Showing 31 items matching "clock industries"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1950

... clock industries..., such as factory time clocks to various industries. Westclox in Scotland..., such as factory time clocks to various industries. Westclox in Scotland ...Westclox had a highly successful factory in Scotland situated in the Vale of Leven Industrial Estate, in Dumbarton, around twenty miles from the City of Glasgow. Westclox had originally planned to start production in Scotland in 1939 but the War intervened and it was not until 1948 that they were able to fully commission their factory in Dumbarton. Westclox Scotland produced its first clock on the 21st September 1948; a spring wound alarm with a 4 inch dial. The Westclox factory in Scotland was a full manufacturing plant with all their clocks assembled from start to finish with only the basic raw materials being brought in by outside suppliers. 95% of the staff were local people and the firm trained their employees from scratch to a high level of skill and had an annual apprenticeship for toolmakers and classes in horology. By 1949 Westclox Scotland were making 10,000 clocks a week, and by 1950, 1,000,000 clocks had been produced since its opening. No home in the Dunbartonshire Vale was without at least one Westclox clock, nor any raffle complete without a clock as one of the prizes! Many of these clocks are still around today. So successful was the Dumbarton factory that in the mid 1950’s Westclox had to expand into adjoining buildings. The factory then added watches to what they made as well as timing devices for other sectors. By the mid 1960’s, employment levels at the Scottish plant were around 1100. Over a third of the clocks manufactured in Scotland were exported to some 110 countries across the globe. Difficult times came in 1967/68 when 400 workers were laid off and the future of the plant was in doubt primarily due to cheap clocks from the then communist countries. However, strong petitions to the UK Government produced the passing of an anti-dumping law allowed production from the factory to pick up. In 1968 General Time was bought out by Talley Industries, which was best known as a manufacturer of timing equipment, such as factory time clocks to various industries. Westclox in Scotland enjoyed several boom years under the then Managing Director, John Santos. Westclox Scotland in October 1974 hosted a Space Seminar for the Astronaut, Neil Armstrong and British Astronomer, Sir Patrick Moore. Both visited the Scottish factory to promote the introduction of Quartz time-keeping. In 1976 the Westclox plant in Dumbarton became the Headquarters of General Time (International Operations) Ltd. John Santos retired from General Time and Westclox in the early 1980s and by 1988 the future of Westclox in Scotland was almost over. The advent of Quartz clock technology, developed largely by General Time for use in the Apollo 11 Command Module, resulted in the reduction of mechanical clock production and sales, and the factory fully closed in 1988.The Westclox factory building in Dumbarton has been converted and is now home to many thriving small businesses. The item marks a time when clock production in the United Kingdom was at it’s peak producing clocks for sale in over a 110 countries, they were keenly priced and available to all. The company had many innervation's during it’s life regards clock and later wrist watch making. In 25 years the factory had produced over 50 million clocks, yet it was perhaps inevitable with the advent of Quartz technology that was ironically evolved, largely by General Time for use in the Apollo 11 Command space Module, that would ultimately herald the end of the mechanical clock.Wooden bedroom alarm clock small painted brown with a criss cross pattern in gold and a white enamel face roman numerals & a glass front, clock case is of a fancy design. Inscribed on face "Made by Westclox Ltd Scotland" .flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mantle, clock, mantle clock, westclox ltd, horology, clock industries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

... clock industries... industries No markings or inscriptions on clock case or mechanism ...In 1902, William E Sessions and other family members purchased a controlling interest in the E.N. Welch Company, a clock manufacturer located in Forestville, Connecticut. Sessions' father owned a foundry located in the town of Bristol, Connecticut that produced cases for E.N Welch Co. On January 9, 1903, the company was reorganized and registered as The “Sessions Clock Company”. Within a few years the Sessions Clock Company was producing clock movements, cases, dials, artwork and castings for their line of mechanical clocks. Between 1903 and 1933 Sessions produced 52 models of mechanical clocks, ranging from Advertisers, large and small clocks with logos of various businesses, to wall, or regulator clocks, and shelf or mantel clocks, designed for the home. Many of the Session clocks from this period are prized by collectors. In 1930, the company expanded to produce electric clocks and timers for radios, while continuing to produce traditional brass mechanical movements. Beginning at the end of World War II Sessions W Model (electric) was widely used by various casting companies for their clocks. The dial of the W Model read Movement by Sessions. In the early 1950s Sessions begin to produce timers for television. In 1956, Sessions was absorbed by a company interested mainly in their timing devices. In 1959, William K. Sessions, grandson of William E. Sessions left the Sessions Clock Company and formed the New England Clock Company. In 1960, one of the Sessions Clock buildings was sold to the Bristol Instrument Gears Company. Kept as the Sessions Company, the new owners ran the operation until 1969 when changes in the market forced the Sessions Company into liquidation. In 1970, the remaining buildings were sold to Dabko Industries, a machine parts manufacturer.The item marks a time when clock production in America was at it’s peak producing clocks for sale in many countries, they were keenly priced, mass produced and available to all. The company had a relatively short life span life regards clock manufacture later diversifying into electric timer mechanisms. Yet it was perhaps inevitable with the advent of electricity along with stiff competition from other clock manufactures that would ultimately herald the end in 1935 of the Sessions company's ability to continue manufacturing mechanical clocks. Clock mantle type face set in a painted black case designed to represent a Greek building with gold decorative pillars. Free standing with decorative feet. No markings or inscriptions on clock case or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sessions, mantel clock, clock, clock industries -

Footscray Community Arts

Footscray Community ArtsIndustrial Hope, De Clario, Emma, 2005 (exact)

... seem to reflect the relentless clock of industry. A patch... and green the colours seem to reflect the relentless clock ...Artist StatementGeneral ALL BlurbMEDIUM: Oil on kiln dried redgum. DESCRIPTION: Black, blue and white, wood block, no frame. A realistic depiction of an industrial crane against a predominantly cloud covered sky, the crane is set in the lower centre of the canvas, almost becoming secondary to the sky and cloud which dominate the canvas. The sky set in bright and vibrant blues contrast the darkness of the clouds, ominous and heavy in shades of grey and green the colours seem to reflect the relentless clock of industry. A patch of light behind the crane gives the crane a strong focal point. art, de, fcac, all, emma de clario, clario, marios cafe, marios -

Footscray Community Arts

Footscray Community ArtsIndustrial Hope, Emma de Clario, (exact); 2005

... clock of industry. A patch of light behind the crane gives... clock of industry. A patch of light behind the crane gives ...MEDIUM: Oil on kiln dried red gum (wood block) DESCRIPTION: Black figure och blue and white background, wood block, no frame. A realistic depiction of an industrial crane against a predominantly cloud covered sky. The crane set in the lower centre of the canvas almost becomes secondary to the sky and cloud which dominate the wood block. The sky set in bright and vibrant blues contrast the darkness of the clouds, ominous and heavy in shades of grey and green, the colours seem to reflect the relentless clock of industry. A patch of light behind the crane gives it a strong focal point. Signed and titled on reverse of imageoil, de, hope, clario, industrial, photograp -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clock, late 1900s early 20th Century

... 225 different clock models being manufactured. In 1899, Phelps... 225 different clock models being manufactured. In 1899, Phelps ...In 1850 the Ansonia Clock Company was formed as a subsidiary of the Ansonia Brass Company by Phelps and two Bristol Connecticut clock makers, Theodore Terry and Franklin C. Andrews. Terry & Andrews were the largest clock manufacturers in Bristol at the time with more than 50 employees using 58 tons of brass in the production of about 25,000 clocks in 1849. Phelps decided to get into the clock making business to expand the market for his brass, while Terry and Andrews got access to better quality brass at better prices. They had then sold 50% of their business to Phelps and moved the business to Ansonia, Connecticut. In 1877 the clock company purchased a factory in New York and moved most of its production thereafter being spun off from the brass company. Henry J. Davies of Brooklyn, himself a clock maker, inventor and case designer, joined the newly reconstituted company as one of its founders. As President, he is thought to have been largely responsible for the figurine clocks, swing clocks and other unusual and desirable novelties for which the Ansonia firm became known. By 1879, a second factory was opened in Brooklyn, New York and by June 1880 employed 360 workers, while the Connecticut factory continued producing clocks as well with a workforce of 100 men and 25 women. Hence, clocks marked "Connecticut" were generally produced before 1879, while those marked "New York" were all produced after 1880 After the New York factory burnt down in 1880 the company rebuilt the factory on the same site, and reopened the expanded factory in 1881, with a capacity to exceed that of the Connecticut factory which by 1883 had closed. By 1886, the company had sales offices in New York, Chicago and London, with more than 225 different clock models being manufactured. In 1899, Phelps' grandson William Earle Dodge Stokes commissioned architect Duboy to build the "greatest and grandest hotel in Manhattan, New York” which became the city's first air-conditioned building. In 1929 the majority of the timekeeping machinery and tooling was sold to the Soviet government's US trading company Amtorg, just before the stock market crash. The parts, machinery and key skilled workers were shipped out of the USA to form the basis, along with the remains of a watch company purchased a year later, of the clock and watch industry in Moscow such as Poljot and Sekonda. In 1969, the rights to the use of the name, trademarks, and goodwill were transferred to Ansonia Clock Co., Inc., Lynnwood, Washington. The item marks the beginning of mass produced clocks in the United States, cheaply priced and available to all. The company had many innervation's during it’s life regards clock and later wrist watch making that led the way for other companies in many different countries to emulate.Clock, pendulum mantle model. Carved scallop "Ginger bread house" cottage clock. Oak case, white enamel face, floral etched glass door. Clock has an hour bell chime. Glass front opens to allow rewinding. Made by Ansonia Clock Co, New York. Marked "Manufactured by Ansonia Clock Co. New York, USA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, mantle clock, clock, pendulum clock, time keeper, horology, ansonia, ansonia clock co, america -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales,Spring Balnce Imperial ‘Household’ Salter, 20thC

In the 18th century, spring scales appeared. To produce these scales, a manufacturer would use the resistance of a spring to calculate weights, which could be read automatically on the scale’s face. The ease of use of spring scales over balance scales is what led most post offices to outfit their clerks with spring postal scales. One of the most common types of spring scales was the kitchen scale—also known as a family or dial scale. Designed for horizontal surfaces, these scales used the weight of goods in a pan at the top of the scale to force the spring down. Such scales were common in early-20th-century households and were sold by Sears and Montgomery Ward. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks made both. SALTER HOUSEWARES began in the late 1760 in the village of Bilston, England. At this time Richard Salter, a spring maker, began making 'pocket steelyards', a scale similar to the fisherman's scale of today. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. and later established a large, well equipped manufacturing site in the town of West Bromwich. The business thrived throughout the 1900s, and in 1972 the company was purchased by Staveley Industries Plc. In 2002, the management team at Salter Housewares Ltd, backed by Barclays Private Equity, bought the company out from the group, to concentrate on its consumer businesses. In 2004 was sold to the US-based HoMedics company, and in 2006, Salter Housewares USA and Taylor Precision Products Inc (also owned by HoMedics) merged. Salter Brand No. 44 Household Spring Balance Kitchen Scales made of green painted metal with a large clock face dial marked in 1oz graduations and with a shallow metal bowl placed on the flat top connected to the mechanism. An adjustable screw tightened or loosened the spring to bring the pointer to zero, prior to adding the material to be weighed.. A common piece of kitchen equipment as most families used this type of scale when measuring goods for cooking or storing.On Clock face ; NO. 44 / HOUSEHOLD SCALE / TO WEIGH 14LB X 1OZ / Pro. Pat. No. 30819 / 32 / MADE IN ENGLAND / SALTER / S in trademark rope with arrow market gardeners, early settlers, fruit, vegetables, farmers, cooking, recipes, scales, weights, measures, brass, balance beam, moorabbin, cheltenham, bentleigh, kitchen scales, dairy products, cereals, wheat flour, salter housewares pty ltd, west bromwich england -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, matchbox 'Redhead' with matches, 20thC

On 15th December 1909, Bryant & May, Australia’s first match factory at Church Street, Richmond, Victoria. was opened by The Honourable Alfred Deakin, Prime Minister of Australia, and Mrs. Deakin. It was heralded by the first Commonwealth Government of newly-federated Australia because the government of the day was anxious to encourage secondary industry and pledged tariff protection of local manufacturers. The building was constructed in 1909 as the Empire Works to a design by prolific Melbourne architect William Pitt and was purchased soon after by British safety match manufacturer Bryant and May, who significantly expanded the building, adding another level and the landmark clock tower. Bryant and May were unique in that they operated as a model factory, providing workers with conditions and amenities that even today seem generous. These included a dining hall and sports facilities such as a tennis court and bowling green which were constructed in the 1920s. Bryant and May ceased Australian match manufacture in the early 1980s as a result of import competition. Their iconic Redheads matches are now imported from Sweden. The complex has since been converted for use as offices and showrooms but is extremely well preserved. It is listed on the Victorian Heritage Register. Bryant and May was a United Kingdom (UK) company created in the mid-nineteenth century specifically to make matches. Their original Bryant and May Factory was located in Bow, London. They later opened other match factories in the United Kingdom and Australia, such as the Bryant and May Factory, Melbourne; and owned match factories in other parts of the world. Bryant and May survived as an independent company for over seventy years, but went through a series of mergers with other match companies and later with consumer products companies. To protect its position Bryant and May merged with or took over its rivals. In 1971 the Northern Ireland factory, Maguire & Patterson closed down following a terrorist attack.. In the 1980s, factories in Gloucester and Glasgow closed too leaving Liverpool as the last match factory in the UK, until December 1994. . The registered trade name Bryant and May still exists and it is owned by Swedish Match, as are many of the other registered trade names of the other, formerly independent, companies within the Bryant and May group. Two French chemists, Henri Savene and Emile David Cahen, proved in 1898 that the addition of phosphorus sesquisulfide meant that the substance was not poisonous, that it could be used in a "strike-anywhere" match, and that the match heads were not explosive. British company Albright and Wilson, was the first company to produce phosphorus sesquisulfide ( Red Phosphorous) matches commercially. The company developed a safe means of making commercial quantities of phosphorus sesquisulfide in 1899 and started selling it to match manufacturers. Matches were first produced by Bryant & May in Australia in 1909. The Redhead name applies to the red striking heads of the matches which were introduced to Australia in 1946. The logo on the matchbox depicted the head and shoulder of a redheaded woman and has had four major updates since that time with a number of special issues depicting birds, animals and notable persons also produced.The Bryant & May Ltd factory in Church St Richmond is a listed building and has been converted to apartments following the closure of the Company 1980. Bryant & May's Ltd were influential in fighting against the dreadful disease known as Phossy jaw which was caused by white phosphorus used in the manufacture of the early matches. They were also the object of the 'Match Girls Strike' in London 1888, which won important improvements in working conditions and pay for the mostly female workforce working with the dangerous white phosphorus. The public were slow to purchase these safety matches because of the higher price .A box of safety matches with unused matches made by Bryant & May Pty Ltd , Richmond Victoria Australia. The tray containing the matches slides inside the open ended cover.. The striking patch is on both sides of the cover. Av. CONTENTS 50 MADE IN AUSTRALIA / Brymay / 1/3 / Safety Matches / Redheads / a colour picture of a Kookaburra / Laughing KOOKABURRAsafety matches, bryant & may pty ltd, phossy jaw disease, early settlers, moorabbin, bentleigh, cheltenham, lights, lamps, tobacco, white phosphorous, phosphorus sesquisulfide, swedish match pty ltd, pitt william, savens henri, cahen emile david , richmond victoria, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

... to the clock industry. Because of his discovery of stamping out ...Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Eight day movement wall clock with Roman numerals, octagonal shaped rosewood veneered casing, hinged face with locking clip. Wound from front. Face has adjustment for Fast-to-Slow.Part paper label on back of case can just make out "Jerome" and "ight and One" probable meaning is "Eight and One Day" describing the movements operational time between winding the mechanism.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock maker, jerome & co, new haven, chauncey jerome, canaan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Clock Frame, ca. 1908

This clock face was recovered from the wreck of the Falls of Halladale. There were twenty boxes of clocks carried on the ship as cargo, destined for the ports of Melbourne and Sydney. The Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barbed wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. She was one of several designs of Falls Line of ships named after waterfalls in Scotland. The company had been founded between 1870- 1873 as a partnership between Joseph Russell, Anderson Rodger, and William Todd Lithgow. During the period 1882-92 Russell & Co. standardised designs, which sped up their building process so much that they were able to build 271 ships during that time. The Falls of Halladale had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. Twenty cases of clocks were carried amongst the cargo of the Falls of Halladale, an example of the need for people in the early 20th century to have easy access to the current time. The Falls of Halladale shipwreck is listed on the Victorian Heritage (No. S255). She was one of the last ships to sail the Trade Routes from Europe and the Americas. Also of significance is that the vessel was one of the first ships to have fore and aft lifting bridges as a significant safety feature still in use on modern vessels today. The subject model is an example of an International Cargo Ship used during the 19th and early 20th centuries to transport goods around the world and represents aspects of Victoria’s shipping industry. Section of a clock frame, brass, with drilled holes and cutout shapes and an arched base. It was recovered from the wreck of the Falls of Halladale. flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock frame, russell & co., falls of halladale wreck, artifact, clock part, time keeper -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

... to the clock industry. Because of his discovery of stamping out ...Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Clock, marine, in octagonal rosewood veneer case. Roman numerals to dial, has a seconds dial. 2 key-winding holes slow-to-Fast adjustment pin through dial. Small lever in lower edge of case activates a chime. "8 day, 8 inch, Lever Striking escarpment " Paper label on the back of the clock "Jerome & Co, New Haven, Conn" "Manufacturers of every variety of Office and Home Clocks and Time Pieces".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, jerome & co, new haven, clock maker, chauncey jerome -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1940's

... for the then developing motor industry making car clocks and the first... for the then developing motor industry making car clocks and the first ...Smiths began with a craftsman named Samuel Smith who in 1851 opened a shop in Newington Causeway, London, where he made and sold watches, clocks and precision instruments. Samuel had a son, Samuel Jnr who was apprenticed in his fathers business. Samuel Jnr eventually opened his own business at 85 Strand and later opened other premises at 9 Strand, Trafalgar Square and 68 Piccadilly. In 1899 he turned his business into a private limited company, S. Smith & Son Ltd. Samuel Jnr son, Sir Allan Gordon-Smith, joined him as Manager at 9 Strand in 1903 and laid the foundation of the vast Smiths organisation of the future, leading the company towards the supply of accessories for the then developing motor industry making car clocks and the first speedometers patented in 1904. In July 1914 a new company was formed under the name S. Smith & Sons (Motor Accessories) Ltd., to take over the motor accessory business of S. Smith and Son Ltd. and this became the main company of the group which eventually grew to become Smiths Industries Ltd. The original company S Smith and Sons Ltd., continued as jewelers and clock and watchmakers until 1930 when the company was taken over by Bravingtons retail jeweller chain. In 1931 Smiths decided to enter the domestic clock market and formed a new company, Smiths English Clocks Ltd., as the Clock and Watch division of S Smith & Sons (Motor Accessories) Ltd. This is the start of "Smiths Clocks" because this is when they began to manufacture domestic clocks in quantity. Moreover, they set out to produce these clocks at a price that the average householder could afford. S Smith & Sons (Motor Accessories) was at this time was the main company in the Smiths group of companies and their business developed both in the motor vehicle field and outside it. Smiths began to make automatic pilots for aircraft and, through the acquisition of a majority interest in Henry Hughes & Sons Ltd., entered the field of marine instruments. During the war from 1939 to 1945, Smiths' production expanded. There was a demand for motor, aircraft and marine instruments for the Services and the production of industrial instruments and it is at this time that our item was made. In 1944 many changes were made to the Smiths' organisation. The name of the principal company was changed from S Smith & Sons (Motor Accessories) to S. Smith & Sons (England) Ltd. and four new subsidiary selling companies were set up. These were Smiths Motor Accessories Ltd., Smiths Aircraft Instruments Ltd., Smiths Industrial Instruments Ltd., and Smiths English clocks Ltd. The manufacture of clocks and watches ceased in 1979 and 1983 saw Smiths withdraw from producing items for the motor industry.An item that is now regarded as a vintage, sought by horology collectors worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by the Smith company a well known British clock manufacture. Its provenance is well established and it was made during the world war II era specifically for merchant and naval vessels of the time. Naval brass ships bulkhead clock. The clock face is of white enamel with black Roman numerals, an outer minutes ring and black steel hands. There is a subsidiary seconds dial with sweeping hand just above the centre and a fast/slow adjustment lever above that. There is no manufactures name on the dial. There are a beveled glass and brass hinged lid to the front of the clock. The clock is housed in a heavy brass case with screw holes around the circumference for mounting. There are no markings on the clock or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s smith and sons, clock, maritime clocks, clock makers, bulkhead clock -

Flagstaff Hill Maritime Museum and Village

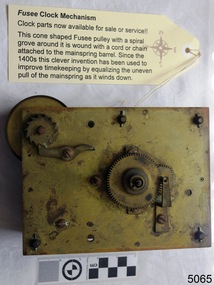

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, safety matches 'Redheads' 2015, c2015

This is a current example of the 'Redhead' logo used by Bryant & May Ltd Richmond,Victoria, Australia c 1946 - 1980 On 15th December 1909, Bryant & May, Australia’s first match factory at Church Street, Richmond, Victoria. was opened by The Honourable Alfred Deakin, Prime Minister of Australia, and Mrs. Deakin. It was heralded by the first Commonwealth Government of newly-federated Australia because the government of the day was anxious to encourage secondary industry and pledged tariff protection of local manufacturers. The building was constructed in 1909 as the Empire Works to a design by prolific Melbourne architect William Pitt and was purchased soon after by British safety match manufacturer Bryant and May, who significantly expanded the building, adding another level and the landmark clock tower. Bryant and May were unique in that they operated as a model factory, providing workers with conditions and amenities that even today seem generous. These included a dining hall and sports facilities such as a tennis court and bowling green which were constructed in the 1920s. Bryant and May ceased Australian match manufacture in the early 1980s as a result of import competition. Their iconic Redheads matches are now imported from Sweden. The complex has since been converted for use as offices and showrooms but is extremely well preserved. It is listed on the Victorian Heritage Register. Bryant and May was a United Kingdom (UK) company created in the mid-nineteenth century specifically to make matches. Their original Bryant and May Factory was located in Bow, London. They later opened other match factories in the United Kingdom and Australia, such as the Bryant and May Factory, Melbourne; and owned match factories in other parts of the world. Bryant and May survived as an independent company for over seventy years, but went through a series of mergers with other match companies and later with consumer products companies. To protect its position Bryant and May merged with or took over its rivals. In 1971 the Northern Ireland factory, Maguire & Patterson closed down following a terrorist attack.. In the 1980s, factories in Gloucester and Glasgow closed too leaving Liverpool as the last match factory in the UK, until December 1994. . The registered trade name Bryant and May still exists and it is owned by Swedish Match Industries as are many of the other registered trade names of the other, formerly independent, companies within the Bryant and May group. Two French chemists, Henri Savene and Emile David Cahen, proved in 1898 that the addition of phosphorus sesquisulfide meant that the substance was not poisonous, that it could be used in a "strike-anywhere" match, and that the match heads were not explosive. British company Albright and Wilson, was the first company to produce phosphorus sesquisulfide ( Red Phosphorous) matches commercially. The company developed a safe means of making commercial quantities of phosphorus sesquisulfide in 1899 and started selling it to match manufacturers. Matches were first produced by Bryant & May in Australia in 1909. The Redhead name applies to the red striking heads of the matches which were introduced to Australia in 1946. The logo on the matchbox depicted the head and shoulder of a redheaded woman and has had four major updates since that time with a number of special issues depicting animals, birds and notable persons also producedThe Bryant & May Ltd factory in Church St Richmond is a listed building and has been converted to apartments following the closure of the Company 1980. Bryant & May's Ltd were influential in fighting against the dreadful disease known as Phossy jaw which was caused by white phosphorus used in the manufacture of the early matches. They were also the object of the 'Match Girls Strike' in London 1888, which won important improvements in working conditions and pay for the mostly female workforce working with the dangerous white phosphorus. The public were slow to purchase these safety matches because of the higher price An empty box of 'Redheads' safety matches made in Sweden for ST-Group, Springvale, Victoria, Australia c2015. The tray for the matches slides inside the open ended cover. The striking patch is on both sides of the cover. The matches have been removed. Matches were first produced by Bryant & May in Australia in 1909. The Redhead name applies to the red striking heads of the matches which were introduced to Australia in 1946. The logo on the matchbox depicted the head and shoulder of a redheaded woman and has had four major updates since that time with a number of special issues depicting animals, birds and notable persons also produced. Bryant and May ceased Australian match manufacture in the early 1980s.Top of cover ; Redheads / 45 safety / matches . Logo ; head & shoulders of a female with red hair Base of coverMade in Sweden / Redheads (R) is proudly marketed / by ST- Group Australia. / 718 Princes Highway Springvale Vic. 3171 / .............../ Readheads is a registered trademark / of Swedish Match Industries AB. / Complies ith European / Match Standard EN 1783-1997-SAF/ WARNING; / KEEP OUT OF REACH / OF CHILDREN. STRIKE / GENTLY AWAY FROM BODY . / barcode.redheads safety matches, safety matches, bryant & may pty ltd, phossy jaw disease, early settlers, moorabbin, bentleigh, cheltenham, lights, lamps, tobacco, white phosphorous, phosphorus sesquisulfide, swedish match pty ltd, pitt william, savens henri, cahen emile david , richmond victoria, match girls strike 1888, -

Bendigo Historical Society Inc.

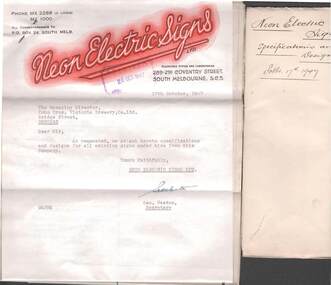

Bendigo Historical Society Inc.Document - COHN BROTHERS COLLECTION: SPECIFICATIONS AND DESIGNS NEON SIGNS

Specifications and Designs of all existing neon signs pinned together and contained within manilla envelope [e] captioned in handwriting 'Neon Electric Signs, specifications and designs. Covering letter enclosed dated 17th Oct 1947 addressed to the Managing Director , Cohn Bros Victoria Brewery, Bridge St Bendigo pinned together with drawing paper designs of neon signs located on various freehold properties. A, Design specifications [Six O'clock Lager] of Mr Marowa above verandah at Ultima. B. Six O Clock Lager, R Veal Confectioner, 5 Alley St Ironbark. C . Six O'Clock Lager, Webb Premises, Pall Mall Bendigo. D. Six O'Clock Lager at Harcourt, Mr J Ely.bendigo, industry, cohn bros brewery -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyBooklet - Amenities Block, J Kitchen & Sons, Unilever Australia Pty Ltd, 1957

Nineteen page booklet with pale blue card cover (with drawing of Amenities Block) and brighter blue binding. The introduction states that the building is about to be completed and it is for all employees use. Written in 1957 it includes section headings - Progress of amenities, Port Melbourne; Design of the building ; Dining and canteen facilities ; Locker and toilet facilities ; Medical centre ; Entrance and time clocks ; Personnel Department ; Social Club library ; Conference room ; Vehicles; Changes in the use ofbuildings ; Use of the building; and drawing of the layout of each floor.industry - manufacturing, business and traders - soaps/candles, built environment - industrial, workers, unilever australia (holdings) ltd, j kitchen & sons pty ltd -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Clock in slip, 22 Dec 1954

The Mathews family have been in continuous ownership of 395 Howe Parade (was 8 Howe Parade until 1964 when addresses re-assigned), Port Melbourne from 1938 to the present (Sept 2019)Six folders of assorted documents relating to the life of Alan Mathews and his family. Employment documents. Alan commenced work with CAC Commonwealth Aircraft Corporation on 27/4/1953. CAC paysheets/packets White slip from Clock #3483 pay no 549industry, workers, alan mathews, commonwealth aircraft corporation, cac -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Clock in slip, 22 Dec 1960

The Mathews family have been in continuous ownership of 395 Howe Parade (was 8 Howe Parade until 1964 when addresses re-assigned), Port Melbourne from 1938 to the present (Sept 2019)Six folders of assorted documents relating to the life of Alan Mathews and his family. Employment documents. Alan commenced work with CAC Commonwealth Aircraft Corporation on 27/4/1953. CAC paysheets/packets White slip from Clock #3483 pay no 4industry, workers, alan mathews, commonwealth aircraft corporation, cac -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Clock in slip, 14 Nov 1962

The Mathews family have been in continuous ownership of 395 Howe Parade (was 8 Howe Parade until 1964 when addresses re-assigned), Port Melbourne from 1938 to the present (Sept 2019)Six folders of assorted documents relating to the life of Alan Mathews and his family. Employment documents. Alan commenced work with CAC Commonwealth Aircraft Corporation on 27/4/1953. CAC paysheets/packets White slip from Clock #3483 pay no 4industry, workers, alan mathews, commonwealth aircraft corporation, cac -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyEquipment - Watchman's clock, J Kitchen & Sons, Detex Corporation, 1960

Portable watch clock with a Detex Newman name badge on black leather casing (front). Used at John Kitchen and Sons in the 1960s (and on?) . Used for security purposes as it records the time when the security officer "clocked on" at each of the numerous points around the premises (i.e. it provided evidence that he had, at least, fully patrolled all areas). Also may be known as the watchman's clock.industry - manufacturing, workers, j kitchen & sons pty ltd, watchman -

Puffing Billy Railway

Puffing Billy RailwaySmiths Setric Electric Clock, circa 1937

Electric Clock - Smiths Setric Clock From 1937 the trademark "Sectric" appears on their synchronous models.Usually on the dial but sometimes also on the back cover. Early clocks had a prominent "T" in sectric. Smiths English Clocks 1931 Smiths, then called S. Smith and Sons (Motor Accessories) Ltd, entered the domestic clock market and formed a new company, Smiths English Clocks Ltd, as the Clock and Watch division with Cricklewood as the main factory. Smiths were one of the first companies to produce synchronous electric clocks. These were put on the market towards the end of 1931. Smiths formed a subsidiary company called Synchronous Electric Clocks to produce these clocks as the first models carry this name. 1932 Smiths purchased English Clock and Watch Manufacturers of Coventry, and acquired the trade names Astral and Empire. 1934 Smiths produced a synchronous alarm clock which they named the Callboy. 1934 They bought the Enfield Clock Co. The Smith's 8 day Calotte clock made its debut at the British Industries Fair in 1934. Prior to this date calottes had been exclusively of foreign manufacture. Also that year, Smiths introduced the Batriclock which was intended for areas where the synchronous clock could not be used. 1935 They introduced the Synfinity, which Smiths described as "the clock that never stops". They said it was "the remarkable combination of a synchronous electric movement with the essential elements of a fine precision lever escapement". If the electric supply failed the clock would run for up to six hours and rewind when the power returned. Apparently the synchronous motor also corrected the mechanical time train at intervals. Smiths produced a synchronous electric chiming clock. 1937 The trade name Sectric appears on Smiths electric clocks. Also the introduction by Smith's of a calotte clock with an alarm movement.Historic - Smiths English Setric Electric Clock Electric Clock - Smiths Setric Clock It is round with the numbers one to twelve, three hands with a white face. Smiths Sectricpuffing billy, clock, time, smiths sectric -

National Wool Museum

National Wool MuseumFunctional object - Time Card Rack

... Clock Textile Industry Metal time card rack. Functional object ...A time clock, sometimes known as a clock card machine, punch clock, or time recorder, is a device that recorded the time an employee entered and left the factory. In mechanical time clocks, this was accomplished by inserting a heavy paper card, called a time card, into a slot on the time clock. When the time card hit a contact at the rear of the slot, the machine would print day and time information (a timestamp) on the card. One or more time cards could serve as a time sheet or provide the data to fill one. This allowed a timekeeper to have an official record of the hours an employee worked to calculate the pay owed an employee.Metal time card rack.time sheet, time card, factory, employee, work life, punch clock, textile industry -

![Artwork - Painting, [Reconciliation] by Leoda Atkinson, 1999](/media/collectors/530576742162ef0fa09a2288/items/534748159821f420f8c03607/item-media/5e86ea5321ea671ae822b1ca/item-fit-380x285.jpg) Federation University Art Collection

Federation University Art CollectionArtwork - Painting, [Reconciliation] by Leoda Atkinson, 1999

Leoda ATKINSON "A few years ago Leoda Atkinson had never painted but now she works around the clock to keep up with the demand for her work. Leoda, a student in Koorie Art and Design at the School of Mines and Industries, Ballarat, was separated from her family as a child and wanted to learn more about her culture. ... (The Age, September 9, 1997) This work was commissioned by the University for the Aboriginal Education Centre's wall. It was designed and painted by Leoda Atkinson, a graduate of the University of Ballarat Koorie Art and Design course. With the assistance of Tom Clark and two third year students the painting of the mural was completed in two weeks. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.A brightly coloured work featuring themes of reconciliation and the University's campuses and learning. The use of the platypus reminded the artist of many different animals, represented the coming together of cultures at the University. art, artwork, leoda atkinson, aboriginal, alumni -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDecorative object - Vintage Battery Clock, Smiths Industries Ltd, c1962

... patented moving coil clocks incorporating transistors, but did ...Smiths patented moving coil clocks incorporating transistors, but did not put any models on the market until 1962 when they announced the Sectronic, which had a moving coil movement. This movement had three hairsprings which served to carry current to the coils. These were one of the first battery operated clocks created. This clock is representative of 1960s timepieces. These were the first battery clocks.A small round clock with Roman numerals and gold circular design around the centre. The clock was produced by Smiths Industries Ltd. in England. It is battery powered and features the Smith Sectronic battery which was first introduced in 1962. In centre of clock face "SMITHS/SECTRONIC BATTERY/MADE IN GREAT BRITAIN" clocks, smith sectronic -

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncPhotograph, Charlton Post Office 1987, c.1987

First Post Office established in Camp St in 1878. Rebuilt on current site in 1879, current Post Office built 1940. Photo part of a Charlton Shire streetscape series 1987.Colour photo of Charlton Post Office. Red brick single storey building. Clock above entrance shows 5 minutes to nine. Yellow combi van, tree and public telephone on LH side of photo. Street light and rubbish bin on right of entrance. Signage above entrance says Post Office Charlton, ER and crown above the clock. Brown fence to right of building,charlton post office, charlton, business, industry, post office -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Hourglass

An hourglass or sandglass is an instrument for measuring a defined time and can be used perpetually by simply turning it over immediately the top bulb empties. The clear blown glass is shaped into two equal sized bulbs with a narrow passage in the centre and contains uniform sized sand or glass particles in the lower bulb. The width of the neck regulates the constant flow of the particles. The glass is held in a stand with top and bottom of equal shape and size. Hourglasses can measure an infinite variety of time by gauging the size of the particles, the shape and size of the bulbs and the size of the passage between the bulbs, thus measuring hours or minutes or even seconds. Generally an hourglass sits between discs of wood at the ends, which are joined by long wooden spindles between the ends and tightened by screw caps. The length of time can be adjusted by adding or removing sand particles. The use of the marine sandglass (or hourglass) has been recorded in the 14th century in European shipping. A one minute sandglass was used in conjunction with the ship’s log for ‘dead reckoning’, (see below) that is, for measuring the ship’s speed through the water. They were also used to regulate ringing the ship’s timetable; for example a 4 hour sandglass was used for the length of the sailors’ watch, and a half hour timer for taking of readings for the ship’s log; the ship’s bell would be rung every half hour. It was usually the role of the cabin boy to watch and turn the sandglasses over at the exact time of them emptying their upper chambers and to ring the ship’s bell. Hourglasses have been used historically for many hundreds of years. Some have been used for timing church sermons, in cooking, in industry and at sea. Even today they are used for measuring the cooking time of eggs and timing a player’s turn in games such as Boggle and Pictionary. The sandglasses at sea were gradually replaced in the late 1700’s to early 1800’s by the more accurate chronometers (marine clocks) when they became reliable instruments. DEAD RECKONING (or Deduced Reckoning) Dead reckoning is the term used to describe the method of calculating the ship’s position from its speed and direction, used in early maritime travel, mostly in European waters. Both the (1) speed and the (2) direction of travel were recorded on a Traverse Board at half-hourly intervals during a helmsman’s watch of 4 hours. The navigator would record the readings in his ship’s log, plot them on his navigational chart and give his updated course directions to the next helmsman on watch, along with the cleared Traverse Board. This was a very approximate, but none-the-less helpful, method of navigation. The wooden Traverse Board was a simple pegboard with a diagram of a compass with eight peg holes along the radius to each of the compass points, plus a grid with ascending half hours in the left column and increasing ship’s speed in knots in a row across the column headings, with a peg hole in each of the intersecting cells. A number of wooden pegs were attached to strings on the board. By placing one peg consecutively in the direction’s radius hole, starting from the centre, and the speed holes when the half hourly reading was taken, a picture of speed and direction for the whole 4 hour watch was created. (1) To measure the ship’s speed a one minute hourglass timer was usually used to measure the ship’s speed through the water and help to calculate its longitude. A rope, with knots at regular standard intervals and a weight such as a log at the end, would be thrown overboard at the stern of the ship. At the same time the hourglass would be turned over and a seaman would start counting the number of knots on the rope that passed freely through his hands as the ship travelled. When the timer ran out the counting would be stopped. A timer of one minute (one-sixtieth of an hour), knots spaced one-sixtieth of a nautical mile apart, and simple arithmetic easily gave the speed of the ship in nautical miles per hour ("knots"). This would be recorded every half hour. The speed could however be inaccurate to the travel being affected by ocean currents and wind. (2) To calculate the ship’s direction a compass sighting would be recorded each half hour.Marine hourglasses or sandglasses were used from around the 14th to 19th century during the time of sailing ships. This hourglass is representative of that era, which is during the time of the colonisation of Australia. Hourglass or sandglass; an instrument used to measure time. Two equal sized clear glass bulbs joined with a narrow passage between them, containing equal sized particles of sand grains in lower bulb. Glass sits in a brass collar at each end, in a frame comprising 3 decorative brass columns or posts, each attached top and bottom, using round screw-on feet, to round brass discs. Disc have Roman numerals for the numbers 1 - 12 pressed into their inner surfaces and hieroglyphics on the outer surfaces. Roman numerals on inner surface of discs " I II III IV V VI VII VIII IX X XI XII " Hieroglyphics impressed on outer surface of discsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, horology, hourglass, hour glass, sandglass, sand glass, timing instrument, dead reckoning, deduced reckoning, finding latitude at sea, sandglass with hieroglyphics and roman numerals, hourglass with hieroglyphics and roman numerals, brass hourglass -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Magazine - HANRO COLLECTION: HANRO AUTUMN WINTER CATALOGUE 1961, 1961

The Hanro company was established in Switzerland in 1884. In 1926 a site in Hargreaves Street Bendigo, behind the School of Mines, was purchased to establish the Bendigo Knitting Mills, a subsidiary of Hanro. The managing director was Charles Handerchin who came from Switzerland. The company was delisted from the Australian Stock Exchange in 1963 when it was taken over by John Brown Industries.Hanro Autumn - Winter Catalogue 1961: The front cover is of a white and pink card background is a sketch in black ink of a lady wearing a matching night dress and dressing gown. To the right top is a sketch of a cuckoo clock. A black banner with Hanro in Pink is also to the right and across the bottom is *Swiss-inspired Lingerie . Catalogue Autumn - Winter 1961*. Inside the cover is advertising and the Index. The Catalogue consists of sketches of ladies wearing a variety of lingerie with the items number, description, material, size, quantity and colours available on gloss paper. The last page is of yellow paper and is the suggested retail selling prices, Style, item number, sizes. On the back is Trade Price List, Style, Size Range and price. On the back of the catalogue on pink and white card is a scene of pink sky with white clouds, sketched in black ink is the Swiss Alps with a Swiss Chalet, trees, flowers and a cow. In a box with a black border on a white background is *Hanro (Aust) Knitting Mills Limited. 163 Hargreaves Street, Bendigo, Victoria. 3024. Sales Offices, addresses and phone numbers of Melbourne, Sydney, Brisbane, Perth, Adelaide and Hobart. There is a sketch in black on a pink background of the Hanro factory in Switzerland *The home of World-Famous Hanro in Liestal, Switzerland*book, magazine, catalogue, hanro. catalogue -

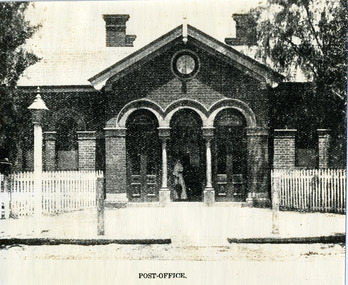

Charlton Golden Grains Museum Inc

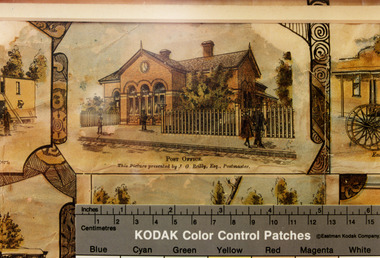

Charlton Golden Grains Museum IncPhotograph - Lithograph, Rider & Mercer, Views of Charlton

Charlton Post Office, High St, December 1891, built in 1879 to replace the original Post Office built in Camp St in 1878.Copy of Charlton Post Office High Street 1891 taken from the lithographs of Rider & Mercer. Possibly hand coloured. Brick building with three arched doorways and a clock above the central arch. Picket fence. One person standing in front of the building, a man walking past and a couple walking past a gate. Ruler showing in lower part of photo with KODAK Colour Control Patches written on it.Post Office. This picture presented by J. G. Reily, Esq., Postmastercharlton, charlton post office, business, industry, lithograph -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Brass Finial, Russell & Co, circa 1886

In the 19th century, the Industrial Revolution meant that shipbuilders could build ships using iron. These iron ships could be much larger, with more space for cargo, and they didn't need as much work to keep them in good condition. Isambard Kingdom Brunel's "Great Britain" built in 1843, was the first ship to be built entirely of wrought iron. In the 1880's steel began to be used instead of iron. Ships also began to be fitted with steam engines, although a great deal of coal was needed to travel even short distances. For this reason, ships continued to be fitted out with sails even though many came with engines. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual, beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908): - Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92, Russell & Co. standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886, they introduced a 3000-ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890, they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four-masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough, south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors, and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. This particular artefact was one of many found by John Laidlaw (a local Warrnambool diver) when diving on the Falls of Halladale in the 1960's. In August 1973, John Laidlaw and Stan McPhee went on to discover the underwater location of the Schomberg - a passenger ship that ran aground on December 26th 1855 near Peterborough and which now lies in almost 9 metres of water. When John Laidlaw died, his family donated a number of artefacts to Flagstaff Hill. The brass finial may have been part of a larger decorative item such as a lamp or clock bracket.This item is significant as it was taken from the Falls of Halladale shipwreck which is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976)A brass, bell-shaped object with a body approximately 3 cm high. It has an outer lip, straight sides that taper in and a flat "cap". The inside of the object is plain with evidence of vertigris. It has a decorative topping almost 2 cm high, which has a double concave hollow neck.flagstaff hill, flagstaff hill divers, flagstaff hill maritime museum and village, great ocean road, warrnambool, falls of halladale, falls of halladale wreck, shipwreck artefact, artefact, brass artefact, brass finial, brass fitting, shipwreck coast, diver, john laidlaw, finial, brass decoration, handmade -

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncPhotograph, The Australasian, Charlton Post Office c. 1910, c,1901

Charlton Post Office High Street built 1879 to replace the original small post office built in Camp St in 1878. Possibly copied from a photograph in the Weekly Times or the Leader c. 1910Poor quality copy of photograph. Brick building with three arched doorways. Woman in long frock carrying an umbrella standing in central doorway. White picket fence and lamp on footpath. Two posts on footpath. Possibly a clock above the central doorway.charlton post office, charlton, business, industry -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Amano Time Clock used in the J. Mann & Sons General Store in Wodonga, c. 1960s

Part of the 'Mann' collection, used for time keeping by employees in the J. Mann & Sons General Store in Wodonga High Street in the c 1960s. J. Mann and Sons was first established as a farm produce store in 1921. The range of products was extended in the 1930s and included groceries and hardware, as well as the first petrol bowser in Wodonga outside the store. After WWII, the premises were extended and the range of products continued to increase. In the 1960s the Mann Family opened a new supermarket in Wodonga, in addition to the hardware business, providing steel, plumbing and industrial supplies, and they employed over 100 people at one stage. With changes in the retail industry, the Mann Family sold the main hardware business to Bunnings and the steel and rural produce business to the Kelly brothers in 2006.The Amano time clock has local significance due to its use in the J. Mann & Sons General Store in High St, Wodonga and the association with the prominent Mann family.Green metal electronic Amano time clock used by employees in the J. Mann & Sons General Store in Wodonga, with a brown clock face and light coloured numbers. Two labels on the lower part of the front surface with a horizontal lock between them, and a small metal plate on the proper left side with the model and serial numbers, plus "S 422" written in black marker below. Slot in the top surface of the time clock for the employees' time cards."AMANO" - on the clock face "TIMETEK SYSTEMS / Phone or Fax: / BU..NESS / BISCOM / COMMUNICATIONS" - on the lower front "Model 6733 Serial No 23229 / Volts /240 / Watts 5 / Hz 50 / AMANO CORPORATION / MADE IN JAPAN / S 422" - on the lower proper left sidemann, general store, wodonga, time clock, commerce, local business, high street, j. mann & sons