Showing 56 items matching "flywheels"

-

Warrnambool and District Historical Society Inc.

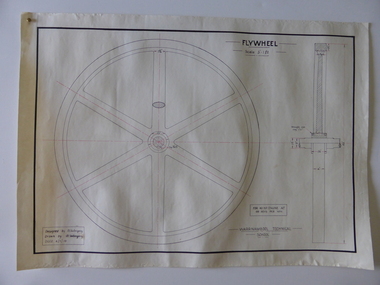

Warrnambool and District Historical Society Inc.Drawing, Warrnambool Tech .1 Fly Wheel.2 Bevel Wheels R Uebergang, 1919

These drawings have been produced by Ron Uebergang at the Warrnambool Technical School in 1919. Uebergang family members were pioneer settlers in the Warrnambool area in the early 1850s. Ronald John Uebergang (1903-1971) was born in Warrnambool to Ernest Uebergang and Mary Watson. Ron Uebergang lived at the family property, Hopkins Hill at Allansford and went to Allansford State School and Warrnambool Technical School. He was mechanically minded, a good photographer and fond of music and dancing. He married Myra Hall and was a dairy farmer at Hopkins Hill and later grazed beef cattle. Warrnambool Technical School was established in 1913, firstly at a Timor Street site and later at Caramut Road (today it is known as Brauer College). These drawing are of considerable interest as works produced by Ron Uebergang. Uebergang family members have been prominent in the Warrnambool-Allansford area since the pioneering days of the district. The drawings also are good examples of the type of work produced by Warrnambool Technical School students in its early years.These are two designs and drawings by Ron Uebergang produced at the Warrnambool Technical School in 1919. They are drawn on white card using black and red ink. The scale of the Flywheel is three inches to one foot and the Bevel Wheels are one-third full size. The drawings are edged with heavy black lines. The two sheets have the signature of Ron Uebergang. There are also four pages of handwritten notes on the Flywheel and Bevel Wheels.‘Designed by R. Uebergang’ ‘Drawn by R.Uebergang’ ‘Date 4/1/19’ (on Flywheel sheet) ‘Date 27/5/19’ (on Bevel Wheels sheet) warrnambool technical school, ronald uebergang, history of allansford -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, 1877

Restored by Maldon Flywheelers Association. Originally owned and used by Zemster Brothers of "Brook Mount" Shellbourne.Known as "Aunty Jack"Large 4 wheeled 9 HP single cylinder (horizontal) steam engine, designed to be towed. Front wheels smaller than rear. Folding smoke stack with spark arrestor. Fire box and smoke stack painted black, boiler and steam cylinder green, wheels grey. In working order but engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Timber front turntable and back brake pad assembly. Brass water drain tap on firebox. Also other brass fittings on firebox.On brass ring near top of firebox:- "Serial No. 5672, Marshal Sons & Co. / Limited / Engineers / Gainsborough England". Metal plate on front turntable:- "Restoration of the Front Undercarriage / and retubing of the boiler by / Castlemaine Technical School / 1979". Cast in relief on wheel hubs:- "Marshal Sons & Co. Gainsborough".machinery - engines - steam -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFlywheel

Flywheel or Governor for a "Walker's Log". Enables the Log to spin at a uniformed speed due to the Flywheel effect of this device. Made of cast brass.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia - Sewing Machine, Wertheim

Wedding present to Mr Clive Richard Harrison and his wife Margret Audrey in 1927. Buried to protect it from the 1939 Bushfires - Pomonal. Remained in use until the death of Mr. Harrison in 1982. Home sewing machine Treadle Pre-electricBlack, Rusted. Flywheel has wooden handle. IncompleteName on top in gold, case has a key hole. carving on sides knob on to - light wood -

Orbost & District Historical Society

Orbost & District Historical Societywheel

Many of the early sewing machines were powered by a treadle mechanism. The treadle was operated by pressing down on it with a foot, or both feet, to cause a rocking movement. This movement spins a large wheel on the treadle frame, connected by a thin leather belt to a smaller driving wheels on the sewing machine.A treadle sewing machine flywheel mad of cast iron. It is three tangent circles within a larger circle.3treadle sewing-machine flywheel -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSewing Machine

Singer sewing machine without base, decorated with stylised flowers (as per VMVM 27). Hand operated with flywheel.domestic items sewing machinery -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncMiniature Water Turbine

Miniature water turbine (pelton wheel, single jet) mounted on a wooden frame. Undershot wheel driving a pulley at one end of the shaft. Flywheel at the other end of the shaft. Small die-cast buckets, some broken and missing. Pelton wheel and flywheel painted red, wooden frame unpainted.Nonemachinery; water turbine; power -

Bendigo Historical Society Inc.

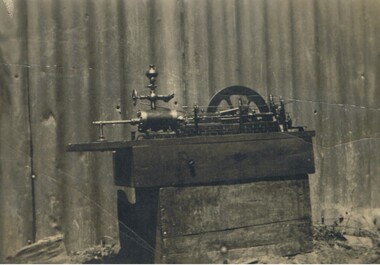

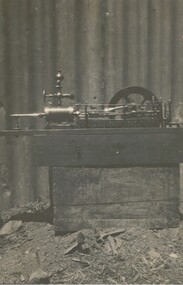

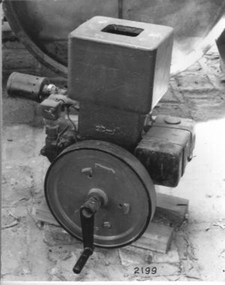

Bendigo Historical Society Inc.Photograph - DONKEY ENGINE

Black and white photo of small machine on box in front of corrugated iron wall. Consists of cylinder, flywheel etc. Donkey engine.topic, objects, tools -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - DONKEY ENGINE

Black and white photograph of small machine on box in front of corrugated iron wall. Consists of cylinder, flywheel etc. Donkey engine.topic, objects, tools -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncDrill Press

Wall mounted hand operated drill press. Flywheel on LHS. Drill lowering hand wheel on top. Painted green and black.Cast in relief on frame "Champion ......... & Forge Co./ Lancaster" on LHS, "Warranted" on RHS.trades, metal working -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, C 1849

Thought to be the world's only working example of this engine. Used for driving overhead shafts in workshops, sawmills etc. Restored by members of the MVMM. Found at the Demsters property Shelbourne. Thought to be the only one of its kind in the world.Horizontal steam engine driving a flat belt pulley. Pulley shaft at right angles to engine shaft also carries a large flywheel. A mechanical oiler mounted on the engine base is activated by the engine valve shaft. Engine cylinder and valve housing painted dark green. Engine base, pulley and flywheel painted maroon. Oiler painted mid green.On engine valve box cover - Light green cast iron oval plate with "Cornelius Pettet / Engineer / Edinburgh" Brass plate on oiler - "Delvac Mechanical Lubricator / Design No 18376 / Made for and supplied by / Vacuum Oil Company Pty. Ltd. / Australia"machinery; engines; steam power source -

Bendigo Historical Society Inc.

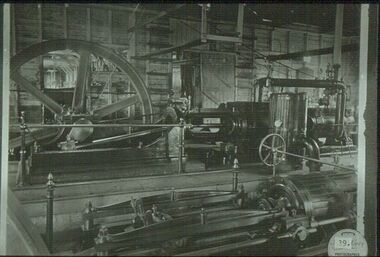

Bendigo Historical Society Inc.Slide - ALBERT RICHARDSON COLLECTION: VIRGINIA CRUSHING BATTERY ENGINE ROOM

Slide.Engine at the Virginia Crushing Battery. Large flywheel on LH side, machinery in front. Possibly stampers visible through window at rear of engine room.No. 39 printed on bottom of slide. Photographer's name covered by number.mine, gold, virginia machinery., bendigo mines-jack hattam collection. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Ship Taffrail Log Flywheel, 1930+

The flywheel possibly belongs to a Walker's Cherub Mark III Ship-log taffrail, how the flywheel operates is a metal loop of the recording log would have been connected to the flywheel, so you could see if it was spinning properly. After the flywheel, is the rotor that was towed behind the ship and the revolutions of the rotor would register on the indicator, thus measuring the distance the vessel had travelled. Thomas Ferdinand Walker (1837–1921) first patented the Cherub log in 1878. It was one of the first logs in which the recorder was placed onboard a ship rather than being incorporated as part of the rotor. The Cherub Mark III series was produced from 1930 it came in two versions a thousand-mile which is quite rare and a five hundred-mile version.This ship log flywheel was invented and made by a significant marine instrument maker and innovator of machinery Thomas Walker. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades to measure the distance travelled at sea updated versions are in use today by mariners.Log Governor (or Fly-wheel) from a Ships Taffrail Log, metal wheel with 6 spokes, hub has rope attached for connecting to ships log. Boss the other side for attachment to the spinner.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, log governor -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncDrill Press

Wall mounted drill press, flat belt pulley driven. Flat belt pulley and flywheel on LHS, hand operated drill lowering mechanism on RHS. Unpainted.Cast in relief on main frame "No 1082" on LHS, "Buffalo Forge Co. / Buffalo N.Y." on RHS.trades, metal working -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncHorizontal Oil Engine, Early 20th century

Horizontal cylinder oil engine in working condition. Mounted on a steel and timber chassis with 4 wrought iron wheels. Axles are fixed to timber spacer beams. Two flywheels. Cylindrical cooling water tank, cast iron exhaust system and vertical exhaust pipe mounted at crankshaft end. Engine painted dark green, crankshaft balance weights red, flywheels black, cooling water tank black. Oval brass plate on cylinder - "The "Blackstone" / Carter's Patent / 92393 / Quote This No. / When Ordering Parts / Oil Engine". Brass plate on engine frame - "British Patents / Nos. 19640-02 / 24611-03" Oval brass plate on Balance weight guard - "The "Blackstone" Oil Engine / Clutterbuck Bros / Adelaide / South Australia". engines .... horizontal cylinder ....oil engine, machinery - engines, oil -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncAir Compressor

Horizontal single cylinder air compressor. V belt driven with 11 belts. V belt on one end of crankshaft and flywheel on the other end. Painted pale green.Logo cast in relief in several places signifying - "Thompsons Castlemaine Engineering Propriety". Stenciled on cylinder "M75".machinery - compressors; metalcraft. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - ROSELLA PRESERVING FACTORY

sepia photo. Tomatoes on open grid conveyor belt dropping into narrow channel. Flywheel, drive belts in background. On back in ball point pen ' Rosella Factgory, Brougham St. 'organization, business, rosella factory -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine

Vertical cylinder steam engine painted black, red and grey. In working order. Large flywheel and pulley on RHS and mounted on a raised concrete base. Belt drive overhead governor.No. "8532" is cast on the LHS of the frame.engines, steam, vertical -

Melbourne Tram Museum

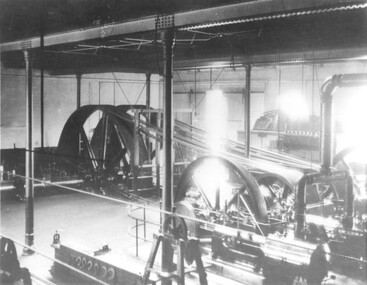

Melbourne Tram MuseumPhotograph, Interior of a Melbourne cable tram Engine House

The photograph shows the interior of a Melbourne cable tram engine house, or powerhouse, with the steam cylinders and flywheels in the view. Location and date unknown.Yields information about the interior of an cable tram engine house.Photograph, black and white, plain papertrams, tramways, cable tram, engine house, power house -

Puffing Billy Railway

Puffing Billy RailwayTool - Drag Saw, New Record Drag Saw, circa 1920s

Circa 1920s petrol driven cross saw. It was mainly used cross cutting felled logs The Land on which the Menzies Creek railway station and Museum are built on was once apart of James Hermon's & his son William Hermon's property on which this Drag Saw was used. reference : Jinkers and Whims: A Pictorial History of Timber-Getting By Jack BradshawHistoric - Industrial Timber working petrol driven cross saw - Drag SawLarge, mechanical saw mounted on a steel shaft connected to tin fuel and water containers. The machine has two large spoked wheels, a rotating Crankshaft and an extended arm/rod attached to a crank and flywheel.New Record puffing billy, drag saw, timber cutting, early mechanical equipment, james hermon & sons, menzies creek, 1920s -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncOil Engine

Bartram type AK, 5 HP horizontal cylinder water cooled magneto ignition oil Engine mounted on a metal and timber chassis with 4 wheels. It has its own cam driven water pump which pumps cooling water over metal gauze for evaporative cooling. Painted green. It has two flywheels, one at each end of the crankshaft, with a flat belt pulley attached to one flywheel. Cooling tank of galvanised steel with Bartram stencilled on one side. In working order.Cast nameplate on front of crankcase with a Bartram logo cast on also "Bertram / Type / AK" -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Equipment - Stationary Motor

Used by Ted Beddiscomb of Gormandale near Traralgon, brother in law of donor. Ted was a dairy farmer and used the motor for about 10 years to pump water. It is possible it was on his farm for some years prior to this. Tom did some reconditioning and preservation on the unit.3 HP 4 cycle motor primarily used to belt drive other equipment such as pumps and machinery on a farm etc. Petrol driven, magneto ignition and water cooled.Bronze plate 'The Rosebery Engine C25387 RPM 1000 HP3 manufacturer Westinghouse Rosebery Ltd Sydney. 3C-103 on water jacket; 3D-1 on engine housing; 3C-15 on flywheel.rural industry, farm machinery, machinery, engines - internal combustion -

Flagstaff Hill Maritime Museum and Village

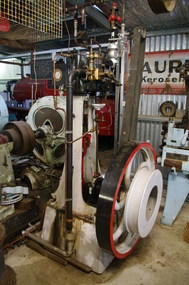

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Bendigo Historical Society Inc.

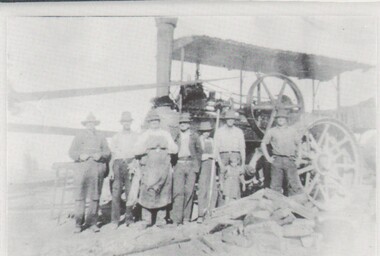

Bendigo Historical Society Inc.Photograph - HARRY BIGGS COLLECTION: TRACTION ENGINE

Photograph (proof 66) of a group of six men, one boy and a small girl standing in front of a traction engine. A belt from the flywheel of the engine can be seen leading off to the left of the photo. Piles of wood are in front of the grouptopic, farming, traction engine, traction engine -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCondenser Air Pump, 1913

Vertical cylinder reciprocating condenser air pump with two 107 cm diameter flywheels (one on each end of crankshaft). The operating cylinder at at top of the machine has a centrifugal governor. Access ladder to platform at front. Painted black and red. On cylinder head "63"machinery pumps reciprocating metalwork -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Bush Sawmill beside the Wimmera River in Dunolly 1993

Dunolly 1993. Bush Sawmill beside the Wimmera River. Wooden buildings in Background. Chimney of what appears to be a steam driven engine with flywheel and belt driving a saw bench. Several men in photo. Original photographic taken by Charles Nettleton.Black & white photograph of timber and logs beside a water body with buildings and a tall chimney in the background. Around seven people in the background.Bush Saw Mill Wimmera River near Stawell 1877 Negative Reversed copy also 2641water industry -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncDC Generator - Steam Powered

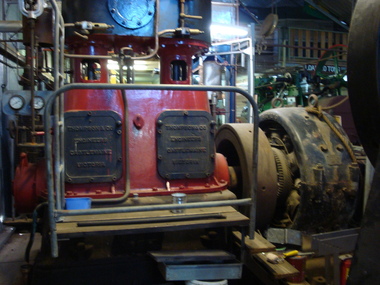

Siemens DC generator driven by a Thompsons two cylinder steam engine. The engine has vertical cylinders and there is a flywheel between the generator and engine. Generator painted grey, engine painted red. The system is connected to low pressure steam and can be run very slowly. Brass plate on generator "Siemens Brothers / Dynamo Works Ltd. / London Stafford / Direct Current Generator", followed by specifications. Thompsons Engineering in relief on steam engine side plates. "60" on base of engine.machinery; generator; steam engine; metalwork -

Bay Steamers Maritime Museum

Bay Steamers Maritime Museummodel steam engine

This model was found in the collection of Bay Steamers Maritime Museum. It is not knowt who created it but it is supposed that it was constructed to educate the many masters of the Wattle in the operation of a steam engine - a not so common mode of power these days. A Bay Steamers Maritime Museum examined the model in March 2012 and discovered that is was in poor repair. Using his existing knowledge, and with reference to some historic texts, he made some repairs and returned the model to working order. Here is his anaylsis of the situation as an excerpt from the Bay Steamers Maritime Museum newsletter Steamlines May 2012 "I was confronted with a model of a steam engine used years ago as a training aid for hopeful steam engineers. Already having a knowledge of steam operations, I considered a museum write-up for that model a ‘piece of cake’. However, on turning the model’s crankshaft, the valve timing seemed ‘out of kilter’ with the movement of the piston. Problem was that the two eccentrics on the crankshaft were not properly secured to it. Eventually I fastened the two eccentrics to the crankshaft where I felt that they should be and then realized that one of them had a chain-driven valve-timing device attached. This would be adjusted while an engine was running to achieve best performance and fuel economy whilst in operation by accurately controlling the period of time during which steam under pressure from the boiler would be admitted to the cylinder and give greater time for the steam to expand in the cylinder, move the piston and turn the crankshaft and thus, drive the attached apparatus. When the valves were correctly set up it was then possible to get the model to function properly.The model comprises a green section, which is the actual the model mounted on a brown painted board. There are two parts of the model, painted white representing the steam passages, and black representing the cast- iron portions of the cylinder-block casting, and of the main valve sliding between the cylinder a second sliding valve. Of the black portions, one slides back and forth being connected to a rod which is connected to an eccentric clamped to the crankshaft and is the nearer to the flywheel of two eccentrics. This eccentric is attached to the crankshaft at an angle of 90 degrees to the crank-pin attached to the flywheel. To operate the model simply turn the flywheel by means of the handle attached to its crank-pin. A second eccentric is also attached to the crankshaft, further away from the first eccentric, and it is adjusted to operate 90 degrees from the first eccentric (that is, 180 degrees from the crank-pin) A piston (painted silver) is located in a plastic cylinder and has a piston rod which passes through one end of the cylinder, (in actual practice a steam-proof gland seals the cylinder against loss of steam) terminating in a cross-head slide between four rails guiding it. From this cross-head, a connecting rod joins the piston-rod to the flywheel via the crank-pin attached to the flywheel which is part of the crankshaft. (In actual practice, a flywheel may not be used, particularly in a multi-cylinder engine.) The white portions of the model painted nearest to the cylinder represent the two steam ports cast into the main cylinder block, whilst one section painted in between those two represents the exhaust outlet (which may be connected to a condenser to conserve water, or to the open air). The main slide valve has three white-painted portions painted thereon. It has two white-painted marks representing the steam passages to the steam ports into the cylinder, and a third section in between the other two, being that part of the valve through which exhaust steam passes in line with the ports in the cylinder block. By rotating the flywheel, the operations of an engine will be observed as steam is admitted to the main valve via the gap between the two jaws of two moveable portions of a second sliding valve which is operated by the second eccentric attached to the crank-shaft. This eccentric is used to finely tune the valve timing of this model to obtain best running results of an engine. There are various methods used for reversing a steam engine. model compound steam engine, steam engine, model, crankshaft, valve, flywheel, wattle, engineer, eccentrics -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncVertical Petrol Engine

Water cooled vertical cylinder stationary petrol engine with magneto ignition. Painted green and black. Two flywheels. Cylindrical fuel tank mounted in front of the engine. Galvanised iron cooling water tank mounted on a stand behind the engine. All mounted on a steel frame with casters. On a cast crank-case cover :- "Manufactured by / R. A. Lister / & Co. Ltd. / 2 1/2 HP No. 2727 / Dursley England"machinery ... engine ... petrol ... metalwork -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreCider Press, 1880s

A 'BUCKEYE" grape and cider press, manufactured by P.P. Mast & Co. of Springfield, Ohio, USA and distributed by P. Rohs, Sandhurst (Bendigo). The PP Mast Company was established in 1854. Their Buckeye drills, seeders and other implements played an important role in the development of American farm machinery, being sold in every American state, Europe and Australia. This press was used by the Gaasch family of Harcourt over several generations from 1898 to crush grapes for wine and vinegar making, subsequently to crush apples and then press the pulp to make apple vinegar and cider. The crushing was accompanied by lusty singing of songs and hymns such as 'Ein Feste Burg ist unter Gott'. The press was designed to be hand-operated but was later used by Harcourt Coolstores to press apples. It was then belt-driven by an electric motor. The press was restored (timber cleaned and varnished, metal shoes on base of wooden uprights, which had rotted ) by Mr. Howard Carr, 2001-An early application of mechanics to the crushing of grapes. Hand-driven, geared drive metal crushing parts, with metal flywheel, wooden feed hopper in vertical arrangement, wooden frame, tray and vat, with metal pressing screw installed in heavy metal yoke at front. Metal crushing section carries cast-in maker's name and patent details'BUCKEYE" manufactured by P.P. Mast & Co. of Springfield, Ohio, USA distributed by P. Rohs, Sandhurst (Bendigo).