Showing 3976 items matching "one handed"

-

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour Photograph, Street Protests in Hong Kong against proposed extradition laws, 2019, 17/06/2019

Carrie Lam, Hong Kong’s chief executive, had plenty of political support in the territory’s pro-Beijing legislature to pass a bill that would allow extraditions to mainland China. The legislators were set to begin discussing the bill in early June, and intended to vote on it just weeks later. A series of protests took place, and after a June 16 protest saw the largest turnout yet, Ms. Lam made a major concession: She postponed the bill, at least temporarily. It was an undeniable victory for the protesters — but it did little to quell the unrest. Since the bill could later be reintroduced, protesters felt they remained in danger. The police tactics to break up the demonstrations on June 12, including the use of more than 150 tear gas canisters to push protesters far away from the government office, created a new set of demands from the protesters. Now, instead of just calling for the withdrawal of the bill and Ms. Lam’s resignation, they said they wouldn’t be content unless there was an independent investigation of officers’ conduct. They also wanted the release of protesters arrested on June 12, and for the government to rescind its description of the demonstrations as a “riot,” a designation that carries legal significance. None of that has happened. Many analysts say Ms. Lam is unlikely to step down, nor would Beijing accept her resignation if she offered it. She has more wiggle room on the other demands, but has not indicated any willingness to budge. The Hong Kong Protests are a leaderless, digital movement.There is no single leader or group deciding on or steering the strategy, tactics and goals of the movement. Instead, protesters have used forums and messaging apps to decide next steps. Anyone can suggest a course of action, and others then vote on whether they support it. The most popular ideas rise to the top, and then people rally to make them happen. At its best, this structure has empowered many people to participate and have their voices heard. Protesters say it keeps them all safe by not allowing the government to target specific leaders. Their success in halting the extradition bill, which was shelved by the territory’s chief executive, speaks to the movement’s power. Despite the lack of a clear leader, protesters have shown extensive coordination at the demonstrations, having planned the specifics online beforehand. Supply stations are set up to distribute water, snacks, gloves, umbrellas and shields made of cardboard. Volunteer first aid workers wear brightly colored vests. People form assembly lines to pass supplies across long distances, with protesters communicating what they need through a series of predetermined hand signals. Anyone walking in dangerous areas without a helmet or a mask is quickly offered one. No individual can speak on behalf of the protesters, which makes negotiations difficult, if not impossible. (https://www.nytimes.com/2019/07/02/world/asia/hong-kong-protest-explained.html, accessed 07/07/2019) Hong Kong’s amended extradition law would allow the extradition of suspects to mainland China for the first time. Supporters say the amendments are key to ensuring the city does not become a criminal refuge, but critics worry Beijing will use the law to extradite political opponents and others to China where their legal protections cannot be guaranteed. The government claims the push to change the law, which would also apply to Taiwan and Macau, stems from the killing last year of a Hong Kong woman while she was in Taiwan with her boyfriend. Authorities in Taiwan suspect the woman’s boyfriend, who remains in Hong Kong, but cannot try him because no extradition agreement is in place. Under the amended law, those accused of offences punishable by seven years or more in prison could be extradited. The new legislation would give Hong Kong’s leader, known as the chief executive, authority to approve extradition requests, after review by the courts. Hong Kong’s legislature, the legislative council, would not have any oversight over the extradition process. Many Hong Kongers fear the proposed extradition law will be used by authorities to target political enemies. They worry the new legislation spells the end of the “one country, two systems” policy, eroding the civil rights enjoyed by Hong Kong residents since the handover of sovereignty from the UK to China in 1997. Many attending the protests on Sunday said they could not trust China as it had often used non-political crimes to target government critics, and said they also feared Hong Kong officials would not be able to reject Beijing’s requests. Legal professionals have also expressed concern over the rights of those sent across the border to be tried. The conviction rate in Chinese courts is as high as 99%. Arbitrary detentions, torture and denial of legal representation of one’s choosing are also common. Many in the protests on Sunday 09 June 2019 said they felt overwhelmed by a sense of helplessness in the face of mainland China’s increasing political, economic and cultural influence in Hong Kong. Hong Kong’s top political leader is not elected by ordinary voters but by a 1,200-strong election committee accountable to Beijing. Half of its legislature are chosen through indirect electoral systems that favour pro-Beijing figures. Many Hong Kongers also cited the jailing of leaders and activists from the 2014 Occupy Central movement– a 79-day mass civil disobedience movement – as well as the disqualification of young localist lawmakers as signs of the erosion of civil freedoms. Resentment towards China has been intensified by soaring property prices – with increasing numbers of mainland Chinese buying properties in the city – as well as the government’s “patriotic education” drive, and the large numbers of mainland tourists who flock to Hong Kong. Many Hong Kongers are also concerned about China’s growing control over the city’s news media, as they increasingly self-censor and follow Beijing’s tacit orders. https://www.theguardian.com/world/2019/jun/10/what-are-the-hong-kong-protests-about-explainerCrowds mass on Queens Way in Hong Kong as an estimated 2 million people march in protest at the government's refusal to withdraw a controverisal law allowing people to be extradited to mainland China. Chants demanded the chief executive apologise and the legislation be withdrawn, while many held signs protesting police violence. Nearly 2 million protesters flooded the streets of Hong Kong on Sunday, organisers claimed, delivering a stunning repudiation of Chief Executive Carrie Lam Cheng Yuet-ngor’s governance and forcing a public apology out of the city’s leader over her campaign to bulldoze a controversial extradition bill through the legislature. A day after Lam suspended her push for the bill, expecting it to defuse a crisis that has seen violent clashes between mostly young protesters and police, the centre of Hong Kong was brought to a complete standstill as the masses marched to chastise her for refusing to withdraw the bill or apologise when first asked to, and declaring that nothing short of her resignation would satisfy them now. (https://www.scmp.com/news/hong-kong/politics/article/3014737/nearly-2-million-people-take-streets-forcing-public-apology ) carrie lam, hong kong protests, extraditions, protest, protestors, admiralty -

Federation University Historical Collection

Federation University Historical CollectionInstrument - Scientific Instrument, Westphal Balance

The Westphal Balance was used in the Science Department at the University of Ballarat, VictoriaA beam Balance, provided with a submersible body at one end, for determining density of water at different temperatures. Housed in a polished wood box.Calibration table, hand written, inside the box.westphal, balance, water density, liquids, science department, university of ballarat -

Federation University Historical Collection

Federation University Historical CollectionElectrical Appliance, Philips Electrical Company, Philips Portable Valve Radio - Model 111F; 1950s, c1950s

Philips Australia: Radioplayer 111F. Portable radio - valves. Silver metal with black bakelite sides. Mesh panels at front and back for sound. Panel (shutter) on front folds back to reveal the radio stations in Australia. Stations use the old format - 3LO instead of 774. Right hand side has knob that changes the station, left side has one to change the volumePhilips badge on frontphilips, portable radio, valves -

Federation University Historical Collection

Federation University Historical CollectionScience Equipment, Hand-held Conductivity/TDS Meter: CON 6/TDS 6, c2002

The Conductivity Meter was purchased for the Food and Allied Sciences Department. It is not known if it was purchased to replace a similar item but obvious that this particular one has never been used. The solutions can be used for measuring conductivity. This measurement can be used as an estimate of total salt content in a solution. Good for quality assurance in a food context.Grey hard plastic case - compartments inside. Contains 1 meter, 1 conductivity probe and 4 small bottles of solution. Three bottles are conductivity solution. The solution is standardized using conductivity meter that is calibrated by potassium chloride solution. One bottle is deionized water. Instruction Manual in compartment in lid.Labels and stickers on outside of case. Serial No: 1428228food and allied sciences, conductivity meter, conductivity probe, conductivity solution, deionized water, potassium chloride, salt content -

Federation University Historical Collection

Federation University Historical CollectionCostume, School of Mines Ballarat Bomber Jacket, Approx 1990s

This jacket was worn and donated by Neil Leckie who on the Engineering staff at the School of Mines Ballarat (SMB) in the 1990s. These jackets were issued to all the trade teachers at SMB at that time. Neil was also an Army Reserve Officer, holding the rank of Major in the Royal Australian Infantry Corps.This black polyester & nylon, lined jacket has ribbing at the neck and cuffs. It has a front zipper and two bound and set in pockets at the lower front and one zippered pocket on the left hand side above the lower pocket and below an embroidered logo showing SMB and the crest.Label showing makers name and composition of fabricsneil leckie, ballarat school of mines, jacket, engineering -

Federation University Historical Collection

Federation University Historical CollectionObject, Glass Desk Ornament: Paper Weight, 1993

Shenzhen Polytechnic was founded in 1993. It is a senior academy with three campuses in China and co-operative relationships with 40 universities outside mainland China. It has been ranked first among China's vocational colleges.Heavy glass with etching on two sides and hologram of clasped hands in baseCircular emblem of Shenzhen Polytechnic - 1993 on one side. Opposite side has University of Ballarat Australia shenzhen polytechnic, senior academy, china, universities, paper weight, glass, hologram -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour, Photographs of Ballarat College of Advanced Education Librarianship Staff, Mid to late 1980s

Group of Ballarat Colleged of Advanced Education librarianship staff in offices and common room Course Staff .1 One Male person with white beard, one female person, each with a mug in their hand Kay Kent,Lecturer Keith Davison, Senior Lecturer 1989 .2 One female, one male persons conversing Goddard , Jennifer. Lecturer Fairhall, Donald. lecturer .3 One female person, sitting at desk Goddard , Jennifer. Lecturer .4 One female person seated at desk on telephone Goh (Sieuw-Choo), Jean. Lecturer, 1985 .5 One female and one male person both seated at each end of the table Goddard , Jennifer. Lecturer Gorman, Garry. Lecturer .6 One female person seated in the staff common room Widdop, E. A. Liz. Lecturer .7 One female person, seated behind desk Taylor, Samatha librarianship, ballarat college of advanced education, library, donald fairhall, jennifer goddard, e.a. liz widdop, liz widdop, samantha taylor, jean goh (sieua-choo), jean goh, kay kent, garry gorman -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Luxford Forklift, n.d

Port of Portland Authority Archievesport of portland archives, forklift, luxford, machinery, k s anderson, jadroplov -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Luxford Forklift, n.d

Port of Portland Authority Archivesport of portland -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Main Breakwater construction, Portland, n.d

Port of Portland Authorityport of portland archives, main breakwater, portland harbour, harbour development -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Main Breakwater construction, Portland, n.d

Port of Portland Authority Archivesport of portland archives, main breakwater, construction, harbour -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Cape Grant Quarry, n.d

Port of Portland Authority ArchivesBack: Quarry\, June 8th - top left, pencilport of portland archives, cape grant quarry -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Early Shipping: Ocean / Railway Pier, Early Shipping: Ocean/Railway Pier, n.d

Port of Portland Authority ArchivesFront: Front- M.E Andrews, Portland,-Printed right hand side bottom Back- Purple stamp-'Portland Harbor Trust Commissioners' 5-blue biroport of portland -

Red Cliffs Military Museum

Red Cliffs Military MuseumCertificate, Certificate of Promotion in Rank, 5/12/1923 (exact)

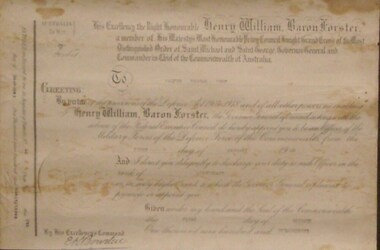

This certificate and 5 other documents from the Walter Thomas West Collection, are in a frame 90.40cm x 66.50cm, which has non reflecting glass.Official Australian Government Certificate.Possibly written in old English script and carries the Royal Seal.Main face of Certificate. "His Excellency the Right Honorable Henry William Baron Forster a member of his Majesty's Most Honorable Privy Council Knight Grand Cross of the most Distinguished Order of Saint Michael and Saint George, Governor General and Commander In Chief of the Commonwealth of Australia. To Walter Thomas West Greeting: By virtue of the provisions of the Defence Act 1903 - 1918 and of all the other powers me enabling I, Henry William Baron Forster, the Goveneror General a foresaid acting with the advice of the Federal Executive Council, do gereby appoint you to be an officer of the Military Forces of the Defence Force of the Commonwealth from the First Day of January 1920. And I direct you diligently to discharge your duty as such officer in the rank of Lieutenant or in any higher rank to which the Governor General is pleased to promote or appoint you. Given under my hand and the seal of the Commonwealth this first day of October One Thousand Nine Hundred and Twenty Three. By the Excellency's Command. (signed) E.K. Bowden" Left Hand side Margin: Entered on record by me, in Register of Patents No 40 Page 2 this 5th day of December, One Thousand Nine Hundred and Twenty Three.of, ww1, walter, thomas, west, mm, mc, photo, register, patents, no40, page, 2, , 1923, collection -

Red Cliffs Military Museum

Red Cliffs Military MuseumDocument, Obituary, 12:MMMM, 1976 (exact); Walter Thomas West passed away 4th December 1976 and his funeral was held 7th of December

Attached to his R.S.L. Membership Card along with the funeral notice, is a subsequent newspaper article written at the time of Walter West's death, which reads: Death of Pioneer Settler/ A pioneer settler of/ the Red Cliffs irigation/ district and one of the/ last men to be evacuated/ from Gallipoli, died sud/denly on Saturday night/ aged 84./ In 1922 Mr. Watler Thomas/ West came to Red Cliffs/ where he established Block/ 86 in the irrigation district./ He lived there until his/ death on Saturday after playing bowls at the Red/ Cliffs rinks on Saturday/ afternoon./ Mr. West was born in Jeparit and served with the/ 24th Battalion in Egypt and/ Gallipoli./ He was awarded the Mili/tary Medal in France in/ 1917 and the Military Cross/ in 1918 when he captured/ single handed an enemy/ machine gun post./ He settled at Red Cliffs/ on his return when the/ area was placed under irri-/gation./ For 25 years he operated/ a unique partnership with/ the late Mr. Martin Nippe, his adjoining property/ owner. The pair pooled their/ horticultural equipment for/ joint use./ Mr. West joined Mildura/ Legacy in 1942 and was an/ active member until his/ death./ The funeral will be held at the United Church, Red/ Cliffs this morning at 10.30Type written obituary, presumably used when Walter West,MC,MM, died.Walter West MC,MM/ Red Cliffs residents were saddened to learn of the sudden passing on Saturday last/ of Walter Thomas West MC,MM., a Pioneer/settler and well respected citizen./ "Wal" as he was affectionately known, was/ born at Dandenong some 84years ago./ He served with distinction in World War 1/ with 24th Battalion. He was an original ANZAC, and also saw service in/ Egypt and France. He received two awards for gallantry in the field - The Military/ Medal in France 1917 and the Military Cross in France/ in 1918 when he was responsible for the/ single handed capture of an enemy gun and crew./ He was an original soldier settler and developed/ his fruit block in Red Cliffs which is still/ operated by his son Tom. In 1922 he/ became an original Trustie of the Methodist/Church and was the last surviving original/ Trustie. He served on the Board of/ directors of the Red Cliffs Co-Operative Co.Ltd/ from 1954 to 1967, and was Chairman of Directors/ in 1963 and 1964. He showed a keen interest/ in youth activities and some excellent cricketers/ were produced as a result of his coaching of/ the Methodist Junior Cricket Team. He was an/ active and keen member of Mildura Legacy/ for 34 years, serving as President in 1947 and 1948./ He was secretary of the Cemetary Trust for many years, served on the Hospital Committee/ was a member of Memorial Lodge, a member of Red Cliffs Senior Citizens Club and a /member of Red Cliffs Sub-Branch R.S.L. since / it's inception./ He was a keen member of the Red Cliffs/ Bowling Club and took part in a club event on/ the day of his passing./ It was the pioneer settler and men with ability/ and initiative of Walter West that brought/ out the Community Spirit which resulted in/ the Red Cliffs we know today.1918, 1917, ww1, walter, thomas, west, mm, mc, 24th, battalion, aif, gallipoli, bullecourt -

Red Cliffs Military Museum

Red Cliffs Military MuseumIdentity Card, Identity Card for A.J. (Blue) Roddy, (estimated); 1943

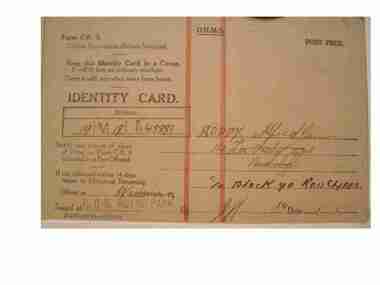

Part of collection of A.J. (Blue) Roddy VX 8007Postcard sized identity card for Alfred james Roddy. Ink print on card Writing in ink, one ink stampO.H.M.S./ Post Free/ Left hand side: Form C.R.3./ Civilian Regidtration (British Subjects). / Keep this Identity card in a cover./ It will fir into an ordinary envelope./ Carry it with you when away from home.// IDENTITY CARD./ Number./ 19118 A45883/ Notify any change of place of living on Form C.R.4/ (obtainable at Post Office)./ If not delivered within 14 days/ return to Divisional Returning/ Officer at royal, red, cliffs, a j, roddy, identity, park, civilian, registration, blue -

Red Cliffs Military Museum

Red Cliffs Military MuseumMenu, POW Dinner Menu 1944, 1944 (exact)

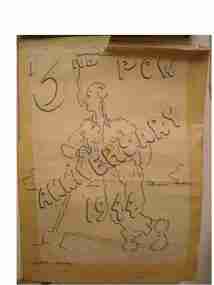

Forms part of the A.J. (Blue) Roddy VX8007 Collection2 sheets of card used to make a menu, hand sketched xartoon on front in grey lead and ink of soldier leaning on a shovel. Inside is two menus. One is the ideal menu the second is the real menu, (Very Humerous) all hand written in ink. Brought home from POW camp by A.J. (Blue) Roddy VX8007Front page: 3rd POW/ Anniversary/ 1944/ Bottom Left corner: Notsch 10811/GW Page 1: MENU/ Hors-d'oeuores/Soup./ Consomme Minestrone Tomato Bouillon/ Fish/ Whiting Dover Soles Oysters./ Emtree/ Roast beef and Yorkshire Pudding/ Roast Pork and White sauce./ Grilled chops and peas./ Dessert. Peach Melba Fruit Salad and Cream/ Carlton Puding, Apple pie and Cream/ Ice Cream/ Coffee.// Page 2: Menu/ Horses Manoeures/ Etwas./ Yeatecomme,Tinned Tomato Bully./ Tons of it./ Salmon Red. Salmon Pink. Sardines Varied./ Enter./ Roast Bully and "Bengers" Yorkshire Pudding./ Roast Meat Roll and Horse radish sauce/ Garlic sausage Grilled spick and Etwas./ Desserted./ Rice Custard, custard,/ Fruit salad and klim, Notsch duff./ Currant Pudding and custard./ Cold klim./ Coffee - if lucky tea./ Captivity Plonk./ K.G.H. Schnapps, Soft Drinks/ Beer cocktails.of, world, war, prisoner, roddy, a j blue, menu, war11, notsch, 1944, stalag, xv111a -

Red Cliffs Military Museum

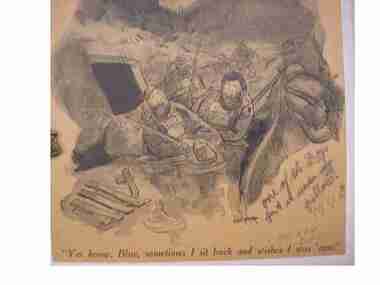

Red Cliffs Military MuseumCartoon, "Yer know, Blue, sometimes I sit back and wishes I was 'ome", 1940 (estimated)

... , sometimes I sits back and wishes I was 'ome'// (hand written) one... and wishes I was 'ome'// (hand written) one of the boys left it under ...A.J. "Blue" Roddy was one of the people who set up the museum as it is today. Unfortunately the men didn't understand the need for records.Cartoon of soldiers in the trenches up to their waists in water wishing they were"ome". It shows the soldiers fully equipped, helmets, webbing, rifles with fixed bayonets. "Blue" was the nick name of A.J. Roddy owner of the cartoon.signed Quincay// Cartoon quotation; "yer know Blue, sometimes I sits back and wishes I was 'ome'// (hand written) one of the boys left it under my pillow 1940ww11, a j, roddy, blue, egypt, ome, helman -

Red Cliffs Military Museum

Red Cliffs Military MuseumLetter

Letter written from (unknown) POW imprisioned by the Japanese on Morotai Island from 1942 - 1945 to (unknown) friend. Descriptive of life and treatment in POW camp. The island was captured by the Japanese in early 1942. Morotai's southern plain was taken by American forces in September 1944 during the Battle of Morotai, and used as a staging point for the Allied invasion of the Philippines in early 1945, and of Borneo in May and June of that year. Japanese soldier Teruo Nakamura was discovered in the Morotai jungle in 1974, as one of the WWII Japanese soldiers who held out subsequent to the Japanese military's surrender.Photocopy of letter, 4 pages, originally written in ink on (unofficial) Australian Red Cross form.Added to head of letter at a later date is inscription ' First letter written home for 3 1/2 years'.Top left hand- FOR SAFETY/ IN YOUR LETTERS DO NOT REFER TO:-/ The name of your ship or other ships in the convoy, or its escorts./The date of sailing, ports of call, or probable destination./ The description of troops, their loca-/tion or any other information/ which, if intercepted, would be of/ value to the enemy. In your Top right hand- Australian Red Cross Society/ (UNOFFICIAL)/ 25-8-45/ (added at later date 'Morotri Island')/ Alex, Have witten this especially/ as i don't wish our women folk to know the tougher side of life./Well Alex for the first/ 2 1/2 years as POWs we lived reasonably/ well, but the last 15 months was like /hell. Heres the worst lot of b-s/ you could find on earth, they worked /us from 7AM till 6 PM, & fed/ us on muck you wouldn't feed to/ Pigs. I'm nothing at all they would 2, pow, morotri island, morotai island, world war, prisoner of war, australian red cross society -

Red Cliffs Military Museum

Red Cliffs Military MuseumCarved Stick

Note with Stick. Kairivu New Guinea This carved stick is Kunja cane of New Guinea. When the war ended my company was in Kairivu, the last outpost in the world to get official notification of the Peace. During the time of waiting for the word from Wewak, for something to do, Dagwood Williamson with the aid of a pen-knife and a nail file carved the names of the places we had been and the name of our Stretcher Bearer Unit - 2/7 Battalion. Next to the Doctor at Regimental Aide Post [R.A. P.]. I was Sgt. in Charge of Stretcher Bearers and when Dagwood Williamson asked me to accept the cane for safe keeping I was pleased to do so. Now most of the boys have gone, so now over to you to look after it, it is the only one in the -----WORLD. Stan Hair Red Cliffs. March 1999The carved stick is made from Kunja Cane of New Guinea. It was hand carved with the names and places the 2/7th Battalion Stretcher bearer unit. Carved by Dagwood Williamson, with the aid of a Penknife and a nail file.Highly decorated and has the names Aitape, Balif, Banyak, Maprik, Yamil, Kiarivu, Wewak, New Guinea, 1944-1945, 2/7th Btn, 6 Div, As a list. Stretcher bearers, Lofty, Stan, Norm, Bob, Jacko, Dagwood, Aussie, Mick, Lyle, Sam, Reg, Ocker, Hulla, Luppy, Stewy, Smithy, Harvey, Graham, Don, Dave, Mac x, Farmer, Vince, Farnell, Lightning. -

Ringwood and District Historical Society

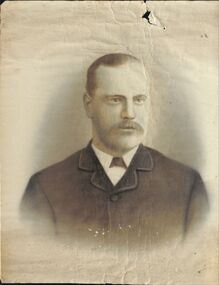

Ringwood and District Historical SocietyWork on paper, Sepia Photogragh of unknown man, on paper in cardboard cylinder with Paris address dated 1903 (In Wieland family collection)

Ernest Ferdinand Wieland was Carl's son and one of the earliest pupils at BayswaterSchool . The title of the property was transferred to him on his father's death in 1904..Cardboard cylinder with partial Paris address with" boutique de portrait " on it and partial hand written address with "Tasma" just visible.Inside a sepia portrait of possibly Ernest Ferdinand Wieland as a young man. Dated 1903. -

Ringwood and District Historical Society

Ringwood and District Historical SocietyLetter, Letter To the Talbot's from friend Shirley about the arrangements for Jack Harker's burial with Ruby. He died 2001

... or address which has been cut off.right hand corner page one..... The Talbots lived in Queensland. 3 pages hand written on heavy pink ...Ruby was Jack (Archie'S) wife who died in 2000. She was buried in Box Hill Cemetery but when Jack died a year later he could not be nuried with Ruby as he wished. So Shirley, who wrote the letter, related how the problem was solved by cremating Jack and then placing the ashes with Ruby. The Talbots lived in Queensland.3 pages hand written on heavy pink paper. No date or address which has been cut off.right hand corner page one. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, Colour 'Reconstruction Box Cottage' Flag Presentation 1985, 1985

The original small, pioneer cottage was built in the late 1840s to early1850s, by an unknown pioneer. It was located on part of a 30 Acre allotment that was originally part of Dendy’s Special Survey granted in 1841. The doors and window sashes, (made of red deal joinery timber), as well as the brass locks and fittings, are from the original cottage, and were imported from England. The fire-place bricks are from the original cottage, and are sun-dried, (not kiln fired), and are hand-made. Convict marks can be seen on two bricks. There is a small display of external cladding shingles from the original pioneer cottage. These shingles were hand-split, and most likely made from locally collected timber The nails included in this display were used to fasten the shingles on the original cottage, and are also hand-made. The cottage was occupied by William Box and family from 1865 until 1914 when it was sold to William Reitman who resided there until 1950. The enamel nameplate, “Colonial”, on the wall of the cottage, was the name chosen for the original pioneer cottage by Mr William Reitman, when he purchased the property in around 1915, for 1200 Pounds approximately. In 1974 Mr Lewis, a timber specialist, found the dilapidated building on property he had recently purchased in Jasper Rd and suggested it be reconstructed and relocated. Moorabbin Council agreed and the cottage was rebuilt just about 250 metres from its original site. The cost of the rebuild was met by 'Victoria's 150th Committee, plus a small grant from the City of Moorabbin, and Mr Laurie Lewis donated much of the timber for the reconstruction. The re-constructed cottage plan has followed faithfully the original dimensions, and plan of the original pioneer cottage, and as many original items from that cottage’s long occupation have been incorporated. The photographs in Album 1 record the progress of the reconstruction from February 1984 to the First Public Open Day November 18th 1984 and this Flag Raising Celebration in February 1985.These 3 photographs taken at the 'Reconstructed Box Cottage' on Sunday 24th February 1985 show the Presentation of the Australian Flag and the Victorian State Flag by Mr Geoff Connard MLC to CMHS President and Moorabbin City Council Cr. Max Fox and CMHS members. Mrs Kinsey, President, Country Womens' Association Bentleigh presented a hand made Quilt, that is a copy of the one exhibited at Como House, South Yarra, to CMHS President Cr. Max Fox . Mr Geoff Lawson MLC and CMHS member was also present.. Mrs H. Deam and Mr A. Smith, CMHS members, took these photographs to record the progress of the ‘Reconstruction’ from February 1984 to November 1984 and this Celebration in 1985. Although 'Box Cottage' is a re-construction, it is an unique museum that, being located in the midst of a modern community in Ormond Victoria, can educate and demonstrate many aspects of the early settler’s way of life in Victoria. As such, it is an invaluable resource for students and all kinds of visitors. 2 x colour photographs of the Australian Flag and the Victorian State Flag presentation at Box Cottage in Joyce Park February 24th 1985 1 x colour photograph of the presentation of a Quilt by the Country Womens' Association Bentleigh at Box Cottage in Joyce Park February 24th 1985 Written on back of photo a) Flag presentation / Cr. Fox Mr Connard / Mrs Fox Mr Lawson / 24th Feb 1985 b) Mrs Kinsey Pres. CWA Bentleigh / Presenting our Pres. Cr. Fox / with hand made quilt / copy of one now in Como / 24th Feb. Sunday 1985 c) Presentation of Vic. State Flag by / Mr G Connard MLC to our Pres. / Cr Fox / with Mr Lawson MLCbrighton, moorabbin, highett, ormond, mckinnon, cottages, pioneers, colonial, dendy henry, box william, box elizabeth, reitman william, convicts lewis timber co. ltd., deam h, smith arthur, museums, box alonzo, moody & smith builders highett, the moorabbin standard newspaper, the leader newspaper pty ltd., fox max , lewis laurie, moorabbin city council, national trust, connard geoff mlc, lawson geoff mlc, kinsey mrs cwa, country womens association, como house south yarra, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph - Washing Day at 'Law Muir Den' Mrs J L Smith c1910, c1910

Mrs J.L.Smith and Ada Smith in the backyard of the house Law Muir Den 510 Centre Rd Bentleigh c 1910. . The early settler women usually devoted a whole day to washing as it was very labourious. A fire was lit in a stone pit and a large tub of water boiled. Soap that had been made, usually in the previous Autumn, from fat drippings and caustic soda, was flaked into the tub to form suds. The clothes were moved around in the tub with a long wooden paddle that was also used to lift the clothes out of the tub into another tub of cold rinsing water..Stains were removed by scrubbing soap on the cloth against a scrubbing board. Clothes were wrung by hand or a mechanical wringer and hung on the clothes line to dry. Mary Ann Smith was married John Logan Smith 1860-1932 who at first rented a cottage 'Law Muir Den' & Shed from Mr Box and commenced business as a wood merchant - sawing logs into shorter pieces using one horse to power the saw. He purchased the property, added to the buildings , began trading in fuel and fodder as well and installed a chaff cutting mill powered by 10hp steam engine. The business prospered As Motor transport was increasing 1926 J L Smith built a small Garage on the opposite corner (Woolworths Supermarket 2005) , employed a good mechanic ( Reg Hunt ) and developed another successful business. J.L.Smith was an early settler in East Brighton now Bentleigh and established successful Wood cutting, Grain & Chaff cutting and Motor garage businesses in Centre Road . He was elected Councillor of the Shire of Moorabbin and, with Mary Ann, his family were involved with local Church, Red Cross, and other community organizations.Photograph, Black & White, showing 2 women washing clothes in a large tub, set over a fire in a stone pit, in the back yard. Clothes are hanging from a rope line strung between 2 trees and held up with a wooden 'prop' -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Decorative object - Ornaments, lady's dressing table set, 20thC

The family of Miss carol Green were early settlers in Moorabbin ShireFour piece lady's white ceramic dressing table set. Comprising of a small rectangular tray, and three small lidded-pots - one pot has a knob. There is a hand-painted dainty red and green floral garland decoration on each of the pots as well as the tray. Remnants of gold painted decoration can also be seen.ceramics, ornaments, early settlers, pioneers, moorabbin, bentleigh, cheltenham, ormond, market gardeners, green carol -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, postcard "Boiling the Billy" c1900, Early 1900's "Boiling the Billy", c1900

Early 1900's. "Boiling the billy". The term billy or billycan is particularly associated with Australian usage, but is also used in the UK and Ireland. It is widely accepted that the term "billycan" is derived from the large cans used for transporting bouilli or bully beef on Australia-bound ships or during exploration of the outback, which after use were modified for boiling water over a camp fire. Postcards developed out of the complex tradition of nineteenth-century printed calling cards, beginning with the advent of the Cartes-de-Visite in France. In the 1850s, Parisian photographer Andre Adolphe Eugene Disderi invented a photographic process involving egg white, albumen, and silver nitrate to create inexpensive portraits on paper cards. These photographic Cartes-de-Visites were 2 1/2 (75mm) by 4 inches (98mm) and became a popular, collectable form of "visiting cards" world-wide. Photographers would reprint portraits of famous individuals they had taken at their studios or during travel and sell them as collectable cards. Postcards as we know them now first began in 1861 as cards mailed by private post. In the 1870s picture postcards grew in popularity throughout the United States, Britain, Europe, and Japan. Cards were first permitted to have a "Divided Back," with text written on the left half of a dividing line and the address on the right half, beginning in England in 1902. Around 1900 the first postcards made of "Real Photos" rather than artwork began to circulate, aided in by advances in amateur photography equipment by companies such as Kodak. Kodak also introduced postcard paper for photographic development and photography studios began to offer portraits printed as postcards Many local town, countryside, and architectural images were captured during this period by local photographers, then printed and sold as postcards . Advances in amateur photography all contributed to a postcard craze that lasted from 1900 to the First World War. Postcards were the preferred means to send a quick note, whether across town or across a continent.Postcard with a black and white Photograph on the front and a 'Divided Back ' for the message and address. There are seven men surrounding the billy suspended over a camp fire. The ground has a lot of dead branches around. One man is bending down towards the billy. Two men on either side of the camp fire are carrying either a white bag across their shoulders or the fish in their hands. You can see, that there is some steam also coming out of the billy, which means that its hot. Court Post Card. / this space may be used for correspondence. / The address only to be written here.1900's, boiling the billy , postcards, photographers, england, hungary, america, cartes-de-visite, visiting cards, moorabbin, cheltenham, bentleigh, market gardeners, early settlers, pioneers, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

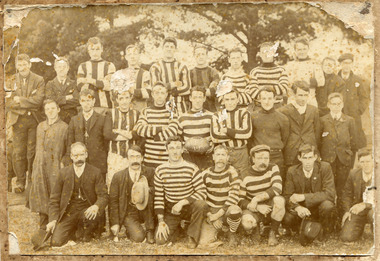

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, 1909 Moorabbin Australian Rules Football Team, 1909 Moorabbin Australian Rules Football Team, 1909

Australian Rules Football history see MAV 00517 1909: Football Team. Only player named is Paddy Green. Since the player guernseys are almost the same and the photographer is the same we presume this is the same team as shown in MAV 00517 named as the Moorabbin Football Team Moorabbin Football Club, nicknamed the Kangaroos, was the name of two distinct Australian rules football clubs which played in the Victorian Football Association (VFA). The first club, founded in the early 20th century, joined the VFA in 1951 and played there until 1963 with great success; they played home matches at Moorabbin Oval and wore royal blue and white hooped jerseys. The second club played in the VFA from 1983 to 1987. Moorabbin played initially in the Federal Football League, making their debut in 1909 and competing until 1950. During this time the club won 12 premierships, including winning all six premierships staged over the nine years between 1940 and 1948 (the competition was in recess from 1942 until 1944). The club entered the VFA in 1951. Its Federal League home ground, the Dane Road Reserve, was not up to VFA standards; so, in 1951 the club played at Cheltenham, and in 1952 moved into the Moorabbin Oval, which the Moorabbin Council had developed during 1951. The Kangaroos made the 1954 and 1955 finals series without success but in 1957 they helped eliminate premiership favourite Williamstown after defeating them by two points in the Semi Final. Moorabbin, who were coached by Bill Faul, took on Port Melbourne in the Grand Final, whom they had not once beaten since joining the league. In another upset, Moorabbin won comfortably to claim their maiden VFA premiership. In the early 1960s, the Moorabbin Council was very keen to bring a Victorian Football League team to Moorabbin Oval. 1964, the Moorabbin City Council secured a deal with St Kilda, who moved to Moorabbin Oval starting in 1965. The club originally intended to seek readmission for the 1965 season, but in July the club committee decided to withdraw permanently from the Association,and disbanded. Photograph is Black and White. Three row of football boys. Some are wearing striped jumpers, either the stripes are going horizontal or parallel. There are twelve men wearing a suits, four in the third row, four in the second row and four in the first row. One of the boys wearing a suit in the front row, has a hat in his hand. The boys in the front row are kneeling, the second row are standing on the ground and the third row are standing on benches. Only player named is Paddy Green. Phillip Jones may also be in the photo Row 2 4th from left Front of Mount : 1909 Back of Mount : written Paddy Green , stamp HEWITT 92 Regent Street North Richmondfootball team, 1909, paddy green, moorabbin, moorabbin football club, 1903, 1908, 1909, philip jones, james jones, paddy green, early settlers, market gardeners, pioneers, herron john, australian rules foorball, victorian footbal league, victorian football association, moorabbin city council, moorabbin shire, city of moorabbin, st kilda football club, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, curved sad iron, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.The Curtis family were early settlers in Moorabbin Shire c1880 and used sad ironsA small, curved, flat iron, with attached handle, used for cuffs, collars and frillsSILVESTER'S/ PATENT/ SALTERS / No 3 with the pretzel & a arrow going through the centresad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Craftwork, heavily carved calling card case, c1900

A visiting card, also known as a calling card, is a small paper card with one's name printed on it, and often bearing an artistic design. Visiting cards became an indispensable tool of etiquette, with sophisticated rules governing their use. The essential convention was that one person would not expect to see another person in his own home (unless invited or introduced) without first leaving his visiting card for the person at his home. Upon leaving the card, he would not expect to be admitted at first, but might receive a card at his own home in response. This would serve as a signal that a personal visit and meeting at home would be welcome. On the other hand, if no card were forthcoming, or if a card were sent in an envelope, a personal visit was thereby discouraged. As an adoption from French and English etiquette, visiting cards became common amongst the aristocracy of Europe, and also in the United States. The whole procedure depended upon there being servants to open the door and receive the cards and it was, therefore, confined to the social classes which employed servants. Some visiting cards included refined engraved ornaments, embossed lettering, and fantastic coats of arms. However, the standard form visiting card in the 19th century in the United Kingdom was a plain card with nothing more than the bearer's name on it. Sometimes the name of a gentlemen's club might be added, but addresses were not otherwise included. If a card was left with a turned corner it indicated that the card had been left in person rather than by a servant. Visiting cards were kept in highly decorated card cases.A timber calling card case, heavily carved with flowers, leaves and huts.craftwork, woodwork, visiting cards, early settlers, moorabbin, bentleigh, cheltenham, market gardeners -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Jewellery, 2 lady's hat pins mauve, c1900

A hat pin is a decorative pin for holding a hat to the head, usually by the hair that was styled in a Chignon or French Roll style and usually worn in a pair. They are typically around 20 cm in length, with the pinhead being the most decorated part. The hatpin was invented to hold veils in place, and was handmade. Birmingham, England was the centre of production when demand eventually outgrew the number that could be supplied by hand-making and they also began to be imported from France. In 1832, an American machine was invented to manufacture the pins, and they became much more affordable. During the 1880s, bonnets gave way to hats, some of which were very large and the popularity of hatpins soared. In the Victorian era, when appearance was everything, it just wouldn't do for a fashionable lady's hat to blow off in the wind. They remained a standard women's' accessory through the 1910s and were produced in a vast range of materials and types. Hat pin holder boxes were also produced. One of the most well-known makers of hatpins is silversmith Charles Horner, of Halifax, whose turn of the century jewellery company became a leader in the market by creating a series of mass-produced pins that were still of exceptional quality. As a result, thousands of Horner's pins are still on the market and on display in museums worldwide. Women of the 1920’s used hat pins as decoration on their Cloche hats that fitted snugly to their heads. The women of the pioneer families liked to dress up in their best hand made dresses and fashionable hats for Church gatherings and special occasions as a relief from the daily chores of hand washing, ironing with flat irons and cooking over open fires.2 lady's long steel hat pins with sequents in a flower design on mauve material bonnets, hats, veils, scarves, moorabbin, bentleigh, brighton, cheltenham, early settlers, pioneers, clasps, hairdressing, combs, steel pins, jewellery