Showing 538 items

matching blue water

-

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomMedal, Atlantic Star, abt 1945

The Atlantic Star was awarded to commemorate the Battle of the Atlantic between 3 September 1939 and 8 May 1945. It was designed primarily for convoys and their escorts and anti-submarine forces, as well as for crews of fast merchant ships that sailed alone. Eligibility Awarded for six months service afloat, in the Navy, the Merchant Navy and by Army and Air Force personnel serving on HM Ships, in the Atlantic and Home Waters. Awarded to aircrew who have taken part in operations against the enemy at sea within the qualifying areas for Naval personnel, subject to two months service in an operational unit after earning the 1939-1945 Star. Qualifying dates are 3 September 1939 to 8 May 1945. The Medal The Atlantic Star is a six–pointed star of yellow copper zinc alloy. The obverse has a central design of the Royal and Imperial cypher, surmounted by a crown. The cypher is surrounded by a circlet containing the words ‘The Atlantic Star'. Stars issued to Australian personnel have recipient names engraved on the plain reverse. The Ribbon The Atlantic Star ribbon has three vertical stripes of blue, white and sea green, shaded and watered. The colours represent the colours of the Atlantic Ocean. Clasps Two clasps were issued for the Atlantic Star: Air Crew Europe France and Germany Regulations only allow one clasp to be worn with the Star. When the ribbon is worn alone a silver rosette ribbon emblem is worn to denote the award of a clasp.Medal, Atlantic Star, miniature, with clasps- Air Crew Europe & France and Germanymedal, atlantic star -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomMedal, British War Medal

British War Medal 1914-20 Instituted by King George V in 1919 to mark the end of World War I and record the service given. Eligibility The British War Medal was awarded for service in a theatre of war between 5 August 1914 and 11 November 1918. Those eligible included members of women's organisations; persons on the staffs of military hospitals and members of recognised organisations who handled sick and wounded; and members of other duly recognised or other authorised organisations as specified in medal regulations. The qualification period was later extended to cover post-war mine clearance and service in Russia during 1919 and 1920. The Medal The British War Medal is cupro-nickel with the effigy of George V on the obverse. The reverse has an image of St George on horseback trampling underfoot the eagle shield of the Central Powers, and a skull and cross-bones, the emblems of death. Above this is the risen sun of victory. The years 1914 and 1918 are contained on the outside edge medal. The Ribbon The British War Medal has a wide central watered stripe of orange, flanked by two narrow white stripes, which are in turn flanked by two black pin-stripes, further flanked by two outer stripes of blue. The colours have no particular significance.british war medal -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomMedal, British War Medal 1914-18, 1919

Established on 26th July 1919. The silver or bronze medal was awarded to officers and men of the British and Imperial Forces who either entered a theatre of war or entered service overseas between 5th August 1914 and 11th November 1918 inclusive. This was later extended to services in Russia, Siberia and some other areas in 1919 and 1920. Approximately 6.5 million British War Medals were issued. Approximately 6.4 million of these were the silver versions of this medal. Around 110,000 of a bronze version were issued mainly to Chinese, Maltese and Indian Labour Corps. The front (obv or obverse) of the medal depicts the head of George V. The recipient's service number, rank, name and unit was impressed on the rim.The medal is silver and circular. A truncated bust of King George V is on the obverse, while there is a depiction of Saint George on the reverse. There is a straight clasp carrying a watered silk ribbon. This has a central band of golden yellow with three stripes of white, black and blue on both sides. The blue stripes come at the edges. 6,610,000 British War Medals were issued. The soldier's regiment and number are inscribed around the rim. Recipient: 908 DVR J E Whyte 3 LH FD AMBwar medal 1914-18 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - Reference Maths, George Bell & Sons, Elementary Algebra Part 11, 1905

This item was a standard maths book used in Victoria. It would have been a continuation of the Part 1 of the same name. Elementary level would have been in the early years of secondary school. This has historic significance as it shows what Elemenetary Algebera was taught in the early - mid 20th century. This book would have been used in the Kiewa Valley schools by a local identity Wilma Davies therefore has social significance and research value. This book is now out of print and is a collectible item.A blue maths book with faded blue coth cover. It has gold lettering on the side of the book stating the name, author and publisher with their logo. It would have had its name on the cover at one stage but it no longer on it due to water damage.Cover has a triangle with Cambridge Mathematical Series enmbossed around the three sides. At the points of the triangle is the letters B D C with the letter A in the middle of the trianglebook, school, algebra, educational, math, kiewa-valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph Tobacco planting, Planting Tobacco seeding, Circa mid to late 1900's

This promotional photograph by the Tobacco Growers Association was in response to a 1935 meeting of tobacco growers from Victoria, South Australia and Queensland which produced four major resolutions for the industry covering the remainder of the 1900s. These four resolutions were: (1) Adequate tariff protection (2) Control of pests and diseases (3) Orderly marketing (4) The formation of an advisory council of growers. History has produced the following results. (1) adequate tariff protection was never achieved,(2) control of disease through benzol vapour (CSIRO) breakthrough, was later identified as carcinogenic, (3) orderly marketing was achieved through (4) the establishment of the Tobacco Growers Association(1984). In October 2006, by way of Government buy back of tobacco leases from growers, resulted in the end of Tobacco farming in Australia (after 136 years of planting the first crop). It was also significant that the major tobacco companies such as Philip Morris and The British American Tobacco Australasia advised the industry that it would source its tobacco requirements overseas by 2009.The remnants of the Tobacco Industry can still be viewed throughout the Kiewa Valley and adjacent regions on the former tobacco farms which still have the tobacco drying sheds and now converted into hay sheds. The problems from the large quantities of carcinogenic infused soil of farmlands in the region, still remains a problem now and for future generations. This particular photograph shows the lack of understanding by farmers and the contracted labour, at that time, and is demonstrated by the bare footed farmer walking next to the seed canister. Some workers did use protective "gum" boots but the majority of farm owners were skeptical of city scientists and their carcinogenic concerns, and it was only after the younger generation of farmers , who had attended Agricultural colleges, encompassed the scientific approach to farm management and began working closely with agricultural scientists. The "she'll be right mate" attitude of the earlier farming/rural community has since mid 1970s, been slowly dissipating. Stricter controls of herbicides and pesticides used in agriculture are now in force. The death of the tobacco industry(2006) resulted in the expansion of the dairy , sheep, beef cattle, venison and lama wool producers in the Kiewa Valley and surrounding regions.Coloured photograph pasted onto a thick wood chip backing. Two galvanised eyelets at the top of the frame, 50mm from each end, with a twine cord stretch from each, for hanging purposes. See also KVHS 0054(B) to KVHS 0054(F)A sign, which has been removed from the picture at some previous point in time is "The Tobacco seed, being so fine, is suspended in water and sown onto the seed base using a watering can [as in the photo] or similar device - August - Sept."tobacco, farming, rural industry, licences, ollie mould, blue mould, benzol vapour -

Kiewa Valley Historical Society

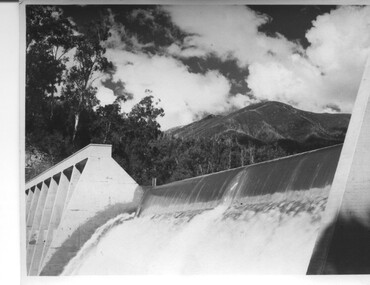

Kiewa Valley Historical SocietyPhotograph of Lake Guy Dam, Spillway, Lake Guy Dam, c1945

In December 1939 the excavation of the diversion tunnel at the site of Junction (Lake Guy) Dam was commenced and finished in February, 1940.This allowed the stream to be diverted to facilitate the dam wall construction. This is a 'slab and buttress' dam. It is framed with timber and concrete then poured into the structure. A contract was let to Lewis Construction Co. for the construction of the dam, and the first batch of concrete was placed in September, 1940. Industrial trouble caused some delays but there was also slow progress on the part of the contractor and the work was taken over by the S.E.C., terminating the contract. The dam was completed in March, 1944. The lake is named after Mr. L.T. Guy who was the Resident Engineer, in charge of construction work and associated activities on the Kiewa area, from 1939 until November 1946. An historical pictorial record taken for the State Electricity Commission of Junction Dam (Lake Guy) on spill. Mt. Arthur is in the background and there is still evidence of the destruction of trees from the 1939 bushfires. Black and white photograph of Lake Guy Dam . The dam is spilling and Mt. Arthur is in the background. Hand written on back of photograph in blue ink " Lake Guy Dam".dam, lake, water, mr. l.t.guy -

Kiewa Valley Historical Society

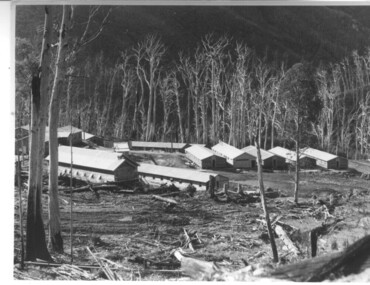

Kiewa Valley Historical SocietyPhotograph of Howmans Dam Camp, Howmans Dam Camp, circa 1948

... . howman's gap camp water dam Handwritten in blue ink on the back ...Howman's Gap camp was erected in 1948. The proposed dam to be built at this site was postponed in 1954 because of financial restraints imposed by the government at this time. It was to have supplied water for No. 2 Power Station at the Junction of the Pretty Valley and Rocky Valley branches of the East Kiewa River. This power station was not constructed until 2008 - 2010 and now gets it water from McKay Creek Power Station. The site of this camp is now occupied by the Howman's Gap Alpine Centre. Some of the original buildings still remain. An excellent photographic record of the type of buildings and size of the camp for accommodation of workmen during construction of the Kiewa Hydro Electric Scheme.Black and white photograph of the buildings erected at Howmans Dam site as accommodation for workmen.Handwritten in blue ink on the back of photograph "Howmans Dam Camp"howman's gap, camp, water, dam -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPolisher Floor, Hoover Appliances, Meadowbank

This appliance was a time saving method of cleaning floors. It appeared at a time (after World War II) when the domestic pressures faced by mothers and domestic staff was on the increase. The necessary "working parents" was through necessity becoming part of the "typical" family environment. It was the start of the ever increasing demand, from an economical reason, for both parents to work outside their property. Historically the period of the 1950s was one of extreme changes. It was an era where established role models were under pressure from an ever increasing demand for new and advancing consumerism. Communication levels via radio, newspapers and television was expanding at an ever increasing rate. Relatively isolated rural areas were opening up (post war) to foreign ideologies of consumerism. The basic restraints of "this will be alright mate, she'll do" was under a slow but effective take over. "I can get this done faster by this new whiz bang gadget that I saw on the TV last night!" was the new way to live by.This item is very significant in that it demonstrates the new consumerism at its infant stage of the social changes occurring due to greater communication levels between the rural Australian communities and other advancing communities world wide. The Kiewa Valley residents (mainly from the intermingling of rural and post World War II refugees working at the construction of the Victorian Hydro electricity installations, resulted in this rural area becoming integrated to new ways of living (both socially and economically). Once the attitude of "we have always done it this way mate!" was challenged and overcome, the acceptance of new time saving "gadgets" which started to pour in from foreign markets, the relative isolation of the Kiewa Valley (being mainly psychological entrenched), was over.This hoover electric floor scrubber and polisher has a main base containing two brushes (can be replaced with polishing pads). The two brushes/pads are fastened or removed from the base unit by pulling/pushing the heads from the small hexagonal shaft on the bottom of the machine motor. A pressure sensitive wire is inlaid at the brush/pad end to hold the brush/pad unit onto the shaft. The discs body and main body covering the electric motor are made from sturdy plastic. The rest of the appliance materials i.e. upright handle and the u framed attaching arm are made from lightweight powder coated steel. A small (350mm) red coloured foot switch protrudes from the back of the motor to release the the upright handle from the storage position to the action position.There are two fork shaped brackets on the rear of the handle, for securing the 6.5 metre long electrical cord and plug. There is no on/off switch on the appliance. A small stainless steel "u" framed clip (for hanging the appliance in the vertical position) for cupboard storage. Within the circle of the cleaning brush is stamped "1 above S.A.B.351" and on the opposite side P/No: 5023792". On the main plastic head of the brush discs are "TO CLEAN" and under this "USE ONLY WARM(underlined) WATER AND SOAP" on the opposite side, and within a circle is the Hoover Trademark. On the front of the blue coloured plastic dome covering the electric motor is (on a raised domed shaped plaque (on a red background) Hoover in slanted print from left to right(in a diagonal level)domestic appliances, floor cleaning, electric floor scrubbers and polishers -

Kiewa Valley Historical Society

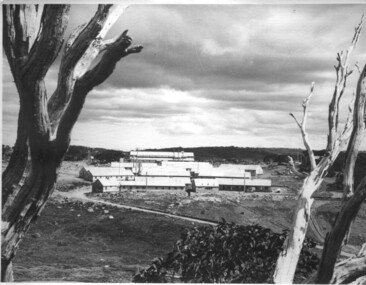

Kiewa Valley Historical SocietyPhotograph of Pretty Valley Workers Camp*, Pretty Valley Camp, circa 1949

Erection of staff quarters at Pretty Valley was completed in April, 1947 and accommodation for construction workers commenced in 1948 but suspended on 11th May for winter and resumed on 9th November. Construction of this camp was completed in 1949. A large dam was proposed at this site but was never constructed. Instead a small diversion dam was built which diverts water either to Rocky Valley Dam or to McKay Creek Power Station.An historical record of the type of accommodation provided for workmen during the construction of the Kiewa Hydro Scheme during the 1940's/50's.A black and white photograph of Pretty Valley Camp, c 1949. Dead trees are in the foreground, on both the left and right side of the photograph and a small snow gum is evident. There are camp huts and a much larger building behind these, possibly a workshop, and power poles are evident bringing electricity to the site.Handwritten in blue ink on back of photograph "Pretty Valley Camp. 5600 ft. above sea level".pretty valley, dam, water, workmen, camp -

Warrnambool and District Historical Society Inc.

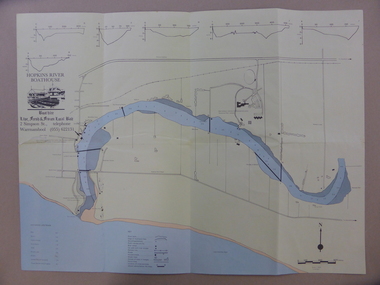

Warrnambool and District Historical Society Inc.Map - An Angler's map of the Hopkins River Estuary, Angler's map Hopkins River, 1980s

This is a map of the Hopkins River Estuary prepared by Dr John Sherwood for the benefit of anglers. The information on the sheet includes the location of sand banks, the water depths, boat ramp facilities and public access facilities. Some of the information has been gathered from aerial photographs. The map has been produced by the Warrnambool Institute of Advanced Education which was developed in the late 1960s from the tertiary section of the Warrnambool Technical College and with all its departments established by 1984 at the Sherwood Campus five kilometres from Warrnambool on the Princes Highway. Today the site is occupied by Deakin University, Warrnambool campus. The Warrnambool Anglers’ Club has its headquarters on the banks of the Hopkins River near the mouth of the river and the Lyndoch Aged Care facility.This map is of interest as a specialist one, providing fishermen with detailed information on all aspects of the Hopkins river estuary. Fishing has been both a profession and a popular recreational pursuit for Warrnambool residents since the early days of the city’s settlement. The Hopkins River Estuary has been a focal point for fishermen throughout Warrnambool’s history. This is a sheet of paper folded three times to produce a folded map. The front cover has a black and white photograph of two fishermen with a large fish. The map of the Hopkins River Estuary is in yellow, blue and black and covers the side of one sheet and three quarters of the other side. There is an advertisement for the Hopkins River Boathouse with a black and white sketch of the boathouse and notes on the map written by Dr John Sherwood. There are several diagrams showing the water depths. The map has some silverfish damage and some tearing at the folds. warrnambool anglers’ club, history of warrnambool, hopkins river, hopkins river estuary, john sherwood -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchHat, Hard Yakka, 2015

This hat is part of a General Purpose Uniform issued by the Australian Airforce to Bernard Farley during service. This uniform type was developed in 2014 and replaced camouflage as the uniform worn during general base duties and in non-warlike environments. Although a camouflage pattern, this design is not intended for use as camouflage. This item has social significance, as an item of uniform worn by Warrnambool RSL community member and Secretary (2019), Bernard Farley during service with the Australian Airforce. The item is a representative example of current Airforce General Purpose Uniform and is in excellent condition. As a set, the uniform has aesthetic significance in it’s design, incorporating GPU uniform design from the Army alongside the colours and motifs of the Australian Airforce. General Purpose Uniform (GPU) hat in Airforce colours of blue and grey in camouflage pattern. Broad brim hat with black plastic cord end fastener on a blue cotton cord. Plastic tag on interior of hat lining with printed inscriptions.Inscription on tag: “Hard Yakka/AUSTRALIA/AUGUST 2015/PO No: CC2XZ8/LAY No: 10609/SQNCOR FARLEY/(broad arrow)/[Mobile Phone Number]/NSN: 8415-66-161-4051/SIZE: M 56cm/NAME:” Inscription on reverse of tag: “PM KEYS No:/75% COTTON/25% POLYESTER/CARE INSTRUCTIONS/HAND WASH IN COLD/WATER WITH MILD/DETERGENT RISE/WELL DO NOT WRING/TUMBLE DRY OR/DRYCLEAN (X)/DRIP DRY IN SHADE”camouflage, airforce, uniform, general purpose uniform, australian defence force -

Warrnambool and District Historical Society Inc.

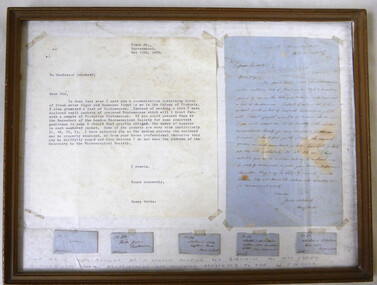

Warrnambool and District Historical Society Inc.Work on paper - Letter, Henry Watts, Letter written 1859

Henry Watts (1828_1889) Died at Melbourne, 16th December, 1889. He was a good microscopist. His botanical studies were chiefly devoted to algae, both fresh-water and marine, and while living for many years at Warrnambool he was a contributor of algae to Harvey, who figured Wrangelia wattsii, Harv., and Crouania wattsii, Harv., in his “Phycologia Australica " He was the author of "On the Fresh-water Algae of Victoria " (Trans. Roy. Soc. Vict., 1861-4, 67) ; .also a paper "On Fossil Polyzoa" (ib.. 82); "A Trip to Mt. Macedon in Search of Fresh-water Algae" (Wing's S. S. Record, iii., 252); "On a Species of fresh-water Algae from Victoria" (Vict. Nat., i., 21); "Some Recent Additions to our Knowledge of Microscopic Natural History" (ib., iii., I33) (includes lists of fresh-water algae and Desmidieae ), First librarian (1881-2), also a vice-president of the Field Naturalists' Club of Victoria. He is further commemorated by Acacia wattsiana. F. v. M. www.anbg.gov.au/biography/watts-henry.html . Henry Watts worked as a bootmaker in Timor and Liebig streets Warrnambool in the 1860’s but it was as an amateur scientist that Watts gained public notice.For an exhibiton in Melbourne in 1861 Henry Watts prepared a collection of over 100 different species of seaweed from the Warrnambool district. It is recorded in the Examiner in 1863 that he had been elected as an honorary member of the Bristol Microscopical Society of England He was a member of the Warrnambool Horticultural society and in 1865 he opted to become a flower distiller.At the 1866 MelbourneExhibition, Henry Watts exhibited 44 bottles of his perfumes. He had a keen interest in microscopes and microscopic organisms.He spent many hours combing the caves and examining the guano of local bats. This letter is written to Professor Quekett advising him that he has sent a collection of packets of samples of diatomaceae asking him to examine and name the same.. Professor Quekett was a famous microscopist of the Victorian era with the Quekett microscopist club one of the oldest in the world dedicated to the use of the microscope and its discoveries. Henry Watts was one of Warrnambool’s first botanists and marine scientists. He also established a flower distilling and perfume manufacturing business in Warrnambool. In 1861 he sent a collection of over 100 species of seaweed to the Melbourne Exhibition.Framed, handwritten letter, ink on blue paper. Transcript of letter is typed black on white paper. Five small numbered pieces of paper containing specimens of diatomaceae collected from marine and fresh water areas around Warrnambool.Names Henry Watts, Professor Quekett. Handwritten along the bottom of the frame, “The above was bought at a London Auction for $12-10-00 by Miss Eddey a Melbourne Book shop Proprietress and recently presented to the W.F.N. Club.: warrnambool, henry watts, watts henry, botanist,microscope, microscopic, quekett, john thomas quekett -

Orbost & District Historical Society

Orbost & District Historical Societyfolder of documents, 1961 - 1962

The first swimming competition was conducted by the Swimming Club at the Orbost Swimming Pool not long after its construction. The results were hand-written on a cardboard sheet pinned up on a notice board. One of the events held was a crazy diving display performed by Neil Rodwell and Malcolm Corner in which they rode bikes off the diving platform.The opening of the Orbost Swimming Pool was a significant event in Orbost's development. The construction of the pool was community driven and the swimming club played a crucial role in helping young people learn about water safety away from rivers.A manila folder of documents related to the Orbost Amateur Swimming and Life Saving Club. It contains the constitution, rules of competition, competition results and a cloth badge- a white silver gull inside a pale blue circle on a darker blue background with ORBOST S & LSC below. Documents are handwritten and typed.orbost-swimming-club sport-swimming leisure-club -

Orbost & District Historical Society

Orbost & District Historical SocietyCoolgardie safe, first half 20th century

Without refrigeration, storage of meat was difficult. Flies were a problem, and it was important to keep meat cool and out of the way of pests. One way of doing this was to use a meat safe: a kind of cupboard designed to store meat and keep it fresh enough to eat. Meat safes are ventilated. They were sometimes made with sides of wire mesh or perforated metal, so that air could circulate around the meat while keeping flies and other animals out.The Coolgardie safe was invented in the late 1890s by Arthur Patrick McCormick, who used the same principle as explorers and travelers in the Outback used to cool their canvas water bags Originally they were handmade using materials to hand. In the early 20th century, Coolgardie Safes were manufactured commercially across Australia, and found their way into homes in both rural and urban areas. These safes incorporated shelving and a door, had metal or wooden frames and Hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (refs ABC-Home; Museum Victoria)The Coolgardie safe was an Australian invention used especially in country areas from the 1890s until the mid 20th century. It began to be replaced by ice chests from the turn of the twentieth century in cities and country towns which had ice works. This item is an example of a domestic appliance commonly used before electricity was widely available for domestic use.A cube-shaped metal Coolgardie safe painted blue. It has a triangular hook on the top for hanging or lifting. There are small feet at bottom . The sides are perforated in a Above the door; Inside a rhomboid shape "WILLOW"food-storage coolgardie-safe domestic -

Orbost & District Historical Society

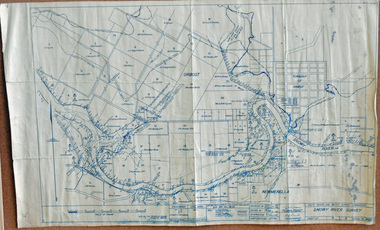

Orbost & District Historical Societysurvey, 1941

this item is a useful reference tool.A survey map produced by the State Rivers and Water Supply Commission. It is on white paper with blue ink. It is a hand-drawn survey of the Snowy River in 1939-40.survey map snowy-river -

Cheese World Museum

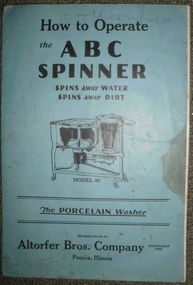

Cheese World MuseumManual, How to operate the ABC Spinner

Donated with the ABC Spinner washing machineBlue heavy paper cover with black lettering and an illustration of Model 60. Full title is 'How to operate the ABC Spinner -Spins Away Water -Spins Away Dirt. The Porcelain Washer -Manufactured by Altofer Bros Company Established 1909 Peoria Illinois Contents include parts price list and instructions for use'allansford, altofer brothers, abc spinner, washing machines, laundry aids -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, Late 19th or early 20th Century

The colander is an extremely useful tool in the kitchen, as it allows food to be fully drained of liquids such as water or oil. Enamelware dates back to 1760 in Germany.This object is significant as an example of a type of item in common use in the 19th Century and that is still in use today.Mottled blue enamel colander with draining holes in the base and sides. Two thin handles on lip of bowl.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, colander, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Water Canteen and Ladle, mid-to-late 19th century

... Water canteen and ladle; blue painted oval metal cylinder... canteen and ladle water canteen Water canteen and ladle; blue ...The horizontal water canteen has been carefully designed to fit snugly on the hip when worn with the straps diagonally across the body. The ladle allows quick and easy scooping of the contents to refresh the lifeboat and rocket launching crew, and the survivors of the disaster Saving lives in Warrnambool – The coastline of South West Victoria is the site of over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. Victoria’s Government responded to the need for lifesaving equipment and, in 1858, the provision of rocket and mortar apparatus was approved for the lifeboat stations. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built for it on the Tramway Jetty, followed by a rocket house in 1864 to safely store the rocket rescue equipment. In 1878 the buildings were moved to the Breakwater (constructed from 1874-1890), and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost a hundred years the lifesaving and rescue crews, mostly local volunteers, trained regularly to rehearse and maintain their rescue skills. They were summoned when needed by alarms, gunshots, ringing bells and foghorns. In July 1873 a brass bell was erected at Flagstaff Hill specifically to call the rescue crew upon news of a shipwreck. Some crew members became local heroes but all served an important role. Rocket apparatus was used as recently as the 1950s. Rocket Rescue Method - The Government of Victoria adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain. It authorised the first line-throwing rescue system in 1858. Captain Manby’s mortar powered a projectile connected to a rope, invented in 1808. The equipment was updated to John Dennett’s 8-foot shaft and rocket method that had a longer range of about 250 yards. From the 1860s the breeches buoy apparatus was in use. The apparatus was suspended on a hawser line and manually pulled to and from the distressed vessel carrying passengers and items. In the early 1870s Colonel Boxer’s rocket carried the light line, which was faked, or coiled, in a particular way between pegs in a faking box to prevent twists and tangles when fired. The angle of firing the rocket to the vessel in distress was measured by a quadrant-type instrument on the side of the rocket machine. Decades later, in about 1920, Schermuly invented the line-throwing pistol that used a small cartridge to fire the rocket. The British Board of Trade published instructions for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle measured by the quadrant, inserting a rocket that had a lightweight line threaded through its shaft, and then firing it across the stranded vessel, the line issuing freely from the faking board. A tally board was then sent out to the ship with instructions in four languages. The ship’s crew would haul on the line to bring out the heavier, continuous whip line, then secure the attached whip block to the mast or other sturdy part of the ship. The rescue crew on shore then hauled out a stronger hawser line, which the ship’s crew fixed above the whip block. The hawser was then tightened using the block on the shore end of the whip. The breeches buoy and endless whip are then attached to the traveller block on the hawser, allowing the shore crew to haul the breeches buoy to and from the vessel, rescuing the stranded crew one at a time. Beach apparatus equipment - In the mid-1800s the equipment could include a line throwing set, coiled line in wooden carrying case, rockets, cartridges, breeches buoy, hawser and traveller block, line-throwing pistol, beach cart, hand barrow, sand anchor, crotch pole, and tools such as spade, pick, mallet and hawser cutter. Around the 1860s Warrnambool had a Rocket House installed beside the Harbour. This water canteen is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.Water canteen and ladle; blue painted oval metal cylinder with a removable round threaded lid. Two adjustable leather shoulder straps are attached to the canteen through metal rings on the sides of the lid. A blue-painted copper ladle with a fixed, 45-degree angled handle is attached to the canteen with a length of string. The water canteen is designed to be carried horizontally.flagstaff hill maritime museum and village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, lady bay, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, rocket crew, lifeboat men, beach rescue, line rescue, rescue equipment, volunteer lifesavers, volunteer crew, life saving rescue crew, lifesaving rescue crew, rocket apparatus, survival canteen, rescue canteen, dipper, cup, canteen and dipper, canteen and ladle, water canteen -

Federation University Historical Collection

Federation University Historical CollectionDocument, Zelda Martin, Central Victorian Goldmining towns - Boom Towns or Ghost Towns?, c1996