Showing 32 items matching "dairy manufacturing industry"

-

Cheese World Museum

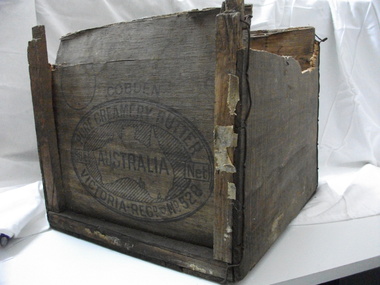

Cheese World MuseumBox, butter

... dairy manufacturing industry... of these exist. butter dairying dairy manufacturing industry butter boxes ...This butter box belonged to Jack Gore of Warrnambool who used it in his garage to store car parts. It is connected to Warrnambool Cheese and Butter Factory Company Limited through the box manufacturer, Peter John McGennan, who was one of the instigators of the factory. Cobden and Warrnambool factories were the first two co-operative factories to produce butter in Victoria, both commencing in 1888. Warrnambool Cheese and Butter Factory Company Ltd is the only remaining independent butter factory still using its original name. It is an example of the manner in which butter was packed for export from the late 19th century until well into the 20th century. Its innovative design is light but strong, using plywood for the box body and struts 'stitched' to the body with wire. The ply was originally pine imported from New Zealand which did not taint the butter. Following the exclusion of the timber from NZ, plantations of local pine were planted and used. McGennan's box factory supplied butter boxes to the majority of butter factories in Victoria, producing up to half a million boxes per year by 1917.This Cobden butter box is historically significant relating to the butter industry and a rare item. Not many of these exist. Wooden butter box with broken ends and a hole in the bottom.Constructed using thin ply ends, sides and base with square wooden struts tied with wire to strengthen the box. The trade mark on the end of the box is an oval with text around a map of Australia with the word AUSTRALIA printing across the map.COBDEN/PURE CREAMERY BUTTER/56lb Net/VICTORIA/REGD No.528butter, dairying, dairy manufacturing industry, butter boxes, cobden -

Cheese World Museum

Cheese World MuseumCheese press, Perfect Cheese company

... Company Avery cheese manufacturing dairy industry J & T YOUNG AYR ...Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This cheese press is significant as it represents the machinery used by an early cheese production company.Stainless cheese press machine with three steel supports and two threaded rods will spring tension wheels to screw down to pressurise the hoops containing cheese.J & T YOUNG AYR UKallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

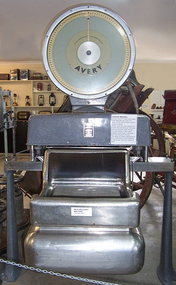

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

... company avery cheese manufacturing dairy industry Made in England ...Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Separator machine. Hand-crank operated milk separator, Crown Separator Co Pty Ltd. Multi-part separator stand with bowls (2) and attachments including a spanner small cone shaped objects on homemade stand. ."42D022" stamped on 2x separator chutes.Manufacture's plate "MADE IN SWEDEN" , "CROWN SEPARATOR / HEAD OFFICE 547 FLINDERS ST MELBOURNE". ."42D022" stamped on 2x separator chutes. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, farm machinery, dairy machinery, dairy industry, crown spearator co, cream -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Milk Churn, Malleys Ltd, 1870-1932

Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. An early item made by an Australian manufacturer of dairy equipment in Australia specifically for the local market. The item gives an insight into early Australian manufacturing processes and is a significant part of Australian early social history.Milk Churn or Milk Can, Medium sized galvanised container to hold milk Malleysflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk container, malleys ltd, dairy equipment -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Souvenir glass, Trufood Employees Reunion 1986, Circa 1986

... to an early manufacturing plant and the dairy industry in the region ...Trufood factory was established in 1911 at Glen Ormiston producing skim milk powder. Along with the Glenormiston Cheese and Butter factory the employed many people in the district.A link to an early manufacturing plant and the dairy industry in the region.Short based glass with gold lettering and gold rim. Trufood Skim milk Employees reunion 26th January 1986.glenormiston cheese and butter factory, trufood glenormiston -

Glen Eira Historical Society

Glen Eira Historical SocietyDocument - Classic Retirement Village, Brighton

Four documents about the history of this site pre Classic Retirement Village: 1/A copy of a description of the sale process of the Gascor site, cnr Nepean Highway and Thomas Street, to Becton Corporation in 1997 And 1998. Printed on 31/07/2010 from the Victorian Auditor General’s Department website with aerial photograph 2/A copy of page one of the Gleneira Planning Scheme dated 19/01/2006 which mentions the Gascor site. 3/Research note by Andrew Frederick dated August 2010 listing occupiers of the site in the 1960 and the 1970 Sands and Mc Dougall Directories. 4/Research note by Claire Barton dated May 2010 containing Ian Swan’s recollections of working at Daylesford Worsted Woollen, occupier of the site, in the 1960s.thomas street, brewer road, bentleigh, gascor, becton corporation pty ltd, virginia park, gas and fuel, hughesdale dairy, east boundary road, moorabin, east bentleigh, hooblerstone, clairmont avenue, glen eira, daylesford centenary woollen and worsted mills pty ltd., nepean highway, f and j industries australia plastic and rubber division., swan ian, korman stanley, mills, wool industry, weaving mills, textile factories, textile manufacturing, manufacturing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cream Can, Malleys Ltd, 1920-1950

This small cream can was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in various sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. This cream can was designed for domestic home use and was used to fetch cream from a dairy or retailer of dairy products between 1920 to 1950s. M Luscombe Diamond Creek on the nameplate suggests this is the farm dairy that supplied the cream the can would hold and that they were the owners of the can. This dairy no longer exists as the area is now a housing estate.Cream can, round metal container with fitted lid and carrying handle. Can has a short wide neck. Body has embossed letters and an attached metal nameplate that has been soldered. Made by Malleys. Embossed raised letters "MALLEYS". Text on nameplate ""M LUSCOMBE / DIAMOND CREEK " warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, domestic object, cream can, dairy container, diamond creek, m luscombe -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales,Spring Balnce Imperial ‘Household’ Salter, 20thC

In the 18th century, spring scales appeared. To produce these scales, a manufacturer would use the resistance of a spring to calculate weights, which could be read automatically on the scale’s face. The ease of use of spring scales over balance scales is what led most post offices to outfit their clerks with spring postal scales. One of the most common types of spring scales was the kitchen scale—also known as a family or dial scale. Designed for horizontal surfaces, these scales used the weight of goods in a pan at the top of the scale to force the spring down. Such scales were common in early-20th-century households and were sold by Sears and Montgomery Ward. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks made both. SALTER HOUSEWARES began in the late 1760 in the village of Bilston, England. At this time Richard Salter, a spring maker, began making 'pocket steelyards', a scale similar to the fisherman's scale of today. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. and later established a large, well equipped manufacturing site in the town of West Bromwich. The business thrived throughout the 1900s, and in 1972 the company was purchased by Staveley Industries Plc. In 2002, the management team at Salter Housewares Ltd, backed by Barclays Private Equity, bought the company out from the group, to concentrate on its consumer businesses. In 2004 was sold to the US-based HoMedics company, and in 2006, Salter Housewares USA and Taylor Precision Products Inc (also owned by HoMedics) merged. Salter Brand No. 44 Household Spring Balance Kitchen Scales made of green painted metal with a large clock face dial marked in 1oz graduations and with a shallow metal bowl placed on the flat top connected to the mechanism. An adjustable screw tightened or loosened the spring to bring the pointer to zero, prior to adding the material to be weighed.. A common piece of kitchen equipment as most families used this type of scale when measuring goods for cooking or storing.On Clock face ; NO. 44 / HOUSEHOLD SCALE / TO WEIGH 14LB X 1OZ / Pro. Pat. No. 30819 / 32 / MADE IN ENGLAND / SALTER / S in trademark rope with arrow market gardeners, early settlers, fruit, vegetables, farmers, cooking, recipes, scales, weights, measures, brass, balance beam, moorabbin, cheltenham, bentleigh, kitchen scales, dairy products, cereals, wheat flour, salter housewares pty ltd, west bromwich england -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, bottle cream 300ml, post 1966

General use of milk bottles is usually associated with the 20th century , with occasional late 19th century. Initially, milk was delivered in cans stacked upright in a wagon. At each stop, someone, usually the wife of the house, would bring a pitcher or a pail to the wagon, and the milk man would ladle out the desired amount of milk. Needless to say, this practice was hazardous and unhealthy. The New York State Tuberculosis Association condemned the practice of selling “loose milk,” still being conducted in New York City in 1922, as a major cause for the spread of tuberculosis (Glass Container1922:8). It is probable that the delivery of milk in glass containers became universal shortly thereafter Melbourne Glass Bottle Works Co Pty Ltd (1903 - 1915) Registered in Victoria in 1903 the company amalgamated with the Waterloo Glass Bottle Works Ltd in 1915 to form Australian Glass Manufacturers Company, Limited. Melbourne Glass Bottle Works Spotswood 1872- 1915 The Melbourne Glass Bottle Works (former), comprising a complex of buildings constructed between 1880 and 1940, at Booker Street, Douglas Parade, 2-38 Hudson Road, Raleigh Street and Simcock Avenue, Spotswood. The former glassworks was established in 1890 and originally made bottles for pharmacists Felton Grimwade before it was sold to the State Government by US multinational, OI glass manufacturers Australian Consolidated Industries Ltd was formed in 1939 when Australian Glass Manufacturers Co Ltd changed it's name to reflect diversification into building products. 1982 a new holding company was formed and the company's name was changed to A.C.I. International Ltd. Metric Measure was introduced in Australia 14/2/1966 A clear glass, cream bottle 300ml Around Shoulder : NO DEPOSIT NO RETURN 300ML CREAM Around Base: (makers stamp) M 10116 38 melbourne, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, manufactured glass, milk bottles, dairy farmers, dairies, decimalisation in australia 1966, metric measures, melbourne glass bottle works, spotswood, felton grimwade pty ltd, pharmacists, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Cheese World Museum

Cheese World MuseumPhotograph, Unknown photographer, The first mechanical milking machine public demonstration in Allansford district, 1905

... in Warrnambool Standard 5 June 1905. uebergang dairy industry rural ...The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This photograph is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No. Photograph tells the story of a special celebration marking the occssion of the demonstration of the first mechanical milking machine on the Ernst Uebergang property Briarwood at Cudgee Victoria. Ernst Uebergang is inside the shed. Reported in Warrnambool Standard 5 June 1905.Photo on badly damaged brown mount board. Image depicts LKG milking machine demonstration. Dignitories, farmers and children present. Two men are inside the shed with two cows. Written on back of photo 'LKG Milking Machine Lawrence Kennedy 1902/ Mr Ernst Uebergang inside shed.'uebergang, dairy industry, rural industry, food manufacture, machinery, lkg, cudgee, briarwood, milking machine, children, cows, dignitories, farmers, bucket -

Cheese World Museum

Cheese World MuseumTrophy, 2001

... in Australia. allansford dairy industry cheese warrnambool cheese ...Awards for cheese quality have been part of the dairy industry since the 19th century and are designed to maintain and continue improving the quality and flavour of cheeses manufactured in Australia.Wooden trophy in form of cut-out shape of Victoria mounted on a plinth by two gold-coloured rods. Details of the award printed in black on the shaped area and a small plaque noting details of winner attached to the plinth.Rhodia DIAA Dairy Product Awards 2001/Rhodia Australia Award/Highest Scoring Cheddar Cheese - Mild in Class 7 Base plate - Presented to/Warrnambool/Cheese & Butter Factory Ltdallansford, dairy industry, cheese, warrnambool cheese and butter factory ltd, wcb, rhodia, dairy industry association of australia, trophies -

Cheese World Museum

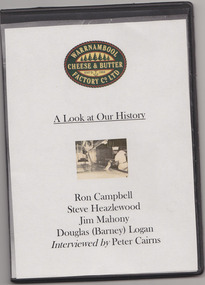

Cheese World MuseumDVD, A Look at our History -Vol.2, 2005

Series of interviews with former employees of Kraft (Allansford) and directors of Warrnambool Cheese and Butter Factory discussing their time and experiences as employees and directors of the factories. Warrnambool Cheese and Butter Company Ltd was established in 1888 and in 1935 developed a relationship with Kraft Foods Australia whereby Kraft leased premises from WCB. The two companies shared the milk collected to make their core products of cheese (Kraft) and butter and milk for domestic use (WCB). This arrangement continued until 1997.Gold DVD in plastic case, B&W cover with colour WCB logo.A Look at our History: Ron Campbell, Steve Heazlewood, Jim Mahony, DJ (Barney) Loganallansford, heazlewood, steve, campbell, ron, mahony, jim, logan, dj (barney), wcb, warrnambool cheese and butter factory company ltd, kraft foods ltd, dairy industry, dairy processors, factories, local history, cairns, peter, cheese manufacture -

Cheese World Museum

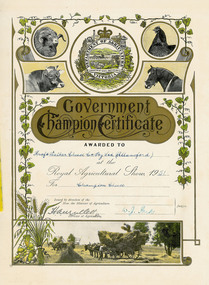

Cheese World MuseumCertificate, Government Champion Certificate, 1951

Kraft-Walker Cheese Company commenced in Allansford in 1935 leasing the factory premises from Warrnambool Cheese and Butter Factory Company. Dairy companies entered competitions organised by the Dairy Industry Association and associated organisations and local agricultural societies to encourage improvement in products. Some of these awards are considered prestigious and highly regarded within the industry. The certificates were passed to Cheese World Museum by the factory management.This certificate was held by the factory management until transfer to Cheese World Museum. The certificate provides an insight into the dairy industry during the 1950s.Cream card certificate from Royal Agricultural Show has a plain line border on left, bottom and right side with inner border of green vine plant on left, top and right side. A sheaf of oats and a scene of haymaking complete the border design. The top of the certificate has the Department of Agriculture Victoria logo flanked by circular images of a sheep and cow on the left and a hen and horse on the right. The centre of the certificate has a gold shape overprinted with black.Government Champion Certificate/ Awarded to Kraft Walker Cheese Co Pty Ltd (Allansford) at the Royal Agricultural Show 1951/ for Champion Cheese/ Issued by direction of/Hon. the Minister for Agriculture/H A Mullett/ Director of Agriculture/ W J Park/ Judgesallansford, kraft walker cheese company, cheese manufacture, dairy awards, product awards, warrnambool cheese and butter factory company, kraft walker pty ltd, royal agricultural show, department of agriculture victoria, cheeses, cheese manufac, warrnambool cheese and butter -

Cheese World Museum

Cheese World MuseumPhotograph, Kraft Walker Cheese Pty Ltd Garvoc Branch factory, c1940

... and was eventually demolished. Garvoc Allansford Dairy industry food ...The Kraft Walker Cheese Co Pty Ltd entered into an agreement with Warrnambool Cheese and Butter Factory Company in 1935 whereby the Kraft company leased premises from WCB. This arrangement remained in place until the 1990s. WCB took over the Garvoc factory in the 1920s. It became outdated and was eventually demolished.Black and white photograph showing timbered building with iron roof and turned wooden finial on the gable end. There are three timber ventilation ducts on the roof. The gable end has sign Kraft Walker Cheese Co Pty Ltd Garvoc Branch. A concrete block addition is at the front. A tray truck with milk cans is in between the main factory building and the outbuilding.garvoc, allansford, dairy industry, food manufacture, kraft walker cheese company, factories, cheese, kraft foods ltd, transport, milk cans -

Cheese World Museum

Cheese World MuseumBook, laboratory notes

Kraft Walker commenced cheese processing at Allansford in 1935 under a lease arrangement with Warrnambool Cheese and Butter Factory. This arrangement remained in place until Kraft officially ceased bulk cheese production at Allansford in February 1993. Kraft was responsible for farm collection of milk which was then shared between the two companies -Kraft for bulk cheese manufacture and Warrnambool Cheese and Butter Factory for whole milk, milk powder and butter manufacture. Laboratory technicians tested milk and cheese during the receival and manufacturing processes to ensure a high quality product. Derek Shaw, whose notebook this is, was the first person in charge of the Kraft Allansford laboratory. He kept notes of testing undertaken and recorded results of anything considered unusual. This notebook is one in a series of 33. Les O'Callaghan commenced work in the laboratory as Derek Shaw's assistant and technician in charge following Derek's retirement. He too kept notebooks of test results.Kraft laboratory technician/bio-chemist Les O'Callaghan was responsible for the introduction of a number of quality control measures which are still in use in the dairy industry today. Les was mentored by Derek Shaw. This note book provides an insight into the dairy processing industry at this period.Black exercise book with lined pages; white sticker on front cover showing dates usedLH/ 17/11/1938 / 2/5/1939allansford, dairy industry, dairy processors, cheese making, kraft foods ltd, warrnambool cheese and butter factory company -

Cheese World Museum

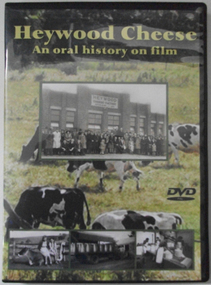

Cheese World MuseumDVD, Heywood Cheese; an oral history on film

For many years the Heywood Cheese Factory was an important part of life for Heywood and district farming and a vital place of employment for up to 40 men and 10 women. The factory opened in 1939 as a subsidiary of the Portland Butter Factory before becoming a world renowned cheese making enterprise. It was felt important to document its history from the surviving factory workers, including dairy suppliers and milk truck drivers. We hear their stories of the long hours and hard work without penalty rates, travelling unsealed roads and mixed with their humour of the bygone days is an important acknowledgement of that era. [blurb on back cover]This oral history provides significant material relating to the dairy industry in south west Victoria during the mid 20th century. The interviews give first-hand recollections of the interviewees involvement in the industry from a point of view of factory workers, milk pick-up drivers and farmers.Full colour DVD cover has photograph of Heywood Cheese factory and photographs of girls with calves, milk cans on a truck and workers in the cheese room, superimposed on a photograph of dairy cows grazing in a paddock. The DVD has the photograph of the cows grazing in the paddock.Heywood Cheese/An oral history on film (front) For many years Heywood Cheese Factory was ... [see historical information] Edited by Garry Kerr for the Heywood Pioneer Wagon Shed/ Museum History Group who wish to gratefully acknowledge the/ support of the Victorian Government and Public Records Office/ Victoria for making this project possible. Duration: 70 minutesallansford, heywood, cheese factories, cheese manufacturing, dairying, cheese -

Federation University Historical Collection

Federation University Historical CollectionBook, Robert S. Brain, Government Printer, Victorian Year Book 1895-8, 1901

This year book was published in the year of Australian Federation. It was the 22nd issue of the Victorian Year BookBrown soft covered book of 1000 page. The book contains a digest of the statistics of Victoria with reference to the other Australasian Colonies and other countries. Topics include the land system of Victoria, Crown lands, Agricultural statistics, cultivation, industry, livestock, wool, dairy farms, cattle, rabbits, manufactures, alcohol production, mining, defense. Statistics were provided by J.J. Fenton, Assistant Government Statist. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

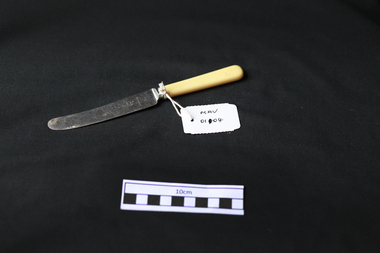

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, cutlery butter knife, c1930

Rodd's was established by George & Ernest Rodd in Melbourne in 1919.They were manufacturers and wholesalers of precious metal jewellery. Later they began to manufacture high quality silver plated cutlery under the brand name “Rodd”. They then expanded into holloware when they took over Platers Pty. Ltd. who produced a very high quality range of silver plated Sheffield Reproduction Silverware, under the brand name “Hecworth”. Rodd’s established a large factory at 150 Barkly St., St. Kilda, Melbourne. During WW2 with a staff some 200, the factory produced ordnance components to help with the war effort. Rodd’s established sales offices in the main city centres of all States. The company prospered. In December, 1960, Rodd [Australia] Ltd. was merged with Mytton’s Ltd., Melbourne, and became part of the newly formed company Mytton Rodd [Australia] Ltd. Mytton’s were also producers of silver plated cutlery under the brand name “Grosvenor” and were strong competitors to the Rodd brand of cutlery Australia wide. It was a friendly take over and the Directors of Rodd [Aust.] Ltd. were appointed to the board of Mytton Rodd [Aust.] Ltd., and some to the Holding Company Mytton’s Ltd. Mytton’s were heavy manufacturing engineers producing a large range of stainless steel products including: kitchen sinks of various design, beer barrels [9 and 18 gallon kegs] for the breweries, milk vats for cooling and storing milk on dairy farms, a large range of dairy and industrial vessels, road transport tanks, LPG tanks, low pressure pre-mix vessels for the soft drink industry. They also produced a range of domestic bathes, steel railway sleepers, using their 3000 ton hydraulic presses. Mytton’s also had their own non ferrous foundry and rolling mill which produced nickel silver sheet used in the manufacturer of their silver plated cutlery. They also produced copper sheet for their own and industrial use. Mytton’s had factories in York St., South Melbourne and Port Melbourne. Rodd [Aust.] Ltd. set up a manufacturing, distribution plant in Auckland, New Zealand, circa 1960. This company began producing precious metal jewellery in a rented space in the premises of Matthey Garret Ltd., Bullion Merchants, in Drake St., Auckland. Later they moved into their own building in Sale St., Auckland. The company prospered and purchased land and built a factory at 121 Apirana Ave. Glen Innes, Auckland, circa 1964. ( B. McCulloch Rodd Pty Ltd)A butter knife with stainless steel blade and bone handle c1930on blade; RODD / STAINLESScutlery, stainless steel, cheltenham, moorabbin, bentleigh, early settlers, rodd aust ltd, mytton rodd pty ltd, aukland, port melbourne -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyContainer - Milk bottle, M Woodruff Royal Dairy, Port Melbourne, c.1950

... to the Superior Dairy. Michael Thomas WOODRUFF Industry - Manufacturing ...Michael Tomas WOODRUFF commenced his Woodruff's Royal Dairy in 1916. It was originally located at 22 Derham Street, Port Melbourne, and later expanded into Bridge Street. In 1956 the name was changed to the Superior Dairy.Glass milk bottle from Woodruff's Royal Dairy, Port Melbourne.MX2769 MX2000 Imperial Pint Woodruff's Royal Dairy Port Melbourne. On bottom 36.michael thomas woodruff, industry - manufacturing, business and traders - dairies, woodruff's royal dairy -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Lister Cream Separator, R.A. Lister & Co. Ltd, c1910

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. LISTER - A prominent make of separator which became very popular with the dairy farmer, was the "Lister" separator. The early separators sold by R. A. Lister in the 1880's, were made by "Koefoed & Hauberg", Copenhagen. Denmark, called the "Alexandria". Ashton Lister became the sole agent for Koefoed & Hauberg made separators in England and all the English Colonies, throughout the world. Being an enterprising salesman, Ashton, sent his son Edward on a three-year sales tour of Australia & New Zealand in 1890, (hence the strong presence of Lister in Australia.) Initially, the separator was totally manufactured in Denmark and assembled in Dursley, England. By 1892 Lister were making parts at their Victorian Iron Works, and around about the early 1900's, Lister began manufacturing separators in their own right, severing ties with Koefoed & Hauberg. The Lister firm is still going today, under the name of Lister Petter, England, but do not manufacture separators, as the manufacture of farm / domestic separators ceased in the early 1960's.This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is metal plated with blue enamel. The vat is made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A metal plate featuring the manufacturer information is attached to the side of the handle. Model CR 15 hand operated table version.On metal plate attached to handle" Lister/ MADE BY R. A. LISTER & Co.LTD. / AT DURSLEY ENGLAND / VICTORIAN AGENTS / GIPPSLAND & NORTHERN CO-OP/ CO. LTD. / MELBOURNE C.1"dairying industry, dairy machinery, milk separators, lister separators