Showing 48 items matching "milk production"

-

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesBook - PhD Thesis, Christy Johanna Vander Jagt, Comparative Analysis of Marsupial and Eutherian Genomes to Identify Genes Critical in Milk Production, 2012

... Identify Genes Critical in Milk Production...milk production...PhD thesis Agricultural Science milk production Typed ...phd thesis, agricultural science, milk production -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesBook - Register, Shed Sheet, 1968

... milk production...Sheet for students to record milk production tests on 18... production tests on 18 cows dated 16 April 1968. milk production cows ...Sheet for students to record milk production tests on 18 cows dated 16 April 1968.milk production, cows, dairy farm -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Bottle, Antarctic Ice Milk Bottle, Mid 20th century

... Milk Production in Warrnambool... by an important Warrnambool business, Antarctic Ice. Milk Production ...These two bottles have contained milk sold by the Warrnambool firm of Antarctic Ice Pty Ltd. in the mid 20th century.In the 1930s a pasteurizing plant was set up in Warrnambool in conjunction with an ice works in Kepler Street known as Antarctic Ice (Good and Stevenson). This firm had secured a milk supply from farmers in the Warrnambool region. Eventually Antarctic Ice was bought by the Warrnambool Cheese and Butter Factory and Kraft Foods as equal partners and the milk was marketed as Sungold. Also a farmer named Kaye Ryan had set up a pasteurization plant in East Warrnambool (Raglan Parade/Verdon Street) in opposition to Antarctic Ice and Sungold. Kraft and Warrnambool Cheese and Butter bought out Ryan and moved Sungold operations to the Ryan site. Kraft Foods sold its share of Sungold to Warrnambool Cheese and Butter and in 1989 the milk factory was moved to the Allansford site of Warrnambool Cheese and Butter and Sungold continues there today.These bottles are of interest, firstly as examples of the half-pint milk bottles familiar to people living in the mid 20th century and secondly because they are good examples of the bottles used by an important Warrnambool business, Antarctic Ice. These are two clear glass bottles. When filled each bottle contained 10 fluid ounces or half a pint of milk. The bottles have a round base with a rounded body tapering slightly to a thick neck and a thick moulded top. The bottles when filled had a seal consisting of a circle of waxed cardboard that was pressed into a recess on the lip of the bottle. These lids are missing.The bottles have lettering impressed into the glass. ‘This bottle contains milk bottled for sale by Antarctic Ice Products Pty Ltd Warrnambool and always remains their property. It is loaned and cannot be legally used or sold by others.’ ‘Contents 10 ozs.’ ‘497’ milk production in warrnambool, antarctic ice pty ltd -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, milk bottle 'Black Rock Dairy', 20thC

... milk production... milk production moorabbin shire moorabbin cheltenham black rock ...Alfred R Varcoe was a dairyman with stables, cart shed and his house in Eliza Street, Black Rock, Victoria. Dairy farming was established early in the settlement of the Brighton / Moorabbin area following the Dendy's Special Survey 1841 and subsequent land sales c1850. The produce was taken to feed the population of Melbourne and local residents.A clear glass ,1 pint , milk bottle used by Black Rock Dairy, MelbourneTHIS BOTTLE CONTAINS/ MILK / BOTTLED FOR SALE BY / BLACK ROCK MODEL / DAIRY / BLACK ROCK / BOTTLE IS THE PROPERTY OF THE ABOVE / IT IS OWNED AND CANNOT BE LEGALLY USED BY OTHERS/ ONE IMPERIAL PINT on base 440market gardeners, early settlers, farmers, dairies, milk production, moorabbin shire, moorabbin, cheltenham, black rock, brighton, dairy farmers, bottles, glass manufacture, varcoe alfred r; black rock dairy, dairy farmer, dairy products sales and deliveries, -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Book, Nestle and Anglo-Swiss Holding Company, This Is Your Company - Nestle's, 1946

... milk production... warrnambool milk production milo nescafe production warrnambool ...The history of the first 80 years of the Nestle's CompanyThis is a book of 122 pages. It has a dark green cover with a gold compass pattern and gold printing on the front cover and spine. The pages contain printed text, maps, diagrams, graphs, colour illustrations and sepia -toned photographs.non-fictionThe history of the first 80 years of the Nestle's Companydennington nestle's factory, dennington, warrnambool, milk production, milo, nescafe production, warrnambool manufacturing -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

... to facilitate the movement of the bottled along the milk production line... milk production from the early 1800's. The Kiewa Valley and its ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

... to facilitate the movement of the bottled along the milk production line... milk production from the early 1800's. The Kiewa Valley and its ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... to facilitate the movement of the bottled along the milk production line... milk production from the early 1800's. The Kiewa Valley and its ...This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

... the movement of the bottled along the milk production line. The method... along the milk production line. The method of pouring milk ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... to facilitate the movement of the bottle along the milk production line... of the bottle along the milk production line. The method of pouring milk ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... to facilitate the movement of the bottled along the milk production line... milk production from the early 1800's. The Kiewa Valley and its ...This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... to facilitate the movement of the bottle along the milk production line... milk production from the early 1800's. The Kiewa Valley and its ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... to facilitate the movement of the bottled along the milk production line... of the bottled along the milk production line. The method of pouring milk ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Greensborough Historical Society

Greensborough Historical SocietyVase, Milk glass bud vase, 1950c

... Vintage bud vase, white/milk cut glass. [The production... glass. [The production of objects made of White Milk glass waned ...Vintage bud vase, white/milk cut glass. [The production of objects made of White Milk glass waned after WW2]White cut glass bud vase.vases -

Warrnambool and District Historical Society Inc.

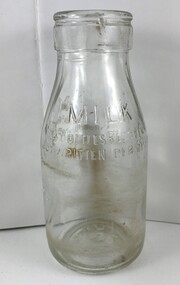

Warrnambool and District Historical Society Inc.Bottle, Milk Bottle, Mid 20th century

... . The commercial production of milk and other milk products in Victoria.... The commercial production of milk and other milk products in Victoria ...This glass milk bottle held one pint of milk and was filled in an assembly line at a milk factory. It would have had a paper top. Milk in the mid 20th century was delivered daily to households in glass bottles and left at the front door or door step. The commercial production of milk and other milk products in Victoria dates back to the 19th century with the Western District still having an important dairying industry. Warrnambool Cheese and Butter Factory, situated at Allansford, commenced operations in 1888 and still operates today. There are other milk-related factories in the Warrnambool area at Dennington and Koroit. This bottle is of interest as an example of the type of milk bottles used in the 20th century before the advent of plastic and cardboard cartons.This is a clear glass bottle with four rounded sides, a short neck and a round opening at the top. One Pintdairying in the warrnambool area, history of warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Milk Stool, Early 20th century

... the next day. The production of milk, cheese and butter has been.... The production of milk, cheese and butter has been an important industry ...This stool appears to have been home-made. It was used in the days (first half of the 20th century) when cows were mostly milked by hand. It was most likely to have been used to milk a house cow, perhaps in Warrnambool or a nearby town. The cow would have been kept during the day time on the town common and brought back to the home for milking and returned to the common the next day. The production of milk, cheese and butter has been an important industry in the Warrnambool district since the second half of the 19th century, with the Warrnambool Cheese and Butter Factory at Allansford being established in 1888. It is the oldest surviving dairy company in Australia. This stool is of considerable interest as an example of the stools used when cows were hand milked and when many households in the towns and outer areas had a house cow to supply milk for the household. This is a hand-made wooden milking stool with a rectangular piece of wood for the seat and four rounded legs that taper slightly outwards. The legs have been inserted into four holes on the top seating part. The seat has a small circular hole in the middle. The stool is well-worn. dairying in western victoria -

Warrnambool and District Historical Society Inc.

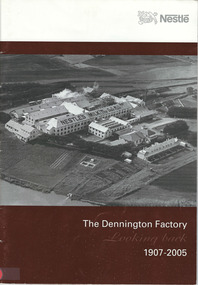

Warrnambool and District Historical Society Inc.Document - Booklet, The Dennington Factory Looking back, 1907-2005, September 2005

This booklet records in brief the history of the Nestles Factory at Dennington, Victoria from its opening in 1911 to its sale in 2005 to Fonterra Milk, Australia and the closing of the Nestles association with the Warrnambool district. The factory initially produced Sweetened Condensed Milk and by 1918 was the largest Milk Condensery in the world. In later years there were productions of cheese, Sunshine Powdered Milk and Nescafe Instant Coffee. Six two-storey residences were built for employees and there were twice-daily trains from Warrnambool to the factory and back for many years. The Nestanglo Social and Sports Club, established in 1923, was important in the community life of Dennington and beyond. This booklet will be of great use as it gives a very good summary of the history of Nestles Factory at Dennington and reveals how important the factory was to the Warrnambool region and to Australia.This is a paperback booklet of 37 pages. The cover is white with a black and white photograph of the Nestles Factory (Alex Wilkins photograph) set in a brown background. The pages contain printed material and photographs and blank pages at the back for autographs. The pages are stapled.Front cover: Nestle (with logo), The Dennington Factory, Looking Back, 1907-2005 Back cover: Nestle (with logo) dennington nestles factory,, dennington, milk condensery, sweetened condensed milk manufacturing -

Warrnambool and District Historical Society Inc.

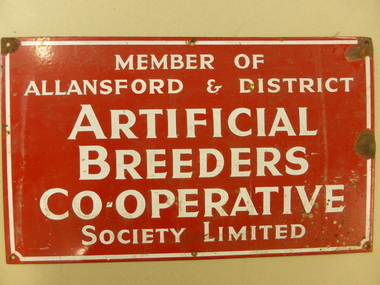

Warrnambool and District Historical Society Inc.Plaque, Artificial Breeders Co-operative, Circa 1965

The Allansford Artificial breeders was commenced in 1960 As a business its main focus was on the improvement of local herds for local farmers.As a result of 32 district farmers meeting at the Allansford Mechanics Hall, the Allansford & District Artificial Breeders Co-operative Society was formed. The subscription for membership was £7 10s. The meeting was instigated through the efforts of Noel Garner, a Hopkins Point farmer, who was manager of No.1 and No.2 Warrnambool Herd Testing Associations, and Gethan Fenton, a field officer with the Warrnambool Herd Testing Association. Bill Quinlan, who had been a herd tester under Noel Garner’s management, became the first employee of the Artificial Breeders. WCB support was available from the beginning as a room was provided behind the factory offices and the AI fees were collected by the factory from suppliers’ milk cheques. In the first 12 months Bill worked alone with some assistance from Russell Learmonth and Roger Walsh, both Kraft employees. Both factories realised the benefits of herd improvement in view of their overall increased production so membership was encouraged. Semen from the best sires in Canada and New Zealand were made available and farmers also could soon see the benefits. The initial board of directors, unlike WCB beginnings, consisted entirely of farmers. These included Michael Melican (Wangoom), Gerald Mugavin (Wollaston), Noel Garner (Hopkins Point), Jim Halford (Naringal East) and Grant Warnock (Southern Cross). Membership grew rapidly and after one year there were 164 members with another 100 joining the following year. After a year of coping alone Bill was joined by Ray Eccles from Purnim and then Pat Gleeson, later a Warrnambool car dealer. John Fitzgerald became a part-time technician. These signs were attached to the entrance gates of users. In the mid 1970s it became known as the Warrnambool Co-operative and while it maintained a strong rural and farming focus a opened a retail store in Warrnambool in Timor Street in the 1970's which became the largest trading department store in the district. By the late 1990s they had 8000 members and employed 84 full time and 120 casual staff. It met a sorry end in the 2000's.This sign is a link to a business which had a large exposure in the latter part of the 20th Century. As such it has social and historical significance. Rectangular metal sign, painted red with white text and white border around the edge. Screw holes in corners. Member of Allansford & district Artificial Breeders Co-operative Society Limited allansford artificial breeders, warrnambool co-operative society limited -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Artefact, Butter ram, Early to mid 20th century

This butter ram appears to have been made locally and was probably hand-made at a local factory. It was used to ram or mould butter into 56 pound butter boxes for bulk supply or for later cutting up into smaller quantities. Warrnambool was, and is still today, the centre of an important dairying industry with several large milk, cheese and butter factories in the area. The Warrnambool Cheese and Butter Factory at Allansford is the oldest operating factory of this type in Victoria and was established in 1888. The production of butter in the area was greatly accelerated by the invention of refrigeration in the early 1880s, enabling butter to be transported overseas. Warrnambool had two butter box factories which both closed in the 1920s. Up to the mid 1950s the production of butter was largely a hand process.This butter ram is of considerable interest as an example of the early tools used in the local butter industry.This is a heavy solid wooden block in a rectangular shape with the top shaped in the form of a pyramidal base. The edges of the base are worn from constant pounding. A long round wooden handle or rod is inserted into the top of the block. dairying industry in western victoria -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Bottle, Tooram Estate, Tooram Milk, 1930-1940

This milk bottle takes its name from the Tooram property near Allansford but the exact decade when this milk bottle was used has not been established. Tooram was established by John Allan when he came to the Allansford area in 1839/1840 with his brother William who established the property of Allandale in the same area. John Allan held the property of Tooram until the early 1860s, with several owners from that date on including John Orlebar, Thomas Palmer and the Owen family. The property was sub-divided in 1897 with the Uebergang family owning Tooram Park from 1912 to 1992. The Torram property was well-known in the late 19th and early 20th century for its cheese production.This bottle is of great interest as one connected with Tooram, a dairying property that was one of the earliest farm properties in the Warrnambool area, being established in the Allansford area in 1839/1840, before the town of Warrnambool was settled. This is a glass bottle with a moulded base and a metal and china stopper. There is lettering etched into one side of the bottle. ‘Tooram Milk Imperial Quart’tooram, allansford, dairying in the warrnambool district -

Warrnambool and District Historical Society Inc.

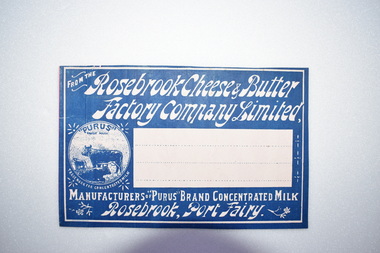

Warrnambool and District Historical Society Inc.Label, Rosebrook Cheese and Butter Factory, Early 20th century

The Rosebrook Cheese and Butter Factory was opened in November 1888 by Messrs Lydiard &T F Rutledge & was a cooperative factory managed by Mr. Goldie. It operated out of the former Rosebrook Flour Mill which was built on the banks of the Moyne River near the Rosebrook bridge in the late 1840s. In 1896 the factory commenced the production of the condensation of milk. The company closed in 1911. The building and machinery were sold in 1917. Rosebrook is situated about 20 kilometres from Warrnambool on the Princes Highway. This label is of some local significance as the Rosebrook Cheese and Butter factory operated for 30 years Rectangular dark blue and white label featuring text and a trade mark. The latter is circular with three cows pictured. There are decorations of flowers and leaves. The central area of the label is white with three lines. The label is adhered to a piece of pink card.FROM THE Rosebrook Cheese & Butter Factory Company Limited, MANUFACTURERS OF "PURUS BRAND CONCENTRATED MILK Rosebrook, Port Fairy. "PURUS" TRADE MARK FOR CONCENTRATED MILKrosebrook, cheese and butter, concentrated milk, lydiard, rosebrook butter factory -

Marysville & District Historical Society

Marysville & District Historical SocietyPhotograph (Item) - Black and white photograph, 1904

A black and white photograph of the Taggerty Butter Factory in Victoria.A black and white photograph of the Taggerty Butter Factory in Victoria taken around 1904. The Taggerty Butter factory opened in 1892 in the township on the Little River. It was run by the Kennedy family and built by J.B. Coombs of Acheron Station. Coombs was later Shire President. Milk had been previously taken daily to the steam-driven separators at Thornton. Upper Thornton. The cream was separated and the remains were taken back to the farms for the pigs and calves. Before these town separators existed butter had been made at home in a barrel, salted, and stored. The operation at Taggerty ceased in 1908 and the Alexandra Dairy Company took over production. The building no longer exists but materials from the original Taggerty Butter factory building now form part of the Williamson house off Swamp Creek Road.taggerty, victoria, taggerty butter factory, little river, kennedy family, j b coombs, acheron station, thornton, upper thornton, alexandra dairy company, williamson, swamp creek road -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Second half of 19th Century or first half of the 20th Century

Although glass containers for wine and beer are probably 1,600 years old, much of their use began only in the late 17th century. In the United States, large-scale production of bottles was pioneered by Caspar Wistar in 1739 at his New Jersey plant. In the 1770s the carbonation process for producing soft drinks was developed, and so began an entirely new bottling industry. At the Great Exhibition of 1851 in the Crystal Palace in London, one million “pop” bottles were consumed. The first beer pasteurised in glass was produced in Copenhagen in 1870. Pasteurisation of milk followed soon after. The moulding of a screw thread on a container was invented by John Mason in 1858. The principles of the “press-and-blow” process for making wide-mouth jars were shown in the United States by Philip Arbogast in 1882, and the “blow-and-blow” process for making narrow-neck containers was demonstrated by Howard Ashley in England in 1885. These processes employed manual delivery; fully automatic jar forming by a suction-and-blow process was perfected by Michael Owens over the period 1895–1917 at the Toledo (Ohio) Glass Company, which subsequently became the Owens Bottle Machine Company. The automatic single-gob feeder was developed in 1919–22 by Karl Peiler at the Hartford-Fairmont Company in Connecticut. Fully automatic machines followed, but the true rugged survivor, utilising fully automatic gob delivery to the maximum versatility, was the Individual Section, or IS, machine invented by Henry Ingle at the Hartford Empire Company in 1925. Source: https://www.britannica.com/topic/glass-properties-composition-and-industrial-production-234890/History-of-glassmakingUnlike item 4018, this is a much smaller ink bottle, and was probably used by an individual, as against the supply of ink to pupils from a much larger bottle.Cotton Reel Ink Bottle, green glass, small, chipped around the lip, bubbles in glass.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ink, bottle, glass -

Greensborough Historical Society

Greensborough Historical SocietyContainer - Bottle, Milk Bottles Recovery Ltd, Milk Bottles Recovery Ltd - one imperial pint, 1930-1950

... . The manufacturer Milk Bottles Recovery Ltd began production in Melbourne ...This bottle holds one imperial pint. The manufacturer Milk Bottles Recovery Ltd began production in Melbourne in 1930 and ended production in the 1970s. Clear glass bottle, embossed inscription.Inscription: "Milk. One Pint. This bottle is the property of Milk Bottles Recovery Ltd 18 Market St Melbourne. Can only be used by written permission and cannot be sold."milk bottles, milk, glass bottles, imperial pint -

Greensborough Historical Society

Greensborough Historical SocietyContainer - Bottle, Milk Bottles Recovery Ltd, Recovery Ltd Milk Bottle - one third pint, 1951 to 1973

This bottle holds one third of an imperial pint. The manufacturer Milk Bottles Recovery Ltd began production in Melbourne in 1930. Possibly used for school milk which was a scheme in place from 1951 until 1973.Clear glass bottle, pressed inscription.Inscription: "Milk. Third Pint. This bottle belongs to Milk Bottles Recovery Ltd and cannot be used with out written permission."milk bottles, milk, glass bottles -

Mortlake and District Historical Society

Mortlake and District Historical SocietyMortlake Butter Factory Co. Ltd, Photograph

This local factory was typical of small butter factories in the 1890's in Western Victoria. It was established in 1894 when farmers brought their milk to the factory on horse drawn drays and carts and waited for their cream to be separated. The skimmed milk was mostly used by farmers to feed calves and pigs and the separated cream was manufactured into butter, some of which was exported to England. By 1910 this butter factory had an electricity generating plant called Mortlake Electricity which supplied both the factory and the township with power and this took precedence over the butter production which continued until 1926 when it was sold to the Electricity Commission. By 1930 the Butter Factory had a yearly turnover of 24,000 pounds sterling and in1935 it was producing 6 tons of butter weekly. But in 1936 the factory was sold to Glenormiston Cheese & Butter Factory who ceased operations. The manager's residence still remains in 2011 as does the remnants of the small timber butter factory (charcoal lined) and the double brick cheese room but the bluestone chimney has long gone. This complex is listed by Heritage Victoria Black and White Photograph Nonecheese factory, mortlake, butter factory -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, milk bottles 600ml, c1970

There are two distinct types of milk consumption: a natural source of nutrition for all infant mammals and a food product for humans of all ages that is derived from other animals. Milk is a key contributor to improving nutrition and food security particularly in developing countries. Improvements in livestock and dairy technology offer significant promise in reducing poverty and malnutrition in the world. Pasteurization is used to kill harmful micro-organisms by heating the milk for a short time and then immediately cooling it. In the past, milk was always packaged in glass milk bottles The first glass bottle packaging for milk was used in the 1870s. The first company to do so may have been the New York Dairy Company in 1877 with a small glass lid and a tin clip. Lewis P. Whiteman holds the first patent for a glass milk bottle c1884,which was sealed with a waxed paper disk. The Express Dairy Company in England began glass bottle production in 1880. Melbourne Glass Bottle Works Spotswood 1880 - 1990. Milk cartons first came to Australia in 1958, when the Model Dairy in Melbourne began packaging milk in 150 ml and 500 ml cartons. At the time, 160,000 new glass bottles were needed in Melbourne alone every week to keep up the delivery of 1.3 million bottles of milk a day c1970, the blow-moulded disposable plastic milk bottle was introduced. In 1987, only about 2% of milk was still being sold in glass bottles. Glass milk bottles are now rare. Metric measures were introduced throughout Australia with Decimalisation 14/2/1966.3 x clear glass milk bottles c 1970 600ml ( 2 shown in photograph)PASTEURISED / 600 ML MILKmelbourne glass bottle works, spotswood melbourne, milk, dairy, dairy produce, dairy farmers, market gardeners, pioneers, early settlers, moorabbin, cheltenham, pasteur louis, pasteurization -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, circa 1948

... (manufactured circa 1950). A rural setting with mining, beef , milk ...This item was in use before electricity and was manufactured after the flat stove irons.The weight of the iron base, is heavy, helping in smoothing out crinkly material being ironed. This item permitted ironing of clothes to be separate and away from heating stoves. It permitted greater flexibility for ironing clothes and permitted more control (consistency) of the temperature of the iron.Historically and significantly this item enforces the relative isolation of the Kiewa Valley and period when and where this domestic item was in use(manufactured circa 1950). A rural setting with mining, beef , milk and tobacco production in the early 1900s. Even though the community was in a rural setting, the standards of dress was the same as in the bigger towns and cities. Social and religious mores and values demanded that the personal appearance be clean and crisp no matter where a person was living or working. Heavy laborious work was considered by some religions as virtuous, therefore the heavy and tiring work of ironing during this period had its rewards. Rural areas where the last to be connected to electricity and therefore this item was a domestic necessity far into the 1950's.This iron has a steel base and a metal body coated with green coloured enamel. The wooden hand grip is painted dark green. The kerosene (spirit) container is a chrome metal cylinder with a flat bottom and top. The top has a small filler/air plug is located on the top side. There are two control knobs located next to and under the metal cylinder. The close to the cylinder is a lock which locks the top lid of the iron and the other knob controls the airflow to the heater rodOn the base of the handle "PEERMAN" and below this P/46, C.I. Thomas & Son Pty Ltd household, ironing, domestic kerosene, dry cleaning -

Cheese World Museum

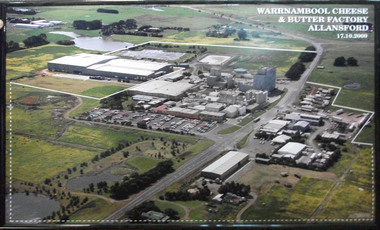

Cheese World MuseumPhotograph, Warrnambool Cheese and Butter Factory Co Ltd site 2000 -aerial view, 2000

Warrnambool Cheese and Butter Factory Company was formed by a group of Warrnambool business men. The company was registered in May 1888 and commenced commercial production in November 1888. The company retained its independence for more than 125 years until acquired by Canadian firm Saputo. It has operated from the same site since its inception and also has an office in Japan. Milk processing is undertaken by Sungold. Milk powder for export is also produced on-site. Cheese World is a retail arm of the company operates on a connected site selling company products, local food products, wine and cheese tasting. Cheese World Museum operates under the Cheese World umbrella.Aerial colour photograph of Warrnambool Cheese and Butter Factory in wooden frame. Shows buildings and surrounds. Lines indicate factory boundaries, dotted lines indicate property extension. Date is recorded on the image.17.10.2000allansford, warrnambool cheese and butter factory company, saputo, dairyiing, dairy manufacturing, diary manufacturers, cheese, butter -

Cheese World Museum

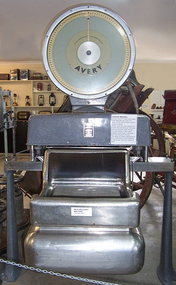

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry