Showing 38 items matching "innovative businesses"

-

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 74, June 1996 to August 1996

... innovative businesses... martin business studies master painters' association innovative ...Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age ad other region papers over the period of 1 June 1996 to 6 August 1996.Book with yellow cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, enrolment for smb courses, counselling course may be lost, myma rance, father son graduate, phil allender, steve allender, building apprentices non payment, proposed changes to industrialrelations laws, brenda huggins winner of award, education is lifelong quest, smb graduation night, her majesty's 121st, food fit for a king, tony leonard, cuts fall on regional takes, administration students placed in workforce, art appreciation through theatre, tenders exceed funding, ray borner to olympic games, shane everard inspiration to all, network caters for chefs, judith beaton and jennifer martin, business studies, master painters' association, innovative businesses, building course for women, deanne jakiel's win a boon for kooris, dr ron wild, bright future for smb, young workers test their skills, melissa cameron, michael ronaldson mhr, peter morey work skill, angela cox, geoffrey richards, a legacy of design, jocelynne scutt - barrister, paralympians at smb, barry jones - alp, tafe cuts hit farmers, smb and red lion hotel - hospitality course -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageParallel Rule, Early 20th Century

John Bliss (1795-1857) was born in Norwich Connecticut, trained as a silversmith and clockmaker in Vermont, and began in business as a jeweller in New York around 1830. In 1834, now trading as Bliss & Creighton, he made and marketed a range of nautical instruments. The business subsequently became John Bliss & Son in 1855 and John Bliss & Co. in 1857. It remained in business until 1957 when it was acquired by West Marine. The Bliss company used to make a range of instruments supplied to a variety of customers including the US Navy. An object made as an aid for marine navigation, to plot a course on a nautical map for a vessel to follow. The item was made by a well known American maker of nautical instruments and is significant in regards to it's provenience and history of the maker and his family who over the years had been innovators and makers of various types of nautical instruments since 1795. Parallel map ruler. Bliss of New York & Nautical instruments engraved on face of ruler, ruler divided into degrees for use on nautical mapsflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, parallel rule, map reading, nautical object, navigation instrument -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageShip Log, 1900-1920

Thomas Walker & Son was internationally renowned in the manufacturing of ships logs. Founding father Thomas Walker (1805–1871), an engineer in Birmingham, patented a mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kick starting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ships log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (British-based organisation promoting ties and trade with the British Caribbean) and the most common log in use for two generations. It took till 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By the time of his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log and the Walker factory was one of the first to introduce the 48 hour work week for employees. This ship log was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades. Ship Log, three analogue dials calibrated in increments of Miles, the Rocket Log is a nautical instrument for measuring a vessel’s speed and distance traveled. The floating log was drawn behind the ship over a fixed time period in order to measure the distance traveled. The counter could measure enough miles to cover the maximum distance traveled by a ship in one day. The log has two distinct parts; a brass register, made by Walker, showing the distance recorded and the rotator made by Reynolds, that spins in the water driving the counter. both parts are connected by a linked chain. The register has a cylindrical brass body approx 4.5 cm diameter containing registering mechanism with hardened steel bearings. Distance is indicated by the three pointers on enamel plate as follows: graduated every 10 miles from 0-100; every mile from 1-10; every 1/4 mile from 1/4 -1. A brass sling and eye secured to the body enables it to be attached to the taffrail. The original rotator would have had a cylindrical tapered wooden body, approx 4.5 cm in diameter with three metal alloy fins or could be all made from brass. A towing eye is fitted to the tapered end. The two pieces of apparatus are connected by a length of linked chain, length 22.9 cm."Walkers Rocket Ship-Log Birmingham (Patented)" printed on face-plate. "Made by Thomas Walker".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ship log, rocket log, mechanical ship log, measuring instrument, marine instrument, nautical instrument, speed recording instrument, ship log register, walker ship log, walkers rocket ship-log, thomas walker, thomas walker & son, thomas ferdinand walker, walker log business, reynolds ship log rotor, taffrail log, taff rail log, west india association -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Edward Preston & Sons, Early 20th century

By the end of the nineteenth century, the firm of Edward Preston & Sons was founded in 1825, becoming one of England's leading makers of hand tools and in many ways a British counterpart to America's "Stanley" for its wide range of quality utilitarian tools at affordable prices. Edward Preston Sr. (1798–1883) was first listed as a plane-maker at 77 Lichfield Street in the Birmingham Directory of 1833, but later listings and advertisements assert that the business was started in 1825. Preston is likewise recorded as a plane-maker living with his family in Lichfield Street in the 1841 census, at which time his younger son Edward was 6 years old. Around 1850, his son Edward left school to join his father's business and is recorded in the 1851 census as a plane-maker at his father's address. He appears to have been quite a talented and resourceful young man, as he had later been able to start up his own "wood and brass spirit level manufacturing business at 97½ Lichfield Street by 1864. By 1866, Edward Jnr had added planes, routers, joiners, coach, gun, cabinet, and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to much larger premises at 22–24 Whittall Street. This location became known as the Whittall Works and later was the office and factory of Edward Preston & Sons, Ltd. In 1889 Edward Preston Jnr and his three sons were brought into the firm and the name was changed to Edward Preston & Sons, becoming Edward Preston & Sons Ltd on incorporation in 1898. Part of the firm's output was a healthy line of malleable and gun-metal planes and patent adjustable iron smoothers, shoulder planes, bull-nose, and block planes - a range that was expanded in later years. The 1901 catalog shows several styles of planes that were unique to the Preston brand, along with the usual styles which had already been set by other makers. The death of Edward Preston Jnr was reported in the Lichfield Mercury of 26 September 1913. "Mr. Preston was decided of an innovative turn of mind," the newspaper wrote, "as many of the machines in use at his works, as well as of the tools produced were the invention of himself and his three sons, who now manage the business." The report noted that at the time of his death, the business was carried on at Whittall Works, Cheston Street, Aston, Birmingham. Falling on hard times, the firm of Edward Preston & Sons was sold to the Birmingham firm of John Rabone & Sons in 1932, and shortly thereafter manufacturing rights to some of the Preston range of planes were sold to the Sheffield firm of C. & J. Hampton, who would later merge with the Record Tool Company. Some of the Preston planes were directly added to the Record line by the Hampton firm, while others were modified or discontinued altogether. Generally, all Preston wooden planes are stamped on the front of the plane, the shape, size, and character type of the stamp indicating the age of the plane. On some metal planes, all the parts were stamped with a number or symbol during manufacture. This number was used to re-assemble the parts following a batch process. Not all Preston tools are trade-marked clearly. Early shoulder, rebate, chariot planes, and chamfer rebates commonly appear without trademarks but may have assembly numbers. The "E P" trade-mark was already in use by 1882. The trade-mark "Preston" also appears on some later tools that were manufactured in Sheffield, England. These are generally smoothing planes and appear modern and very similar in construction to other modern manufacturers' planes.The item gives a snapshot of one of England's premier tool manufacturing companies at a time when significant industrial changes were occurring in manufacturing and business structures in the World that were beginning to affect social changes.Ogee moulding Plane Maker E Preston & Sons sticker with date 1904 -1931flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Warrnambool and District Historical Society Inc.

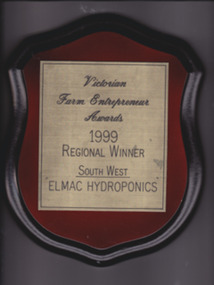

Warrnambool and District Historical Society Inc.Award - Victorian Farm Entrepreneur Awards 1999, 1999

Elmac Hydroponics operated at Allansford from 1997 to 2004, growing tomatoes hydoponically. The owners were Keith Ellerton and Graeme MacLeod. There were 2000 Square metres of hothouses with over 5000 plants. This trophy from the Victorian farm Entrepreneur Awards was for the use of a system called autopots. This system relied upon a process of automatic watering through valves at the bottom of the pots.The growing of vegetables hydoponically was a relatively new and innovative system of agriculture. The Elmac business proved that it could be done in the climate of the region. Timber shield shape with bevelled edge, painted dark maroon with engraved brass metal plaque.Victorian Farm Entrepreneur Awards 1999 Regional Winner South West Elmac Hydoponicsallansford, elmac, keith ellerton, graeme mcleod, elmac tomatoes, victorian farm entrepreneur awards 1999. -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Window weights, Circa 1890

Dutton and Wiggs operated a brass and iron foundry known as the Warrnambool Brass and iron Foundry situated in Timor St. Mr Dutton was a mechanical engineer and Mr C Wiggs was an experienced foundry worker. They were innovative in their work and also manufactured a large number of everyday items such as verandah posts, brackets and milk aerators.The significance lies in the fact that the items were manufactured in Warrnambool by a well- established local business. Two solid cast iron rods of cylindrical shape with one flattened edge with name imprinted. Hollowed out section on one end. S. Wiggs W,bool. One has the number 7 and the other 5 cast into the metal. warrnambool, wiggs, dutton & wiggs, window weights -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Bottle, H London Chemist & Dentist, Circa 1990's

... and cameras. A common item with links to an innovative business ...Harry London was a chemist and surgeon dentist who came to Warrnambool in 1891 and brought out the business of the late W.F.G Nettleton.he used the Pasteur filter for water in the making of his medicines. He held a large number of patents for his medicines and mixtures. In 1896 London erected a new chemist shop at the corner of Koroit & Liebig Streets. As well as operating as a chemist and dentist he also dealt in all types of photographic materials and cameras.A common item with links to an innovative business in Warrnambool.Rectangular shaped bottle with embossed writing of company details on front and graduated measurements in ½ tablespoons along the narrow edges. Pale blue in colour. Round lipped neck.H London chemist & Dentist Warrnambool on front. One and two tablespoons along sides.warrnambool, harry london, harry london chemist and dentist , harry london liebig street, -

Eltham District Historical Society Inc

Eltham District Historical Society IncBusiness Card, Mrs E. Reynolds, Dressmaker and Costumer, Yarramie, Research, Vic

The Reynolds family were early settlers in Research. The Reynolds/ Prior collection of photographs were taken by Tom Prior, the maternal uncle of Ivy Reynolds, around 1900 and the 60 photos in the album give a fine overview of many of the landmarks of Research and Eltham over 100 years ago. lvy lived in the family home for many years at 106 Thompson Cres Research. Ivy's father, Ernst Richard Reynolds and grandfather, Richard Reynolds, lived at the same address. Ivy's father Richard worked for Mr. Trail on his property in Research. Reynolds Road is named after the family. Mr Tom Prior (wife Eva) worked at the Melbourne zoo. He was very innovative and made his own camera, using the black cloth hood to exclude the light. The photographs are a reminder of the rural nature of Research and Eltham and its rich heritage. Buisness card, manilla coloured cardreynolds prior collection, research (vic.), e. reynolds, dressmaker shop -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 73, February 1996 to May 1996

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age ad other region papers over the period of 13 February 1996 to 30 May 1996.Book with yellow cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, enrolment for smb courses, students set high standards, chef robin terry, smb brings back mining course, literacy course - survival skills, laptops for farmers, secondary students at ballarat university study camp, backing for pre-training, new horticultural centre, smb tabaret plan training venture, smb plan gives city a boost, adult course reaps rewards, maureen green, sandra young, jing levinson, move heavy machinery, business advice network, the fest a go-gos, ruth zegir in male dominated industry, $4.8m fof bsc proposed relocation, $3.2m for primary schools upgrade, learn on the internet, workforce equality, kevin martin tafe campus co-ordinator, $2m for ararat tafe, calendar outlines courses, dispute between smb and aeu, ryan white top apprentice, stair building, betty's sculptures on show, betty collier, art teacher, course in fish farming, john mosig, funding cuts - smb, chemical course for farmers, learn the internet, mark bevelander, hotel reception course, students help teach art at gallery, ballarat big loser from cuts, restructure aim is cuts, innovative training grant, traineeship milestone for bendix mintex, youth wage bill, freighter leads way -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Edward Preston & Sons, Early 20th century

By the end of the nineteenth century, the firm of Edward Preston & Sons was founded in 1825, becoming one of England's leading makers of hand tools and in many ways a British counterpart to America's "Stanley" for its wide range of quality utilitarian tools at affordable prices. Edward Preston Sr. (1798–1883) was first listed as a plane-maker at 77 Lichfield Street in the Birmingham Directory of 1833, but later listings and advertisements assert that the business was started in 1825. Preston is likewise recorded as a plane-maker living with his family in Lichfield Street in the 1841 census, at which time his younger son Edward was 6 years old. Around 1850, his son Edward left school to join his father's business and is recorded in the 1851 census as a plane-maker at his father's address. He appears to have been quite a talented and resourceful young man, as he had later been able to start up his own "wood and brass spirit level manufacturing business at 97½ Lichfield Street by 1864. By 1866, Edward Jnr had added planes, routers, joiners, coach, gun, cabinet, and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to much larger premises at 22–24 Whittall Street. This location became known as the Whittall Works and later was the office and factory of Edward Preston & Sons, Ltd. In 1889 Edward Preston Jnr and his three sons were brought into the firm and the name was changed to Edward Preston & Sons, becoming Edward Preston & Sons Ltd on incorporation in 1898. Part of the firm's output was a healthy line of malleable and gun-metal planes and patent adjustable iron smoothers, shoulder planes, bull-nose, and block planes - a range that was expanded in later years. The 1901 catalog shows several styles of planes that were unique to the Preston brand, along with the usual styles which had already been set by other makers. The death of Edward Preston Jnr was reported in the Lichfield Mercury of 26 September 1913. "Mr. Preston was decided of an innovative turn of mind," the newspaper wrote, "as many of the machines in use at his works, as well as of the tools produced were the invention of himself and his three sons, who now manage the business." The report noted that at the time of his death, the business was carried on at Whittall Works, Cheston Street, Aston, Birmingham. Falling on hard times, the firm of Edward Preston & Sons was sold to the Birmingham firm of John Rabone & Sons in 1932, and shortly thereafter manufacturing rights to some of the Preston range of planes were sold to the Sheffield firm of C. & J. Hampton, who would later merge with the Record Tool Company. Some of the Preston planes were directly added to the Record line by the Hampton firm, while others were modified or discontinued altogether. Generally, all Preston wooden planes are stamped on the front of the plane, the shape, size, and character type of the stamp indicating the age of the plane. On some metal planes, all the parts were stamped with a number or symbol during manufacture. This number was used to re-assemble the parts following a batch process. Not all Preston tools are trade-marked clearly. Early shoulder, rebate, chariot planes, and chamfer rebates commonly appear without trademarks but may have assembly numbers. The "E P" trade-mark was already in use by 1882. The trade-mark "Preston" also appears on some later tools that were manufactured in Sheffield, England. These are generally smoothing planes and appear modern and very similar in construction to other modern manufacturers' planes.The item gives a snapshot of one of England's premier tool manufacturing companies at a time when significant industrial changes were occurring in manufacturing and business structures in the World that were beginning to affect social changes.Ogee wood moulding plane Maker E Preston & Sons No 5 (Owner A T Nipe) also has A's stamped on ends and the No 7flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Warrnambool and District Historical Society Inc.

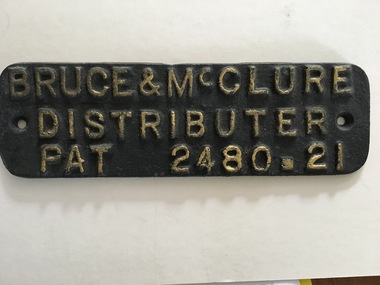

Warrnambool and District Historical Society Inc.Brass Plate, Bruce & McClure Distributer, C early 20th century

... . A tangible link to one of Warrnambool's manufacturing businesses ...Bruce & McClure were manufacturers of windmills and agricultural machinery including motor engines , pumps, tanks,and appliances for supplying and conserving water.Also included was brass,iron and steel foundry works. They won 11 first prizes at the Grand national Show of 1907 and in 1914 designed and manufactured a new water boring machine which could also be used for oil and gold exploration They operated from Lava Street well into the 1940's as well as from the geelong area. This plaque is possibly from one of their machines.A tangible link to one of Warrnambool's manufacturing businesses which was innovative and an essential part of the beginnings of machine use in farms and industry in the district. Cast iron plaque with moulded text which is coloured in gold. rectangular with rounded corners. Back is painted grey.Bruce & McClure Distributer Pat 2480.21warrnambool, bruce & mcclure, bruce & mcclure machinery -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Medal - Medal VHAS, Villiers and Heytesbury Agricultural Association, Circa 1880

Historical information: this medallion has historical details on three fronts. Firstly the Villiers & Heytesbury Agricultural Association. This association began with the first meeting held on May 17th 1853 at Woodford. The minutes of that meeting read “That in the opinion of this meeting, the formation of an agricultural association would be of great benefit to persons in this district engaged in farming and pastoral pursuits. It initially embraced the following: ploughing, agricultural produce, machines and implements, and livestock of all descriptions. The first show was held at Warrnambool on April 10th 1855 on a green bounded by Fairy, Henna, and Koroit Streets. It was held there until 1875 when it moved to the present Showgrounds site in Koroit Street. At the 37th Annual show in 1890 Warrnambool held its first Grand National Show, being granted by the Chamber of Agriculture in turn, in Victoria. It became known as the Warrnambool Agricultural Society in 1911. Secondly the winner, Mr Hugh Lennon. He was one of the most successful innovators and manufacturers of agricultural implements in early Australia. Although born in Ireland, he served an apprenticeship in Scotland in mechanical engineering. The Lennon plough became known Australia wide. For many years he operated his business at the northern of Elizabeth Street in Melbourne. He was active in local affairs. He died in 1886 at the age of 52. Thirdly, Stokes and Martin. Thomas Stokes came to Australia in the 1850’s and established a successful business at Mincing Lane Melbourne, manufacturing buttons, medals and tokens. Martin joined the partnership in 1873, which lasted until a disastrous fire in 1893. The business was renamed Stokes & Sons Pty Ltd and it became a public company in 1962. It is currently situated at Ringwood in the business of spare parts for electrical equipment The Villiers and Heytesbury Agricultural Association was a significant event and organisation within the Western District over a large number of years. It was one of the earliest organisations in the district and is testament to its importance to the agricultural, social, and cultural life of the district. It is significant that this particular medallion was awarded to an innovator in the ploughing industry and that it was made by a company which is still in business 130 years later. Circular copper medallion cast with Villiers & Heytesbury Agricultural Assoctn around edge with winner and event details engraved in centre. The reverse is cast with horse, cow and sheep standing above wheat sheaf and farm implements. The edge of the medallion is plain.Villiers & Heytesbury Agricultl Assoctn around rim. 1st Prize awarded to Hugh Lennon for double furrow plough, Warrnambool Oct 19 1880. Stokes & Martin Melbourne in small lettering on the reverse.warrnambool, villiers & heytesbury, hugh lennon, stokes & martin, lennon plow, lennon plough -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor, John Clarke Ltd, 1930s

In 1848, 43-year-old John Clarke launched a cutlery business in Harvest Lane in Neepsend, Sheffield UK. Clarke entered the trade late in life he was indenture and apprenticed to Octavius Twigg, a razor maker. Clarke was granted his Freedom in 1856 and began using the trademark 'NEVA'. By the 1860s, Thomas Clarke's son by his wife Elizabeth had joined the firm. When John Clarke died at his home at Augusta Place, Rock Street, Sheffield on 25 July 1873 (aged 68), he only employed six workmen. By 1881, Thomas had expanded this number to twenty. He sold a wide range of cutlery and was also an ‘emigration agent’, the Sheffield Independent, of 7th September in 1886 had an article published stating Thomas helped to recruit personnel from England for cutlery centers in America. In 1893 Clarke’s showroom displayed miniature knives from '5/16ths-inch long to the most expensive sportsman's knives, that were gold and silver mounted. Table knives and carvers were also manufactured (or factored). Agencies were opened in London, New York, and Melbourne. Besides ‘NEVA, the ‘EXPRESS’ and ‘RING’ marks were used on razors; and Clarke’s marketed the American ‘GEM’ safety razor. By 1901, the firm had moved to Mowbray Street, where its Mowbray Works overlooked the River Don. Thomas Clarke died at Harrogate on 26 April 1902, aged 62, and was buried in the same Burngreave cemetery as his parents. Thomas’s sons, John Roome Clarke (1860-1925) and Thomas Edward Clarke, were directors, another son George William Clarke was a shareholder. John Roome Clarke died on 3 February 1925, aged 64 his son, John Clarke, of Crimicar Lane, remained as the senior partner. Clarke’s was one of the last producers of hand-made pocket knives and it also produced a large output of sheath knives for scouting associations. The firm was liquidated in 1964, but the company name was resurrected and Its last address after 1980 was at 65 Garden Street Sheffield. The company trademark passed on to Meteor Industries and then to Egginton Ltd. Weber & Co: The Clarke company purchased or (factored) many of its blades for razors and knives from Weber & Co of Solingen Germany. The full name of the firm originally was Jowika Stahlwarenfabrik Eugen Weber & Altenbach KG. It was founded in Solingen prior to 1928, under the name Johann & Wilhelm Kleinewefers GMBH, Messerfabrik. JWK for short, hence JoWiKa. The company was sold to Eugen Weber in the 1930s. Weber was married to a woman named Altenbach, from a family that manufactured innovative low-priced pocketknives, as well as other cutlery items. In 1960 Weber opened a branch factory in Listowel Ireland. It was sold to Albert M. Baer of Imperial Schrade in 1978. The Listowel factory was closed about a year and a half before the U.S. Schrade factory closed in 2004 and the Jowika factory in Solingen had closed in 1984.An item with an interesting manufacturing history from the 1930s showing how one man can grow a business into a successful concern that made quality products that stand the test of time.Razor metal folding blade with horn handle in its original cardboard box Inscription Made by John Clarke and Son England. "Champion" razor. On box " The Champion 10/6d" and "Weber Lohmann & Co SOLINGEN".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSign - Hudson's Soap Enamel Advertising Sign, Patent Enamel Co Ltd, c. late 19th century- early 20th century

Hudson's Soap Powder, was the first satisfactory and commercially successful soap powder and was made in Liverpool by Robert Spear Hudson. He was also an innovator in using advertising, commissioning striking images from professional artists and paid for publicity , something which few other businesses did, and as such Hudson's soap became a household name. Horse, steam and electric tramcars, print periodicals and chemist shops carried his advertisements. This sign was manufactured by Patent Enamel Co Ltd was a company built in 1889 at Selly Oak, Borough of Birmingham, West Midlands, England, United Kingdom. The business was the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides. It is believed that the factory was decommissioned and demolished in the 1960's.the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides.The factory was decommissioned and demolished in the 1960s.The signage demonstrates the increasing demand for domestic soap products and new forms of advertising. The soap business was apart of the flourishing export trade between Australia and Britain during the height of the British Empire.Enamel advertising sign for Hudson's soapflagstaff hill, warrnambool, maritime museum, hudson's soap, advertising signage, patent enamel co ltd, selly oak, borough of birmingham, robert spear hudson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1903

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Wertheim sewing machine in carry case, hand operated with two spindles, handle with locking pin, which turns lever between spokes of main handle, hand brake. The machine is table-mounted with a Turkish walnut base. The base can be attached to a cast iron table with a foot treadle as an optional extra. The walnut base has marquetry to the front set out as a measure for material. There is also an accessory box inside the carry case containing 20 additional items for use with the machine. Wertheim brass trademark badge riveted to the body of the machine of a crouching dwarf with a hammer with the name of the company Wertheim and Frankfurt. Gold filigree decoration in gold paint adorns the main body of the machine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated sewing machine, crank handle sewing machine, wertheim, dressmaking, taylor, domestic, clothing, hugo wertheim, joseph wertheim -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Ships Navigation Lamp, William Harvie & Co, First half of the 20th century

William Harvie was granted a patent in 1868 for improvements in the manufacture of lamps, lanterns and lenses for ships navigation and signal lamps 1868. Production began at 222 Broomielaw street Glasgow Scotland. Another patent was issued in 1873 for additional improvements to the companies lamps. Records show that in1873 William Harvie was in partnership with Malcolm Graham & Co, grease manufacturers and rosin distillers at 50 Anderson Street Gallowgate Glasgow. It appears around this time the business was transferred to George Moffat of 128 Garthland Drive Dennistoun Glasgow to continue under the same name (William Harvie & Co at premises situated at 100 East John St Gallowgate Glasgow. It is unclear but at some point W T George & Co were one in the same with William Harvie & Co. W T George made lamps with the trade name “Meteorite” and after gaining a patent for improvements to his lamps in 1941 the patent numbers were affixed to his lamps. In the Scottish Post Office annual Glasgow Directory 1900-1902 William Haveie & Co. Ltd is listed with two addresses; 222 Broomielaw and 24 McAlpine Streets, Glasgow. In the early 20th century the business moved to Birmingham until 1983 when the company went into voluntary liquidation after a meeting was held at Newhall Street Birmingham on the 10th January 1983 for WT George and William Harvie. This meeting was for the purposes regarding the insolvency of a company as set out in Sec 294 & 295 of the companies Act 1948 as a result Harvie & Co cease production of their products.An item made by a company that was an innovator of significant improvements in the manufacture of marine signal and navigation lamps during the late 19th and 20th centuries. Lamps made by this manufacturer are now sought after collector's items that are of significant value. Navigation lamp, round ship's lamp with clear glass and a red filter, handle at top, fitted with hinged and catch section at top to service lamp. Bracket at back for hanging lamp item painted red with black handles.Black nameplate is unreadable. Front reference plate reads " Meteorite" then "Meteorite No. 92276" warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, meteorite, william harvie, navigation lamp, kerosene lamp, signal lamp, marine equipment, marine navigation, w t george & co, george bocock & co, william harvie & co. ltd. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Dioptric Apparatus, mid 19th century

Before the introduction of electricity, lighthouses had a clockwork mechanism that caused the lens to rotate with a light source inside that was either powered by Kerosene or Colza oil. The mechanism consisted of a large weight attached by a cable through the centre of the lighthouse to the top where the cable wrapped around a barrel, drum or wheels that controlled the speed of the lights rotation by a clockwork mechanism. The keeper would crank the clockwork mechanism, which would lift the weight ready for the next cycle similar to an old grandfather clock mechanism. Once the weight lifted to its apex at the bottom of the first landing, the keeper would let it fall, which would pull on the cable, which would, in turn, operate a series of gears activating the rotation of the Fresnel optical lens, which would then rotate to create the lighthouse’s unique light speed of rotation characteristic. Creating a specific characteristic required a way to regulate the speed of the rotation, and was important as sailors could identify a particular light by its speed and time between flashes. The weight had to fall at a certain rate to create the proper rotation speed of the lens and a regulator within the mechanism accomplished this. History: From 1851, Chance Brothers became a major lighthouse engineering company, producing optical components, machinery, and other equipment for lighthouses around the world. James Timmins Chance pioneered placing lighthouse lamps inside a cage surrounded by Fresnel lenses to increase the available light output these cages, are known as optics and they revolutionised lighthouse design. Another important innovation from Chance Brothers was the introduction of rotating optics, allowing adjacent lighthouses to be distinguished from each other by the number of times per revolution the light flashes. The noted English physicist and engineer, John Hopkins invented this system while employed at Chance Brothers. Chance Brothers and Company was a glass works and originally based in Spon Lane, Smethwick, West Midlands England. The company became a leading glass manufacturer and a pioneer of British glass making technology. The Chance family originated in Bromsgrove as farmers and craftsmen before setting up a business in Smethwick near Birmingham in 1824. They took advantage of the skilled workers, canals and many other industrial advances taking place in the West Midlands at the time. Robert Lucas Chance (1782–1865), known as 'Lucas', bought the British Crown Glass Company's works in Spon Lane in 1824. The company specialised in making crown window glass, the company ran into difficulty and its survival was guaranteed in 1832 by investment from Chance's brother, William (1788 – 1856). William owned an iron factoring business in Great Charles Street, Birmingham. After a previous partnership that Lucas had dissolved in 1836, Lucas and William Chance became partners in the business which was renamed, Chance Brothers and Company. Chance Brothers invented many innovative processes and became known as the greatest glass manufacturer in Britain. In 1848 under the supervision of Georges Bontemps, a French glass maker from Choosy-le-Roi, a new plant was set up to manufacture crown and flint glass for lighthouse optics, telescopes and cameras. Bontemps agreed to share his processes that up to then had been secret with the Chance Brothers and stayed in England to collaborate with them for six years. In 1900 a baronetcy was created for James Timmins Chance (1814–1902), a grandson of William Chance, who had started the family business in 1771 with his brother Robert. Roberts grandson, James became head of Chance Brothers until his retirement in 1889 when the company became a public company and its name changed to Chance Brothers & Co. Ltd. Additional information: Lighthouses are equipped with unique light characteristic or flashing pattern that sailors can use to identify specific lighthouses during the night. Lighthouses can achieve distinctive light characteristics in a few different ways. A lighthouse can flash, which is when brief periods of light interrupt longer moments of darkness. The light can occult, which is when brief periods of darkness interrupt longer moments of light. The light can be fixed, which is when the light never goes dark. A lighthouse can use a combination of flashing, oscillating, or being fixed in a variety of combinations and intervals to create individual light characteristics. It is a common misconception that a lighthouse's light source changes the intensity to create a light characteristic. The light source remains constant and the rotating Fresnel lens creates the various changes in appearance. Some Fresnel lenses have "bulls-eye" panels create beams of light that, when rotated between the light and the observer, make the light appear to flash. Conversely, some lenses have metal panels that, when rotated between the light and the observer, make the light appear to go dark. This Dioptric clockwork apparatus used to turn a lighthouse optical lens is very significant as it is integral to a lighthouses operation, we can also look at the social aspect of lighthouses as being traditionally rich with symbolism and conceptual meanings. Lighthouses illustrate social concepts such as danger, risk, adversity, challenge and vigilance but they also offers guidance, salvation and safety. The glowing lamp reminds sailors that security and home are well within reach, they also symbolize the way forward and help in navigating our way through rough waters not just on the oceans of the world but in our personal lives be it financial, personal, business or spiritual in nature. Nothing else speaks of safety and security in the face of adversity and challenge quite the way a lighthouse does. Revolving dioptric clockwork apparatus used to turn a Fresnel optical lighthouse lens. A cylindrical cast metal pillar and cabinet painted green with 3 glass doors enclosing the top section. Inside the pillar/cabinet is a large clockwork mechanism used to turn and regulate a lighthouse light by means of weights and a chain attached to same. One door has the name "Adams Mare" in metallic dots similar to "Braille" to the inside edge of door frame.shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff hill, maritime-museum, shipwreck-coast, warrnambool, flagstaff-hill-maritime-village, revolving dioptric mechanism, dioptric mechanism for lighthouse, lighthouse clockwork timing mechanism, acetylene lighthouse light mechanism, 19th century lighthouse mechanism, kerosene light, fresnel lenses, colza oil, chance brothers -

Federation University Historical Collection

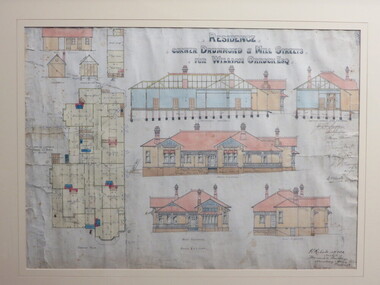

Federation University Historical CollectionPlan - Architectural Plan, Architectural Drawing of 222 Drummond Street North, Ballarat, 1904, 1904

Perceval Selwyn Richards (ARVIA) was a Ballarat architect who from 1900 to 1940 was responsible for innovative Edwardian and Art Deco style buildings in the district. In 1904 his office was at the Mercantile Building on the corner of Armstrong and Dana Streets, Ballarat. Perceval Selwyn Richards was born 21 July 1865 at Christchurch, New Zealand. He married Alice Emma Nicholson. Percy Richardson sailed to Melbourne, Australia in 1887 to find employment in an architect’s office. On arrival in Ballarat started as an assistant in the architectural firm of William Brazenor, where he worked for six years before continuing with the business after Brazenor's death. He taught Architecture at the Ballarat School of Mines from 1918 to 1921. As well as his work from the Ballarat and District Anglican Diocese and the Ballarat and the Western Districts. Ballarat & Clarendon College is also one of his designs. Framed original architectural by Percival Richards of 222 Drummond Street North, Ballarat, on the corner of Mill Street.perceval richards, percy richards, architecture, ballarat, drummond street noirth, cappell, dobson, w.a. cappell, mary cappell, mary dobson, tom cappell, robert r.g. dobson, alexander edward, cant, n. wellington, william orrack -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Machine - Dairy, Milk Separator manual, c1900

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past where farmers milked a few cows, usually by hand, and separated by letting milk sit in a container until the cream floated to the top when it could be skimmed off by hand. Some of the skimmed milk was consumed while the rest was used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. Manual rotation of the separator handle turns a mechanism which causes the separator bowl to spin at thousands of revolutions per minute. When spun, the heavier milk is pulled outward against the walls of the separator and the cream, which is lighter, collects in the middle. The cream and milk then flow out of separate spouts. Montgomery Ward was founded by Aaron Montgomery Ward in 1872.as a mail-order business in Chicago, Illinois USA. Rural customers were attracted by the wide selection of items that were unavailable to them locally and were also inspired by the innovative company policy of "satisfaction guaranteed or your money back".This milk separator is typical of the type used by early settlers in Moorabbin Shire where every family owned a 'house cow' to supply their dairy needs. Households also kept a few chickens for eggs and developed a vegetable garden with additional fruit trees. A 'primrose' manual milk separator 'Montgomery Ward', Chicago USA c1900'primrose ' / SATTLEY / MONTGOMERY WARD/ CHICAGOearly settlers, dairy farmers, milk products, dairies, market gardeners, blacksmiths, tools, moorabbin shire, bentleigh, mckinnon, highett, cheltenham, moorabbin -

Chiltern Athenaeum Trust

Chiltern Athenaeum TrustPhotograph

Clara Jane Matthews was born in 1870 as the eldest daughter of Robert Matthews. She married William Frederick Busse on the 5th of December, 1894 at St Columb’s church, Hawthorn. Clara and her husband lived on Main Street in Chiltern, and her husband was a Clerk of Courts in Chiltern and Wodonga throughout his life. Clara and William also owned a 640 acre farm called Clairedale Park, four miles (6.5km) outside of Barnawartha. They had both crops and sheep on the property, and adopted innovative farming practices. It appears that Clara was heavily involved in the farm business, as she is listed as a purchaser of sheep in multiple stock reports between 1914 and 1918. This is very unusual for the era, as women were not generally involved in stock markets, especially if her husband was still alive. Clara’s husband’s work at the court likely meant that he wasn’t able to travel to the markets in order to purchase stock. Clara’s taking the reigns in this manner was highly unusual, and signals just how strong of a woman she must have been. Clara Busse died in Chiltern in 1968, when she was 98 years old. She is also the mother of Wilfred C Busse, who was an author and a member of the Chiltern Athenaeum. This photograph is of a woman who lived most of her life in Chiltern, and undoubtedly contributed to the community of the town within her 98 years. She will most likely be remembered as the wife of William Frederic Busse, Clerk of Petty Sessions, or as the mother or Wilfred Clarence Busse, author and barrister. Although the records of her time almost entirely connect her with the men of her life, her father, husband and then her son, some digging can reveal that she was an entire person of her own, who broke norms of her time and is worthy of being remembered for her own sake.Black and white rectangular photograph printed on matte photographic paper mounted on board in a textured metallic frameObverse: Clara Jane Busse / (nee Mathews) / Mother of W. C. Busse / clara jane busse, clara busse, c j busse, busse, women in agriculture, remarkable women, 20th century women, women's history, working women, wilfred busse, wilfred clarence busse -

![Manual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065ed29821f50e3cc9ea4b/item-media/601344e16061d010347e22d5/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumManual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions

This handbook contains the setting instructions for a Standard Hattersley Loom developed by George Hattersley and Sons Ltd. The Hattersley loom was developed by George Hattersley and Sons of Keighley, West Yorkshire, England. The company had been started by Richard Hattersley after 1784, with his son, George Hattersley, later entering the business alongside him. The company developed several innovative looms, of which the Hattersley Standard Loom – developed in 1921 – was a great success. The Hattersley Standard Loom was designed and built in 1921. Thousands of models were expected to be sold, which would bring considerable financial success to the company. After the recapitalisation boom of 1919, cotton yarn production peaked in 1926 and further investment was sparse. Rayon, an artificial silk, was invented in the 1930s in nearby Silsden, and the Hattersley Silk Loom was adapted to weave this new fabric. An example of this type of loom can be seen on Vic Collections here ( https://victoriancollections.net.au/items/54065d0f9821f50e3cc9c122 ) and is also on display within the National Wool Museum in Geelong, Victoria. A copy of this manual may be available by contacting the National Wool Museum Collection Team. Book, 64pp. Red and black loose leaf, soft cover, printed black ink. "[Hattersley] Standard Loom Tuners Handbook: Setting instructions " - George Hattersley and Sons LtdTHE BRUCE WOOLLEN MANUFACTURING CO LTDtextile industry - history textile machinery weaving textile industry - education, george hattersley and sons ltd, weaving looms, weaving machinery, textile industry - history, textile machinery, weaving, textile industry - education -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article, Finding solutions to complex social woes, 1993

A conference, convened after growing problem of youth violence in shopping centres, held at Forest hill Chase last week.A conference, convened after growing problem of youth violence in shopping centres, held at Forest hill Chase last week. Forest Hill Chase has worked with local police and Nunawading Council to find innovative ways to overcome problems in the municipality.A conference, convened after growing problem of youth violence in shopping centres, held at Forest hill Chase last week. businesses, forde, elaine, forest hill chase, youth -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article, Blackburn business launches CFC recovery unit, 1992

Actrol Parts, in Blackburn, have produced innovative new productsActrol Parts, in Blackburn, have produced innovative new products, they will allow users of Chlorofluorocarbons to recover and re-use the product in automotive, commercial and industrial air conditioning and refrigeration systems.Actrol Parts, in Blackburn, have produced innovative new productstechnology, actrol parts, woodhouse, alan, pullen, barry -

Unions Ballarat

Unions BallaratA super history : how Australia's $1 trillion+ superannuation industry was made, St Anne, Christine, 2012

An historical account of the creation of the superannuation system in Australia. The author has interviewed some of the pioneers of the system. Table of contents: A few good men Chicago racket or dream of the romantics? Getting the show on the road Holdens and Rolls Royces A woman's job The business of super Lear jets and cuff-links The greatest victory of all The Howard years The politics of super Other people's money A time to imagine and innovatePertinent to financial and social history.Paper; book. Red and brown cover, with drawings of various persons.Front cover: title and author name.btlc, ballarat trades hall, ballarat trades and labour council, finance, superannuation, money, retirement, history, actu, australian council of trade unions, pensions, superannuation funds, old age pensions, trade unions, alp, australian labor party, howard, john -

Bendigo Historical Society Inc.

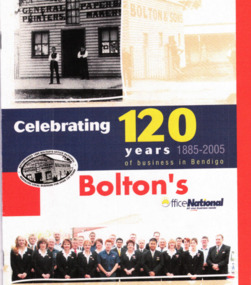

Bendigo Historical Society Inc.Booklet - Boltons Office National Celebrating 120 years of Business in Bendigo, 2005

Parry Collection History tells us that Benjamin Bolton and his two eldest sons, William and Arthur, began a printing business known as Bolton & Sons on March 25, 1885. But the Bolton name could just as easily have been erased from the annals of Bendigo during the treacherous sea journey that brought them from England in 1883. Benjamin, his wife and eight children (the youngest of whom was only three months old), boarded the “clipper” ship Ivanhoe on 17 July 1883 with little idea of what lay in store for them. Halfway through their 84-day journey, the Ivanhoe found itself in the midst of an equinoxial gale. For two days and nights, the ship was battered by huge seas and winds, while the Boltons and other passengers were battened down below deck with just a few candles and no fresh food or water. The ship and its passengers survived, but many of the crew were injured, and the ship was badly damaged. Having survived the gale, a week later, the Ivanhoe was hit with sleet, hail and snow, and the peril of icebergs. It must have been a great day for the Bolton family when Cape Otway appeared out of the fog, and the cry of “land ho!” echoed about the ship. The Bolton’s had arrived, and a Bendigo institution was about to be born. The location of the original printing business was in High Street but later moved to Williamson Street where the business underwent a name change to Bolton Bros and expanded into manufacturing paper bags and other stationery lines. In 1902, Bolton Bros moved to 43 Mitchell Street, which housed the retail stationery department and the main office, while the printing factory was on the second and third floors. Next door at 47 Mitchell Street, the wholesale division and machine service department operated. William and Arthur Bolton and their sons travelled throughout central and northern Victoria selling their own products and representing other companies. They are credited with being the innovators of the loose-leaf ledger. Today, of course, the business is back in Williamson Street with an even greater presence but the same entrepreneurial flair that has seen it survive and flourish through everything history has thrown at it. Having gone through five generations of family ownership, current company director-David Bolton, is proud of his company’s history and contribution to the local economy.Boltons Office National Celebrating 120 years of Business in Bendigo - 41 pages covering 1885-2005history, bendigo, merle lummis collection, boltons office national bendigo -

Surrey Hills Historical Society Collection

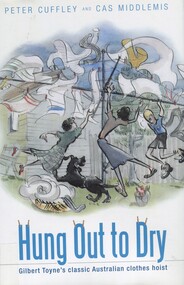

Surrey Hills Historical Society CollectionBook, Hung out to dry: Gilbert Toyne's classic Australian clothes hoist, 2009

Archibald McKirdy purchased the Toyne's hoist business in 1925 and moved its production from Carnegie to Mont Albert where the family had lived since the 1880s. The factory was in Mont Albert Road near the railway line and the family lived at 2 Stanhope Street. 'Hung Out to Dry' is based on detailed and innovative research and analysis; part family history, part social history, part industrial history, part garden history. It is the story of the rotary clothes hoist.'Hung Out to Dry' is based on detailed and innovative research research and analysis; part family history, part social history, part industrial history, part garden history. It is the story of the rotary clothes hoist.(mr) gilbert toyne, inventors, (mr) archibald mckirdy, clothes lines, (mr) peter cuffley, cas middlemis -

Brighton Historical Society

Brighton Historical SocietyClothing - Dress, Evening dress

Margaret Law (nee Bartholomew) was born on 3 December 1837 in Stirling, Scotland. She emigrated to Australia with her family aboard the Ticonderoga, arriving in Melbourne on 22 December 1852. Around one hundred passengers died of typhus during the journey, and around seventy more after arrival. Two of Margaret's siblings were among the casualties. The Bartholomew family settled in Ballarat. Around 1861, Margaret married James Nicol Law in Ballarat. They had several children, the youngest of which was James Lindsay Gordon "Lin" Law, (1881-1963). James Nicol Law was killed in a train accident in Fingal Tasmania in July 1886. Lin Law married Elsie Russell on 12 January 1915 (BHS also holds a bridge jacket given to Elsie by Lin; see T0047). They settled in Brighton, moving into 'Blairgowrie', 306 St Kilda Street, in 1920. The eldest their four children, Pauline Margaret Law (born 15 December 1915) ultimately purchased the house with her husband Hugh McLean in 1956 and lived there until 1965 when the house was demolished. In 1906, Lin and his business partner James Kerr Pearson (also a Brighton local, who lived at 12 Moule Avenue) established the shirt manufacturing company Pelaco. In 1922 the company established its factory at 23 Goodwood Street on the top of Richmond Hill; the 4.3 metre high neon 'Pelaco' sign, erected in 1939, is today heritage listed. The company was known for its innovative approach to efficiency and labour relations, discontinuing Saturday morning work in 1908 and appointing an industrial relations officer in 1928.An orange pink (salmon) with cream spot, very fine silk organza dress from circa 1840. The dress features a wide scooped neckline, almost to the shoulder. The sleeves are set low with a gathered head to the sleeve and finished with a flounce, dropping to just above the elbow. The bodice is shaped and fitted to the body and features a centre front detail of the bodice fabric that is gathered, ruched and tapers in a v to the waist. The waistline of the dress sits on the true waist at the sides and tapers to a v at the centre front and centre back. The full skirt is gathered to the piped waistline and falls to the floor. The skirt features three horizontal pleats in the skirt fabric in between four bands of cream floral self embroidered detail. The dress is open at the back where it is boned and features lacing holes. The lacing is missing from the item. The bodice of the dress is lined with a very fine cotton lawn and boned.james nicol law, brighton, pauline margaret law, elsie russell, james lindsay gordon law, margaret bartholomew, pelaco -

Brighton Historical Society

Brighton Historical SocietyFootwear - Shoes, 1880-1900

These shoes belonged to Margaret Law (nee Bartholomew). Born on 3 December 1837 in Stirling, Scotland, Margaret emigrated to Australia with her family aboard the Ticonderoga, arriving in Melbourne on 22 December 1852. Around one hundred passengers died of typhus during the journey, and around seventy more after arrival. Two of Margaret's siblings were among the casualties. The Bartholomew family settled in Ballarat. Around 1861, Margaret married James Nicol Law. They continued to live in Ballarat for some years, and it is likely that Margaret purchased the shoes during this period. They had several children, the youngest of which was James Lindsay Gordon "Lin" Law, (1881-1963). In 1906, Lin and his business partner James Kerr Pearson (also a Brighton local, who lived at 12 Moule Avenue) established the shirt manufacturing company Pelaco. In 1922 the company established its factory at 23 Goodwood Street on the top of Richmond Hill; the 4.3 metre high neon 'Pelaco' sign, erected in 1939, is today heritage listed. The company was known for its innovative approach to efficiency and labour relations, discontinuing Saturday morning work in 1908 and appointing an industrial relations officer in 1928. Lin married Elsie Russell on 12 January 1915 (BHS also holds a bridge jacket given to Elsie by Lin; see T0047). They settled in Brighton, moving into 'Blairgowrie', 306 St Kilda Street, in 1920. The eldest their four children, Pauline Margaret Law (born 15 December 1915) ultimately purchased the house with her husband Hugh McLean in 1956 and lived there until 1965 when the house was demolished.Dark brown leather shoes with Louis heel. Vamp and strap are decorated with cut metal beads. Strap secured with one boot button and button hole.Made in Austria for / J. T. MORRIS / 306 Sturt Street / BALLARATshoes, j. t. morris, ballarat, margaret law, margaret bartholomew, james lindsay gordon law, pelaco