Showing 421 items

matching hammerly

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Mallet, Prior to 1950

Wooden mallets are usually used in carpentry or by a cooper to knock wooden pieces together, or to drive barrel bungs, dowels or chisels. A wooden mallet will not deform the striking end of a metal tool, as most metal hammers would. It is also used to reduce the force driving the cutting edge of a chisel, giving better control. Hardwood mallets are also used by a cooper to knock bungs or other wooden parts of a barrel in place.A significant tool a carpenter or cooper would use to knock wooden staves or furniture parts in place without damaging the soft surface of the timber being used. Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Mallet wedge shaped with metal handleNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, wooden mallet, barrel bung, carpenters tool, hammer -

Bendigo Military Museum

Bendigo Military MuseumEquipment - TOOL KIT, BREN GUN, Unknown

1. Multi purpose carry pouch, khaki with over the shoulder carry strap. 2. Small metal oil bottle. 3. Multi purpose repair tool, with hammer, spanner and slide-out adjusting tools. 4. Metal container, with firing pins, springs and keys. 5. Rope barrel pull though. Each item has its own sewn-in storage pouch fitted with individual closures. On oil container; F & S LTD On metal container; TD On repair tool; NIC -passchendaele barracks trust, kit, armour's tool kit, bren gun -

Whitehorse Historical Society Inc.

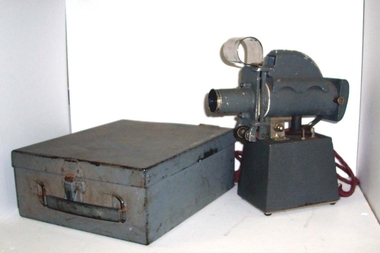

Whitehorse Historical Society Inc.Machine - Film Strip Projector, late 1030s

Projector was used at Christ Church Anglican Church Mitcham (now All Saints Mitcham) for showing film strips to the congregation, Sunday School and youth groups.Early 'Shelton' film strip projector in a steel grey painted and hinged metal case with carrying handle. Projector has been finished in a 'hammered' meta paint with a large transformer as its base. It is a 240 volt projector. The film strip is manually rolled through the slots of the projector to show each frame separately. Project lens is adjustable for focus and it has a small angle of adjustment foe aligning the image on the screen.Shelton Projector Made in Australiaphotography, projectors -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Miners candle holder, Late 19th century

This candle holder has a sharpened point to push or hammer into soft rock and a hook to hang on a ledge or piece of rock. It is intended to be used in a mine and many residents of Warrnambool and district went to the gold mining districts in the 19th century. But it could have been used in the Warrnambool district if a small night light was required in one of the many local quarries or even in the search for coal deposits in the region. It could also have been used in a household.This miner’s candle holder has no known local provenance but it is retained as an interesting example of a candle holder used in the past.This is a thin piece of metal tapering to a point at one end and curving around in a loop at the other end to make a handle. Along the straight metal piece is attached a curved metal hook. At the end of the loop is an open-ended circular piece with a serrated top. The circular piece has a rectangular-shaped end piece which enables the hole in the curved piece to be pushed out or pulled in to make the hole smaller or bigger. The metal is much rusted. 19th century mining, history of warrnambool -

Bendigo Military Museum

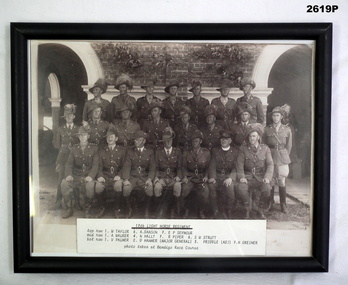

Bendigo Military MuseumPhotograph - PHOTOGRAPH, FRAMED, 1939

List of names printed on card on photograph: 17th Light Horse Regiment Photograph taken at Bendigo Racecourse Top row: 1. W TAYLOR 6. A DANSON 7. E P SEYMOUR Mid row: 1. A WALKER 4. N HALL? 7. R PIPER 8. W STRUTT Bottom row: 1. V PALMER 2. D HAMMER (MAJOR GENERAL) 3. P RIDDLE 7. H GREINERPhotograph, black white colour, group portrait of 22 uniformed Officers of the 17th Light Horse Regiment. Wooden frame painted black. Label on photograph, black print on white cardboard showing list of names.On frame cardboard back in blue ink: “Passchendaele Barracks / Trust”photography-photographs, frame accessories, passchendaele barracks trust -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBottle Corker, late 1800's to early 1900's

This hand held, wooden bottle corker would have been used by soft drink or wine producers to insert corks into their bottles to seal the drink inside. It seems it may have had a metal tip on the end of the plunger, as do other similar bottle corkers, because this plunger has a compressed end and a ring shape impressed into the wood a little way up from the tip. How to use the bottle corker … - soak a long, bullet shaped cork in water to soften it - place the bottle corker over the bottle’s neck - insert the cork through the side opening and place onto the metal funnel - push the plunger down onto the cork, forcing it into the tapered, which will squeeze the cork to size as it enters the bottle. Use a mallet or hammer if necessary The design of this bottle corker is very similar to “"Redlich's Apparatus for Corking Bottles", which was invented and patented by Henry Redlich of Chicago, USA, in 1862, US patent #35,325. H. Redlich’s gave the following instructions for the use of the bottle corker: “DIRECTIONS: SOAK THE CORK, DROP INTO THE OPENING AND TAP THE PLUNGER WITH A MALLET OR HAMMER.” This hand held, wooden bottle corker would have been used by soft drink or wine producers to insert corks into their bottles to seal the drink inside. It seems it may have had a metal tip on the end of the plunger, as do other similar bottle corkers, because this plunger has a compressed end and a ring shape impressed into the wood a little way up from the tip. How to use the bottle corker … - soak a long, bullet shaped cork in water to soften it - place the bottle corker over the bottle’s neck - insert the cork through the side opening and place onto the metal funnel - push the plunger down onto the cork, forcing it into the tapered, which will squeeze the cork to size as it enters the bottle. Use a mallet or hammer if necessary The design of this bottle corker is very similar to “"Redlich's Apparatus for Corking Bottles", which was invented and patented by Henry Redlich of Chicago, USA, in 1862, US patent #35,325. H. Redlich’s gave the following instructions for the use of the bottle corker: “DIRECTIONS: SOAK THE CORK, DROP INTO THE OPENING AND TAP THE PLUNGER WITH A MALLET OR HAMMER.” Bottle corker, a hand operated wooden corking device for sealing bottles. Bottle corker has two parts comprising a wooden plunger rod with knob handle, and wooden cylinder containing a metal tube that is flared to a funnel shape on the top. The cylinder has a hole the diameter of the rod at both ends and an oval insertion slot in one side. The tip of the plunger rod is slightly compressed and it has an indented line around the circumference as though it has had something attached to it. Manufactured in the late 1899s to early 1900s in Melbourne.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cork -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, late 19th -mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This is an example of an implement used locally in the livestock industry.A branding iron with letter R on circular end. Handle loop is oval shaped. It has been painted blue to half way.branding-iron rural-industry -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This item is an example of a common implement used in the livestock industry in Orbodt.A long-handled branding iron with an S or 2 on the end. There is a loop at the top for hanging.branding-iron rural livestock-industry -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by archaeologist, Joanna Freslov on 2.6.2008. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt.This is able to withstand repeated impact, and and so was suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were some of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This artefact is an exaample of the stone tools that Aboriginal people used.A dark stone handmade Aboriginal axe head.aboriginal axe-head stone-artefacts tool -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basaltwhich is able to withstand repeated impact, and is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rockThe necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Eastern Australia.A handmade stone Aboriginal axe head.aboriginal tool stone-artefact axe-head -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joonna Freslov, archaeologist 2.6.2008. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt which is able to withstand repeated impact, and is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock.The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Eastern Australia.A handmade stone Aboriginal axe head. Finger grips are clear.axehead aboriginal tool stone-artefact -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBlacksmith's Bellows

In the Middle Ages double-acting bellows was introduced. It had 2 parts, one operated by hand or foot, the other took air from it and was weighted so it forced air out while the part was filling. Blacksmithing is the shaping of hot iron and steel, usually by hammering. Very hot fires were produced by 1.a hot air blast. 2. burning charcoal (not wood). Bellows were used to make tools, fix equipment including machinery, drays, carriages, harnesses etc. Farmers in the Kiewa Valley often had their blacksmith forge. They made their own tools, were able to mend equipment, drays etc., gates, and most items that were made of iron and steel.Large Double Acting bellow with wooden top and bottom, shaped like a 'water drop' - narrow at one end and broad at the other. The wood is held by strips of wood and leather bound and placed around the perimeter. The wood on the top side has inscriptions (illegible). The wood on the bottom side has a rectangular hole. The narrow end feeds into a pipe to enable the fire to receive a hot blast of air. When the bellow is squeezed it allows both pieces of wood to be pushed together.Illegibleblackmiths, bellows, double acting bellow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This handmade tool was made for the particular purpose of joining sheets of metal together. The metal formed in this way could be used for water tanks, boilers and other similar items. It is an example of the equipment made and used in the trades of a metalsmith and blacksmith in the 19th and early 20th centuries.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTools - Vice and Clamp

Very old vice. The clamp is 50 to 60 years old when they were made by Technical School students in metal work class.Used by carpenters, woodworkers, furniture makers, welders, construction and metal workers in the Kiewa ValleyMathieson's Hand Vice, the smallest at 3 inches. Ref. Page 74 Tools for all Trades Catalogue. Small steel vice consisting of two parallel jaws for holding a workpiece. One jaw is fixed and the other movable by a screw. The clamp is used for holding a workpiece during hand operations eg. filing, hammering or sawing. Small steel clamp is a versatile tool that serves to temporarily hold work securely in place by screwing each jaw together.vice/vise tool, clamp tool, hand tools -

Bendigo Historical Society Inc.

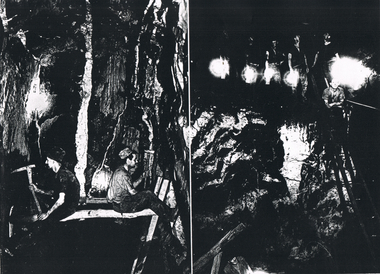

Bendigo Historical Society Inc.Photograph - LONG GULLY HISTORY GROUP COLLECTION: TWO UNDERGROUND PHOTOS

Copies of two dark black and white photos of underground mining at the Hercules mine. The left side one shows two miners facing the sides of the shaft prior to the boxing in with red gum slabs. one man is using a sledge hammer and the other is using a hand pick. The right-hand side photo This photo was either the Shenandoah or the New Chum Railway. Five men standing on a higher part are holding lamps and one man is standing on a ladder.bendigo, history, long gully history group, the long gully history group - two underground photos, hercules, shenandoah, new chum railway, victoria quartz -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine and case, Joseph Wertheim, late 19th century

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Sewing machine, Wertheim brand “ Syst 182” hand crank operated machine with folding handle, timber case and carry handle. Metal machine is painted black, with remnants of gold, red and green scrolls and floral decoration. Machine has base with inlaid measuring rule across front and 2 holes drilled through the base (perhaps for mounting machine to a bench). Machine tilts open, hinged on one side, after thumb screw is unwound, revealing machine’s workings and serial number. Base has a fitted round, concave, silver metal pin holder with lid that hinges open, and symbol pressed into lid; several pins are inside. Body of machine has brand name transfer across front and oval metal trademark disc on front. Metal sliding covers over footplates have stamped lettering. Timber machine case or cover includes an accessory box with sliding cover and metal hook and eye latch, and inside the box are 23 metal sewing attachments, a disc and a stick of black crayon with maker’s trademark on it paper cover. Workings of machine have seized up. The crayon wrapper has printed on it “For the wonderful Wertheim new family machine made in Germany ‘Syst. 182’”, and the maker’s symbol with “Trademark” beside it. Made for Hugo Wertheim.“WERTHEIM” transfer across front and back of machine body. Cover of pin holder has symbol ‘Wings above a shield’. Maker’s trademark on gold oval disc, “WERTHEIM / FRANCFURT” and picture of a dwarf with a hammer. Left footplate has script “Syst 182”, right footplate has stamp in oval shape “MANUFACTURED IN - - /SPECIALLY FOR / HUGO WERTHEIM” Serial Number “7501”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand crank sewing machine, hugo wertheim, wertheim, clothing manufacturer, sewing, syst 182 -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, Late 19th -mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This item was used in Orbost in the livestock industry.This item is an example of an implement once used in the livestock industry in Orbost.A branding iron with the letter W on the end. It has a long iron handle with a ring grip at the top.branding-iron rural-industry -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, late 19th -mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This item was used in Orbost in the livestock industry.This item is an example of a common implement used in rural industry in Orbost.A branding iron with the letter J on the end. It has a long handle with a ring grip at the top.branding-iron livestock-industry rural-industry -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, Late 19th century - mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This branding iron was used in Orbost. This item is an example of an implement commonly used in the livestock industry in Orbost.A long-handled branding iron with J H at the end. There is a hanging loop at the top.branding-iron rural livestock-industry -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Digital Image - Cable tram grip in workshop, c1900

Digital Image of a cable tram dummy or grip car in a workshop being repaired. The seats have been removed and car partly dismantled. The grip is handing from the roof of the car. The original apron mesh is fitted along with a different coupling fitting to that of later grip cars. There are three workmen in the photo, one holding a large engineer's hammer. The car is lettered for the North Carlton to Brighton Road route with lettered glass in the the roof section, including one for "HBRy Station" - Hobsons Bay Railway Station.Yields information about the repair of cable trams at car houses or depots or the principal Nicholson St Car Repair shop.Digital image of a photograph.cable trams, workshops, depots, grip car, dummies, repairs -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Badges, Warrnambool Technical School

This is a Warrnambool Technical School badge of the 1920s and 30s. Warrnambool Technical School was established in Timor Street in 1913. The senior section was later called Warrnambool Technical College and then Warrnambool Institute of Advanced Education. The latter institute moved to Sherwood Park, Warrnambool and became the present-day Warrnambool campus of Deakin University. Warrnambool Technical School moved to Caramut Road, Warrnambool and is today known as Brauer College. The badge was donated by Mirth Marfell, the daughter of Henry and Helena Marfell. She was born in Warrnambool in 1919. Her grandfather, John Marfell, a Warrnambool hay and corn dealer and miller connected to the Warrnambool Co-operative Milling Company, was prominent in community and civic affairs in the town. Mirth Marfell completed her nursing training at the Warrnambool Base Hospital and served in the Australian Army Nursing Service in World War Two for five years. She then became the first Australian nursing organizer for the Victorian Royal College of Nursing. This badge is of interest, firstly as a memento of Warrnambool Technical School from the 1920s and 30s and secondly because it came from Mirth Marfell, a Warrnambool person who had a distinguished nursing career..1 Shield shaped metal and enamel badge with green border including text enclosing a silver area featuring raised images of a torch, scales, compass, hammer, nails, artist's palette, brushes , a bar and the numbers 192. A pin clip is on the reverse .2 Circular metal and enamel badge with a golden edged green border surrounding a bronze coloured centre with a stylised golden edged scarlet torch and three horizontal bars of varied length. A pin clip is on the reverse..1 WARRNAMBOOL TECn SCHOOL LABOR TO EFFICIENCY .2 WARRNAMBOOL TECHNICAL SCHOOLwarrnambool institute of advanced education, warrnambool technical school, brauer college, warrnambool co-operative milling company, victorian royal college of nursing, history of warrnambool -

Bendigo Historical Society Inc.

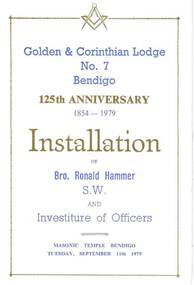

Bendigo Historical Society Inc.Document - INSTALLATION OF BRO. RONALD HAMMER GOLDEN AND CORINTHIAN LODGE NO 7

Small white booklet with blue printing inside and gold and blue printing with gold border and the Masonic emblem at the top. 125th Anniversary of the Golden & Corinthian Lodge No. 7 Bendigo 1854 - 1979. Installation of Bro. Ronald Hammer S. W. and Investure of Officers. Masonic Temple Bendigo Tuesday, September 11th 1979. Inside the booklet is a Short History of The Golden and Corinthian Lodge No. 7 of Bendigo; Ceremonial; List of Officers 1979 - 80; List of Members; toasts and Harmony and a space for autographs.organisation, masonic lodge, investure of officers, installation of bro ronald hammer, golden & corinthian lodge no 7 bendigo, criterian hotel, freemasons hotel, view point hotel, pembroke house, black swan hotel, golden lodge of bendigo, corinthian lodge of sandhurst, vahland, getzschmann, zenith lodge, 'a history of freemasonry in the bendigo district diring the firt 50 years of its existence', a h stone, k r grabasch, r hammer, m j luxford, t c k secombe, a g mcarthur, c c maskell, f a turpie, c m phillips, t k griffiths, b marett, g f turpie, r j m berry, f j palmer, l s shepherd, g e adams, w h shay, w s clemens, s n gillam, g a fraser, s b webster, j g penberthy, a k rollinson, k j beale -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Sculpture - JOHN BOMFORD PSYCHIATRIC CENTRE, COPPER BAS RELIEF EAGLE, 1970s

Bomford Bas Relief Eagle. Created from Sheet Copper. Carved and hammered Bas relief of a large Eagle.. The Carving was created by an artist in residence at the Bendigo Psychiatric Centre ( Golden City Support Services) prior to closure. It is approximately 2.00 metres high and 1.20metre wide. Mounted on a Large green wooden board. See 7311 also. Items represent the constellations Capricorn and Aquila. Once completed, they were used to identify the Squila and Capricorn patient areas at the Psychiatric Centre.artwork, sculpture -

Orbost & District Historical Society

Orbost & District Historical Societyboots

Hobnailed boots are boots with hobnails (nails inserted into the soles of the boots), usually installed in a regular pattern, over the sole. They also usually have an iron horseshoe-shaped insert, called a heel iron, to strengthen the heel, and an iron toe-piece. The hobnails project below the sole and provide traction on soft or rocky ground and snow, but they tend to slide on smooth hard surfaces. They may also have steel toecaps. When Army boots were made 100% of leather, to get some grip on the soles hob-nails were hammered into them. These boots are an example of the foot wear worn by the eA dark brown leather pair of very heavy hob-nailed boots. They have nails inserted into the soles of the boots in a regular pattern, over the sole. The toes and the heels have been strengthened with metal. The boots are made to lace up at the front.boots-hobnailed footwear -

Melbourne Legacy

Melbourne LegacyCeremonial object - Trench Art, Bell, Comradeship Bell, 1929

Bell was presented to the Melbourne Legacy Club by the departing president E.R.F. Serman in 1929. It was used during Comradeship Committee meetings.E.R.F. Serman was the Melbourne Legacy Club president in 1928-1929. Comradeship Committee meetings were very important to the Legatees.18 Pounder Shell casing that has been polished and had a small brass hook welded to the base. The casing has been split and bears the signs of being hit with a hammer. There is an inscription engraved on the front. The shell is hung from a brass arch which has been mounted to a wooden base. Two small brass hooks on the base act as a mount for the mallet. The brass arch and hooks are attached to the wooden base via flat head screws from the underside. The mallet is constructed of a brass rod with a felt head.Presented to the Melbourne Legacy Club by E.F. SERMAN PRES.1928-9comradeship, committee, legatee event -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Sculpture - JOHN BOMFORD PSYCHIATRIC CENTRE, COPPER BAS RELIEF MYTHOLOGICAL GOAT

Bomford Bas Relief Mythological Goat. Created from Sheet Copper. Carved and hammered Bas relief of a mythological creature resembling a goat with long straight horns. The Carving was created by an artist in residence at the Bendigo Psychiatric Centre ( Golden City Support Services) prior to closure. It is approximately 1.5metres high and 1.00metre wide. Mounted on a Large green wooden board. See 7312 also. Items represent the constellations Capricorn and Aquila. Once completed, they were used to identify the Squila and Capricorn patient areas at the Psychiatric Centre.artwork, sculpture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking mallet, Mid 19th to early 20th centuries

The subject item is a vintage Nautical Shipwrights Ship Boat Caulking Hammer Mallet, Unusual Small Size. These mallets were routinely used in the 1800s when ships were made of wood. This mallet was used with caulking irons to drive the oakum (caulk) between the ship's bottom planking to seal them up. The mallet has slots to dampen the vibration of the mallet blows on the user's elbows. The head is made of a very hard wood, possibly Lignum Vitae or another dark tropical wood. The item seems to be of a very early design with the two preened-over metal rods for reinforcing the head. Item appears to be of early manufacture by an unknown maker from the mid to late 19th century and is significant as tools of this era are quite rare. This tool is also significant as it gives an insight into how ships made of wooden planks were made sea-worthy by inserting caulking material between the boards thereby making the vessel watertight. Caulking Mallet Wooden with iron ferrules on each end. Wooden head with two large bolts passing through body. Stamped W Milne. James S Steele tool box.Stamped W Milne & James S Steele tool box.mallet, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking mallet, caulking, james steele, shipwrights tools -

Bendigo Military Museum

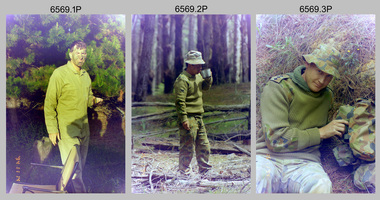

Bendigo Military MuseumPhotograph - 4th Field Survey Squadron Regimental Training - Exercise ‘Fuggy Hollow’ in SA, 1994

This is a set of 30 photographs of 4th Field Survey Squadron personnel undergoing regimental training in 1994, at Second Valley Conservation Park in South Australia. The aim of Exercise ‘Fuggy Hollow’ was typically to provide personnel a practical knowledge of infantry and minor tactics (IMT) at the section level, navigation and map reading, RATEL and survival in the Field.This is a set of 30 photographs of 4th Field Survey Squadron personnel undergoing regimental training in 1994, at Second Valley Conservation Park in South Australia. The colour photographs are on 35mm negative film and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 96 dpi. .1) - Photo, colour, 1994. Unidentified soldier. .2) - Photo, colour, 1994. CPL Phuc ‘Charlie’ Tran. .3 to .5) - Photo, colour, 1994. CAPT Chris Topovsek. .6) & .7) - Photo, colour, 1994. Unidentified soldiers. .8) - Photo, colour, 1994. L to R: SPR Fran Calvert, unidentified (x2), SPR Mark Linford, unidentified. .9) to .17) - Photo, colour, 1994. Unidentified soldiers. .18) & .19) - Photo, colour, 1994. L to R: LT Andrew Caudle, SSGT Brian Collings, OC Maj Peter Demaine. .20) - Photo, colour, 1994. WO2 Peter Hammer. .21) - Photo, colour, 1994. L to R: CAPT Chris Topovsek, SSGT Brian Collings, WO2 Peter Hammer .22) - Photo, colour, 1994. SSGT Brian Collings. .23) - Photo, colour, 1994. L to R: unidentified, SPR Fran Calvert. .24) - Photo, colour, 1994. L to R: SPR Mark Sinderberry, SGT Steve McGuiness, unidentified. .25) - Photo, colour, 1994. SPR Mark Linford. .26) - Photo, colour, 1994. L to R: unidentified (x2), SPR Fran Calvert, unidentified. .27 & .28) - Photo, colour, 1994. L to R: SSGT Brian Collings, WO2 Peter Hammer. .29) - Photo, colour, 1994. WO2 Simon ‘Andy’ Capp. .30) - Photo, colour, 1994. SGT H. Evertz..1P to .30P – There are no personnel identified. ‘1994 EX FUGGY HOLLOW (IMTs) Second Valley Conservation Park’ annotated on negatives sleeve.royal australian survey corps, rasvy, 4 fd svy sqn -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2/6/2008. Genuine Aboriginal axe head up to 2000 years old. Possibly came through trading from western district. Stone tools were used for a variety of purposes, in ways similar to those of the steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt.This stone is able to withstand repeated impact, and and wqas generall used for stone axes. The stone was dug or found and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Victoria.Small grey oval-shaped axe head.axehead stone-artifact aboriginal tool