Showing 406 items matching "textile fabrics"

-

National Wool Museum

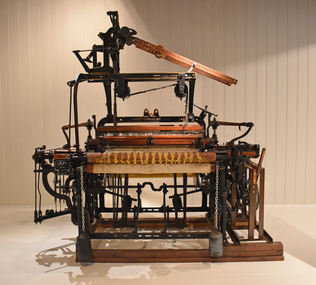

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

National Wool Museum

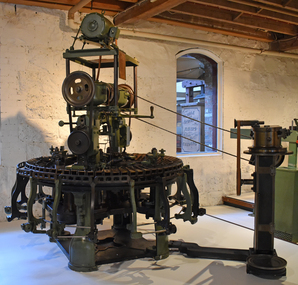

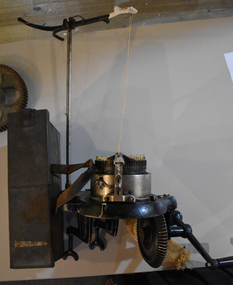

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

National Wool MuseumSample, Cloth

... Baruffa fabric Textile Industry Weaving Zegna Baruffa Cloth ...Sample swatch book,100% merino extafine Zegna Baruffa fabrictextile industry weaving, zegna baruffa, cloth - woollen, textile industry, weaving -

National Wool Museum

National Wool MuseumBook, Cloth Sample, Cumberland "extra light" new trends

... of Cumberland "extra light" suiting fabric. Textile Design Cumberland ...A cloth sample book, containing samples of Cumberland "extra light" suiting fabric.textile design, cumberland, cloth - worsted -

National Wool Museum

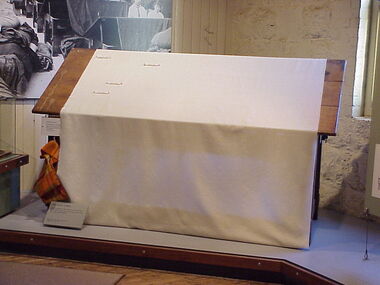

National Wool MuseumFunctional object - Mending Table, c1930

... Processing Fabric Textile Industry Large wooden table with tilted top ...Any faults in the final product can be repaired by mending. Prior to more advanced machinery, fabric was draped over a mending table and carefully inspected for faults. Quick eyes and nimble fingers were needed. Repairing faults was a highly skilled manual operation. Any knot or thickness had to be removed without affecting the quality of the fabric and mending had to be invisible. In the 1930s to make the day pass faster, popular records were played to the factory workers in the mending room. The top of the table is propped up to make it a well-lit surface over which bolts of fabric were unrolled to check for faults. Menders repaired them with invisible hand stitching. Each weaver stitched a coloured thread in the selvage to show the start of their shift, therefore if mistakes were found the company could easily find who was responsible. This table was used by Gail Morris in teh 1960s. Large wooden table with tilted top. mending table, wool processing, fabric, textile industry -

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

National Wool Museum

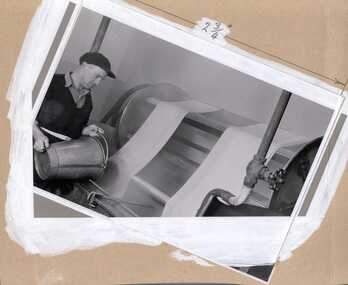

National Wool MuseumPhotograph

Depicts a wet finishing process within a mill, c.1950s. Possibly some sort of size or mordant is being added to the vat in which the fabric is being dipped. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, wet finishing, sizing, mordanting -

National Wool Museum

National Wool MuseumBook, Fibre and Fabric

... "Fibre and Fabric: the wool, cotton, textile and allied...-and-the-bellarine-peninsula "Fibre and Fabric: the wool, cotton, textile ..."Fibre and Fabric: the wool, cotton, textile and allied industries in Melbourne's West" - Gary Vines, 1993. This book is a short history of the wool, cotton, textile and allied industries of the area west of Melbourne. It looks at how, why and when these industries developed and their effect upon the cultural and geographic landscape.FIBRE AND FABRIC / Gary Vines / Melbourne's Living Museum of the West Incorportatedtextile industry - history woollen mills - history, textile industry - history, woollen mills - history -

National Wool Museum

National Wool MuseumTextile - Red Cross Quilt, 1930-1949

... . The quilt is backed with a blue and green striped fabric. Textile ...This quilt was purchased from an op shop in Clifton Hill, Vic. by Lois Densham, a quilter and former member of the Running Stitch group who has an interest in historic Australian quilts. The quilt has been displayed in NSW, where it was part of an exhibition of Historic Australian Quilts curated by Annette Gero and held at Old Government House, Paramatta between 5 June and 22 August 2000. Initially purchased in Clifton Hill, it originally came from a source in Highton, Geelong. It is a double bed sized quilt in the classic 'crazy' style with extensive use of herringbone and feather stitching.The pieced style of the quilt, made from squares of patchwork is similar to the style of quilts made by members of the Country Women's Association (CWA). The women sometimes made a quilt as a group activity and Lois suggested that the quilt may have been made by this group.Quilt, rectangular. Made with crazy patchwork in twelve large blocks. The blocks at each corner are fairly regular, whereas the others are full of random pieces. The patches are oversewn with hand embroidered feather stitch in different colours. In the centre there is a block with a maroon cross. Many of the pieces have central 'sprigs' of green embroidery in bullion stitch. The quilt is backed with a blue and green striped fabric.quilting patchwork, running stitch group national trust of australia (nsw), running stitch collection, densham, ms lois, geelong, quilting, patchwork, cwa -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine, G Stibbe and Co, c.1928

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Dellruss Pty Ltd original owner Llyold Henry Coburg. Mock ribber fitted post World War 2. In use from c.1928 until 1978.Stibbe Maxim circular sock knitting machine.sock knitting machine, manufacturing, textiles, socks, machines, circular, clothing, industry, wool -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Griswold bench-type sock knitting machine hand operated by turning the handle.sock knitting machine, textile industry, wool, fashion, clothing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Textile - Embroidered piece, circa end of 19th century

... of leaves on purple silk background. Bound with gold metallic fabric ...From the estate of Jenny LangOval piece of hand embroidery. Yellow flowers and two sets of leaves on purple silk background. Bound with gold metallic fabric and apricot silk.handcrafts, embroidery -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace, Late 19th or early 20th Century

Machine made "Chemical" lace motif. Cotton thread embroidered onto a base fabric which is later dissolved away. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace

Machine made lace "Chemical" oval lace motif. Cotton thread embroidered onto a base fabric which is later dissolved away. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace

Machine made "Chemical" lace edging. Cotton thread embroidered onto a base fabric which is later dissolved away. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Flemish Lace, Early 17th century

... " Flemish lace edging attached to a piece of black fabric. Textile ...This lace is similar in appearance to Genoese collar laces but the thread is much finer and the lace softer. At the time it would have been an expensive fashionable lace trimming. This particular piece was borrowed and used as an illustration in Pat Earnshaw's book "The identification of Lace"Flemish lace edging attached to a piece of black fabric. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace: Chemical lace, Early 20th Century

Chemical lace. The design was machine embroidered onto a base fabric which was then chemically dissolved away.Collar with standing neck edge. -

Bialik College

Bialik CollegeTextile - School banner, embroidered

School banner made out of blue cotton fabric. School name, logo and motto embroidered in yellow, white and blue thread. Please contact [email protected] to request access to this record. -

Bialik College

Bialik CollegeTextile - United Israel Appeal banner

Banner made out of white cotton fabric, with blue printed words: United Israel Apppeal Keren Hayesod "Bialik College" Melbourne, Australia The text is surrounded by handwritten signatures and messages from students. Please contact [email protected] to request access to this record.fundraising -

Bialik College

Bialik CollegeTextile - Fabric swatches for library redevelopment, 2009-2010, 2009-2010

... to this record. 2000s buildings Textile Fabric swatches for library ...Fabric samples and options for library redevelopment, Ron Unger Architects with Genevieve Johnstone Interior Design, 2009-2010. Includes furniture fabrics and internal finishes samples. Please contact [email protected] to request access to this record.2000s, buildings -

RMIT Design Archives

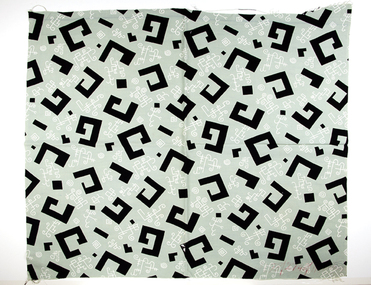

RMIT Design ArchivesTextile - Textile Design Sample

The Polish born artist, designer and filmmaker, Stanislaus Ostoja-Kotkowski (1922-1944), who arrived in Melbourne in 1949 on the 'Fairsea', a ship carrying displaced persons from Europe and the Baltic States. He sought employment in architectural and design practices, and also enrolled in classes at the National Gallery School. From 1952 until 1953 Ostoja-Kotkowski had a brief, but productive, period working as a designer in the Prestige Fabric Design Studio in Melbourne. Ann Carew, 2017The textile design has aesthetic significance as an example of the early Australian work of noted emigre artist, designer and filmmaker, Stanislaus Ostoja-Kotkowski, and it has historical significance for its association with the Prestige's Textile Design Studio, and the studio's art director, Gerhard Herbst. Small sample of pale green rayon fabric with a bold, repeating geometric pattern printed in black and white.emigre, polish, design, textile design, rmit design archives -

RMIT Design Archives

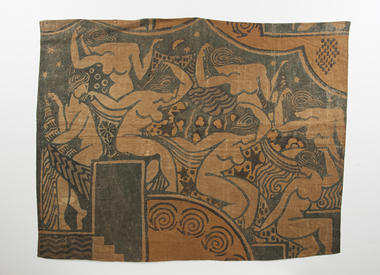

RMIT Design ArchivesTextile pieces

Michael O’Connell (1898-1976) arrived in Melbourne in 1920 with no professional training apart from that of a soldier on the Western Front. During the 1920s however he discovered a talent for design and, returning from a visit home to England via France and Italy in 1929, focussed on textile design with his wife Ella. This fragment of a wall hanging shows clear indebtedness to the School of Paris, Matisse in particular, and other designs from the early 1930s indicate that O’Connell was familiar with the work of Raoul Dufy who had created some successful and popular fabric designs for Paul Poiret.Textile piece featuring women and geometric patterntextile design, rmit design archives, mid-century modern -

RMIT Design Archives

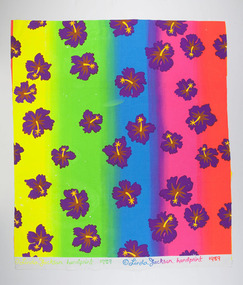

RMIT Design ArchivesTextile pieces, Hibiscus

A cotton fabric printed with a fluorescent rainbow striped background, and scattered purple hibiscus. Designed for Bush Couture's 'Bush Kids' children's line.Printed on the selvedge: 'Linda Jackson handprint 1989'textile design, australian fashion -

RMIT Design Archives

RMIT Design ArchivesScarves

Scarf featuring fish designtextile design, textile, australian fashion -

RMIT Design Archives

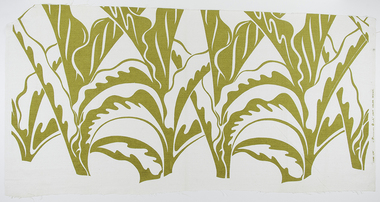

RMIT Design ArchivesTextile lengths, Canna leaf

Dr. Frances Mary Burke (1907 - 1994) was a textile designer and printer, businesswoman, artist and Australian design advocate and retailer. Burke’s modern abstract textile designs incorporated motifs and colours inspired by Australian Indigenous art, Pacific Island cultures, Australian flora and fauna, English gardens, and the sea and its wildlife. Following Burke’s death in 1994, her life-long companion Miss Fabie Chamberlain donated the contents of Burke’s studio to RMIT University.Single colour screenprint, white fabric with chartreuse coloured print of positive large format design featuring large stylised canna leaf motif.Printed on selvedge 'CANNA LEAF' a "Frances Burke" UNIT COLOUR DESIGN'textile, australian flora, rmit design archives -

RMIT Design Archives

RMIT Design ArchivesTextile - Woman's dress, Norma Tullo, Garment Designer, Shirley Lyle, Textile Designer, Woman's Dress

This light woollen evening dress is made from Peppinella, a new fabric Norma Tullo introduced into her range in 1973. The fabric was used exclusively by Tullo, and came from the wool of Peppin Merino (first introduced into Australia in 1858 by the Peppin brothers). According to the papers of the day Tullo’s 1973 winter collection featured ‘St. Trinian’s styles to garments dripping lace, in bold plain colours to floral prints.” Shirley Lyle designed the floral fabric. Norma Tullo (1935-2019) was one of the leading fashion designers of her time, establishing her label in 1956. After establishing a business the Old Metropole Arcade in Melbourne in 1956, with three sewing machines, Tullo's ready to wear fashions for young women became sought after, and her business flourished. In 1966 the Japanese department store chain Isetan Co Ltd began to mass-produce her garments for their stores across Japan. Tullo closed her label in 1977, and later worked for Fletcher Jones. Ann Carew, 2020The dress is historically significant as a dress designed by Norma Tullo, a leading fashion designer of the 1960s and 1970s. During this period the Australian Wool Industry strove to promote wool, and to develop light woollen fabrics to compete with new synthetic fibres such as rayon. The garment is historically significant for the use of a merino wool showcasing its versatility for dress fabrics. Full length woman's dress with full skirt and long sleeves, collared with open neck and pleat work on bodice. Material is predominately red with a repeated pattern featuring posie of blue and mauve flowers.Inscribed, black label on back neck left of zip, 'TULLO/IN/PEPPINELLA/AUSTRALIA MERINO WOOL'; Inscribed, white satin label on back neck right of zip, 'DRY CLEAN ONLY'; Inscribed, white satin label underneath above label, 'SIZE 12/To Fit Bust 34"/To Fit Waistwool, rmit design archives, rmit university, woman's dress, textile design, australian fashion -

Brimbank City Council

Brimbank City CouncilTextile - Printed fabric, Unknown

... Unknown Black cloth with asian art in a box Textile Printed fabric ...Black cloth with asian art in a boxunknown -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.File, "Carlotta Tye Ladies Guild Correspondence"

A folder of correspondence of the Carlotta Tye Memorial's Ladies Guild. Includes: -Letter from A.F Brockoff and Co Pty Ltd Biscuits, 10/10/1939, willing to donate biscuits and face masks. --Order form from A.F Brockoff./-Letter from the Rosella Preserving and Manufacturing Co. Ltd, 10/10/1939, willing to give product samples to the church./-Letter from Nicholas Limited, 11/10/1939, offering samples of Aspro./-Letter from Robur Tea Company Limited, 12/10/1939, giving advice on who can provide samples to the church./-Letter from The Kiwi Polish Co, 16/10/1939, regretably informing Gwen that they cannot provide any samples./-Letter from Nugget Polish Pty.Ltd, 16/10/1939, informing Gwen they cannot provide samples for the church./-Receipt from AF Brockoff and Co. Pty. Ltd, dated 31/10/1939./-Letter from Bushells to Gwen Thomas, 16/11/1939, willing to donate tea to the guild./-Form from Entertainments Tax Assessment Act 1942, dated 17/9/1946, registering entertainment for the Parish Hall, Selby. Comes with attached envelope./-Invitation to Annual Anglican Ball, 11/10/1946./-Letter from Bushells, 26/3/1947, refusing a request to provide samples. Attached is a small letter from the Secretary, dated 23/5/1947./-Letter from Ferntree Gully Shire Council to Gwen Thomas, 24/8/1947. Says that the Shire president Violet B.Lambert is willing to come to "Australian Tea" at Parish Hall, Selby./-Handwritten letter from Mr and Mrs H.W Shepherd, 9/9/1947./-Handwritten letter to Gwen, from "A.Grace(?)", dated 14/9/1947./-Handwritten shopping list, undated./-Handwritten letter to Gwen, from Mrs Langford, 14/9/1947, with attached envelope./-Handwritten letter to Gwen, from G.Coling, 19/9/1947, with attached envelope./-Handwritten letter (2 pages) to Gwen, from M.Allchurch(?), 1/11/1947./-Handwritten letter from W.Tompkins, 8/11/1947./-Handwritten letter to Gwen, from Emily Noble, 10/7/1948, with attached envelope./-Handwritten letter to Gwen, from Hadwen and Houghton (specialists in church furniture), 2/11/1949./-Handwritten letter to Mrs Pearce from Majorie Tye, 7/3/1951./-Handwritten letter to Gwen, from G.Waring Lee(?), 18/6/1951./-Handwritten letter to Gwen, from Iris Wood, with attached shopping list, 2/12/1952./-Handwritten letter to Gwen from N.R Geffery, 23/7/1954./-Letter of appreciation from the family of the 'late Mrs Ruby Clinton Cartledge'. Attached envelope says the date 6/4/1955./-Typed letter to Gwen, from R.K Sutherland, 14/1/1957./-Handwritten letter to Gwen, from R.K Sutherland, 9/2/1959./-Handwritten letter (on card) to Gwen, from Violet Lambal 16/6/1959./-Handwritten letter (2 pages on folded piece of paper) to Gwen from Mary H Chessell, 4/7/1959./-Handwritten letter from St Pauls Vicarage, 6/7/1959./-Handwritten letter to Gwen, from Faye Gronlund, 8/7/1960, with attched envelope./-Handwritten letter to Gwen, from Majorie Cromie, with attached envelope with the date 1/8/1960./-Handwritten letter to Gwen from the Church Missionary Society, 18/4/1962./-Letter of sympathy for the death of Percival William Stephenson on 29/5/1962./-Handwritten letter from Miss Thomas to Edna Lindsay, 29/8/1962./-Letter to Gwen from Moran and Cato Pty. Ltd., 19/6/1963./-Handwritten letter to Selby Church of England Guild from a "Martin", 25/6/1963./-Handwritten letter to Gwen from Doris Pearce, 25/6/1963, with attached envelope./-Handwritten letter to Gwen from Dorothy M Donnelly, 1/7/1963, with attached envelope./-Handwritten letter to Gwen from Violet Lambal, 6/7/1963, with attached envelope./-Undated small card to Gwen, from Marjorie Cromie (circa 1963 as it mentions the guild's 25th anniversary)./-Letter to Gwen from Textile Promotions Pty. Ltd., 29/11/1965, promoting Fashion Fabrics Demonstration for 15/6/1966./-Handwritten letter to Gwen, 14/2/1966./-Letter to Gwen from R.K Sutherland, 12/4/1966./-Handwritten letter to Gwen from Kathleen Sutherland, 13/4/1966./-Letter to Gwen from Holdenson and Nielson Marketing Pty. Ltd., 29/4/1966. Written on date says 'April 10th 1967'./-Handwritten letter from Sean Buckley to Gwen Thomas thanking her for an invitation to her guild, with envelope attached, 14/6/1966./ -2 Handwritten letters from Beatrice Thomson to Gwen Thomas, 22/6/1966 and 23/6/1966. Has an attached envelope./-Handwritten letter from L.E.Heard(?) to Gwen Thomas, 4/7/1966. Has an attached envelope./-Handwritten letter from Eva Blyth(?) to Gwen Thomas, 13/7/1966. Has attached envelope./-Handwritten card to Gwen Thomas from Violet Allen and Mr R.Allen. Attached envelope dates the message as 18/7/1966./-2 page handwritten letter to Ladies Guild from H.R and J.E Herod, 24/7/1966./-Handwritten letter to Gwen Thomas from D.Dickinson (Mrs D.Dickinson), 10/8/1966./-Invitation from the St Cuthbert's Church of England Ladies Guild, Menzies Creek to celebrate their birthday on 20/9/1966. Handwritten financial calculations on the back./-3 page handwritten letter (photocopied) from 'The Most Reverend D.J Penman' to the Ladies Guild. Attached is a note saying "Gwen, Please read this and get back to me if you need to. I will get it typed on Thursday, 24/11/1987'./-Handwritten letter from Majorie Cromie to 'Friends of All Saints Tye Memorial Church', 20/4/1996. With envelope attached./-Letter from The Mission of St.James and St.John, promoting donations for homeless children and families, 28/5/1996. Comes with envelope and donation card./-Undated handwritten note on the back of a Cadbury's advertisement./-Card of acceptance of an invitation signed by Emily Buckley, undated. (?)/-Handwritten note, dated 'March 26th', from Majorie Cromie to Mrs Pearce./-Card of two birds on branches, written to Gwen Thomas hoping to see Gwen at a special occasion on October 11th (year unknown)./-Card with purple flowers on the front cover, written to Gwen from Winnie Dea(?)./-Card of roses on the cover, written by Mrs Cromie as she accepts an invitation to the Selby Ladies Guild's 21st birthday./-Handwritten note, consisting of the address of Gwen Simpson./-Letter (typed and handwritten), to Gwen Thomas from Eva Blyth, inviting the president and members of the ladies guild to a group meeting with the Women's Fellowship of the Union Church, Belgrave./-Invitation card from Violet Allen to the Ladies Guild, for a party on 26th July (year unknown)./-Card with roses on it from Gwen Thomas to Majorie Cromie, July 20th (year unknown), thanking Gwen for a recent visit./-Handwritten note to Gwen (authors name hard to read), on Parish of Belgrave paper./-Handwritten letter to Gwen from L.E Herod, date unknown./-2 envelopes to Gwen Thomas. Both are empty but years unknown./-Card with illustration of Carlotta Tye Memorial Church to Susan, Marian and Peter, from 'Julie', November 4th 2009. -

Bendigo Historical Society Inc.

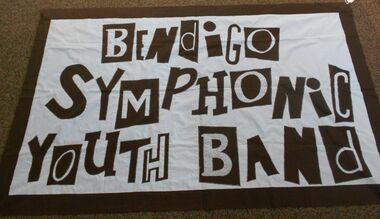

Bendigo Historical Society Inc.Textile - Banner

... has a black fabric backing. Textile Banner ...Large banner for Bendigo Symphonic Youth Band. Fabric block letters have been individually machined onto a sky blue background to form the band's name. At the top of the banner there is an insert for a rod to enable the banner to be hung or carried in a march. Two selected letters - O and B have spotted fabric within the outlined letters so that these stand out at a distance. The banner has a black fabric backing.bendigo bands, youth bands, bendigo symphonic youth band, band banner -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - Fabric remnant

... of crochet lace fabric, the lower one with scalloped edging. Textile ...A remnant of pin-tucked cotton and crochet lace fabric, cut from another article, cylindrical in shape with machine stitching joining the edges. There are two bands of crochet lace fabric, the lower one with scalloped edging.favaloro, pin-tucks