Showing 106 items matching "c wheeler"

-

Moorabbin Air Museum

Moorabbin Air MuseumBook - MILITARY AIRCRAFT MARKINGS & PROFILES, BARRY C WHEELER, 1990

... BARRY C WHEELER... AIRCRAFT MARKINGS & PROFILES BARRY C WHEELER Golden Press Pty Ltd ... -

Narre Warren and District Family History Group

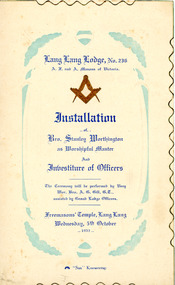

Narre Warren and District Family History GroupProgramme, Masonic Lodge Lang Lang No 236 Installation of Bro. Stanley Worthington dated Wednesday 5th October 1932

... C Wheeler... A Tomlison A H Turner T R Vizard C Wheeler J A Wiltshire E N Wiseman ...Booklet produced by the Lang Lang Masonic Lodge 236 on the occasion of the Installation of Bro. Stanley Worthington as Worshipful Master and Investiture of Officers 5 October 1932. Booklet is made up of one page folded in half to make up four pages, and is made of thickened cream paper with a frilled edge on the front page. Front page shows the masonic square and compass symbol in gold print, with information on the ceremony in blue ink, surrounded by a raised embossed border. All text printed in blue ink. Page 2 lists past masters from 1915 to 1931.Page 3 is titled The Festive Board and page 4 has a list of officers 1932-33.dr s t appleford, g r burhop, herbert clark, w cole, w p cole, w r l currie, frank m dale, m f dale, m dally, joseph f davis, w eason, a g gill, g t gill, a g glasscock, len greaves, wallace g greaves, e chas hartshorne, r hawley, n jaboor, chas jones, w h koetsveld, lang lang masonic lodge, jas longmuir, p j mcgay, d n mcmillan, c potter, wm c sim, h thomas, keith thomson, wm c tibballs, w a tomlison, a h turner, t r vizard, c wheeler, j a wiltshire, e n wiseman, stanley wothington -

Leopold Tennis Club

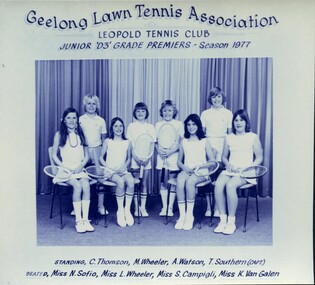

Leopold Tennis ClubPhotograph, Robert Pockley Studios, Geelong Lawn Tennis Association Leopold Tennis Club Junior D3 Grade Premiers - Season 1977, 1977

... Standing: C. Thomson, M. Wheeler, A. Watson, T. Southern... Geelong Lawn Tennis Association C Thomson M Wheeler A Watson T ...Image taken of the Geelong Lawn Tennis Association Junior D3 Grade Premiers for Season 1977.1 photograph of Premiership tennis teamStanding: C. Thomson, M. Wheeler, A. Watson, T. Southern (Capt.) Seated: Miss N. Sofio, Miss L. Wheeler, Miss S. Campigli, Miss K. Van Galenleopold tennis club, geelong lawn tennis association, c thomson, m wheeler, a watson, t southern, n sofio, l wheeler, s campigli, k van galen -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumCertificate, Certificate of Discharge Sergeant Wheeler, 27 February 1946

... sgt c l wheeler... sgt c l wheeler Wood framed photocopy of a certificate ...The recipient of the Certificate of Discharge, SGT. Wheeler C.L. V374575, served in the Volunteer Defence Corps on part time war service. Clarrie Wheeler was a local (Tatura) Farmer, married to May Wheeler.Wood framed photocopy of a certificate of discharge with crest of Australia at top & signatures at bottom. Black printing. No 39219certificates, raaf, certificate of discharge, sgt c l wheeler -

Supreme Court of Victoria Library

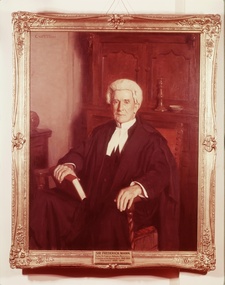

Supreme Court of Victoria LibraryPortrait, Sir Frederick Mann

... Signed upper left C. Wheeler. Plaque identifies Sir... left C. Wheeler. Plaque identifies Sir Frederick Mann, the Hon ...The portrait was presented by the legal profession ot the Court in 1946. It would appear to have been commissioned at the time of Chief Justice Mann's retirement. Charles Wheeler, had won the Archibald prize in 1933 and was the head of the art gallery schools during World War two. Chief Justice Sir Frederick Mann (1869-1958) studied the law and worked at the Crown Law Department before his stint in the Army during the Boer War. After the war, he practised as a barrister, mainly working in the common law and equity area including appearences in the High Court on constitutional matters. He was appointed to the bench in 1919 along with William Schutt, to help remedy a shortfall in the number of judges on the Bench, after measures of economy during World War One. He became Chief Justice in 1935 following the retirement of Sir William Irvine, and retired in 1944.The portrait is of interest because of whom it portrayed, it is a well executed work by a well known artist of the period.Half Length portriat painting in oils of Sir Frederick Mann, seated and balancing a book on his knee. He sits of a chair with carved arms. The frame is painted dull gold.Signed upper left C. Wheeler. Plaque identifies Sir Frederick Mann, the Hon. Sir Frederick Wollaston Mann, KCMG, a Justice of the Supreme Court 1919-1935, Chief Justice 1935-1944 -

Whitehorse Historical Society Inc.

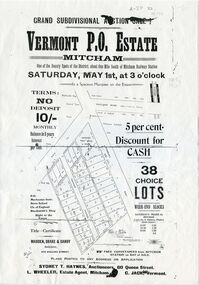

Whitehorse Historical Society Inc.Document, Vermont P.O. Estate, 1926 0r 1915

... lots, 1 May 1920. Auctioneers: Sydney T. Haynes, L. Wheeler.... Haynes, L. Wheeler, C. Jack. Vermont P.O. Estate Document ...Brochure advertising auction of Vermont P.O. EstateBrochure advertising auction of Vermont P.O. Estate, 38 lots, 1 May 1920. Auctioneers: Sydney T. Haynes, L. Wheeler, C. Jack.Brochure advertising auction of Vermont P.O. Estateauctions, vermont post office estate, canterbury road, vermont, boronia road, frances avenue -

Ringwood and District Historical Society

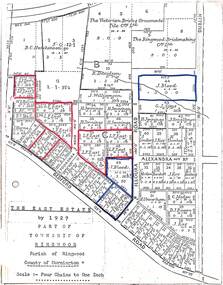

Ringwood and District Historical SocietyMap, The East Estate, Township of Ringwood, Victoria - 1927

... . Burchett, B.J. Hosking, D.J. Rogers, C. Wheeler, H. Frost, G.G.... Burchett, B.J. Hosking, D.J. Rogers, C. Wheeler, H. Frost, G.G ...Photocopied page - partial Parish map of Ringwood labeled The East Estate, showing street names and properties marked with names of individual owners or businesses.Page titled The East Estate by 1927 Part of Township of Ringwood, Parish of Ringwood, County of Mornington, Scale: Four Chains to One Inch. L.F. East blocks are marked by red outline. J. Blood blocks are marked by blue outline. Other names include B.C. Hutchinson & Co., The Victorian Brick & Ornamental Tile Coy., Ltd., The Ringwood Brickmaking Coy., Ltd., R. Davidson, J. Williamson, W.E. Bower, H. Jennings, G.J. Sims, J. Smallman, J. Horne, J. Lindsay, J. Kay, H. Unverhan, B.C. Hutchinson, M.A. Williamson, J.S. Woodworth, J. Price, C. Medew, S.W. Burchett, B.J. Hosking, D.J. Rogers, C. Wheeler, H. Frost, G.G. Miller, L. Winchcombe. Streets include Dublin Road, Illoura Road, Alexandra Road, and Bedford Road. -

National Wool Museum

National Wool MuseumSpinning Wheel

... Fabb purchsed the wheel c. 1985-1990 from a secondhand/antique... Fabb purchsed the wheel c. 1985-1990 from a secondhand/antique ...The wheel came in a container from Liechenstein - Anitque Export Establishment (P.O. Box 21 498, FI - 9493 Mauren, Liechtenstein). It came with a number of dressers and tables. The flax on the original bobbin was present when Mrs Fabb purchased the wheel. Mrs Fabb purchsed the wheel c. 1985-1990 from a secondhand/antique shop in Para Road, Greensborough, Melbourne. The wheel was repaired by Mr Carrington (Zakrzewski) He made two more bobbins and the last piece on the distaff (which was missing when Mrs Fabb acquired it).W7230 Email dated 09 May 2008 regarding donation of spinning wheel from Felicity Ellis to Lynette Christiehandicrafts - history flax, spinning wheels, spinning, zakrzewski, mr wlodzimierz, denmark, handicrafts - history, flax -

Orbost & District Historical Society

Orbost & District Historical Societysewing machine, late 1860's - 1870's

... . It has a backwards C-shaped body. The wheel and base... machine. It has a backwards C-shaped body. The wheel and base ...The early settlers of Orbost had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. Many women were skilled dressmakers and craft workers. This item reflects that time.A small black hand-cranked lockstitch sewing machine. It has a backwards C-shaped body. The wheel and base are decorated with a gold pattern. On the end above the needle assembly is a brass plate The balance wheel has a handle. The pattern on the wheel is a gold border with two gold, red and green stars formed by interwoven triangles. On the cloth plate is stamped "Patent March 1867 Heron Gresham" with some indecipherable marks.sewing-machine needlework -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Photograph - Cissie Johns in jinker, c.1913

... the driveway, partly obscured by the jinker's wheel. Dated c.1913. ... the driveway, partly obscured by the jinker's wheel. Dated c.1913 ...B&W photo shows Cissie Johns and another person who may be her brother Percy, sitting in a jinker. A dark horse with a white blaze is harnessed to the jinker. Cissie is seated nearest the camera. She is wearing a pale wide-brimmed hat and pale clothing. Her long fair hair is loose around her shoulders. The other person is holding the reins and is wearing a dark hat and pale shirt. This photo may have been taken at the same time as M0104. The subjects are facing south. The sun is shining. They are on a flat expanse of grass. Beyond them are several cypress trees. These are most likely part of the cypress hedges lining the driveway to Glen Park Farm farmhouse. In the background is the eastern flank of Black Hill. A small shed can be seen beside the driveway, partly obscured by the jinker's wheel. Dated c.1913. -

Puffing Billy Railway

Puffing Billy RailwayD21 - Diesel Mechanical locomotive, 1968

... : Gardner 8L3 (V) or Gardner 6L3 (VA) Wheel Arrangement: - C...) or 114kW (153hp) Motor: Gardner 8L3 (V) or Gardner 6L3 (VA) Wheel ...D21 - Diesel Mechanical locomotive Date built - 1968 Original owner - TGR Original gauge - 1067mm Withdrawn - 1983 Built to 3'6" gauge in 1968 by the Tasmanian Government Railways and numbered V12, ownership of this Diesel Mechanical locomotive was transferred to Australian National Railways (Tas.) in 1978. It was withdrawn and sold to the E.T.R.B. in 1983 1968 - D21 ex-Tasmanian Government Railways (TGR) V class No.12, built by the TGR Launceston Workshops in 1968 to a design of Vulcan-Drewry (England). Tasmanian Government Railways V class The V class were the first diesel locomotives operated by the Tasmanian Government Railways (TGR) with four delivered by the Vulcan Foundry in 1948 to a design by the Drewry Car Co. They were a narrow gauge version of the British Rail Class 04. In 1951 a fellow two were delivered followed by another two in 1955. Between 1959 and 1968 the TGR built a further four at its Launceston Workshops. Two identical locomotives were purchased by the Mount Lyell Mining and Railway Company in 1953. When it closed in 1963, 2405 was sold to the Emu Bay Railway as number 22, while 2406 went to the TGR as V13. All the TGR units were withdrawn between 1983 and 1987 while the Emu Bay unit remained in service until 2000. Ten have been preserved: V1 by the Bellarine Peninsula Railway, Victoria V2 by the Don River Railway V4 by the Hotham Valley Railway, Western Australia V5 by the Hotham Valley Railway, Western Australia V7 by the Derwent Valley Railway V8 by the Bellarine Peninsula Railway, Victoria V9 by the West Coast Wilderness Railway V12 by the Puffing Billy Railway, Victoria (regauged to 760 mm gauge and numbered D21) V13 by the Zig Zag Railway, New South Wales, sold to the West Coast Wilderness Railway, renumbered D2 22 by the West Coast Wilderness Railway, renumbered D1 Tasmanian Government Railways V class Manufacturer Vulcan Foundry Tasmanian Government Railways Entered service 1948 Number built 14 Number preserved 10 Fleet numbers TGR: V1-V13 Emu Bay: 22 Power: 152kW (204hp) or 114kW (153hp) Motor: Gardner 8L3 (V) or Gardner 6L3 (VA) Wheel Arrangement: - C - Weight: 25.6t Allowable load on 1:40 grade: 170t Length over headstocks: 6.8m (22ft 6in) Introduced: 1948 Built By: Vulcan Foundry, England; TGR Workshops, Launceston; Using parts supplied by Drewry Car Co (UK) Number Preserved: 10 Number In Service: 0 Total Number Built: 14Historic - Tasmanian Government Railways - Diesel Mechanical locomotive - V12 / Puffing Billy Railway Diesel Mechanical locomotive D21D21 - Diesel Mechanical locomotive made of steel D21diesel mechanical locomotive, puffing billy, d21, v12 diesel mechanical locomotive, d21 diesel mechanical locomotive, tasmanian government railways -

Wangaratta High School

Wangaratta High SchoolWHS Sporting Honour Board, 1985-2013

... . GANNON K. WHEELER C. FURZE K. WHITE C. WHITE H. OLIVER.... USSHER K. KIKER Jnr 2000 A. POTTER S. GANNON K. WHEELER C. FURZE ...Square wooden honour board with gold text, cut corners and a protrusion at the top with a simplified WHS logo and heading.JUNIOR HOUSE CAPTAINS YEAR OVENS KING MERRIWA WAREENA GIRLS BOYS GIRLS BOYS GIRLS BOYS GIRLS BOYS Jnr 1985 L. REID J. DOWLING M. FLYNN B. MARTIN J. FISHER J. BOULTON R. WARREN D. BARHAM Jnr 1986 K. DODSON C. LEWIS A. PLUMRIDGE J. HODSON J. FISHER J. ARCRI R. WARREN D. McDONALD Jnr 1987 S. SCHOLZ C. DERRICK T HEMPEL B. DERRICK M. WILLIAMSON M. DOBROWOLSKI J. BECHAZ S. CLAYTON Jnr 1988 K. McCORMACK A. CLARK M. IMRIE M. GREGORY J. O'FLYNN S. NORMAN M. HERTIC C. GOULD Jnr 1989 K. SOUTHERN L. SCHOLES D. McLAUGHLIN M. MOSCROP A. GREALY O. ROODENBURG H. NOLAN D. ILOTT Jnr 1990 J. SHERIDAN C. CLARK C. NORTON B. MORRIS G. WOODWARD D. PRESTON D. FRASCA A. ROSSER Jnr 1991 K. WELCH D. DEMAJ J. STEPHENS B. MORRIS K. JENKINSON P. FLYNN N. WILLIAMS A. ROSSER Jnr 1992 K. WELCH R. GRAHAM K. GLENISTER A. WISE L. REA D. FURNELL D. BIGGER R. JOHNSON Jnr 1993 R. STEFANIAC T. LEWIS C. HORN A. BARROW R. BARROW M. STAMP A. NOLAN A. WHOLERS Jnr 1994 B. SPASOJEVIC R. ROSSER M. CHILCOTT H. FULTON J. HARRISON S. HIBBERSON L. HILDEBRAND R. WOODWARD Jnr 1995 D. SMITHERAM D. FURSE M. CHILCOTT J. McCORMICK J. HARRISON D. CONSTANTINO S. KNOX A. BROWN Jnr 1996 D. SMITHERAM J. MULLINS K. DOUSSET J. FISHER K. GRAHAM S. CHALLMAN K. BREW D. OATES Jnr 1997 R. CONROY H. STAMP N. EVERITT M. BELL R. HOGARTH D. BREESE C. JONES J. DOODY Jnr 1998 J. MORONEY R. GLOVER L. RITCHENS T. LAMBERT E. BRIGGS J. PORTER M. DEFAZIO J. KIKER Jnr 1999 T. WINZER R. GLOVER K. GOODEY B. SOLIMO A. COOTE D. COOTE D. COLES J. USSHER K. KIKER Jnr 2000 A. POTTER S. GANNON K. WHEELER C. FURZE K. WHITE C. WHITE H. OLIVER A. SHELDRICK Jnr 2000 R. GILBERT R.GOLVER K. GOODEY B. SOLIMO G. JONES D. COLES A. NAISH C. DOUG Inter 2001 K. O'BRIEN S. GANNON K. WILLIAMS M. CONROY V. STEWART J. AMMITZBOLL H. OLIVER C. MANGUBAT Jnr 2002 J. BORDIGNON T. SORRAGHAN N. TAVARE M. ANDERSON B. KERLIN D. GAUT K. SURACE M. GLOVER Inter 2002 A. POTTER S. GANNON S. DAWS T. CHIVERS M. WATKINS D. MORGAN H. OLIVER J. PATRICK Jnr 2003 S. PENNY N. PORTER E. NEWMAN A. ROBERTSON S. McSWINEY B. REVELL K. SURACE B. McMILLAN Inter 2003 R. CLARKSON D. McCULLOUGH S. ANDERSON M. CONROY G. ATKINSON T. CROCKETT H. OLIVER D. SEYMOUR Jnr 2004 C. WESLEY R. STONE E. PANE J. DWYER G. BLANCH M. GATHERCOLE C. BODLER R. LUGG Inter 2004 A. VELJANOSKA D. McCULLOUGH N. TAVARE D. BAKKER E. HARRINGTON J. AMMITZBOLL M. BASSIER M. GLOVER Jnr 2005 E. KEIR J. PARTINGTON A. WESCOMBE J. SIRIANNI A. MARTIN R. ALLEN J. SCHULZ-BAHLEBURS D. SCOTT Inter 2005 J. ROBBINS T. STAFFORD E. PANE J. DWYER K. GRAHAM M. GATHERCOLE K. SURACE M. MACLEISH Jnr 2006 M. BRUCE S. ALDOUS H, PANE L. BRABAZON C. TYLER J. ANDERSON O. HUTCHINGSON B. MORTIMER Inter 2006 L. TINDILL J. DAVENPORT E. PANE D. MORGAN A. FULLER M. GATHERCOLE S. COOTE S. CARUSO DONATED BY P.A.S.T.A. 1988 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jar Base

Human beings appear to have been making their own ceramics for at least 26,000 years, subjecting clay and silica to intense heat to fuse and form ceramic materials. The earliest found so far were in southern central Europe and were sculpted figures, not dishes. The earliest known pottery was made by mixing animal products with clay and baked in kilns at up to 800°C. While actual pottery fragments have been found up to 19,000 years old, it was not until about ten thousand years later that regular pottery became common. An early people that spread across much of Europe is named after its use of pottery, the Corded Ware culture. These early Indo-European peoples decorated their pottery by wrapping it with rope, while still wet. When the ceramics were fired, the rope burned off but left a decorative pattern of complex grooves on the surface. The invention of the wheel eventually led to the production of smoother, more even pottery using the wheel-forming technique, like the pottery wheel. Early ceramics were porous, absorbing water easily. It became useful for more items with the discovery of glazing techniques, coating pottery with silicon, bone ash, or other materials that could melt and reform into a glassy surface, making a vessel less pervious to water. https://en.wikipedia.org/wiki/CeramicThe discovery and development of ceramics in numerous shapes, form and materials, revolutionised the world.White ceramic container, glazed with single groove around circumference near lipNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics -

Glen Eira Historical Society

Glen Eira Historical SocietyArticle - Joyous Gard

... Boroondara Cemetery Gilbert Web C Gilbert Webb The Wheel of Life ...Two copies of a one page photocopy from the book Australian Sculptors (1980) by Ken Scarlett, describing the Springthorpe Memorial at Boroondara Cemetery, Kew. The file also includes a photocopy of an article by Chrys Spicer, date and source unknown, about the Springthorpe Memorial. The article includes seven photographs of the memorial. A research note by Chloe Stapleton, dated 31/08/12, suggests a possible source for this article. The file also includes a copy of a typed letter from Allan M Doble to Melbourne University Art Curator Heather Lowe, dated 24/03/1995, concerning the history of the Wheel of Life Sculpture originally located at Joyous Gard. The file also includes a copy of a typed letter, dated 19/05/1995, from Allan Doble to the Melbourne University Gallery with information about the Wheel of Life sculpture Also included in the file are photocopies of two Melway maps showing the location of Joyous Gard and Springthorpe Reserve with notes by Allan Doble, dated 24/03/1995. The file also includes eight coloured photographs (100mm x 150mm) of the Wheel of Life sculpture now located in the Medical School of the University of Melbourne, date and photographer unknown, probably 1990s. Negatives are also included.springthorpe memorial, boroondara cemetery, gilbert web c, gilbert webb, the wheel of life, springthorpe john william, inglis annie constance, springthorpe dorothy, springthorpe annie constance, springthorpe enid, springthorpe lancelot, springthorpe guy, joyous gard, doble allan m, doble mrs allan, murrumbeena primary school, springthorpe reserve, joyous gard court, tyers s w, outer circle railway, boyd park, wahroonga crescent, murrumbeena, caulfield city council, boyd’s pottery, linear park -

Waverley RSL Sub Branch

Waverley RSL Sub BranchCalaid Hearing aid, ¬1955

Made by Commonwealth of Australia (Commonwealth Acoustic laboratories) to address the problem of providing hearing aids to ex-service men with impaired hearing due to war related events. They were issued by the then Repatriation Department a cheaper alternative to imported more expensive but lower quality units. The were also used for the large number of children who had impaired hearing due to the Rubella epidemic in Australia during WWII. http://www.acoustics.asn.au/journal/2000/2000_28_3_Upfold_Piesse.pdfIssued to Henry Claude Roussac a veteran of both WWI and WWIISteel square case with a white plastic thumb wheel with volume marks on the side and two holes for the insertion of the earpiece plug, front contains a small (10mm x 5mm) microphone covered by a wire grill.There is a small retaining clip on each side to clip the unit into a shirt pocketC of A CALAID D11849calaid, hearing aid, australian acoustic laboratories, roussac, gallipoli, repatriation department, cal -

Bendigo Military Museum

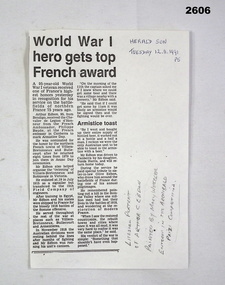

Bendigo Military MuseumNewspaper - NEWSPAPER CUTTING, Herald Sun, 12.11.1991

See also: 2605.2, 2607, 2608.3 Article details the awarding of the French Chevallier de Legion d'Honneur (Legion of Honour) to ARTHUR EBDON and the reason of awarding.Newspaper article reporting the awarding of the Legion of Honour to ARTHUR EBDON.Top RH corner: "Herald Sun Tuesday 12.11.1991 p5" Bottom RH corner: Life size portrait of "ARTHUR C EBDON painted by Mary Wheeler. Entered in Archibald prize Competition"documents - newspapers, military history, passchendaele barracks trust -

Federation University Historical Collection

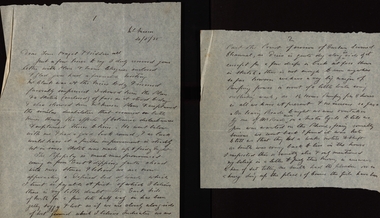

Federation University Historical CollectionLetter, Letters from Richard Squire to his son Tom 1935

In 1905 Richard Squire was manager of the West Berry Consols at Allendale, and developed an improved system of mine ventilation, which was supported in "The Age." He was successful in combating and remedying the gas and ventilation troubles of the Deep Mines of Creswick and Allendale Districts after all had failed. MINE MANAGERS’ ASSOCIATION. Ballarat Branch. ... Mr R. B. Squire, manager of the West Berry Consols, at Allendale, submitted a paper detailing what he had done tor the betterment of ventilation in the alluvial mines of Smeaton and Mary borough districts- Members gave Mr Squire every credit for the results that he claimed to have effected; the adoption of his ideas had testified to their value to mine-owners. It was painted out, however, that for want of a thorough debate of the subject with experienced men the author had unwittingly included some general statements that required modifying in some points and extending in others, in justice to other workers among the earlier and the present day managers of mines. It was decided to invite the author to meet a sub-committee on this subject!Various handwritten Letters from Richard Squire to his son Tom 1935richard squire, tom squire, hazel squire, jack squire, jim squire, ned, mt mercer, basil, plant, skids, pump, c. hayes, illness, poppet, carburetor, shaft, balance weight, pearson, pulleys, syndicate, goon, suction, lease, reports, estimates, flat fields, reef, banagwanth, trucks, pipeclay, sandstone, suction pipe, valves, honeycomb rock, mr kermode, yarrowee, ballarat, reef combs, cheques, earthquake, yellow slate, leigh river, dyke, the madame bay coy, allendale, berry west, quartz, ballarat deep leads, ballarat deep leads extension, bore, reads, bedrock, j. hayes, harmen premier distributors, middletons, cemented sand, electricity commission, g m of a, gold mines of australia, dick harry, pearsons, hawksburn, crown wheel, rice's paddock, liz the car, volcanic ridge, lrg coy, mcnaughton's paddock, madison's lead, cameron & sutherland, crabhole, rokewood, glenfine, mrs gibbs, dobson, booth, shiels, thomas mitchell, mcpherson's reward, haddon, trunk lead mine, elaine, pitfield plains, mr clarke, daylesford, kuchel, shelford, geoff squire, lode, quartz reef, bladder attack, kidneys, income tax, reginald murray, grenville, blasting, john b. dennison, martin t. taylor, durham and buninyong deep lead, sebastopol plateau, mr wilkie, the premier petrol distributing agency of ballarat, lawaluk, ryan's western leads, mr nichol, mr hodge, knox schlapp and co., dr griffiths, state accident insurance office, magdala mine stawell, mining -

Federation University Historical Collection

Federation University Historical CollectionBook, Education Department Certificates 1908 - 1922

School of Mines Ballarat was a predecessor of Federation UniversityBlack cloth covered book with handwritten pages and loose foolscap pages at the front and sticer on front cover with CERTIFICATES written on it.education department, school of mines ballarat, leslie bennett, eulali perry, hector osborne, doris mcdougall, mary mullins, john mclean, mary morrish, francis kelly, robert gullan, henry bull, clara clegg, john david, albert ferguson, ina westcott, vera walker, agnes walker, eileen tremain, florence smith, lizzie pier, annie reynolds, charles peverill, william pearson, doris patterson, rebecca mcphan, constance mchenry, jean mcgregor, florence mingst, gwen mann, roz kelly, edward jones, freddi jacobi, percy baker, doris carter, stephen chambers, ruth catt, arthur dousey, d'arcy, bessie doncaster, alan eggleston, lena featherstone, clarice fisher, sylvia williams, james walker, annie treloar, shearer, cora sandberg, elsie pearce, jan mcgregor, cyril mcgibbon, margaret moore, thomas kierce, william james, alice horan, lucy hamilton, beatrice blake, catherine bowers, mona callow, lillian cameron, joyce dopel, iva denovan, william thompson, irene hewitt, catheriine kardens, beatrice stuart, hugh ross, mavis regelhuth, isabelle bell, melba perriman, vera muny, alan bernaldo, kathleen conway, dorothy darling, walter dunston, mary dwyer, agnes fraser, enid gates, maude williams, violet wheeler, jean tunbridge, maud auberry, john b. allen, rose c. andrews, willie banagwanath, john n. bennett, alfred bayley, geo h. blake, ida bolte, allison brown, eva brown, harold r. brown, henry f. bull, arthur burge, olive cotton, gertrude f coxon, alice culph, curtain, r.l. cutter, florence davis, w.m davies, helen dempster, ed dopel, l.c.m. dovey, ernest duncan, hugh elliott, nelson h. ferguson, mary featherstone, amelia field, david cochrane, phyllis polson, frederick proctor, geoff richards, bessie robertson, catherine ronald, cora saudberg, mary sheppard, scott smith, leonard steele, j.b. suttcliffe, nellie thornhill, vernon fisher, gordon fletcher, elsie ford, constance furness, grace m. geddes, ada giacometti, mary gleeson, v. hall, harold herm, dorothy hambley, clemence hill, evelyn hodgson, annie holmes, glynis humphreys, augus henderson, joseph james, queenie johnson, harold jolly, francis n. king, william knott, mary kinnear, adelaide leash, doris lonie, a lilbourne, f.j. llewellyn, herb malui, muriel mathew, nellie moloney, mabel morris, ernest morshead, w.k. moss, winifred moyley, eileen mcinerney, jack mclean, chas mcnamara, maryanne medwell, alice osbourne, elsie pitts, percy trompf, basil tunbridge, david walker, ruby walton, annie whitla, kenneth whittle, walter wilberforce, alb e williams, masie wise, amy wolff, olive wunhym, beryl atkins, hector ashby, geo banagwanath, g.n.j. barker, marion r. bailey, kathleen bowe, lelia brough, cecil campbell, basil craddock, ida chapman, iris campbell, una campbell, eileen cleary, reg m.l. cuttter, lyle eves, violet elston, eric embling, violet evans, f.l. ellsworth, vera fisher, una fowles, colin graham, victor greenhalgh, clarence grose, dororthy hall, margaret hannaby, leslie henderson, harold herbert, effie holmes, herbert hopkins -

Mission to Seafarers Victoria

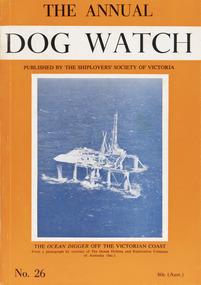

Mission to Seafarers VictoriaJournal (item) - Periodicals-Annual, Shiplovers' Society of Victoria, The Annual Dog Watch, 1969

This journal provides the reader with glimpses of the adventures and hardships of a seaman's life. Many of the stories are of sailing ships.Contributes to our knowledge of the importance of shipping and places on record those stories of the sea which would otherwise be lost.Contents Foreword - Commodore Michael Parker, C.V.O. - 8 Editorial - S.A.E.S. - 17 An Unusual Cruise Through Bass Strait - T. E. Goldfinch - 23 Reminiscences in Sai - George Oakes - 27 My First Christmas in the Service - Lt.-Com. H. A. Willian, M.B.E., V.R.D., R.A.N.R. (Ret) - 30 Fortune's Wheel - Captain W. E. Eglen - 34 A Very Near Thing - Ralph Ingram - 37 The Time Charter - Captain Ruben Fogelstrom - 49 Ninety Years Under the Sea - J. M. MacKenzie - 53 Many hogs and Three Serpents - Captain C. E. Parkes - 58 Feathered Navigators - Arthur E. Woodley - 60 Human Radar - T. F. Roberts - 65 The Wreck of the Dutch Ship "Vergulde Draeck" - C. Halls - 67 The Port of Portland -- Victoria - - 78 The Barque "Carrazal" - From the papers of the late Captain J. Bull - 81 Pilots (verse) - C. E. Bonwick - 83 Hazards of Sail - A letter from Commodore John Rodgers, U.S.N. - 84 Dhows - C. W. Hawkins - 88 "Full Astern" Without "Stand-by" - S. F. P. Brown - 98 The "Lightning" Passage - More extracts of the Diary of a Passenger - 103 The "Royal Charter" - J. M. Mackie - 114 More on the "Royal Charter" - Dr. H. Cohen. C.B.E. 115 An Echo of Courage - a letter from J. S. Matthews - 117 A Wartime Passage - T. S. Shoesmith - 120 Book Reviews - - 130sailing ships, steamships, shipping, seafaring life, shiplovers' society of victoria, dog watch -

Glenelg Shire Council Cultural Collection

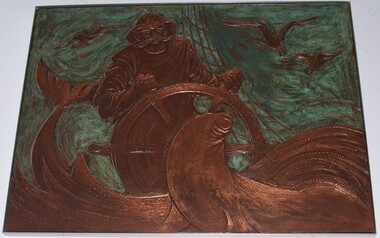

Glenelg Shire Council Cultural CollectionSculpture - Bas-relief, Ronald C. Skate, Untitled (Early Maritime Industries), n.d

Commissioned by State Bank to produce 5 copper bas-reliefs for 73 Percy Street, Portland. Spoke with Miss Betty Vivian (Member of the Portland Historical Society) re Portland's history. Commonwealth Bank stored objects in Melbourne (c.1991). Negotiations between Portland Historical Society and Commonwealth Bank of Australia led to gift of works to People of Portland. Stored at Council depot c.1998, retrieved for Maritime Discovery Centre display.Copper bas-relief. Depicting a man in raincoat and wide-brimmed rain hat at a ship's wheel. Behind him are flying birds and in front of him is the tail of a seal diving into waves on the left and the front of a seal on the right. -

Victoria Police Museum

Victoria Police MuseumPhotograph (police car)

Studebaker Lark Wireless Patrol car registration number HNM-107 with three men leaving the car and the driver remaining behind the wheel. Circa 1962Rear - Cliff Schwab, driver. R/Rear - Rod Sheddon. Front - S/C Ken Chandlerpolice vehicles; wireless patrol; motor transport branch; studebaker lark car; sheddon, rod; chandler, ken; schwab, cliff -

Orbost & District Historical Society

Orbost & District Historical Societynewspaper clippings

This collection of articles was collated by Mary Gilbert. 743.1 - In the group are, from left to right:—First Row—Councillors T. W. Murphy (Bairnsdale), J. R. Coate (Lakes Entrance); T. Hodgd (Tambo), W. Wilson (Berwick), A. Inglis (Mirboo), E. S. Whittakers (Traralgon), and W. C. Kingston (Warragul). Second Row—J. S. Lister (Rosedale), R. Stockdale (Narracan), W. Grose (Omeo), and J. Allan (Toora). Back Row—S. Purdy (Maffra), E. Heesom (Morwell), J. Arohibald (Bruthen), Mr. Lind, M.L.A., Councillor A. E. Rodwell (Orbost), Mr. S. Langslow (Health department), and Mr. C. S. Ogllvy (Warragul). A manila folder of newspaper cuttings related to commerce and government in Orbost. 743.1 is titled, " Gippsland Councillors Wait on State Ministers and is from The Argus, July 1926 .It has a large black / white photograph of the representatives of shires and boroughs of Gippsland who formed a deputation to meet which waited most of the State Ministers with various requests. 743.4 is from the Snowy River Mail and is titled, "Cann RIver's first Hotel" and has a black and white photograph of a four-wheeled buggy pulled by four horses standing outside a hotel. 743.5 is titled "At the End of a Long Trip" and is from the Snowy River Mai. It has a black and white photograph of the Cann River hotel with Mr W. Dreverman standing outside. 743.6 is from the Snowy River Mail, September 6, 1967, and is titled, " Orbosr Businessmen 20 Years Ago" and has a black and white photograph of a group of men in business suits.orbost-business cann-river-hotel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Pulley, Ca 1889

Wooden pulley wheel section from the wreck “Newfield”. The Newfield was a three-masted iron and steel barque, built in Dundee, Scotland, in 1889 by Alexander Stephen and Sons. It was owned by the Newfield Ship Company in 1890 and later that year It was registered in Liverpool to owners Brownells and Co. The Newfield left Sharpness, Scotland, on 28th May 1892 with a crew of 25 under the command of Captain George Scott and on 1st June left Liverpool. She was bound for Brisbane, Australia, with a cargo of 1850 tons of fine rock salt, the main export product of Sharpness. At about 9pm on 28th August 1892, in heavy weather, Captain Scott sighted, between heavy squalls, the Cape Otway light on the mainland of Victoria but, due to a navigational error (the ship’s chronometers were wrong), he assumed it to be the Cape Wickham light on King Island, some 40 miles south. He altered his course to the north, expecting to enter Bass Strait. The ship was now heading straight for the south west Victorian coast and at about 1:30am ran aground on a reef about 100 yards from shore and one mile east of Curdie’s Inlet, Peterborough. The ship struck heavily three times before grounding on an inner shoal with 6 feet of water in the holds. Rough sea made the job of launching lifeboats very difficult. The first two lifeboats launched by the crew were smashed against the side of the ship and some men were crushed or swept away. The third lifeboat brought eight men to shore. It capsized when the crew tried to return it to the ship for further rescue The Port Campbell rocket crew arrived and fired four rocket lines, none of which connected with the ship. A local man, Peter Carmody, volunteered to swim one mile to the ship with a line to guide the fourth and final lifeboat safely to shore. Seventeen men survived the shipwreck but the captain and eight of his crew perished. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. The Marine Board inquiry found the wreck was caused by a "one man style of navigation" and that the Captain had not heeded the advice of his crew. According to Jack Loney ‘… when the drama was over . . the Newfield was deserted except for the Captain’s dog and two pigs.’ Flagstaff Hill Maritime Museum has several artefacts that have been salvaged from the wreck. See also other items in the Flagstaff Hill Newfield Collection.The report from SHP documented the following in regards to the Newfield collection: Flagstaff Hill’s collection of artefacts from the Newfield is of historical and archaeological significance at a State level, because of its association with the shipwreck, which is on the Victorian Heritage Register. The collection is significant because of its relationship between the objects. The Newfield collection is archaeologically significant as it is the remains of an international cargo ship. The Newfield collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 (Living with natural processes). The collection is also historically significant for its association with the shipwreck. The Newfield collection meets the following criteria for assessment: Criteria A: Importance to the course, or pattern, of Victoria’s cultural history Criteria B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history Criteria C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history This item is an oval-shaped brown and orange wooden shell from a ship’s pulley. The original wooden material is now petrified but the lighter coloured concentric rings of the wood's grain are still visible. A metal sheave or drum is fitted into the centre hole and some of the edge of its sheave’s collar has corroded and broken away. The collar has three holes of equal size that are evenly spaced around it. The bearing ring is now detached but still connected to the pulley with a string on which a label is attached. Most of the six cylindrical metal roller bearings are sand encrusted but some are still visible. Recovered from the wreck of the ship NEWFIELD.The pulley has a string through it that attaches it to the bearing. The label on the string bears the handwritten words “PULLEY WHEEL / NEWFIELD / PETER ROLAND”.block, flagstaff hill, maritime museum, shipwreck coast, warrnambool, peter carmody, carmody, newfield, shipwreck, pulley, wheel, pulley block, sheave, drum, peterborough, south west victoria, rocket, rocket crew, shipwreck artefact, flagstaff hil maritime museum -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bowl, Late 19th or early 20th Century

Human beings appear to have been making their own ceramics for at least 26,000 years, subjecting clay and silica to intense heat to fuse and form ceramic materials. The earliest found so far were in southern central Europe and were sculpted figures, not dishes. The earliest known pottery was made by mixing animal products with clay and baked in kilns at up to 800°C. While actual pottery fragments have been found up to 19,000 years old, it was not until about ten thousand years later that regular pottery became common. An early people that spread across much of Europe is named after its use of pottery, the Corded Ware culture. These early Indo-European peoples decorated their pottery by wrapping it with rope, while still wet. When the ceramics were fired, the rope burned off but left a decorative pattern of complex grooves on the surface. The invention of the wheel eventually led to the production of smoother, more even pottery using the wheel-forming technique, like the pottery wheel. Early ceramics were porous, absorbing water easily. It became useful for more items with the discovery of glazing techniques, coating pottery with silicon, bone ash, or other materials that could melt and reform into a glassy surface, making a vessel less pervious to water. https://en.wikipedia.org/wiki/CeramicThe discovery and development of ceramics in numerous shapes, form and materials, revolutionised the world.Plain cream ceramic bowl with flat bottom inside. Shiny glaze fades to flat texture towards base. Possibly hand thrown pottery. No backstamp. Bad crazing and staining.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMorse key

Morse key telegraphic printer, 250 ohm resistors inward and outward switch and teleprinter with tape reel to record messages spare wheel on wood base to collect and store full reels from teleprinter.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, morse key, teleprinter, telegraphic printer, codes, signals, communication, telegraphy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate