Showing 25 items matching "cleaning engines"

-

Moorabbin Air Museum

Moorabbin Air MuseumManual - Rolls Royce Derwent engines, Rolls Royce Derwent OHM Microfilm Print Workshop Copy

... Cleaning engines...-assemblies Dismantling sub assemblies Cleaning engines Rebuilding ...Microfilm copies of Derwent Overhaul Manual pages, circa 1953Faded microfilm copy of original overhaul manualnon-fictionMicrofilm copies of Derwent Overhaul Manual pages, circa 1953dismantling engine to sub-assemblies, dismantling sub assemblies, cleaning engines, rebuilding engine from sub assemblies, rig testing sub assemblies, engine testing, tools & equipment -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Rolls Royce Derwent engines, Derwent Overhaul Manual

... Cleaning engines...-assemblies Dismantling sub assemblies Cleaning engines Inspection ...Overhaul instructions for Derwent turbo jet engine, circa late 1950snon-fictionOverhaul instructions for Derwent turbo jet engine, circa late 1950sdismantling engine to sub-assemblies, dismantling sub assemblies, cleaning engines, inspection of engines, rebuilding sub assemblies, rig testing sub assemblies, rebuilding engine from sub assemblies, engine testing, packing the engine, testing, tools & equipmemt -

Warrnambool and District Historical Society Inc.

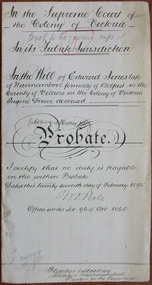

Warrnambool and District Historical Society Inc.Document - Edward Jones Probate 1895, 1895 with additional material added in 1899 by the lawyer Ernest Chambers

Tait collection: item 40 of 62 This document gives the details of the Will and Probate of Edward Jones, an engine driver who died in Warrnambool in January 1895 at the age of 69. He had previously been a resident of Port Fairy. He left real estate to the value of £640 and personal estate to the value of £187. The beneficiaries of the will were his daughters, Margaret and Mary Jones. The lawyers connected with this document were Ernest Chambers and the legal firm of Fletcher and Mackay. Ernest Chambers had legal offices in Port Fairy, Koroit and Warrnambool at the end of the 19th century and the beginning of the 20th century and the signatures of two of his law clerks, Thomas Goodall and John White are included in this document. James Fletcher had a legal office in Port Fairy and in Warrnambool in the 1870s and in Warrnambool in the 1880s (Koroit Street). In the late 1890s he commenced a partnership with George Mackay who had previously had his own practice in Warrnambool. In the 1920s the firm became known as Mackay and Taylor and later Mackay Taylor (Kepler Street). This document was in the possession of Ernest Chambers and was passed down to successive lawyers occupying the Kepler Street premises. It was located in 2014 with other documents in these premises last occupied by the firm of Mackay Taylor. This document is of some interest as it gives details of the Will and Probate of Edward Jones who had been a resident of Warrnambool in the late 19th century. It will be useful for researchers. This is a cream-coloured piece of parchment paper folded in two and containing handwritten material on three sides of the paper. It gives details of the Will and Probate of Edward Jones of Warrnambool who died in 1895. The pages have printed red lines on the edges of three pages. The written material is clean and readable.In the Supreme Court of the Colony of Victoria In its Probate Jurisdiction in the Will of Edward Jones late of Warrnambool and formerly of Belfast in the County of Villiers in the Colony of Victoria Engine driver deceasedfletcher and mackay, lawyers,, warrnambool, ernest chambers,, edward jones, tait collection -

Federation University Historical Collection

Federation University Historical CollectionUnknown - Model, Poppet Head Model

This scale model of a mining plant was made by Donald Douglas Mather of Talbot. The engine shed houses the winches, which raise and lower the cages carrying the workmen. The winches also control the water-Baling tanks, which are lowered into the pump shaft to clean the water. The Pump Shaft is part of the main shaft partitioned off for keeping the water down. The old style plant (or cas commonly known poppet legs), were all of timber construction and, when erected, straddled the main shaft. This scale model allows for steel construction, and is set over the shaft to permit an unobstructed view of the operations. The Bad level is where the workmen enter and leave the shaft. The staging platform on the first level is where the trucks and mullock or other material are wheeled out on rails and then tipped to form the mine dump. The top level is to allow for maintenance of plant. Donald Douglas Mather of Talbot worked in mines in Ballarat, and made the model of the poppet head. The poppet head is a replica of those used at many mines in Ballarat. Back in the 1850s Ballarat was a god rush town and many mining claims were made and poppet heads built this is a replica of those poppet heads which are a part of Ballarat's Heritage and a full size poppet head is erected at Sovereign Hill Theme Park in Ballarat. Mining is a huge part of Ballarat's history.A timber poppet head and engine room model. "This scale model - the modern construction of a mining plant - was made by Mr Donald Douglas Mather* of Bonnie Doon, Talbot, Victoria. The engine shed houses the winches, which raise and lower the cages carrying the workmen. The winches also control the water-baling tanks, which are lowered into the pump shaft to clean the water. The pump shaft is part of the main shaft partitioned off for keeping the water down. The old style plant (or as commonly known poppet legs), were all of timber construction and, when erected, straddled the main shaft. this scale model allows for steel construction, ans is set over the shaft to permit an unobstructed view of the operations. The bad level is where the workmen enter and leave the shaft. The staging platform on the first level is where trucks ad mullock or other material are wheeled out on rails and then tipped to form the mine dump. The top level is to allow for maintenance of plant. * Mr Mater, previously of Ballarat, worked for many years as a miner and plant erector" (Old interpretive panel)mining, mather, mining plant, poppet head, engine house, model, donald douglas mather -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBrush

Tube Brush also called a Flue Brush. Used for cleaning the tubes and flues of a steam engine or other boiler. L 6' 2"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - BILL ASHMAN COLLECTION: PIECES OF CARBON, SECTION OF EXHAUST STACK

Black and white photo showing: 1. Carbon removed from the exhaust stack of the semi diesel engine of the Bendigo City Council road roller. 2. Section of exhaust stack before being cleaned out. 3. Piece of carbon taken from Victorian locomotive cylinder and 4 Samples of scale scabs taken from the cylinder of the diesel engines at the Little 180 Gold Mining Coy. Vincent Kelly Bendigo impressed in the bottom left corner. Information typed on the back of the photo.sciences, instruments - general, scalebuoy, bill ashman collection - correspondence, bendigo city council, little 180 gold mining coy bendigo, vincent kelly -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - BADHAM COLLECTION: LOCOMOTIVE MANAGEMENT FROM CLEANING TO DRIVING

A blue hard covered book titled ''Locomotive Management from Cleaning to Driving'' by Jas. T. Hodgson and John Williams. London. The Proprietors of 'The Railway Engineer,'' 15 Farringdon Avenue, E.C. 529 pages. (ill.) Some questions related to the railways have been attached to the inside of the book and a sheet titled, 'Everyday essentials in railway working.'Jas. T. Hodgson, John Williamsbooks, technical, railways, book, books, trains, railways, engines, locomotives, badham collection, collection, collections -

Stratford and District Historical Society

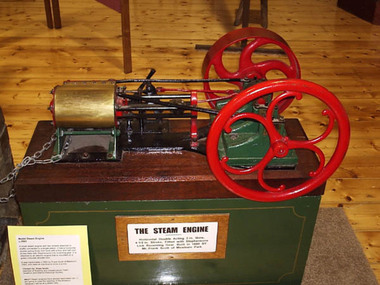

Stratford and District Historical SocietyModel Steam Engine

This working-model steam engine was hand-made c.1893 by Frank Scott of Mewburn Park, and used to drive a pump. The entire engine and base were repaired, cleaned and restored by participants in a LEAP program hosted by Eastern Victorian Group Training, Bairnsdale, in June 1995. This included repairing a broken piston arm.This small steam engine has two wheels attached to shafts connected to a single piston. It has a horizontal double-acting three inch bore with a four and half inch stroke fitted with Stephensons link reversing gear. It is mounted on a green-coloured wooden box.engines -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Atar Engine Overhaul Manual Cleaning And Surface Treatments - Text

... of Importance: . Manual Atar Engine Overhaul Manual Cleaning And Surface ...Description: 200 pages. Published by SNECMA/RAAF. Published on unknown date. AAP 711.55 Vol.6/Part 1 (PLATES) Level of Importance: . -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Technical Information - ATAR 08, 09 B And 09 C Turbojet Engines

Cleaning Of Compressors And Protection Of Engines Against Corrosion -

Rutherglen Historical Society

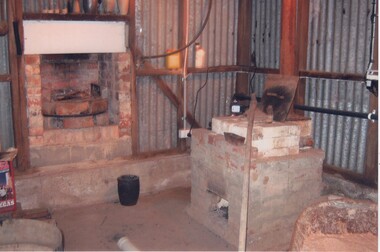

Rutherglen Historical SocietyImage, c1990

This photograph shows the pre-heater on the left and the furnace on the right. After clean up of stamper table, amalgam is placed in a retort, then placed in the furnace where mercury is condensed and runs down the small pipe into an enamel bucket and can be reused. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the interior of a room with corrugated iron walls, with a fireplace on the left and a furnace on the right.gold battery, gold processing -

Mansfield Historical Society

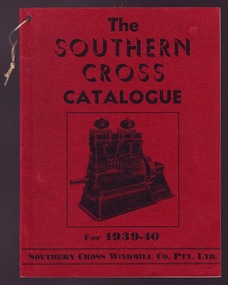

Mansfield Historical SocietyBook, "The Harbour" Newspaper & Publishing Co Ltd, Southern Cross Catalogue 1939-40, 1939

The Southern Cross Organisation had its origin in a small Foundry in Toowoomba, Queensland, in 1871, and has grown into a Commonwealth-wide organisation with a selling network serving the whole of Australia and supplying Southern Cross Products as far away and Deccan, in India.This object is significant because it is complete and the pages are clean, straight & unmarked with the binding is in good condition.Soft Red CoverSouthern Cross Catalogue for 1939-40windmills, petrol engines, kerosine engines, pumps, milking machines, tanks, lighting plants, home light batteries -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - RECOMMENDATIONS FOR VICTORIA HILL

BHS CollectionHandwritten notes on recommendations for cleaning up and signposting Victoria Hill. Also contains list of photos from the Bendigonian of 1899. List of photos: Shamrock Mine, Undershot Water Wheel at Diamond Hill for Phillips Crushing Battery. Mr. Ballerstedt's Crushing Battery at Victoria Hill, Thompson's Foundry at Castlemaine, Machinery made for Bendigo Mines, Air Compressor at Shenandoah Mine, Winding Engine at Koch's Pioneer Mine, Poppet Legs at Koch's Pioneer Mine, Air Compressor at New Chum Railway Mine, Fortune Hustlers G M Co Bendigo View of Mine, Winding Plant and Afternoon Shift and Underground Work in the New Chum Railway. Also mentioned are notes on Machinery made by Thompsons. Also, a carbon copy of Annual Report to Bendigo Branch Royal Historical Society, Victoria 1/7/71. Mentioned in the Report are: Historical Ball, The Central Deborah, Victoria Hill, Tours and Society Business. Albert Richardson document?document, victoria hill, recommendations for victoria hill, north old chum, ballerstedt's rich 24 yard claim, floyds battery lansell's big 180, the bendigonian 26/1/1899, 2/2/1899, 20/4/1899, 11/5/1899, 10/8/1899, 14/9/1899, shamrock mine, undershot waterwheel at diamond hill, phillips crushing battery, mr ballerstedt's crushing battery, thompson's foundry, shenandoah mine, koch's pioneer mine, new chum railway mine, fortuna hustlers g m co bendigo, new chum railway, st mungo lady barkly, catherine reef, new moon, rae's open cut, old court house eaglehawk, police barracks, vic wodetzki, joss house, central deborah, central nell gwynne, mr harold curnow, bendigo branch royal historical society victoria, mrs kingerlee, felicity kingerlee, mr h biggs, city council, rotary club of bendigo south, white hills cemetry, chinese joss house, bendigo pottery, mr derham, reservoir high, princess theatre, a n a hall, mr hattam, col. sprenger, survey corps, a richardson -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Griffon Engines, Griffon Mk. 61, 65, 66, 67 and 74 Aero Engines

... Dismantling & cleaning Inspection Engine rebuilding General ...Instructions for repair & conditioning Griffon Mk 61,65,66,67 &74 engines, circa 1949Spring back binder, Photocopies. Full title inside manualnon-fictionInstructions for repair & conditioning Griffon Mk 61,65,66,67 &74 engines, circa 1949servicing engine repair equipment, tools, dismantling & cleaning, inspection, engine rebuilding, general arrangement drawings -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Avon engines RAAF, Royal Australian Air Force Avon Mk 109 Repair and Reconditioning Instructions

Instructions for repair & reconditioning of Avon Mk 109 engine, circa 1957. Includes amendment listnon-fictionInstructions for repair & reconditioning of Avon Mk 109 engine, circa 1957. Includes amendment listreconditioning, tools & equipment, dismantling & cleaning, inspection, rebuilding, rig testing, bench testing -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Avon engines, Royal Australian Air Force Avon Mks 20 &26 Repair and Reconditioning Instructions

Instructions for the repair & reconditioning of Avon Mk 20 & 26 engines, circa 1957non-fictionInstructions for the repair & reconditioning of Avon Mk 20 & 26 engines, circa 1957list of schedules, reconditioning instructions, tools & equipmemt, distmantlng & cleaning, inspection -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - CATHERINE REEF UNITED MINE MANAGERS REPORTS

Handwritten notes, with typed transcript of same, on Catherine Reef United Mine Manager, J. M. Eyre Report 20/5/'72. Recommends the purchase of a new boiler. S. Jackson killed in a boiler explosion which the jury said was due to an error of judgement on his part. Recommendations, re New Winding Engine and Poppet Legs by Rbt. Coakes 18th May, 1905. Truck road from the shaft to the battery. Recommendation to call for tenders for a new changing house and a blacksmith shop. Reports about boilers, ropes, cleaning of machinery, testing of brakes, slack coal from the Powlett North Woolamai Collieries, crushings, number of batteries, low wood supply and a visit to the New Moon & South New Moon which are burning the Powlett slack coal. Albert Richardson Collectiondocument, gold, mining reports, mining reports, catherine reef united mine managers reports, j m eyre, myrtle creek coy, s jackman, rbt coakes, great northern co, virginia co, mr roberts, mr harkness, mr mcgrath, ernest mueller, roberts & sons, mr bennett, mr abrahams, mr sluyterman, j langdon, electrical supply coy, smiths, powlett north woolamai collieries, m j gwatkins, new moon, south new moon -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - VISITOR PLANS FOR VICTORIA HILL

Handwritten carbon copy and typed copy of notes on 1st and 2nd stage plans for a tourist area on approx. 20 acres at Victoria Hill. First stage was to clean up the area, locate and sign post shafts, engine beds, etc and prepare a topographical map with these features on it. Second stage was to arrange for the purchase of typical miners homes and shops in the vicinity to be restored for inspection by visitors. Mining equipment to be placed in the area. Prepare brochures for sale. Set up a mining museum.Prepare an area near BCV 8 with direction finder to mining and general features, as this has the best natural ground level view in the City. Notes prepared by Albert Richardson.mine, gold, victoria hill, victoria hill, visitor plans for victoria hill, darrel mcclure, bendigo city council, bendigo historical society, central nell gwynne, caleb thomas, bcv 8, lazarus, old chum, new chum, victoria, repeater station (p. m. g.) -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - NORTH JOHNSON'S MINE MANAGERS' REPORTS

The North Johnson Gold Mine was situated in California Gully, Bendigo. See Trove article and plan of mine: https://trove.nla.gov.au/newspaper/article/7918876Handwritten extracts, by Albert Richardson, with typed copy of same, from the North Johnsons Mine Managers, F. Agnew, G. Roberts and J. Veale's Reports dated from 8th July 1898 to 27th Feb 1908. Report mentions cage being hung up and rope being caught and stuck, cutting down of shaft, repair of winding rope, cutting down and timbering of shaft, miner burnt when candle flared, which was believed to be caused by gas, sinking of shaft and water heavy and recommend to stop sinking shaft and start to cut a plat. (b) Report dated 29-11-1906 mentions a typhoon destroying the east side of the engine-house. This was repaired and also cleaned flues and boilers and ventilation at 3273 and 3471 feet.gold, mining reports, north johnson's mine managers' reports, f agnew, p schadendorff, the 'rose' plant, g roberts, j veale, inspector williamson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - Albert Ernest Richardson, Peter Anderson's article 2020

Albert Richardson was born on 22nd. June, 1902 to George Albert Richardson and Catherine Agnes (nee Flynn). He married Mavis Irene Yarwood on 23rd. December, 1931. Albert Richardson's childhood activities in Duncan Street, Long Gully, were influenced strongly by the occupation of his father and grandfather, both of whom were engine drivers on the Bendigo field. Albert had his own model goldmine, complete with poppet head, baling tanks etc and was up and ready to start work with the sound of the 7 a.m. mine whistles. Albert spent a short time working as a motor mechanic and then took up0 welling insurance with T & G. However, his heart was with the mines and he worked daytimes with T. & G. and then took off to learn engine driving with night shift in one of the mines. He gained his engine drivers' ticket in 1938 and began work at the Nell Gwynne. His longest work time was at the North Nell but he also had shorter spells at other mines. His leter work years were spent at John Brown, from where he retired in 1968. Albert had a deep regard for the working man and worked for many years in the position of Secretary at the Trades Hall, Bendigo. (adapted from biography in BHS Collection, written by I. Hendry, 1972) The Bendigo Historical Society holds a wide range of Bendigo mining records researched and written by Mr. Albert Richardson. He was President of the Bendigo Branch of the Royal Historical Society of Victoria from 1969 to 1971.When he joined the Bendigo Branch in 1966 he began compiling a history of the Bendigo mines. He spent many long hours researching at the Bendigo Mines Department, summarising mine records. He gathered relevant mining material wherever it could be obtained. He devoted most of his spare time and energy to the Society, conducting tours of the goldfields, writing articles and presenting talks to various organisations. His first and foremost interest lay in Victoria Hill. He examined mining reports and early newspaper articles to document its history. He envisaged the once fabulously rich hill as becoming a tourist attraction and campaigned vigorously to achieve this. In 1971 his dream was realised, when, with the help of South Bendigo Rotary Club 'The Hill' was cleaned up and historical site4s sign-posted. In 1972 the Bendigo Trust produced a booklet on Victoria Hill. Albert Richardson is acknowledged as the person ' on whose work and writings the text of this booklet has been based' The park adjoining Victoria Hill was named the Albert Richardson Reserve in his honour. Four newspaper clippings on mining, focusing on Albert Richardson's life; his passion for mining history and more generally, the work of engine drivers on the Bendigo goldfield. Clippings taken from the 'Bendigo Weekly' 2016, dated September 29 'Learner Drivers' , October 7 'Becoming qualified', October 14 'Steam power in his veins' and November 11 ' Victoria Hill over the decades'. All articles written by James Lerk in a series titled 'Discover Bendigo'. albert richardson, engine driver, mining, bendigo, boiler, engine room, mining cage, albert richardson reserve, victoria hill, george ellis, south bendigo rotary club -

Victorian Railway History Library

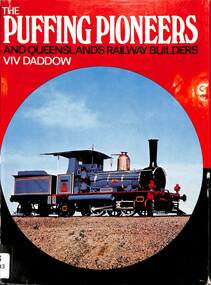

Victorian Railway History LibraryBook, Daddow, Vivian, The Puffing Pioneers - and Queensland's Railway Builders, 1975

... be spent outside rostered working hours cleaning their engine ...INTRODUCTION Until well into the twentieth century, driver, fireman and guard — with a locomotive — set out on something resembling a safari. Tucker boxes crammed with food, a change of clothing, a roll of blankets, and armed with a sheaf of time-tables, they worked trains hither and thither not to return home for almost a week. But the passing of time, plus union pressure, brought an end to the need for "waltzing Matilda". Not only blankets but sheets, pillow slips, then later mosquito nets, along with other aids to civilized living, were provided by the Department in living quarters away from home. Few wives took kindly to the chore of selecting and preparing food and packing tucker boxes. Railwaymen seeking board and lodgings in a new depot could receive a set-back by being told "no tucker boxes packed". Until pooling of locomotives in depots became the order, a driver and fireman had "their own engine", and great was the competition between engine crews to display the best groomed horse. Much time might be spent outside rostered working hours cleaning their engine with kerosene and polishing with tallow and bath brick. So spotless and sparkling were some that a proud engineman would say a clean white handkerchief could be rubbed even over a hidden part. While miners talked of what made their day, farmers discussed crops and harvests, seamen their ships, and trainers and jockeys their horses, wherever steam men gathered, discussion soon turned to locomotives and the trains they hauled. Like jockeys with their mounts, iron horses with excellent traits were praised while those with annoying peculiarities were criticized and remedies suggested. Methods of firing to get best results from slow steaming locos were debated. Driver warned driver of weaknesses found in locomotives on recent "trips", spoke of developing defects calling for close attention — this one is "knocking Badly on one side", that one "priming badly (give her a good blow down before leaving the shed)", another with a "big end inclined to run hot", one with "a lot of slop in the boxes", one "getting down on the springs", or the sloth that was slow pulling on steep climbs to the chagrin of a driver striving to run on time. Things of no small concern when handling a locomotive on a train for a shift of maybe eight hours straight, or ten, even twelve, and on occasions longer. Foreknowledge of the particular loco allotted his train on the next job could fill the preceding hours for a driver or fireman with pleasant contentment, or with nagging trepidation and disgust……index, ill, p.217.non-fictionINTRODUCTION Until well into the twentieth century, driver, fireman and guard — with a locomotive — set out on something resembling a safari. Tucker boxes crammed with food, a change of clothing, a roll of blankets, and armed with a sheaf of time-tables, they worked trains hither and thither not to return home for almost a week. But the passing of time, plus union pressure, brought an end to the need for "waltzing Matilda". Not only blankets but sheets, pillow slips, then later mosquito nets, along with other aids to civilized living, were provided by the Department in living quarters away from home. Few wives took kindly to the chore of selecting and preparing food and packing tucker boxes. Railwaymen seeking board and lodgings in a new depot could receive a set-back by being told "no tucker boxes packed". Until pooling of locomotives in depots became the order, a driver and fireman had "their own engine", and great was the competition between engine crews to display the best groomed horse. Much time might be spent outside rostered working hours cleaning their engine with kerosene and polishing with tallow and bath brick. So spotless and sparkling were some that a proud engineman would say a clean white handkerchief could be rubbed even over a hidden part. While miners talked of what made their day, farmers discussed crops and harvests, seamen their ships, and trainers and jockeys their horses, wherever steam men gathered, discussion soon turned to locomotives and the trains they hauled. Like jockeys with their mounts, iron horses with excellent traits were praised while those with annoying peculiarities were criticized and remedies suggested. Methods of firing to get best results from slow steaming locos were debated. Driver warned driver of weaknesses found in locomotives on recent "trips", spoke of developing defects calling for close attention — this one is "knocking Badly on one side", that one "priming badly (give her a good blow down before leaving the shed)", another with a "big end inclined to run hot", one with "a lot of slop in the boxes", one "getting down on the springs", or the sloth that was slow pulling on steep climbs to the chagrin of a driver striving to run on time. Things of no small concern when handling a locomotive on a train for a shift of maybe eight hours straight, or ten, even twelve, and on occasions longer. Foreknowledge of the particular loco allotted his train on the next job could fill the preceding hours for a driver or fireman with pleasant contentment, or with nagging trepidation and disgust…… railroads -- queensland -- history, railroads -- australia -- queensland -- history. -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Fred Rochow Railways Collection - Wodonga Railway Station Panorama, Before 1938

... right: Engine shed with car cleaning on its left. The Albury... to date the photo. Far right: Engine shed with car cleaning on its ...The Fred Rochow Railways Collection incorporates photos related to the operation of the Wodonga Railway Station including different types of trains and railways staff C. 1930 – 1990. It was donated to the Wodonga Historical Society by Fred Rochow, a railwayman who spent many years based in Wodonga. He joined the Victorian Railways on 17th June l947 and retired in 1988. For some time, he was a member of the Australian Federated Union of Locomotive Enginemen and served a term as a member of the Trades Hall Council. He had an extensive knowledge of the struggles that took place to achieve better conditions for railway workers. Fred worked for many years as a fireman and then worked his way up the ranks to driver, experiencing many changes from the days of steam locomotives through to diesel trains, locomotives and even the modern XPT train. He worked throughout Victoria at different stages of his career, with his final working years focused on the northeast of Victoria and the Albury to Melbourne line. After his retirement, Fred continued to share his love of steam miniature trains with the community.This collection has local and statewide significance as it captures images of trains, locomotives and personnel who operated the railway services in Wodonga and throughout Northeast Victoria. The railways played a critical role in opening up Victoria and connecting Australia for trade, business, social communication and transport.Panorama of Wodonga Railway Station Far left: Crew's bike shed, then Fitter and Turner's working quarters. Neither building remains. Centre: Building comprised the Office and store. This building was demolished in 1938, so helps to date the photo. Far right: Engine shed with car cleaning on its left. The Albury Express went in on the right and the "Spirit of Progress" entered on the left.railways wodonga, fred rochow, wodonga railway station