Showing 754 items matching "metal work"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

... with both hands! Before your work can be bisque fired it should... to finish the work completely – use a metal kidney to polish ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

... with both hands! Before your work can be bisque fired it should... to finish the work completely – use a metal kidney to polish ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBadge - ACF Australian Comforts Fund badge, P J King Pty Ltd, 1940

This Australian Comforts Fund badge is part of a set of eleven badges collected from the 1920s to the 1940s by Dr W. R. Angus. The badge was sold by the ACF in 1940 to raise funds for gifts to send to the Australian troops serving overseas. The badge is one of a set of badges that represents various organisations that he had interests in. The Australian Comforts Fund was a mostly female, volunteer-run organisation officially recognised by the Government. It began in 1916 as an amalgamation of groups of people who wanted to support the Australian troops abroad with Items of comfort to supplement the essential items provided by the Australian Military Forces. The ACF raised funds to purchase goods, pack them and send them overseas. One of their fund-raising activities was 'button days' where buttons such as this one were given to those who gave donations. The ACF closed down after World War I but was re-formed at the start of World War II. Items that the ACF sent to the troops included personal toiletry items such as toothbrushes and toothpaste, magazines, pyjamas, singlets and socks. They also provided sporting equipment, recreational music, writing materials and postcards. Special hampers were sent to the troops at Christmas time. The maker, P J King, (Percy John King), originally established his engraving and ie casting business in Russell Street, Melbourne in 1893 in partnership with Charles Walder Bridgland, continuing on his own from 1899. Percy and his son John Howard King set up a new business P J King Pty Ltd in 1928 making uniform buttons. In the late 1980s, it merged with two other companies that then became J J Cash, now known as Cash's Australia. The set of badges was donated to Flagstaff Hill Maritime Village by the family of Doctor Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” which includes historical medical equipment, surgical instruments and material belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) and Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. The W.R. Angus Collection: - The W.R. Angus Collection includes historical medical equipment, surgical instruments and material belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) and Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. It includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. During World War II He served as a Military Doctor in the Australian Defence Force. Dr Angus and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the planning stages of the new Flagstaff Hill and the layout of the gardens there. Dr Angus passed away in March 1970.This badge represents the efforts of the women volunteers in Australia to support the Australian troops overseas in WWI and WWII. This badge is one of a set of significant badges that connects Doctor Angus with Australian organisations of the early-to-mid 20th century, including those relating to military service support. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The Collection includes historical medical objects that date back to the late 1800s.The ACF Badge is a star-shaped, gold, glittered red enamel and metal badge. The star has six points. The enamel surface is textured. The border and front inscription of the badge is gold. It is the badge of the Australian Comfort Fund, made by P.J. King and dated 1940. This badge is part of a set of badges collected by Dr W R Angus. the set represents organisations that he was involved in, and is part of the W.R. Angus Collection.Front: “ACF / 1940” Reverse embossed “P.J. KING”flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, metal badges, enamel badges, organisation badges, acf, presbyterian brotherhood, oikumene, w.r. angus, flagstaff hill maritime museum and village, australian comforts fund, button day, volunteer, australian military forces, christmas hamper, 1940 acf badge, fund-raising, p j king pty ltd, percy john king, donor's badge, world war ii, 1939-1945, australians at war, voluntary work, volunteers, home front, w.r. angus collection -

Federation University Historical Collection

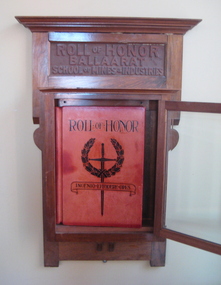

Federation University Historical CollectionBook - Roll of Honor, Ballarat School of Mines Honor Book, c1920

The Ballarat Technical Art School made many honour boards for schools and organisation in Victoria and interstate. Their own was made, but the names were not listed. The Ballarat School of Mines Annual Report for 1921 states: 'It has been decided, for the present, to record the names of our students who served in the warm, in an Honor Book, and to defer the erectin of an Honor Board until we can feel ssured that the Roll is complete. the wide spread occupations of our students has rendered it very difficult for us to secure detailed information of their service. A handsome Honor Book and Case has been designed and executed by the staff ad students of the technical Art School, and the engrossing of the names and military records will be proceeded with as soon as possible. The Technical Art School was quite busy with commissions. The SMB Annual Report of 1918 states: 'under the direction of the Art principal (Mr H.H. Smith), the work of the Art School continues to receive wide public recognition. Handsome Honor Boars have been designed and executed for the Sydney Sports' Club, the St Arnaud High School, the Birregurra State School, the Wendouree State School and the Ballarat Old Colonists' Club. The School also designed the certificates for the Young Workers' Patriotic Guild, the 'Herald" Shield for perpetual competition at the technical Schools' athletic meetings, the "Hansen" Shield for competition among the Northern District High Schools, two metal tablets for the Castlemaine high School, and a certificate for the Grampians Secondary Schools' Association. Numerous Honor Books and Mural cases have also been designed for State Schools.' Over 400 former students and staff of the Ballarat School of Mines served during World War One. The 1920 SMb Students' Magazine said' 'Many students left Australia with the first Contingent, and since then, the School has been represented on every field where Australians have fought, from the first landing at Gallipoli to the decisive victory on the 8 August 1918.' The influence of the school was appropriately shown in the fact that at least 13 of its students were officers in the Australian Mining Corps. The title page has the initials 'D.J.' which most probably stands for Donald I. Johnston, a teacher with the Ballarat Technical Art school from 1920 to 1949. The Ballarat School of Mines World War 1 Honor Book remained uncompleted for more than 90 years. The names of over 400 SMB staff and students who served their country were not inscribed until 2012, despite names, ranks and service records being compiled. A restoration project was instigated as part of the 140th anniversary of the Ballarat School of Mines in 2010. Names were inscribed into the book by Calligrapher Lyn Forrester. The University of Ballarat believed this project is important not only to SMB's history, but the families and descendants of those who served while studying or teaching at SMB. The restoration project involved names being hand written in calligraphy into the Honor Book and was funded with the assistance of the 'Restoring Community War Memorial Grant'. The memorial was designed and made by the staff and students of the Ballarat School of Mines Technical Art School under the direction of Principal Herbert H. Smith. In 1921 the Ballarat School of Mines Annual Report recorded: "It has been decided, for the present, to record the names of our students who served in the war, in an Honor Book, and to defer the erection of an Honor Board until we can feel assured that the roll is complete. The wide spread occupations of our students has rended it very difficult for us to secure detailed information of their service. A handsome Honor Book and case has been designed and executed by the staff and students of the Technical Art School, and the engrossing of the names and miliatary records will proceed with as soon as possible. The Ballarat Technical Art School and was involved with the design and manufacture of numerous WW1 memorials. When it came time to complete their own memorial, the Principal died, and the Honor Roll must have been overlooked in the confusion that ensued. There have been numerous theories about why the Honor Roll was never completed, one being that it was because the SMB Principal, Maurice Copland, literally worked himself to death organising repatriation classes for ex-soldiers who attended SMB. The Courier of 18 November 1922 said of Maurice Copland: “He put his very best into the work for the welfare of the soldiers; in fact, he did too much for the good of his physique, for he wore himself out in the services of the returned men. If ever there was a war victim the late Mr Copland was one. But for the stress of work entailed by those repatriation classes and the amount of general war work which he performed Mr Copland would probably have been with them today." Understandably, SMB was thrown into some disarray by their Principal's death and the Honor Book was not completed. The University of Ballarat would like to finally honor its SMB war veterans by completing the Honor Book and as a further mark of respect, dedicate the project to Maurice Copland. The Ballarat Technical Art School undertook many honor boards. The Ballarat School of Mines Annual Report 1918 states: "Under the direction of the Art Principal (Mr H.H. Smith), the work of the Art School continues to receive a wide public recognition. handsome Honor Boards have been designed and executed for the Sydney Sports' Club, the St Arnaud High School, the Birregurra State School, the wendouree State School and the Ballarat Old Colonists' Club. The School also designed certificates for the Young Workers' patriotic Guild, the "Herald" Shield for perpetual Competition at the Technical schools athletics meetings, the "Hansen" Shield for competition in the northern District High Schools, two metal tablets for the Castlemaine High School, and a certificate for the Grampians Secondary Schools' Association. Numerous Honor Gooks and mural cases have also been designed for State Schools." The 1920 Ballarat School of Mines Annual Report stated: Public appreciation of the High standard of design and artistic craft work produced by the students of the Art School, under the direction of the Principal (Mr Herbert H. Smith), continues to be demonstrated by the lage number of important commissions entrusted to the school, not only by the public bodies and business firms by the Education Department and public bodies all over the State." "Amongst the important local commissions received during the year was the designing and supplying of the Municipal Council's Address of Welcome Casket for presentation to His Royal Highness the Prince of Wales, the designing and supervising of a large four-light stained glass window for the Lydiard Street Methodist Church, ... and supply numerous honor books, honor boards, etc., for public institutions and school." "The School has been honored by, and has acceded to the request of the Education Department to supply designs for the title page, chapter headings and initial letters for the War Service Book which it is about to publish, Mr F. Tate, director of Education, recognising the students' work in this direction by an appreciative letter of thanks. The Education Department has also been instrumental in directing to the School applications from all parts of the State, including Melbourne, for the School to supply competitive sports shields, honor boards, books and designs for certificates, and various decorative objects. The School has therefor been responsible for much work coming to local Ballarat firms which would otherwise have found its way to Melbourne or other centres. In 2011, as the result of a 'Restoring Community War Memorials Grant' calligrapher Lynton Forrester was commissioned to record over 400 names into the honor book. A red leatherbound Ballarat School of Mines Honor Book. The book includes a title page relating to the Ballarat School of Mines and Industries. The Ballarat School of Mines Honor Book was not finally inscribed with names until 2011-2012. world war one, ww1, ballarat school of mines, world war 1, world war i, honour roll, calligraphy, don johnston, honor book, honor roll, copeland, maurice copeland, honour book, roll of honour, percy coltman, arthur e. tandy, leslie coulter -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBiscuit Forcer

... baking woman s work appliances Tin/metal outer cylinder/case/open ...Dough was put in forcer/case/cylinder and wooden pin pressed down to force dough out as a star-shaped biscuit. In use in a working-class home in the mid 20th century.Representative of kitchen utensils in common use in working class kitchens in 20th century prior to the common availability of packaged biscuits. Tin/metal outer cylinder/case/open one end, lid other end, with star pattern (can be removed for washing). Inner wooden pin or forcer, knob on end to be pushed into metal cylinder to force dough out through patterned disc.domestic, kitchen, food, technology, biscuit, forcer, baking, woman s, work, appliances -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeInk-well, ceramic insert, steel-nib pen

This ink-well was used in the Bacchus Marsh Court House, possibly for book-keeping and/or for court records. This type of ink-well and pen were in use everywhere in schools, businesses, courts, etc before the invention of the type-writer and the ball-point pen. Clerks were usually male and a good copperplate hand-writing was admired. Ink was often mixed by hand used a powdered ink mixed with water.Of local significance in the history of the town of Bacchus Marsh.Round pewter ink-well, with hinged lid and ceramic insert. Five round holes pierced in inner rim of metal to hold pens. Two ribbed bands around exterior of pot. Two bands indented around top of lid. Insert designed to hold ink. Pen with marbled blue handle, metal nib holder and metal nib.Indecipherable imprint on bottom of pot, possibly machine markings. Illegible written marks on side of pewter pot. Ceramic insert marked on side and bottom by red and black ink.ink, ink well, hand writing, record keeping, pens, nibs, clerical work, court records -

Gippsland Vehicle Collection

Gippsland Vehicle CollectionBelsize Wheel Nut, Belsize Motors Limited, Early twentieth century

This wheel nut was found in a long abandoned car yard (Gino's) located in Maffra, Gippsland, and it belonged to a car from the Belsize Motorcar Company (England). A then local man, Frank Straw who found the wheel nut (in 1968) is the grandson of John Hughes. The latter did an apprenticeship as a coachbuilder with the Belsize Company of Manchester, England. He then emigrated (with his wife) to Australia in 1910 and settling in Maffra opened a coachbuilder's shop . He told his grandson that seven Belsize cars came to Australia and that one made its' way to Maffra where John Hughes worked on it at his shop. John Hughes). Old gold coloured Belsize Wheel Nut (metal) and mounted on a rectangular block of wood.Wheel nut is inscribed as follows: BELSIZE in middle of nut surrounded by four (one in each corner) decoration emblems (as seen in photo) surrounded by a gold circle. Around the outside of the circle are the words Belsize Motors Limited -an asterisk at the beginning and end of the company name. Outside the circle at the bottom is the word MANCHESTER. Around the edge of the top of the wheel nut are two gold line circles. -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, George Coop, Interior of a Red Rattler Tait train passenger carriage, 22 August 1983, 1983

Note the graffiti. Older 20th.c and earlier railway cars were rolling palaces of the cabinet makers art. Full of polished timber, plated & embossed metal fittings, soft upholstery & beveled glass. In their earliest form, the Tait’s and earlier swing door cars for even modest suburban work, reflected some level of this design approach. Plus of course large sepia toned photographs on dividing walls displaying tourist spots trains could take you to.Digital TIFF file Scan of 35mm Kodak Safety 5062 black and white transparencygraffiti, interior, passenger carriage, red rattler, tait train -

Glen Eira Historical Society

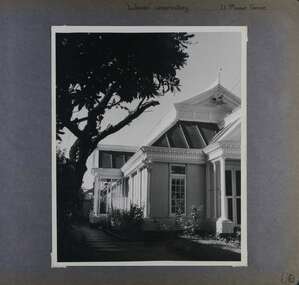

Glen Eira Historical SocietyAlbum - Album page, Labassa Conservatory, 21 Manor Grove, Circa 1972

This photograph is part of the Caulfield Historical Album 1972. This album was created in approximately 1972 as part of a project by the Caulfield Historical Society to assist in identifying buildings worthy of preservation. The album is related to a Survey the Caulfield Historical Society developed in collaboration with the National Trust of Australia (Victoria) and Caulfield City Council to identify historic buildings within the City of Caulfield that warranted the protection of a National Trust Classification. Principal photographer thought to be Trevor Hart, member of Caulfield Historical Society. Most photographs were taken between 1966-1972 with a small number of photographs being older and from unknown sources. All photographs are black and white except where stated, with 386 photographs over 198 pages. WHAT IS SIGNIFICANT? [From Victorian Heritage Database citation for Former Labassa Conservatory - H2005 Victorian Heritage Register http://vhd.heritage.vic.gov.au/places/result_detail/12504 (25/01/2021)] The former Labassa Conservatory is believed to have been built as part of the extensive reworking of the Labassa estate in c1890 for the new owner Alexander Robertson, proprietor of the Cobb and Co line. Robertson commissioned the architect JAB Koch to remodel the house, and Koch may have been responsible for the conservatory as well. Alternatively, the conservatory may have been imported. The gates installed at Labassa in 1890 were manufactured by the MacFarlane foundry of Glasgow, Scotland, a firm known to have manufactured conservatories. Around 1917 the glass house from 'Labassa', Caulfield was offered for sale to Malvern Council for its own gardens but the offer was declined. Following subdivision of the Labassa estate in the 1920s the conservatory was converted into a residence. The structure has a simple rectangular plan, with a brick base and superstructure of cast iron columns and roof trusses. The hipped roof is surmounted by an elaborately decorated gable structure. Most of the original glass has been replaced by metal sheeting. The decoration comprises pressed metal fascias including an egg and dart style cornice moulding, mullion mouldings and gable end panels with a rising sun motif. Cast iron ridgework and finials add to the lively roof form. Internally the floor appears to have been raised as part of the conversion work to a residence, and stained timber panelling introduced to provide room spaces. Boilers probably heated the conservatory in the colder months, but these do not survive.From Victorian Heritage Database citation for Former Labassa Conservatory - H2005 http://vhd.heritage.vic.gov.au/places/result_detail/12504 (25/01/2021) HOW IS IT SIGNIFICANT? The former Labassa Conservatory is of historical and architectural significance to the State of Victoria. WHY IS IT SIGNIFICANT? The former Labassa Conservatory is historically significant for its associations with the Labassa estate. Subdivision of the estate separated a number of outbuildings from the mansion. The former conservatory is significant as part of the large scale improvements carried out to the estate in the 1890s. The nineteenth century was the great age of conservatory designs, enabled by technological developments in heating, glazing and iron. Whilst conservatories were common in botanical gardens and universities, where they were primarily used for cultivating, studying, and experimenting with plants, they had also become an accessory of the wealthy on private estates. The former Labassa conservatory is architecturally significant as a rare example of a building type. Many Victorian mansion houses had attached conservatories, but detached conservatories were much less common. The only other detached example associated with a residence known to survive on its original site in Victoria is an earlier example at Warrock homestead, near Casterton. Conservatories attached to nineteenth century mansions are far more numerous. The Labassa example is very ornate, and its decoration draws on the versatility of pressed metal and cast iron. This highlights the dual purpose of the conservatory, as both a functional structure and a picturesque building on the Labassa estate. This building is unusual as an example converted to residential use. Page 130 of Photograph Album with one portrait photograph of Labassa's conservatory.Handwritten: "Labassa" conservatory 21 Manor Grove [top right] /130 [bottom right]bracketed eaves, caulfield north, labassa, balaclava road, orrong road, sylliott hill, alexander william robertson, ontario, john a. b. koch, john boyd watson, mouldings, 1920's, la bassa, manor grove, st kilda east, architects, john koch, greenhouses, gardens, plants, land subdivisions, gates, macfarlane foundry, brick, cast iron work, hipped roofs, gables, 1890's -

Glen Eira Historical Society

Glen Eira Historical SocietyPhotograph, Beauville Avenue, 28, Murrumbeena, 2001

Originally labelled "Beauville Estate, Established 1936, Still Thriving 65 years on, 10th March 2001", the Beauville Estate Album contains colour photographs of houses in the Estate. They were taken around the time of the Beauville Estate’s 65th Heritage Celebration held on 10/03/2001 and donated to the Caulfield Historical Society shortly afterwards. Photographer unknown.City of Glen Eira’s Heritage Management Plan Vol 2 p79 (this is p84 of the pdf version) – HO12 Beauville Estate and environs, Murrumbeena: The Beauville Historic Area is important at the State level as the first large housing estate undertaken by the AV Jennings Construction Co, later Jennings Group Limited, Victoria’s largest home builder. It is important also as a very early estate development incorporating a range of features other than houses and including made roads, shops and recreation facilities. In this respect it was the forerunner of the comprehensively planned housing estate of the post war era. The estate is distinguished by its aesthetic values, as is the earlier and comparable Hillcrest Estate, which are formed by a combination of restrained diversity in house styles, with the exception of no. 30 in the emerging International style, and by a landscaped garden environment. See Significance Statement in Glen Eira’s Heritage Management Plan by Andrew Ward (1996) Vol 2 p.79. Available from https://www.gleneira.vic.gov.au/media/4779/heritage_management_plan_volume_2.pdf (Note see p.84 of pdf)Colour photograph of unpainted variegated brown brick house with "Kileen 28" in cast iron on the front wall. Other features include a porch with white cast iron work door, tiled roof, chimney, striped window awnings and low unpainted brick fence with a brown metal letterbox in the foreground beside the driveway. The house has an unusual pitched roof with timber eave on the right side of the house.Kileen / 28murrumbeena, houses, beauville avenue, architectural styles, 1930's, inter war style, a.v. jennings, av jennings, jennings, brick houses, beauville estate, porches, arches, letterboxes, sir albert victor jennings, a v jennings construction co, beauville estate heritage area, glen eira city council, architectural features, jennings group limited, land subdivision, gardens, beauville historic area, cast iron work, house names, kileen, brick features, brick chimneys, striped awnings, brick fences, metal letterboxes, roofs -

Glen Eira Historical Society

Glen Eira Historical SocietyPhotograph, Beauville Avenue, 33, Murrumbeena, 2001

... awnings sash windows brick walls metal letterboxes cast iron work ...Originally labelled "Beauville Estate, Established 1936, Still Thriving 65 years on, 10th March 2001", the Beauville Estate Album contains colour photographs of houses in the Estate. They were taken around the time of the Beauville Estate’s 65th Heritage Celebration held on 10/03/2001 and donated to the Caulfield Historical Society shortly afterwards. Photographer unknown.City of Glen Eira’s Heritage Management Plan Vol 2 p79 (this is p84 of the pdf version) – HO12 Beauville Estate and environs, Murrumbeena: The Beauville Historic Area is important at the State level as the first large housing estate undertaken by the AV Jennings Construction Co, later Jennings Group Limited, Victoria’s largest home builder. It is important also as a very early estate development incorporating a range of features other than houses and including made roads, shops and recreation facilities. In this respect it was the forerunner of the comprehensively planned housing estate of the post war era. The estate is distinguished by its aesthetic values, as is the earlier and comparable Hillcrest Estate, which are formed by a combination of restrained diversity in house styles, with the exception of no. 30 in the emerging International style, and by a landscaped garden environment. Colour photograph of unpainted variegated brown brick house with an arched porch, tiled roof, striped awnings, sash windows and low unpainted matching brick fence in the foreground with "33" on the brick pillar beside the driveway next to a low black cast iron gate. murrumbeena, houses, beauville avenue, architectural styles, 1930's, inter war style, a.v. jennings, av jennings, jennings, brick houses, beauville estate, porches, arches, sir albert victor jennings, a v jennings construction co, beauville estate heritage area, glen eira city council, architectural features, jennings group limited, land subdivision, gardens, beauville historic area, striped awnings, sash windows, brick walls, metal letterboxes, cast iron work -

Glen Eira Historical Society

Glen Eira Historical SocietyPhotograph, Beauville Avenue, 34, Murrumbeena, 2001

Originally labelled "Beauville Estate, Established 1936, Still Thriving 65 years on, 10th March 2001", the Beauville Estate Album contains colour photographs of houses in the Estate. They were taken around the time of the Beauville Estate’s 65th Heritage Celebration held on 10/03/2001 and donated to the Caulfield Historical Society shortly afterwards. Photographer unknown.City of Glen Eira’s Heritage Management Plan Vol 2 p79 (this is p84 of the pdf version) – HO12 Beauville Estate and environs, Murrumbeena: The Beauville Historic Area is important at the State level as the first large housing estate undertaken by the AV Jennings Construction Co, later Jennings Group Limited, Victoria’s largest home builder. It is important also as a very early estate development incorporating a range of features other than houses and including made roads, shops and recreation facilities. In this respect it was the forerunner of the comprehensively planned housing estate of the post war era. The estate is distinguished by its aesthetic values, as is the earlier and comparable Hillcrest Estate, which are formed by a combination of restrained diversity in house styles, with the exception of no. 30 in the emerging International style, and by a landscaped garden environment. Colour photograph of white rendered, corner house with unpainted variegated brown brick features. Other features include a wide arched porch, tiled roof, tall brick chimney, cast iron work black porch door, window awnings and low unpainted matching brick fence in the foreground with "34" on the white metal letterbox on top of the right brick pillar beside the concrete pathway leading to the porch. Well-established garden including 2 matching pencil pines.murrumbeena, houses, beauville avenue, architectural styles, 1930's, inter war style, a.v. jennings, av jennings, jennings, brick houses, beauville estate, porches, sir albert victor jennings, a v jennings construction co, beauville estate heritage area, glen eira city council, architectural features, jennings group limited, land subdivision, gardens, beauville historic area, rendered houses, corner houses, brick features, awnings, brick fences, metal letterboxes, trees, cast iron work door -

Glen Eira Historical Society

Glen Eira Historical SocietyPhotograph, Lindsay Avenue, 42, Murrumbeena, 2001

Originally labelled "Beauville Estate, Established 1936, Still Thriving 65 years on, 10th March 2001", the Beauville Estate Album contains colour photographs of houses in the Estate. They were taken around the time of the Beauville Estate’s 65th Heritage Celebration held on 10/03/2001 and donated to the Caulfield Historical Society shortly afterwards. Photographer unknown. City of Glen Eira’s Heritage Management Plan Vol 2 p79 (this is p84 of the pdf version) – HO12 Beauville Estate and environs, Murrumbeena: The Beauville Historic Area is important at the State level as the first large housing estate undertaken by the AV Jennings Construction Co, later Jennings Group Limited, Victoria’s largest home builder. It is important also as a very early estate development incorporating a range of features other than houses and including made roads, shops and recreation facilities. In this respect it was the forerunner of the comprehensively planned housing estate of the post war era. The estate is distinguished by its aesthetic values, as is the earlier and comparable Hillcrest Estate, which are formed by a combination of restrained diversity in house styles, with the exception of no. 30 in the emerging International style, and by a landscaped garden environment. Colour photograph of an unpainted variegated brown brick house. Other features include an open porch with brick pillar and white trellis on one wall, tiled roof, white sash windows, feature brick wide and tall chimney and low unpainted brick fence with "42" on the wooden letterbox atop the brick pillar alongside a black metal gate in the foreground.42murrumbeena, houses, architectural styles, 1930's, inter war style, a.v. jennings, av jennings, jennings, brick houses, beauville estate, porches, lindsay avenue, sir albert victor jennings, a v jennings construction co, beauville estate heritage area, glen eira city council, architectural features, jennings group limited, land subdivision, gardens, beauville historic area, brick features, chimneys, sash windows, brick fences, cast iron work -

Glen Eira Historical Society

Glen Eira Historical SocietyPhotograph, Dalny Road, 11, Murrumbeena, 2001

Originally labelled "Beauville Estate, Established 1936, Still Thriving 65 years on, 10th March 2001", the Beauville Estate Album contains colour photographs of houses in the Estate. They were taken around the time of the Beauville Estate’s 65th Heritage Celebration held on 10/03/2001 and donated to the Caulfield Historical Society shortly afterwards. Photographer unknown. City of Glen Eira’s Heritage Management Plan Vol 2 p79 (this is p84 of the pdf version) – HO12 Beauville Estate and environs, Murrumbeena: The Beauville Historic Area is important at the State level as the first large housing estate undertaken by the AV Jennings Construction Co, later Jennings Group Limited, Victoria’s largest home builder. It is important also as a very early estate development incorporating a range of features other than houses and including made roads, shops and recreation facilities. In this respect it was the forerunner of the comprehensively planned housing estate of the post war era. The estate is distinguished by its aesthetic values, as is the earlier and comparable Hillcrest Estate, which are formed by a combination of restrained diversity in house styles, with the exception of no. 30 in the emerging International style, and by a landscaped garden environment. Colour photograph of an unpainted variegated brown brick house with decorative brickwork. Other features include tiled roof, enclosed porch with an arched entrance and black metal lantern, garden and a low unpainted brick fence in the foreground with a cast iron work letterbox on top.murrumbeena, houses, architectural styles, 1930's, inter war style, a.v. jennings, av jennings, jennings, brick houses, beauville estate, dalny road, porches, sir albert victor jennings, a v jennings construction co, beauville estate heritage area, glen eira city council, architectural features, jennings group limited, land subdivision, gardens, beauville historic area, brick features, brick fences, arches, cast iron work, letterboxes -

Glen Eira Historical Society

Glen Eira Historical SocietyPhotograph, Dalny Road, 11, Murrumbeena, 2001

Originally labelled "Beauville Estate, Established 1936, Still Thriving 65 years on, 10th March 2001", the Beauville Estate Album contains colour photographs of houses in the Estate. They were taken around the time of the Beauville Estate’s 65th Heritage Celebration held on 10/03/2001 and donated to the Caulfield Historical Society shortly afterwards. Photographer unknown. City of Glen Eira’s Heritage Management Plan Vol 2 p79 (this is p84 of the pdf version) – HO12 Beauville Estate and environs, Murrumbeena: The Beauville Historic Area is important at the State level as the first large housing estate undertaken by the AV Jennings Construction Co, later Jennings Group Limited, Victoria’s largest home builder. It is important also as a very early estate development incorporating a range of features other than houses and including made roads, shops and recreation facilities. In this respect it was the forerunner of the comprehensively planned housing estate of the post war era. The estate is distinguished by its aesthetic values, as is the earlier and comparable Hillcrest Estate, which are formed by a combination of restrained diversity in house styles, with the exception of no. 30 in the emerging International style, and by a landscaped garden environment. Colour photograph of an unpainted variegated brown brick house with decorative brickwork. Other features include tiled roof, enclosed porch with an arched entrance and black metal lantern and open window on the left side , garden, drive and a low slightly damaged unpainted brick fence with cast iron work railing in the foreground with a cast iron work letterbox on top.11murrumbeena, houses, architectural styles, 1930's, inter war style, a.v. jennings, av jennings, jennings, brick houses, beauville estate, dalny road, porches, sir albert victor jennings, a v jennings construction co, beauville estate heritage area, glen eira city council, architectural features, jennings group limited, land subdivision, gardens, beauville historic area, brick features, arches, cast iron work, letterboxes, brick walls -

Federation University Historical Collection

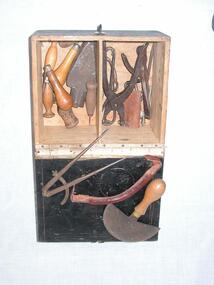

Federation University Historical CollectionTool - Leatherwork Toolkit, Leatherwork Toolkit in Timber Box, c1920

Thought to have been used in shoemaking classes held for repatriated soldiers at Ballarat School of Mines. At the Ballarat Technical Art School, during the early twentieth century, leather art was popular but had little industrial value and was usually a minor study. The Victorian Education Department set examinations in art leather work. Copies of many Technical School Examination Papers are kept within the University's historical collection.Black wooden box with metal latch and handle. Contains assortment of tools, some with timber handles, some metal. Two halves inside box. Lid is attatched by canvas nailed to bottom. leather, tools, box, world war one, ballarat school of mines, shoemaking, bootmaking, bootmaker, leatherwork, repatriation -

Flagstaff Hill Maritime Museum and Village

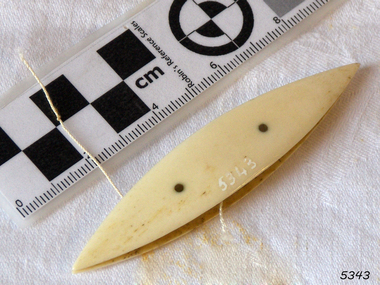

Flagstaff Hill Maritime Museum and VillageDomestic object - Tatting Shuttle, Aero Needles Group Ltd, Mid to late 20th century

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots.The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century.Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic (as is item 8535.1). The second type has a post in the center where the thread is wound (e.g. item 8535.2). The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace. One type of tatting shuttle produced by "Aero" from the 1930's to the late 1960's was an anodized grey coated aluminium shuttle with a sharp pick at one end. In the 1970's it was superseded by the grey plastic "Aero" which has a removeable bobbin which you can put on the end of the shuttle to make thread winding easier and an embedded crochet hook for joining picots. The "Aero" company developed in Redditch, England - a town renowned as a centre for manufacturing needles. Firms run by Henry Milward and Abel Morrall were based in Redditch and by the 18th century Redditch was manufacturing one million sewing needles per year. Abel Morrall Ltd launched the "Aero" brand in 1936 and greatly expanded the firm's product line to include tatting shuttles and knitting needles. The classic plastic "Aero" tatting shuttle was manufactured in England from the early 1970's until the 1990's. These items are significant as examples of easily accessible handiwork tools that enabled women in the 1930s -1960s to be able to decorate and personalize their household linen and clothing.Shuttle no. 8535.1 is a beige, boat shaped plastic shuttle with enclosed ends, small round central indentations on both sides and an enclosed black removeable bobbin. The shuttle has a grooved point at one end to hold a bobbin and a small metal crochet hook at the other end. Shuttle no. 8535.2 is a beige, boat shaped metal shuttle with pointed ends that are open but snug, small round central indentations and two smaller circular markings (on both sides) and two internal posts with cream thread wound around.Shuttle no. 8535.1 - "AERO" / "ENGLAND" Shuttle no. 8535.2 - "AERO' / "ENGLAND" "39c" (written in ball point pen)flagstaff hill maritime museum and village, flagstaff hill, warrnambool, shipwreck coast, great ocean road, tatting shuttle, aero company, handwork, handwork tool, craft, handcraft, needlework, tatting -

Federation University Historical Collection

Federation University Historical CollectionTool, British Oxygen Company Ltd, Oxy-cutting and Welding Blow Pipes, c 1904

In 1903 the oxyacetylene welding process was developed. Around the same time, new cryogenic air separation processes, based on work undertaken by Carl von Linde and others, replaced the barium oxide process. This paved the way for larger scale and more efficient production. British Oxygen Company, [1905 to 1969] was formally BRIN'S Oxygen Company Ltd from 1886 to 1905. In 1969 it became BOC. These Blowpipes were used at the Ballarat School of Mine c1916 Interesting article = 1917. https://trove.nla.gov.au/newspaper/article/1629321Boxed Universal Blow Pipe, presented under a perspex top. Pipes mounted by metal bar and hooks to polished wooden board. Display case is 69.0cm x 12.0cm x 25.0cmBoth pipes have metal plates indicating information of maker.blowpipes, ocyacetylene, ballarat school of mines, welding, cutting, commonwealth industrial gases, boc, brin's oxygen company, british oxygen company -

Federation University Historical Collection

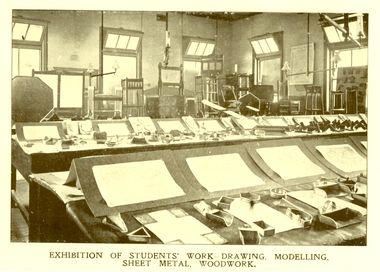

Federation University Historical CollectionPhotograph - Image - black and white, Ballarat Junior Technical School Exhibition of Student Work, 1914, 1914

Ballarat Junior Technical School was a division of the Ballarat School of Mines. During this era the Ballarat Junior Technical School was located at the Dana Street Primary School and was in its second year of operation.Exhibition of Ballarat Junior Technical School Sloyd work, including drawing, modelling, sheet metal and woodwork. ballarat junior technical school, ballarat school of mines, education, trade, sloyd, drawing, modelling, metalwork, sheet metal, woodwork, classroom, dana street primary school, exhibition -

Federation University Historical Collection

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894