Showing 274 items

matching clamping

-

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fitting of Time Capsule, Eltham, 1987, 1987

In November 1985 a monument was installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria's 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society's 20th anniversary. The main feature of this monument is a ?tyring disc?, a blacksmith?s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red hot iron hoop, previously forged to the correct size was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel.Four colour photographs (laser printed on paper); two showing the fitting of the time capsule into the monument and two showing Joh Ebeli during the dedication presentation.eltham, joh ebeli, time capsule -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fitting of Time Capsule, Eltham, 1987, 1987

In November 1985 a monument was installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria's 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society's 20th anniversary. The main feature of this monument is a ?tyring disc?, a blacksmith?s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red hot iron hoop, previously forged to the correct size was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel.Four colour photographs (laser printed on paper); two showing the fitting of the time capsule into the monument and two showing Joh Ebeli during the dedication presentation.eltham, joh ebeli, time capsule -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fitting of Time Capsule, Eltham, 1987, 1987

In November 1985 a monument was installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria's 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society's 20th anniversary. The main feature of this monument is a ?tyring disc?, a blacksmith?s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red hot iron hoop, previously forged to the correct size was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel.Colour photograph (one of four)eltham, joh ebeli, time capsule -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fitting of Time Capsule, Eltham, 1987, 1987

In November 1985 a monument was installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria's 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society's 20th anniversary. The main feature of this monument is a ?tyring disc?, a blacksmith?s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red hot iron hoop, previously forged to the correct size was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel.Colour photograph (one of four)eltham, joh ebeli, time capsule -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fitting of Time Capsule, Eltham, 1987, 1987

In November 1985 a monument was installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria's 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society's 20th anniversary. The main feature of this monument is a ?tyring disc?, a blacksmith?s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red hot iron hoop, previously forged to the correct size was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel.Colour photograph (one of four)eltham, joh ebeli, time capsule -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fitting of Time Capsule, Eltham, 1987, 1987

In November 1985 a monument was installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria's 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society's 20th anniversary. The main feature of this monument is a ?tyring disc?, a blacksmith?s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red hot iron hoop, previously forged to the correct size was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel.Colour photograph (one of four)eltham, joh ebeli, time capsule -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fitting of Time Capsule, Eltham, 1987, 1987

In November 1985 a monument was installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria's 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society's 20th anniversary. The main feature of this monument is a ?tyring disc?, a blacksmith?s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red hot iron hoop, previously forged to the correct size was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel.Four colour photographs (laser printed on paper); two showing the fitting of the time capsule into the monument and two showing Joh Ebeli during the dedication presentation.eltham, joh ebeli, time capsule -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Instruction, The British Westinghouse Electric & MFG Co. Ltd, "Westinghouse Magnetic Brake", c1905

Instruction - 3 sheets of a former 8 or 12 page document titled "Westinghouse Magnetic Brake" describing the mechanism for magnetic and clamp brakes on 21E trucks, bogies, 22E, trailers. Lists the advantages of the Westinghouse Magnetic Brake. Has a note on the last pages that 2000 Westinghouse Magnetic Brakes have been sold in Great Britain along up to Nov. 1904. Presumed published in the UK by The British Westinghouse Electric & Manufacturing Co. Ltd. London and Manchester.trams, tramways, westinghouse, instructions, maintenance, brakes -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Book - Illustrated Catalogue of Malleable Iron Hardware, The Eberhard Manufacturing Company, No. 7 Illustrated Catalogue Malleable Iron Hardware, 1908

Catalogue from American company of malleable hardware itemsThis is a book of 732 pages. It has a yellow cloth cover with black printing and pages edged in red. The contents contain an index and pages of black and white sketches and text.non-fictionCatalogue from American company of malleable hardware itemscarriage and wagon hardware, eberhard manufacturing company -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Office Equipment, Stamp holder, Mid 20th century

This item would have been used in an office or business for holding stamps of various kinds. It would have been particularly useful in a legal business or a Government Department such as a Post Office where several different kinds of stamps and seals were needed. Stamps are still used in some business and office circles and an object such as this could still be useful. This item is of interest as an example of office equipment in frequent use in the years gone by. It will be useful for display.This is a black metal object. It has a metal stand with a circular column inserted in the centre of the stand. The top of the column has an oval-shaped handle. A circular piece of metal is attached to the column by a series of radiating spokes. Attached to the outer rim are twelve metal clips for holding office stamps (usually held by the handle of the stamp). The metal clips are held in place by metal studs. The ends of the metal clips clamp over to hold the stamps. The metal clips are all slightly misshapen. history of warrnambool, vintage office equipment -

Bendigo Military Museum

Bendigo Military MuseumArtwork, other - LAMP - TRENCH ART, Post WW2

Possibly made by the donor.This object is an example of trench art. .1 The lamp base consists of a chrome plated deactivated mortar bomb attached to a turned brown wooden base. A globe and switch socket are attached to the tip of the bomb. An electrical cord with power plug is threaded through the base of the bomb. .2 The lampshade is made of stiffened brown paper laced to a wire frame with dark brown cord. Handpainted coloured flowers decorate the outer surface of the shade. The shade is attached to the globe via a wire clamp.On the base of the mortar bomb: ' ?LB, IM, MF, 1940'ornaments, lighting - electrical, trench art, souvenir -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Map Calipers/ Divider, Unknown

Compass, divider, and caliper are basically instruments that have two legs pivoted to each other at the top and are concerned with small-distance measurement or transfer. The compass and divider have straight legs; the caliper has curved legs. Dividers and Calipers were known to both the Greeks and Romans, though the caliper was uncommon. A divider with a circular sector, or wing, connecting the two legs was sketched in 1245, its modern counterpart is the wing divider with a thumbscrew clamp and screw for fine adjustment. Or the marine dividers used to measure the distance a vessel has travelled by transferring the vessels distance from a map with the divider and transferring that measurement to a marine ruler to mathematical calculate the distance.Item is believed to be a replica/ copy of a 19th century map calipers used in marine navigation to determine distance travelled. Item was probably purchased between 1972-1975 to add to the marine displays at Flagstaff Hill.Stainless steel dividers used in navigation charts. Top half is alloy plated. "W & HC" and "Made in England".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, stainless steel dividers, steel dividers, dividers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, early to mid 1900's

This cast iron kitchen appliance was made in England in the early 1900's and shipped to the "colony" Australia. This was before World War II and the "growing up" of a colony to an independent member of "the British Commonwealth". It was a period when most appliances (be they household) where manufactured in England and shipped to Australian ports. It was not until the late 1960's that the Asian manufacturing giant woke up and started to dominate the market palce.This domestic kitchen appliance is very significant to the Kiewa Valley because it highlights the "made at home" period when food processing was made "in house" due to inability to source food from specialised shops e.g. the butcher or slaughter houses. It was a period before mass food processing factories were established and roads constructed up to the standard for distribution to semi remote regions such as Kiewa Valley was in the beginning of the 1900's.This cast iron (malleable iron) mincer for meat products has a large "funnel" to direct "chunks" of meat to the grinding "wheels". These "star" shaped wheels with "teeth" of three different cutting surfaces (fine, medium and coarse) provide for texture types of the final meat product. The meat is placed into the "loading" funnel and push downwards(gravity feed) through the mincing chamber and out through the front side. There is a long "screw worm" which is rotated by turning the handle. The appliance is table mounted by a vice "G" screw on clamp (hand operated). "BEATRICE No. 3" and "MADE IN ENGLAND", "P 3181"household cast iron appliances, food processors -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Trolley Wire Sample, Trolley Ear

Short ear (3 screw) with worn trolley wire bent at either end. Ear - brass, with clamp on fitting used to hold trolley wire in position and steel bolt, steel spring washer. Trolley wire cut about 40mm on either side. One side has pulled out of ear - has no groove on one side. Shows how ear has worn while in service. Screws could not be removed while attached to wire. See original worksheet for sketch. Images added 3-12-2016ballarat, overhead, trolley wire, fittings -

Arapiles Historical Society

Arapiles Historical SocietyTimber Wheel Spoke Shaver

The spoke shave is a traditional woodworking tool dating back centuries, commonly used by wheelwrights, carpenters, and furniture makers. It was designed to refine and shape rounded or curved surfaces, particularly in the crafting of wooden wagon wheels, tool handles, and furniture legs. The tool in the image has a well-worn appearance, suggesting significant use over time. The provenance note indicates that this specific tool was donated by Keith SUDHOLZ and was connected to Changi Camp, Toowoomba, possibly referencing an Australian military or post-war connection. This adds historical value to the artifact. Timber Wheel Spoke Shaver donated by Keith SUDHOLZ of Natimuk from 'Changbool' property owned by Errol OFFICER family of Toolondo (c 1950s)The tool is a vintage wooden spoke shave, a hand tool used for shaping and smoothing curved surfaces, especially wooden spokes, chair legs, and other rounded objects. The spoke shave consists of a curved wooden handle with an inset metal blade held in place by a clamp mechanism. The handles extend outward on either side, allowing the user to grip and pull the tool along the wood surface. A handwritten tag attached to the tool reads: "Spoke Shave, Donated by Keith SUDHOLZ of Natimuk from Changi Camp, Toowoomba."timber, wheel, spoke, horse, tool, farm equipment, commercial equipment, shaver -

Bendigo Military Museum

Bendigo Military MuseumBanner - 38th BATTALION BANNER

The banner and frame were carried by representatives of the 38th Battalion during parades..1) Rectangular red cloth banner with gold coloured fringing sewn to the bottom edge. Red cloth loops are sewn onto each side and the top to facilitate attachment to the metal frame - see .2). Printed on both sides in gold, black and white - '38 Battalion AIF'. The '38' is printed on a replica of the 38th Battalion colour patch. .2) Rectangular frame in khaki coloured tubular metal. Each corner is clamped and secured with bolts and wing nuts to allow for the frame to be dismantled. The top LH and RH corners are topped with a cast meat Rising Sun Badge over the letters AIF.Nilbanners - military, 38th battalion, metalwork, badges, passchendaele barracks trust -

Arapiles Historical Society

Arapiles Historical SocietyDomestic object - Apple Corer and Peeler

This is a classic mechanical apple peeler, corer, and slicer, commonly used in kitchens to quickly prepare apples for cooking, baking, or preserving. The user would attach the apple to the pronged fork, turn the crank, and the machine would peel the skin, remove the core, and slice the apple in one motion. These devices were popular in the 19th and early 20th centuries and were often found in home kitchens and food preparation areas.This is a vintage hand-cranked apple peeler, corer, and slicer. It consists of a metal frame painted green with a rotating mechanism operated by a hand crank. The device is designed to be clamped onto a table or countertop using an adjustable screw mechanism at the base. The main components include: A hand-crank with a wooden handle, attached to a spiral metal rod. A spiked fork where an apple would be secured. A cutting blade assembly, which includes a coring blade and a peeling blade, positioned to remove the skin while rotating the fruit. A support arm with rollers and gears, which moves the apple through the peeling and coring process.apple, corer, peeler, kitchen, fruit, household item -

Vision Australia

Vision AustraliaPhotograph - Image, RBS workers with Opticons

1. Male sits at a desk with a Wang computer terminal in front of him and Optacon device to his left. The Optacon was a device that allowed printed material to be turned into Braille through the use of a small camera connected to a vibrating array that produced the Braille. To his right is a cassette recorder, another computer and recorder, whilst a long cane rests against a wall. The man is possibly wearing a sonic guide and listening to the cassette whilst he types on to the screen. 2. Male sits in an office with an Opticon to his left, which he is using, and a manual typewriter in front of him. The typewriter has the camera of the Opticon clamped into position over the typewriter. Behind the man is a reception desk, with a bell and small switchboard visible on upper counter of the desk, and a coffee mug, portable cassette recorder, telephone books and piles of paper stacked neatly under the upper counter.Digital image taken from pictures on chipboard15 - Group with 13, 14 please - no caption available 12 - Group with 13, Optacon captionemployment, royal blind society of new south wales -

Alfred Hospital Nurses League - Nursing Archive

Alfred Hospital Nurses League - Nursing ArchiveEquipment - Thoracic suction measurement unit, Bookcase 1, shelf 4, AHNL Archives Room 8, unknown

suction regulating deviceOf significance to AHNL as similar to equipment used by nursesLarge glass test tube, with rubber stopper with two holes in top. Through one hole is inserted a long hollow glass tube, through the other hole is inserted a plastic y connector. On one arm of y connector is a short length of orange rubber tubbing, to the other end of this tubing is another larger y connection, with another short length of orange rubber tubing, with a metal clamp attached to bottom. The test-tube is attached to a varnished wooden board by two metal brackets. At the base of the test tube is a small wooden shelf for protection. On this backboard is a marked gradient of 60 cms. Two instruction diagrams are attached. Old catalogue numbermedical equipment, surgical drainage, suction regulator, thoracic surgery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ridgway & sons, wood boring tool, carpenters tools, coopers tools, marine tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Ring Auger, Double Twist with Lead Screw, square shaft (which has had a welded repair), socket set at right angle. Broad arrow mark Ridgway Sheffield and DO stamped. warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMedical - Portable Inhaler

The inhaler can be used in hospitals in the labour ward for the patient to absorb trichloroethylene. The inhaler can be mounted on the bracket which can be secured to the leg of a labour bed. The inhaler contains a wick which absorbs trichloroethylene and will function for several hours.This inhaler was used in the Tawonga District Hospital.Wooden box with corners strengthened with steel plate and lid on 2 hinges. Lid has 3 rectangular lengths of wood attached to enhance packing and a yellow piece of paper with red writing stapled on. Box contains 2 metal clamps, a light metal stand/bracket with screw and holder and a hard black plastic mask. In the other side: 2 sheets including Instructions, a small paper bag with spare washers, a light brown extendable hose with metal attachment at one end and a light brown oval rubber bladder with a hole at one end to fit over the hose. Light metal Inhaler - 3 cylinders of different diameters attached to a plate. Red markings / writing and plate incl. serial no. Yellow paper on lid explains "...packing box is supplied free with the Tecota mark 6 Inhaler..." Mask: Cyprene Ltd / Keighley /Made in England Instructions / for the preparation of / Tecota / Mark 6 / Trichloroethylene B.P. / Inhaler Bladder: A Cig Product / 4 litre / Made in England to Inhaler: Cyprane Ltd. / Max Min / Pat No 646680 / Patents Pending / Tecota Mark 6 / Charge with / Trichloroethylene B.P. / Cyprane Ltd. / Serial No. / Keighley / Yorks.medical. hospital. inhaler. trichloroethylene. childbirth.tawonga district hospital -

National Wool Museum

National Wool MuseumGriswold stocking knitting machine, c1890 - 1900

The machine was most recently used by donor's father c2008 to knit socks, but had been used for many years earlier. According to family history, it is believed that the machine came to Australia with donor's grandparents in the early 20th century, and was created c1890-1900. It is still in working order and a demonstration was given by the donor during the acquisition process.Griswold stocking knitter machine. Black steel manual machine which clamps on to the edge of a table and is operated by turning a handle. Centre of machine is a cylinder which can be lined with pins to create the sock/stocking. Two detached parts of the machine include a bobbin holder and yarn feeder. Accompanying items include: 3 examples of incomplete attempted socks made by donor. 4 envelops containing instructions, pattersn, notes and advice on using the machine, created by donor's father and grandfather. 1 bobbin with grey yarn. 2 metal machinery pieces. 2 tins containing pins for the machine. 1 metal yarn feeder cone. 10 weights plus two weight stands. Stocking knitter machine has an identifier plate with patent numbers on the side. -

Bendigo Historical Society Inc.

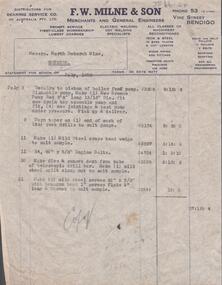

Bendigo Historical Society Inc.Document - NORTH DEBORAH G. M. CO. N. L. - STATEMENT TO NORTH DEBORAH G. M. CO. N. L. from F.W. Milne & Son

Statement from F. W. Milne & Son, Merchants and General Engineers, Vine Street, Bendigo to North Deborah G. M. Co. N. L. Copy of statement for the month of July, 1958. Top of the page is printed with 'F.W. Milne & Son, Merchants and General Engineers' of Vine Street, Bendigo and the name and types of goods and services offered. Statement is for repair to boiler feed pump, turn taper on end of rock drills to suit sample, make a mild steel cross head wedge to suit sample, supply of bolts, make dies and remove dent from tube of telescopic drill bar, make mild steel split clamp nut to suit sample, make 2 mild steel screws 2 1/2'' x 5/8'' with hexagon head 1'' across flats 1/2'' long and thread to suit sample. Statement is a typed, carbon copy. It has copy written in pencil under the typing. Albert Richardson Collection. document, gold, north deborah g. m. co. n. l., north deborah g. m. co. n. l., statement to north deborah g. m. co. n. l., f w milne & son -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChest of drawers, early 20th century

This medical bureau / cabinet shows several signs of being used for a different purpose before being a medical bureau. It once had the words "GENUINE PURE QUALITY" lettered across the top of the front, as can been still seen from the impression left behind in the stained timber. On each drawer above the handle is a faint impression of something long and rectangular, as though there had been a label attached. The front panel of the drawers is made of the same wood as the rest of the outer cabinet, most probably blackwood. The handles on the drawers are not the original handles either. There are 3 filled-in holes that would form the corners of a triangle, apex at the top, around the perimeter of the current handles. The sides of the drawers are made from plywood and the base made from alternating lengthwise strips of oak and beech wood pressed together, rounded corners at the back and joined to the front panel with metal brackets. The backs of the base of the drawers have four round impressions in them. Along the back edge of the base, in the centre, is a rectangular hole. Between the front pair of round holes is a faint black rounded marking, like the impression made by rubber. The cabinet may have once been a filing cabinet, with the drawers used as document drawers, each with a spring-loaded clamp attached to the back of them to secure documents within. The original handles could have been the half-cup type used for filing cabinets. The construction and use of plywood could place this cabinet in about 1950's.Chest of drawers (or Medical Bureau, or Apothecary Chest, or Filing Cabinet) wooden, dark stained, with 30 small drawers (10 rows, 3 columns). The outer wood of cabinet is possibly blackwood and the edges of top and sides have carved wood decoration. Drawer fronts have bevelled edges and round silver-coloured metal knobs. Drawers have plywood sides, and oak and beech wood bases/, Each drawer has four round depressions (in a square-shaped arrangement) at the back plus a small rectangular hole cut in the centre back of base. A faint impression from previous lettering is evident in the wood stain across top front of cabinet.Impression of previous lettering across top front of cabinet "GENUINE PURE QUALITY". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, drawers, bureau, cabinet, chest of drawers, furniture, bedroom furniture, household storage, medical bureau, apothecary cabinet, document drawers, filing cabinet -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Arapiles Historical Society

Arapiles Historical SocietyDomestic object - Food Mincer

Era: This type of hand-cranked food mincer was popular in late 19th to mid-20th century kitchens, before the rise of electric meat grinders. Use: Typically used for grinding meats, making sausages, or mincing vegetables, often as part of home food preservation. Manual operation: The auger forces food through the grinding plate, allowing the user to control the consistency of the minced product.This is a vintage cast iron hand-cranked food mincer, consisting of several detachable parts. It is designed to grind meat, vegetables, or other food items by manually rotating the handle, which turns the auger inside the main body. The components include: Main body (casing): A heavy cast-iron structure with an open funnel at the top for inserting food. The body features a clamp or screw holes for securing it to a workbench or table. Handle with wooden grip: A long metal arm with a rounded wooden handle, used for manually turning the auger. Auger (screw-like piece): A large metal spiral component that pushes the food through the mincing plate when the handle is rotated. Mincing plate (grinder disc): A perforated metal plate that determines the texture of the ground food. Additional attachments: Includes a funnel-shaped attachment and small metal parts stored in a plastic bag, likely used for securing or adjusting the mincer. The mincer shows signs of wear and oxidation, indicating age and prior use. The wooden handle appears intact, but the metal components show some surface rust, which is typical for vintage kitchen tools.food, mincer, kitchen, household item -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Time Capsule Ceremony, 10 November 1985, 10/11/1985

On Sunday, 10 November 1985 a time capsule was lowered into a monument installed near the corner of Main Road and Pitt Street in Eltham, within the gardens at the front of what is now the Eltham Community and Reception Centre. This monument commemorates Victoria’s 150th anniversary and the former location of the Eltham Town Centre, which existed along this section of Main Road, then known as Maria Street. Beneath the site is a time capsule to be opened in the year 2035. A plaque was also erected at this site in October 1987 to commemorate the Shire of Eltham Historical Society’s 20th anniversary. The main feature of this monument is a ‘tyring disc’, a blacksmith’s implement that was found on this site. This consists of a large iron disc that was used as a platform for fitting iron tyres (like the one shown on top of the platform) to wooden-spoked cart wheels. The local blacksmith and wheelwright worked together to assemble the wheel, which was clamped to the platform placed close to the fire. The red-hot iron hoop, previously forged to the correct size, was lifted with tongs by the blacksmith over the outside of the rim, then hammered down amid flames from the scorching timber. The wheelwright drenched the tyre with cold water as soon as it was in position. A clamp placed on the naff (hub) and screwed down tightly kept the spokes at a constant angle as the tyre cooled. An even pressure from the contracting tyre tightened the joints at each end of the spokes and formed a vice-like grip, which would last for the life of the wheel. [from EDHS Newsletter No. 45, November 1985:] TIME CAPSULE CEREMONY: Our 150th Anniversary Monument is now under construction in the gardens in front of the Eltham Community Centre. Further details of the project are given under a separate heading below and this item deals with the proposed ceremony. We propose to formally lower the time capsule into its container underneath the monument as part of the Eltham Community Festival. All members are invited to attend the ceremony at 2.00 p.m. on Sunday, 10th November. Come earlier with a picnic lunch if you like. Local people and firms who have contributed money or services for the monument will also be invited. As part of the Festival programme the public are welcome to attend. This is one of the most significant projects the Society has undertaken and members' participation in its finalization would be most gratifying to the organizing committee. 150TH ANNIVERSARY PROJECTS: We have concentrated our efforts on finishing the monument and time capsule project within the 150th year and have found it necessary to abandon the historical tour project. We have applied to the State 150th Committee to transfer the funds allocated for the tour to construction of the monument. The historical tour project will be continued at a later date and photos of historic houses in the area, taken by Doug Orford, will be available for use in an associated display. At the time of writing, the monument construction is on schedule for the ceremony on 10th November. The concrete base has been completed and the main feature of the monument, which is an old tyring plate or disc, will be lifted into place in the next week. The final ceremony will involve lowering the sealed time capsule into place, bolting down its container lid and then concreting over the lid. The capsule will contain mainly items relating to present day Eltham and its people and is to be opened in the year 2035, a video film made by Joh Ebeli and also details of families and organizations who have contributed to construction of the monument. It is proposed to place the items in the capsule on 5th November and any items members think could be included may be submitted up to that date. The Society has received an excellent response from local people, firms and organizations by way of assistance with this project. Graham Beyer, who originated the project, has arranged many of the donations. He and his firm, Package Handling Equipment, have donated the time capsule itself and have carried out fabrication of sections of the monument. The design of the monument was adapted by Graham Beyer from drawings by Joh Ebeli. Charmac Industries has donated the container for the time capsule and a cast gun metal name plate for the monument. BMG Concrete has donated concrete for the base which was constructed by Caridi Construction Company. Northbourne Garden Supplies has donated materials for the paving around the monument. Robert Becker from Eltham Apex directed construction of the paving by Society members. Terry Hutchinson has agreed to donate the use of his crane to lift the tyring disc into place. Financial contributions have been made by the Eltham Chamber of Commerce and the Rotary Club of Eltham. We are grateful to all who have helped, and members' support for firms who have donated their services would be an appropriate recognition. It is planned to print "Time Capsule Certificates" which can be held by organizations or passed on to descendants by individuals. The certificates will indicate an interest in the contents of the capsule when it is opened in fifty years. Certificates will be distributed to Society members and those who have contributed to the project.Nine colour photographsactivities, 1985, time capsule, eltham, eltham festival