of Commerce and the Rotary Club of Eltham. We are grateful to all who have helped, and members' support for firms who have donated their services would be an appropriate recognition. It is planned to print "Time Capsule Certificates" which can be held by organizations or passed on to descendants by individuals. The certificates will indicate an interest in the contents of the capsule when it is opened in fifty years. Certificates will be distributed to Society members and those who have contributed to the project.Two colour photographsactivities, 1985, time capsule, eltham, eltham festival -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Sinking the capsule, Graham Beyer on left and Joh Ebeli, Time Capsule Ceremony, 10 November, 1985, 10/11/1985

On Sunday, 10 November 1985 a time capsule was lowered into a monument installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria’s 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society’s 20th anniversary. The main feature of this monument is a ‘tyring disc’, a blacksmith’s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden-spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red-hot iron hoop, previously forged to the correct size, was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel. [from EDHS Newsletter No. 45, November 1985:] TIME CAPSULE CEREMONY: Our 150th Anniversary Monument is now under construction in the gardens in front of the Eltham Community Centre. Further details of the project are given under a separate heading below and this item deals with the proposed ceremony. We propose to formally lower the time capsule into its container underneath the monument as part of the Eltham Community Festival. All members are invited to attend the ceremony at 2.00 p.m. on Sunday, 10th November. Come earlier with a picnic lunch if you like. Local people and firms who have contributed money or services for the monument will also be invited. As part of the Festival programme the public are welcome to attend. This is one of the most significant projects the Society has undertaken and members' participation in its finalization would be most gratifying to the organizing committee. 150TH ANNIVERSARY PROJECTS: We have concentrated our efforts on finishing the monument and time capsule project within the 150th year and have found it necessary to abandon the historical tour project. We have applied to the State 150th Committee to transfer the funds allocated for the tour to construction of the monument. The historical tour project will be continued at a later date and photos of historic houses in the area, taken by Doug Orford, will be available for use in an associated display. At the time of writing, the monument construction is on schedule for the ceremony on 10th November. The concrete base has been completed and the main feature of the monument, which is an old tyring plate or disc, will be lifted into place in the next week. The final ceremony will involve lowering the sealed time capsule into place, bolting down its container lid and then concreting over the lid. The capsule will contain mainly items relating to present day Eltham and its people and is to be opened in the year 2035, a video film made by Joh Ebeli and also details of families and organizations who have contributed to construction of the monument. It is proposed to place the items in the capsule on 5th November and any items members think could be included may be submitted up to that date. The Society has received an excellent response from local people, firms and organizations by way of assistance with this project. Graham Beyer, who originated the project, has arranged many of the donations. He and his firm, Package Handling Equipment, have donated the time capsule itself and have carried out fabrication of sections of the monument. The design of the monument was adapted by Graham Beyer from drawings by Joh Ebeli. Charmac Industries has donated the container for the time capsule and a cast gun metal name plate for the monument. BMG Concrete has donated concrete for the base which was constructed by Caridi Construction Company. Northbourne Garden Supplies has donated materials for the paving around the monument. Robert Becker from Eltham Apex directed construction of the paving by Society members. Terry Hutchinson has agreed to donate the use of his crane to lift the tyring disc into place. Financial contributions have been made by the Eltham Chamber of Commerce and the Rotary Club of Eltham. We are grateful to all who have helped, and members' support for firms who have donated their services would be an appropriate recognition. It is planned to print "Time Capsule Certificates" which can be held by organizations or passed on to descendants by individuals. The certificates will indicate an interest in the contents of the capsule when it is opened in fifty years. Certificates will be distributed to Society members and those who have contributed to the project.Colour photographactivities, 1985, time capsule, eltham, eltham festival -

Kiewa Valley Historical Society

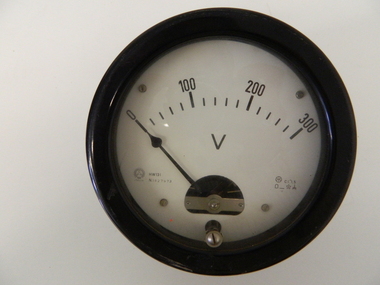

Kiewa Valley Historical SocietyMeter Volt, mid to late 1900's

This analog voltmeter is quite a large (industrial type) apparatus which permits the easy monitoring of electrical variations within the large SEC Victoria Hydro Scheme's electrical generators. These generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro schemes was achieved from the mid 1900's to the 1960's. At this point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years. This voltmeter is very significant to the Kiewa Valley as its use was introduced during the Kiewa Hydro Scheme. Although only a small apparatus it was part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both an industrial and a larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley. This analog volt meter has two metal rods protruding from the "back" of instrument with screw on points for the negative and the positive leads allowing the "current" to flow across the calibrated resistors to indicate on the "face" side the strength of the voltage "power". The "face" of the instrument has a zero point and then five evenly graduated marks from Zero to the "100, 200 and 300" marked points of measures. A large "V" below these pointers indicates that they represent levels of voltage. Three small screws hold the "face" in place. At the back of the meter is an aluminium "clasp" with three protruding screws (positioning fasteners) and a a screw tightening fixture for the correct fastening of the "clasp" into the correction location on the meter "board".Manufacturer's logo "CSG" underneath "ITALIA"kiewa valley tourism, victorian alps, alternate energy supplies, alpine population growth -

Kiewa Valley Historical Society

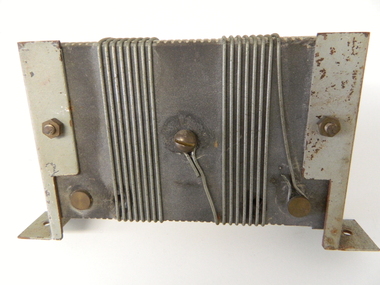

Kiewa Valley Historical SocietyResistor 2000 Amperes, circa mid to late 1900's

This resistor was part of the Hydro generator control metering system which displays what electricity is produced at the underground generators. The control centre can be hundreds of meters above the generators and this resistor reduces the large current to a small voltage entering a calibrated control monitor. This resistor is highly significant to the Kiewa Valley because it represents a major construction and ongoing operational industry dealing with the supply of hydro electricity to Victoria. Although it is relatively small in size it is part of the controlling mechanism for the supply of a non polluting energy source for home and industrial use.This mainly metal and wire resistor has been built of copper and brass and designed to carry a current of 2000 Amperes. Wires are wound around a non conductive cement block which has grooves on the top and bottom ledges to hold the wires snuggle into place. At the rear there are three connection rods which have long 5mm thick screws (to fasten cable ends)On one side it is scribed "0.2 OHMS" and underneath this "10 AMPS"kiewa hydro electricity scheme, victorian state electricity commission, transformers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyRelay Protection Instrument, Circa 1950's

This protection relay apparatus (a large electrical fuse), which permits the easy monitoring and disconnection of faulty electrical apparatus connected to the large SEC Victoria Hydro Scheme's electrical power producing generators. These generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro Schemes was achieved from the early 1900's to the 1960's. At this point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This protection relay is very significant to the Kiewa Valley as its use was introduced during the Kiewa Hydro Scheme. Although only a small apparatus it was part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both an industrial and a larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley.This protection relay unit has a black painted metal shell with four copper enclosed "prongs" fastened to the rear of the housing(from a bake-lite plate) . Between these "prongs" are four "empty" points allowing additional "screw on" bases. The front glass enclosed meter and recorder allows for the identification and automatic disconnection of any faulty equipment connected to the main power generator. This equipment acts similarly to a modern day circuit breaker found on the electrical circuit boards of residential homes.On the top section of the front panel "ASEA" to the left "Made in Sweden" and to the right "Frabrique en Suede" below this "RIS" below this a graph and next to it two columns of numbers and a pointer for each setkiewa hydro electricity scheme, victorian state electricity commission, relays, generators -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWest Kiewa Alpine Way and Day Ski Resort

In June 1982 This research report on the West Kiewa Alpine Way Proposal was sent to the Mt Beauty Chamber of Commerce. "The economic, tourist market and geographic factors are the kernel of the proposal." From Industrial Relocations Consultants Pty. Ltd.The proposal was to benefit the tourism industry.Manila foolscap folder with metal fastener. Papers dated June 1982 re - "Proposed West Kiewa Alpine Way and Day Ski Resort" Also enclosed but not related: Letter from Falls Creek Tourist Area Management Committee July 1984B. Goss written on coverwest kiewa alpine way, day ski resort, mt beauty chamber of commerce -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Mrs Potts No. 1

A clothes iron is used, when heated, to press clothes to remove wrinkles and creases.The early irons were heated over a stove or in a fire. Irons were used very early in time and cast-iron irons during the 18th century. Mrs. Potts invented many irons starting from an early age thus making a difference to the clothing industry. She invented clothes irons with detachable wooden handles. Her first patent was in October 1870.This iron was used in the Kiewa Valley.Vintage cast iron body invented by Mrs Mary Florence Potts 1890s to 1940s. Detachable wooden handle (not attached) was cooler than a metal handle. It is double pointed for ironing in both directions. Body is hollow the top part being held by two screws. It can be filled with a light material. The No. 1 size is for specific ironing task. compared with No. 2 or No. 3. One handle with other bases enabled some to be reheating while using one. This iron has a stand. Formerly KV88B)Mrs Potts / No. 1 / Iron"" embossed on the topmary florence potts iron, cast iron, laundry, mrs potts -

Kiewa Valley Historical Society

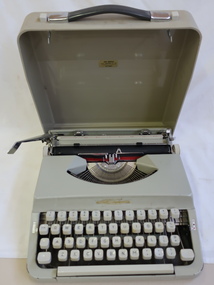

Kiewa Valley Historical SocietyTypewriter - Portable

These typewriters were imported fully assembled from Japan by CFM Industries. CFM (Curvie Furniture Manufacturing). The Nakajima portable typewriters were imported in the 1970s. Typewriters replaced hand written writing. Their benefits were that the work was written faster and was legible. The portable typewriter enabled the typist to take her typewriter with her. Typewriters have now been replaced by computers with the advantage of editing the work before the final copy is made and with the ability to add eg. photos, create different settings etc. Used by a resident of the Kiewa Valley in the 1970s.Beige hard plastic case with dark grey handle with chrome fittings and white buttons either side of the handle. Metal typewriter 'querty' key board, white keys with black inscriptions. Includes typewriter ribbonLabel inside cover for servicing. "CFM Industries Pty Ltd address, phone number" Label on back of typewriter for CFM Industriesportable typewriter