Showing 38 items matching "safety products"

-

Ambulance Victoria Museum

Ambulance Victoria MuseumDressing, Burns, Brenguard Safety Products, Circa 1970s

... Brenguard Safety Products... in clear plastic bag. Dressing, Burns Brenguard Safety Products ...Not carried in ambulances but made available to ambulance officers if burns cases needed treatment. These items were not considered a success and were rarely used and soon replaced by better dressings. Source Chas Martin AHSV curator.Rolled yellow foam sheet in clear plastic bag. -

Greensborough Historical Society

Greensborough Historical SocietyBusiness card, and Sticker, All Things Safety Wear Briar Hill, 2018_

... safety products...All Things Safety Wear sell products including Safety... products including Safety products, Workwear, Screenprinting ...All Things Safety Wear sell products including Safety products, Workwear, Screenprinting, Embroidery and Bolts & nutsBusiness card printed both sides in black and yellow; with adhesive sticker printed in black and yellow, one sidesafety products, sherbourne road briar hill -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkHeadwear - Fire Fighters Helmet, MSA, c.1970s

... general worker protection and safety products. ... general worker protection and safety products. This helmet ...During the 1960s in Australia, helmets evolved from metal construction to that of polymer and other plastics. This helmet was donated by the Emerald Fire Brigade which was established on 14 March 1941 as the Emerald Bush Brigade. Originally its equipment was stored at Madigan's butcher's shop near the corner of Monbulk Road. The Brigade's first fire station was built around 1945. In 1966, this station was recorded as containing the fire truck and a Land rover pumper, three radio sets, 40 knapsacks, six lengths of hose, helmets, rake hoes and other hand tools. In 2010, the Brigade moved into a new purpose-built building in Monbulk Road. The manufacturer of this helmet, MSA, was founded in 1914 in the USA. MSA began as a mine safety company but since expanded into more general worker protection and safety products. This helmet is an historical artifact worn by members of a crucial volunteer fire fighting service operating in the Emerald district since 1941.Yellow, lightweight, hard plastic or polymer helmet with black leather detachable chin strap with Velcro fastening. inside the helmet is an adjustable head harnessInside helmet on a partly torn label: 'MSA / VGARD / Type 2 ...? / STANDARDS AUSTRALIA' Inside the brim black pen writing EMERALD SPARE 5 EMERALD at one end engraved: 'MSA'' and at the other end: '1801-1881 On the outside of the helmet there is a yellow reflector on each side and at the front and the back there is evidence of labels that have been removed.helmets, fire fighting, msa, emerald fire brigade, cfa -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkHeadwear - Fire Fighters Helmet, MSA, c.1970s

... protection and safety products. The Emerald Fire Brigade... protection and safety products. The Emerald Fire Brigade ...Helmets protect firefighters from heat, falling objects and cinders. During the 1960s in Australia, helmets evolved from metal construction to that of polymer and other plastics. The manufacturer of this helmet, MSA, was founded in 1914 in the USA. It began as a mine safety company but since expanded into more general worker protection and safety products. The Emerald Fire Brigade was established on 14 March 1941 as the Emerald Bush Brigade. Originally its equipment was stored at Madigan's butcher's shop near the corner of Monbulk Road. The Brigade's first fire station was built around 1945. In 1966, this station was recorded as containing the fire truck and a Land rover pumper, three radio sets, 40 knapsacks, six lengths of hose, helmets, rake hoes and other hand tools. In 2010, the Brigade moved into a new purpose-built building in Monbulk Road.This helmet is an historical artifact worn by members of a crucial volunteer fire fighting service operating in the Emerald district since 1941.Yellow, lightweight, hard plastic or polymer helmet with black leather detachable chin strap with velcro fastening.Inside helmet on a partly torn label: 'MSA / VGARD / Type 2 ...? / STANDARDS AUSTRALIA' Inside the brim at one end engraved: 'MSA'' and at the other end: '1801-1881 / LN70' On front of helmet a label with logo and red lettering: 'CFA' helmets, fire fighting, msa, emerald fire brigade, cfa -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Information, VIOSH: Ballarat College of Advanced Education; Notice of Seminar, "Product Safety and Product Liability", 1982

... Seminar, "Product Safety and Product Liability", 1982...product safety and product liability... is "Product Safety and Product Liability". The growth in product... is "Product Safety and Product Liability". The growth in product ...Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Notice advertising a seminar to be held at Ballarat College of Advance Education on Friday 16th July, 1982. Registration is at 9.00 to 9.30am, It is planned to conclude at 5.00pm. The speaker will be Professor Ralph Vernon from the Industrial Hygiene and Safety Engineering Division, Texas A&M University U.S.A. Topic is "Product Safety and Product Liability". The growth in product liability litigation in the U.S.A. is a major concern to manufacturers. Australian manufacturers should be aware and protect themselves. Cost of Seminar - $50.00 (including lunch). Those wishing to attend to return slip to Mr T Norwood, Head of Mechanical Engineering by 1st July.A4 sheet - printed sheet - rust colour ink. Small return slip re attendanceBCAE Letterheadviosh, victorian institute of occupational safety and health, seminar, ballarat college of advanced education, professor ralph vernon, texas a&m university, product safety and product liability, t d norwood, industrial hygiene and safety engineering division, department of mechanical engineering -

Orbost & District Historical Society

Orbost & District Historical Societycar wheel rim splitter, 1920's

A rim splitter was used on the outer rims of older vehicles to facilitate removal and replacement of tires. The tool was used to remove a tyre and replace it onto a split wheel rim. After the air was let out, the safety rim key was pulled. The swing arms were spread out and the three arms evenly spaced around the rim. The single arm with the screw gear needed to be close to the split so that the hooks fit on the rim and the rim was then pulled inward and the tyre could be be removed from the rim. After the tire was repaired or a new one was ready to be put on the collapsed rim the tool was used to push the rim back together and the safety key could be reinserted. A rim splitter were a universal type tool used for many cars of the 1920's and 1930's.A cast iron rim splitter which has two hinged side arms with hooked ends. The middle shaft has a hooked end and an inner bolt that can be screwed up or down.St Joseph Michigan Hercules Product Co Made in U.S.A. L 7motoring rim-splitter tyres tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Diving Suit, boots and weight, 1900

This diving suit with helmet, boots and weight is part of the E.G.Ward collection, along with the diving compressor and a photograph of a diver in this equipment. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12-bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunnelling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diving suit including helmet, boots and a weight. Diving suit is made of canvas with knitted cuffs. The helmet is metal. The boots have a thick sole and thick leather upper that is held on with leather straps and buckles. The toe of the boot is heavy metal. The weight is worn next to the trunk of the diver and it has an inscription to mark the front. It is worn with straps and buckles holding it in place. Royal Navy Admiralty Pattern 6 bolt No 3 light Siebe Gorman light diving helmet circa 1960 used by the Royal Navy before and after World War 2"Siebe Gorman & Co Ltd Marine Engineers London. Patent" with "E G Ward" on front and back plate. On weight "FRONT"flagstaff hill, warrnambool, diving suit, siebe gorman and co ltd., siebe gorman and co ltd marine engineers london, marine engineers, diving helmet, diving boots, diving weight, marine diving, maritimemuseum, maritime village, maritime history, marine technology, life saving, deep sea diving -

Ringwood and District Historical Society

Ringwood and District Historical SocietyNewspaper, Scrapbook Clipping, Library Collection, Ringwood, Victoria, `

``Newspaper clipping from "The Mail", 13-4-93, P 14. Sponsors Ringwood Council's lollipop people could soon be advertising products as part of a plan to make up for lost State Government subsidies for the school crossing supervisor scheme. Council's corporate services director, Bill Black, is investigating possible sponsors for the scheme. Mr Black sugggested that sponsors could be associated with school wear, safety equipment or children's goods and services. No consideration would be given to a sponsor that was not appropriate for children. ` -

Kiewa Valley Historical Society

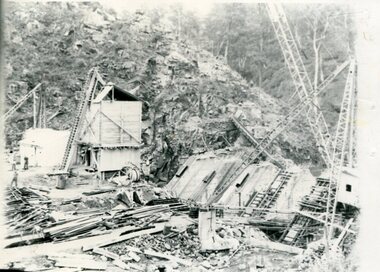

Kiewa Valley Historical SocietyPhotographs x 2 - Clover Dam, Circa 1940's

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level. Photographs also document early engineering and building techniques used in the construction of dams and power stations during the 1940’s and 1950’s. Note the lack of safety equipment and suitable work attire worn by construction workers on the sites 1. Black and white photograph of Clover Dam under construction. Has a .5cm white border around photo 2. Black and white photograph of Clover Dam under construction showing workmen at work. Has a .5cm white border around photo Written in pencil on back of both photographs - Clover Damclover dam, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotographs x 2 1. Lake Guy & Bogong Village 2. Bulldozer moving rocks

1. In 1940 Field Headquarters for the Kiewa Scheme were established at Bogong with office, workshop facilities and accommodation for workmen, staff and some families constructed. (There had been a 'tent camp' on this site in 1939 but was destroyed by bushfires) Construction of accommodation continued until 1947. A total of 40 houses plus a hostel for single staff, post office, police station, medical centre and primary school all with water and sewerage and electricity supply. The staff hostel was known as Kiewa House and is now occupied by the Education Department. Lake Guy was named after Mr. L.T. Guy who was the Resident Engineer in charge of construction work and associated activities on the Kiewa area. He held this position from 1939 to November 1946 when he was transferred to Head Office. 2. Example of the type of heavy machinery used in clearing and building of Lake Guy, Bogong Village and Clover Dam 1. The Bogong Township was developed firstly as an accommodation centre (base camp) for construction workers employed under the Kiewa Hydroelectric Scheme. At the completion of the scheme, in the 1960's, the village was opened to public/tourism use. Strict environmental control has not allowed for any extensive redevelopment in tourist accommodation and basically restricted it to the accommodation initially built for the construction workers. Lake Guy is one of the many water storage reservoirs used to supply the power stations their main power to run the huge turbines generating the final product, electricity 2. Pictorial record of the types of machinery used in the development of Bogong Village and the Hydro-electricity scheme including the Clover Dam. Note the lack of safety equipment worn by construction workers of the period. 2 black and white photographs taken at Bogong 1. Lake Guy with Bogong Village in the background 2. Workman in bulldozer clearing rocks, possibly for construction at Bogong1. Handwritten in blue ink on back of photo 'Lake Guy showing Bogong Village' 2. No markingslake guy, bogong village, secv -

Waverley RSL Sub Branch

Waverley RSL Sub BranchRazor

... ., 305 East 45th St., New York. The eponymous product ...Used by J McRorie during WWII Assumed to be a "Going away gift" The factory address was 255 Cricklewood Broadway, London, N.W. 2, with showrooms located at 197a, Regent St., London, W.1. A U.S. importer was Lee & Schiffer, East 44th St., New York City. By 1937 the U.S. distributor was Rolls Razor, Inc., 305 East 45th St., New York. The eponymous product was a sophisticated safety-razor which promoted with the slogan "The razor that is stropped and honed in its case" the claimed first use was 1922. The U.S. patent for the method of attaching the blade to the handle was filed in 1925 and issued in 1930. The name "Rolls Razor (1927) Ltd." was used in advertising. The razor was still manufactured and sold until 1958 when the company was purchased by entrepreneur/corporate raider John Bloom who decided to focus on washing machines rather than the razor. Rolls Razor open case. The blade handle on the left is attached to the honing mechanism lever via a spring-loaded bearing. The nickel plated blade on the right side is attached to the honing bar that slides on the red leather strop. The grey honing stone is part of the closing lid. The leather strop and the hone lids are not interchangeable as the blade needs to push against the hone but pull against the strop. The blade has a safety guard with pivot action that allows it to vary the shaving angle while providing safe operation. The head of the blade handle locks perpendicular to the blade using a slide type of action with the spring-loaded bearing providing additional stabilityRolls razor in a plush lined leather covered metal case containing Razor, leather strop with automated blade sharpening mechanism and a changeable carbide plate fitter inside a silver inner caseRolls Razorrazor -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Safety Report, VIOSH: Safety Report conducted by University of Ballarat and the Association of Wall and Ceiling Industries, Victoria, 2007

Safety Development Fund Final Report, January 2007. This was conducted by the University of Ballarat and the Association of Wall and Ceiling Industries, Victoria. This was for the prevention of falls and manual handling injuries in the industries. Part of the Safety Development Fund Project was funded by Worksafe Victoria and supported by the Construction, Forestry, Mining and Energy Union and the Transport Workers Union. The authors of the Report are Steve Cowley and Susan Leggett of The University of Ballarat. The project presented an opportunity to increase the adoption of risk control measures that had potential to reduce musculo-skeletal injuries and falls among plasterers and those involved in handling and distribution of plaster and related products.Ninety-eight pages - includes diagrams and photographs in form digital.viosh, victorian institute of occupational safety and health, university of ballarat, steve cowley, susan leggett, association of wall and ceiling industries, awci victoria, cfmeu, construction forestry mining and energy union, transport workers union, risk control measures, safety development fund, twu -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Equipment - Hydrometer, VIOSH: Humidity Hydrometer; Wet/Dry and Sling Psychrometer

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Instrument used to determine the humidity in a location. Made in England by Brannan. Established in 1913, Brannan are a global manufacturer of thermometers, pressure gauges & associated instrumentation productsBrown leather case with brass clip. Wooden frame with thermometer tubes. Black handle used to swing meter around. Gauge for temperature scale Made in England. Brannanviosh, victorian institute of occupational safety and health, brannan, england, thermometers, pressure gauges, humidity hydrometer -

Federation University Historical Collection

Federation University Historical CollectionBanner - Banner - Course Promotion, VIOSH: Banner promoting "Occupational Health and Safety" Course

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Banner used for Open Days and Expos to advertise/promote the VIOSH Program. Product made by BannerUp. When retracted it is easily carried in a heavy cotton fabric bag, black.Retractable banner in black carry bag.Occupational Health and Safety. "BannerUp" on caseviosh, victorian institute of occupational safety and health, banner, occupational health and safety, open days, exposes, promoting course -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Proposal, VIOSH: Proposal for a Post Graduate Course in Safety and Loss Control - Ballarat College of Advanced Education

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Ballarat College of Advanced Education made a preliminary submission for a Post Graduate Institute Course in Safety and Loss Control in 1975. This was forwarded to the External Advisory Panel and other experts for comment, etc. Comments were constructive and some modifications were made. These have been incorporated in this Second Draft dated August 1976. The aim of the course is to assist the administrator in identifying such accidental loss producing areas as - injury. plant damage, fire, breaches of security, property and storm damage, pollution, transportation, product liability and occupational disease. Sixteen A4 sheets - typed. Front sheet - Title page. Some pages have hand written notations in pencil. Last page has section hand written in ink.viosh, victorian institute of occupational safety and health, ballarat college of advanced education, post graduate institute, pgi, safety and loss control, external advisory panel, second draft, accidental loss, injury, plant damage, fire, security breaches, property and storm damage, pollution, transportation, product liability, occupational disease -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

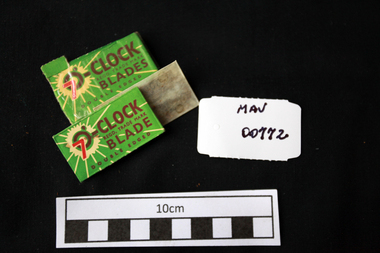

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, man's razor blade in box, 20thC

Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor. Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. In 1918, when the U.S. entered World War I, the Gillette company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. An unused, wrapped, man's razor blade in a box. 7 O'clock brand '7 O'CLOCK / REGD. TRADE MARK / BLADES / DOUBLE EDGED shaving equipment. razorblades, safety razors, cheltenham, moorabbin, bentleigh, pioneers, early settlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

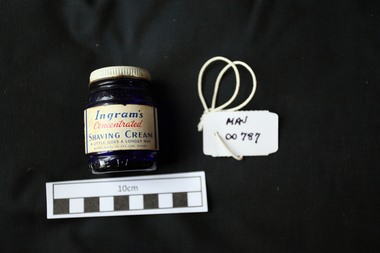

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, Shaving cream, blue glass jar, 20thC

Shaving cream is a cream applied to the face, or wherever else hair grows, to facilitate shaving. The use of cream achieves three effects: lubricates the cutting process; swells keratin; and de-sensitizes skin. Shaving creams commonly consist of an emulsion of oils, soaps or surfactants, and water. Until the early 20th century, bars or sticks of hard shaving soap were used. Later, tubes containing compounds of oils and soft soap were sold. Newer creams introduced in the 1940s neither produced lather nor required brushes, often referred to as brushless creams. Creams that are in tubes or tubs are commonly used with a shaving brush to produce a rich lather (most often used in wet shaving). Bristol-Myers Squibb Australia Pty Ltd is a foreign owned proprietary company that obtains its revenue through the importation and distribution of pharmaceutical products. Bristol-Myers Australia is now headquartered in Mulgrave, Victoria and with an Australian presence dating back more than 80 years, Bristol-Myers Squibb Australia is a long-standing contributor to Australia’s health and economy. A blue glass jar with a screw top lid containing 'Ingrams' men’s shaving cream. Lid : Ingrams / Shaving / Cream Bottle Label : Ingrams / Concentrated / SHAVING CREAM / A LITTLE GOES A LONGER WAY / BRISTOL MEYERS CO. PTY. LTD. SYDNEY.shaving equipment, soap, safety razor, straight razor, cutthroat razors, moorabbin, bentleigh, cheltenham, early settlers, ingram pty ltd, bristol-myer squibb australia pty ltd, shaving cream, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers,Shaving cream, J.B.Williams Co, mid 20thC

... , a manufacturer of hair and skin products. shaving equipment razors safety ...Shaving cream is a cream applied to the face, or wherever else hair grows, to facilitate shaving. The use of cream achieves three effects: lubricates the cutting process; swells keratin; and de-sensitizes skin. Shaving creams commonly consist of an emulsion of oils, soaps or surfactants, and water. James Baker Williams was born in 1818 in Lebanon, Connecticut USA and, in 1834, began employment with F. and H.C. Woodbridge, a general store located in Manchester. Williams was offered half-interest in the store in 1838, after which its name was changed to Keeny and Williams. Two years later, Williams sold his interest in the store, but retained his share in the drug department. He began experimenting with various soaps to determine which were best for shaving, and eventually developed Williams' Genuine Yankee Soap, the first manufactured soap for use in shaving mugs. In 1847, Williams moved his enterprise to a rented gristmill on William Street in Glastonbury, Connecticut, and his brother, William S. Williams, joined the firm around 1848, when the firm's name was changed to the James B. Williams and Company. William's shaving soaps were sold throughout the United States and Canada and James Williams supervised many aspects of the company until shortly before his death in 1907 at the age of eighty-eight. The Williams family continued to manage the company until it was sold in 1957. By the early 1900s, the company was known throughout the world. In addition to its line of shaving creams, the firm produced talcum powder, toilet soaps, and other toilet preparations. The original 1847 factory is still standing in Glastonbury and, in 1979, was converted into a condominium complex. I In 1983 it was placed on the National Register of Historic Places. 1927 - 1990 Salmond and Spraggon (Australia) Limited , Sydney , New South Wales, was registered as a company on 10 June 1927 following the liquidation of Salmond and Spraggon (Australia) Limited known as the Old Company. The company distributed household cleaning and mineral, metal and chemical wholesaling, pharmaceutical wholesaling throughout Australia on behalf of manufacturers. In 1990 the company was taken over by Alberto Culver, a manufacturer of hair and skin products. A clear glass jar with a screw lid containing 'Williams Shaving Cream' Front Label : J.B WILLIAMS / LUXURY / SHAVING CREAM Back Label : The contents of this jar are guaranteed to be / The J.B.WILLIAMS Luxury Shaving Cream Jar has been changed to meet the Wartime conditions but / the cream is of the same high quality / made in Australia for / J.B. WILLIAMS COMPANY / Glastonbury, Conn. U.S.A. / Vendors / SALMOND & SPRAGGON (AUST.) PTY.LTD. / All Statesshaving equipment, razors, safety razors, cutthroat razors, soap, world war 11 1939-1945, moorabbin, bentleigh, cheltenham, early settlers, shaving cream, williams j.b. company ltd, connecticut usa, glastonbury connecticut usa, salmond & spraggon pty ltd, sydney, new south wales, toiletries, shaving soap, -

Federation University Historical Collection

Federation University Historical CollectionBook, The Economics of Mining (Non-Ferrous Metals), 1938, 1938

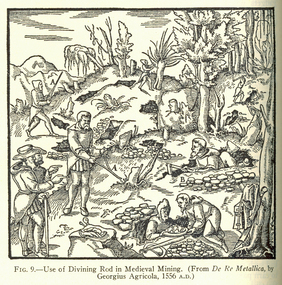

The book was used by Charles Bacon who studied at the University of Nevada in the late 1930s/early 1940s. Bacon worked at Bunker Hill Mines and Kellogg Idaho, before arriving in Australian in 1951. He worked for CN Myers, a company involved with paper converting. CN Myers was a family business (on Charles Bacon's maternal line). The Mackay School of Mines, Nevada was established in 1908. At the time of writing this mook T.J. Hoover was Professor of Mining and Metallurgy and Dean of the School of Engineering at Stanford University. Theodore Jesse Hoover, brother of the 31st President of the United States, was born in West Branch, Iowa, on January 28, 1871. He attended Stanford and received the Bachelor of Arts degree in Geology and Mining in 1901. Following graduation his professional career started with the position of assayer for the Keystone Consolidated Mining Company. After one year, he became assistant manager for the Standard Consolidated Mine, and a year later he was promoted to manager of the operation. In 1907 Hoover went to London as general manager of Minerals Separation, Ltd. This company was developing the froth flotation process for recovering minerals from ores. Hoover took an active part in the development of the flotation concentration process and authored one of the first books on the concentration of ores by flotation. After four years with Minerals Separation, Ltd., Hoover entered private practice as a consulting mining and metallurgical engineer with offices in London and in San Francisco. He was very successful and held positions of consulting engineer, managing director, director, and president of many mining companies in America, Europe, Asia, Africa, and Australia. He returned to Stanford in 1919 as Professor of Mining and Metallurgy and Executive Head of the Department of Mining and Metallurgy. His experience and ability in organization made him a natural leader. He was influential in the formation of the School of Engineering at Stanford. The School was formed in 1925 and he was made dean, a position he held until his retirement in 1936. As dean of engineering, he promoted a broad fundamental training program for undergraduate engineering students. Under his guidance, emphasis was placed upon graduate work and he was responsible for developing strong graduate engineering curricula at Stanford. While dean he continued teaching and his course, "The Economics of Mining," developed into a book which was published in 1933. He became interested in the functions of engineers and, with Professor Fish, wrote a book entitled "The Engineering Profession" which was published in 1940 and revised in 1950. In addition to his academic activities he was generous in his hospitality. Faculty and students alike enjoyed the annual field day and barbecue at his Rancho del Oso, near Santa Cruz. He was widely read and had a lively interest in all the things he encountered. He speculated on the antiquity of man and man's early production processes. To verify an idea regarding flint tools, he studied their shapes and became proficient in making arrow heads. He was also interested in wild life, and was one of the founding members of the Cooper Ornithological Society. (http://engineering.stanford.edu/about/bio-hoover) Blue hard covered book of 547 pages including an index. Contents include mine valuation (sampling, ore deposits, ore reserves, financial provisions, sale of mineral product, metal prices, reports) and Mining Organization (Co-operative effort, Mining Companies, Promoting Mining Enterprises, fluctuations of share prices, valuation of mining shares, fakes and fallacies, the mining Engineer and the law) and Mine Management (Organization of staff, mine manager, efficiency, industrial relations, training and discipline, safety). Inside front cover 'Charles Bacon Mackay School of Mines"charles bacon, mining engineering, metallurgy, university of nevada, mackay school of mines, stanford, bacon, mining, economics, divining, theodore hoover -

Federation University Historical Collection

Federation University Historical CollectionMining Lamp, E. Thomas and Williams Ltd, Welsh Mining Lamp

This lamp is typical of lamps used in Welsh Coal Mines. It was purchased from the supplier around mid 1995. The Welsh Miners’ Lamps were ingeniously designed over 180 years ago to alert coal miners to danger. It ensures the burning of a protected flame in the presence of explosive gas, by regulating the necessary supply of atmospheric air, and by allowing the products of combustion to pass through without igniting the gaseous atmosphere. If the atmosphere is so heavily charged that noxious gas enters the lamp, its presence will be indicated by a change in the length and color of the flame, and (unless there are exceptional circumstances), the miner has sufficient warning to secure his safety. (http://www.welshminerslamps.com/info_lamp_personaluse.shtml, accessed 06/05/2015) E. Thomas & Williams, Ltd. mining lamps have been in continuous production since 1860. Cambrian Lamps are approved for use in coal mines where methan gas and oxygem deficinecy are hazards.Solid Brass traditional miners Flame Safety Lamp with Copper Chimney. The base of this lamp is tooled from solid brass because brass does not spark when it hits rock and is therefore the safest metal to use underground. The lamp burns lamp oil (kerosene). R. Thomas and Williams Ltd Makers Aberdare Wales Cambrian No 152897mining lamp, miner's lamp, thomas and williams, wales, welsh, welsh miners lamp, mining, cambrian lampworks, miners flame safety lamps -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, safety razor blade 'King Gillette'', 20thc

King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. Gillette's safety razor retailed for a substantial $5 half the average working man's weekly pay — yet sold by the millions. The most difficult part of development was engineering the blades, as thin, cheap steel was difficult to work and sharpen. This accounts for the delay between the initial idea and the product's introduction. To sell the product, Gillette founded the American Safety Razor Company on September 28, 1901 (changing the company's name to Gillette Safety Razor Company in July 1902). Gillette obtained a trademark registration (0056921) for his portrait and signature on the packaging. Production began in 1903, when he sold a total of 51 razors and 168 blades. The following year, he sold 90,884 razors and 123,648 blades, thanks in part to Gillette's low prices, automated manufacturing techniques and good advertising. By 1908, the corporation had established manufacturing facilities in the United States, Canada, England, France and Germany. Razor sales reached 450,000 units and blade sales exceeded 70 million units in 1915. In 1918, when the U.S. entered World War I, the company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. The company continues in the present day as the Gillette brand of Procter & Gamble, USA. Throughout the 20thC most men used this type of safety razor with disposable stainless steel razor blades to shave their beards prior to the introduction of affordable electric razors in 1960'sA blue packet of unused 'King Gillette' safety razor blades.on top of packet; Press with thumb / and snap end open / GILLETTE QUALITY THE / SAME THE WORLD OVER / FACTORIES IN / USA / CANADA , GREAT BRITAIN / MEXICO , FRANCE / COLUMBIA, GERMANY / BRAZIL, SPAIN / ARGENTINA, AUSTRALIA / GILLETTE TRADE MARK / KING C GILLETTE / RED. TRADE MARKS / GILLETTE (AUST.) PTY. LIMITED / MELBOURNE / DE 2023 / MADE IN AUSTRALIA / shaving equipment, safety razors, gillette king, proctor & gamble, moorabbin, bentleigh, cheltenham, -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: PRODUCTS OF LOCOMOTIVE FIREBOX COMPANY - BROCHURE

Product of locomotive firebox company - glossy printed brochure Circ 1931. Title 'Syphon Safety from boiler explosions caused by low water' advert for the Thermatic Syphon.document, memo, railway, (x ref 1325.39) locomotive firebox company / thermatic syphon -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumSoap, TI-TROL ANTISEPTIC AND GERMICIDAL TOILET SOAP, c. 1928-1968

TROVE : Evening News (Sydney, NSW : 1869 - 1931), Thursday 11 October 1928, page 13. NEW COMPANIES The following new companies were registered this afternoon :- Australian Essential Oils Ltd : Nominal capital. £50,000, in 93.000 ordinary and 7,000 deferred shares at 10/-. to engage in business of distillers, manufacturers of, and dealers in oils from vegetables and other sub-stances, chemists etc. First directors: N. H.B.Keynor, R.K.Allport, E.M Humphries, and H. James. Head office Sydney. TROVE : Government Gazette of the State of New South Wales (Sydney, NSW : 1901 - 2001), Friday 26 July 1968 (No.89), page 3028 IN the matter of the Companies Act, 1961-1966, and in the matter of AUSTRALIAN ESSENTIAL OILS LTD (Receiver and Manager Appointed).—Roy Leslie Pegler, Receiver and Manager of Australian Essential Oils Ltd (Receiver and Manager Appointed)„ appointed by debenture holders on the 11 th July, 1966, hereby gives notice that any debenture holders and others having any claim against or to Australian Essential Oils Ltd (Receiver and Manager Appointed) are required to send particulars of their debenture or claim to the Receiver, Roy Leslie Pegler, at c.o. Messrs Pegler, Ellis & Co., Chartered Accountants, 235-7 Elizabeth Street, Sydney, N.S.W., on or before the 27th September, 1968, at the expiration of which time the Receiver and Manager will distribute the assets of the said Company to the persons and/or companies entitled, having regard only to the claims of which he then has notice.—Dated 24th July, 1968. PEGLER, ELLIS & CO., Chartered Accountants, 235-7 Elizabeth Street, Sydney, N.S.W. 8744—$5 White cardboard box printed in dark green with a round blue and white sticker on one side, containing a cream paper leaflet printed in dark green, wrapped around a greaseproof paper wrapped rectangular cake of translucent brown soap with impressed text on one side.Impressed on one side of the cake of soap ' A PRODUCT OF AUSTRALIAN ESSENTIAL OILS LTD SYDNEY'. On reverse of soap impressed 'TI-TROL ANTISEPTIC TOU\ILET SOAP'. Printed on the box 'TI-TROL ANTISEPTIC AND GERMICIDAL TOILET SOAP. Printed Leaflet wrapped around cake of soap 'Germicide TI-TROL Antiseptic, Toilet Soap ELEVEN TIMES MORE POWERFUL THAN CARBOLIC. NON IRRITANT ………NON POISONOUS. “Ti –Trol” GERMICIDAL ANTISEPTIC SOAP is the most modern of all toilet soap …..Distilled and manufactured by Australian Essential Oils Ltd., the pioneers of Tea-Tree Oil Industry in Australia, and manufacturers of that famous antiseptic solution Melasol. It has taken years of patient research, of test, trial and experiment to reach the pinnacle of perfection which Ti-Trol Soap is now offering to the public. Ti-Trol is a hand-made glycerine base soap in which only the finest ingredients are used. One of its most attractive features is that it contains a full three per cent. of “Ti-trol”. In medical and clinical practice, both in Australia and abroad, Ti Trol has given remarkable results…particularly in its cleansing properties: its soothing HEALING action on dirty and inflamed septic wounds. By incorporating Ti-Trol in a glycerine base soap, experts are agreed that the result….. Ti-Trol soap is unequalled-anywhere- for its soft soothing healing and germicidal properties. Ti-Trol soap is non-irritant and non-poisonous and can be used on the tenderest skins…babies’ or the most delicate peach-bloom complexions, with most excellent results. . PRODUCT OF A SOAP MAKER OF INTERNATIONAL EXPERIENCE Australian Essential Oils Ltd., have been fortunate in procuring the services of a soap-maker of International experience and world-wide knowledge of Soap Production, whose genius has produced Ti-Trol, and whose uncanny sense of blending has made Ti-Trol the most famous of all Germicidal Toilet Soaps. Ti-Trol is non-irritant and non-poisonous and has been proved by medical and specialised authorities top\ possess great healing and cleansing properties. It is a powerful Germicide and antiseptic….ELEVEN TIMES QUICKER THAN PURE CARBOLIC. . DANDRUFF CAN’T LIVE WITH Ti-Trol. Dandruff ......that horrible “give away” which many men and women suffer from…..can easily be dispelled by using Ti-Trol Soap this way : Rub a little Olive Oil into the scalp before retiring at night, and the following morning wash your head thoroughly with Ti-Trol Soap, allowing the lather to remain on the scalp for about a minute and a half. Then rinse the hair thoroughly in warm water. .WASH BRUSHES AND COMBS WITH Ti-Trol SOAP When you’ve done this and dried your hair, wash all your brushes and combs in a strong, soapy solution made with Ti-Trol Soap, and then carefully sponge the inside of the hat bands with a flannel or cloth moistened with this soapy solution. Follow these directions and you’ll never need to fear dandruff. .Ti-Trol…WONDERFUL HEALER OF CUTS. SORES, WOUNDS, ETC. There never was a more patent healer of CUTS, SORES, WOUNDS, ABRASIONS AND SEPTIC SORES than Ti-Trol… Here’s how to use it : Wash the affected parts with a fairly strong Ti-Trol soapy solution made with warm water, and then apply with lint soaked with Melasol, which is the miscible form of Ti-Trol (Melasol is obtainable at all chemists and stores everywhere). . Ti-Trol SOAP……..A DEODORANT, A BEAUTIFIER……a safeguard for tender skins Ti-Trol Soap, because of its delicate, pungent, aroma and antiseptic properties, is unequalled as a deodorant, and is never failing when used for this purpose. Ti-Trol Soap can be used on the tenderest skins, and even baby’s skin, with greatest safety. It’s delightful fragrance will give added pleasure to your toilet. . DO NOT WASTE Ti-Trol Soap is too valuable to waste. Therefore, use it carefully. Do not leave it in the water. To obtain greatest economy it is preferable to use a face cloth when using Ti-Trol Soap. For health, for the most economical means of insuring against disease, use Ti-Trol Ointment…..for cuts, bruises etc. Ti-Trol….for boils, cuts, sores, abrasions and septic conditions. MELASOL…..for Tinea, Mouth Wash and as a Dentifice. . All are products containing Ti-Trol, distilled and provided by Australian Essential Oils Ltd. 18 Loftus Street, Sydney. N.S.W.'. tea tree oil, soap, glycerine, antisptic, germicide -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Robert Harper & Co, Jenny Bell, unknown

A three page document about Robert Harper and his company, including a 1920's black & white photograph of the packaging and 13 colour photographs of labels of products including coffee, rice, tea, oatmeal and safety matches.industry-manufacturing, industry - food, manufacturing, robert harper & co ltd -

Victorian Interpretive Projects Inc.

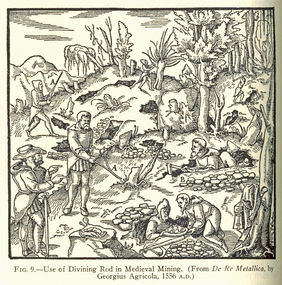

Victorian Interpretive Projects Inc.Book, Theodore Jesse Hoover, The Economics of Mining, 1938

Theodore Jesse Hoover, brother of the 31st President of the United States, was born in West Branch, Iowa, on January 28, 1871. He attended Stanford and received the Bachelor of Arts degree in Geology and Mining in 1901. Following graduation his professional career started with the position of assayer for the Keystone Consolidated Mining Company. After one year, he became assistant manager for the Standard Consolidated Mine, and a year later he was promoted to manager of the operation. In 1907 Hoover went to London as general manager of Minerals Separation, Ltd. This company was developing the froth flotation process for recovering minerals from ores. Hoover took an active part in the development of the flotation concentration process and authored one of the first books on the concentration of ores by flotation. After four years with Minerals Separation, Ltd., Hoover entered private practice as a consulting mining and metallurgical engineer with offices in London and in San Francisco. He was very successful and held positions of consulting engineer, managing director, director, and president of many mining companies in America, Europe, Asia, Africa, and Australia. He returned to Stanford in 1919 as Professor of Mining and Metallurgy and Executive Head of the Department of Mining and Metallurgy. His experience and ability in organization made him a natural leader. He was influential in the formation of the School of Engineering at Stanford. The School was formed in 1925 and he was made dean, a position he held until his retirement in 1936. As dean of engineering, he promoted a broad fundamental training program for undergraduate engineering students. Under his guidance, emphasis was placed upon graduate work and he was responsible for developing strong graduate engineering curricula at Stanford. While dean he continued teaching and his course, "The Economics of Mining," developed into a book which was published in 1933. He became interested in the functions of engineers and, with Professor Fish, wrote a book entitled "The Engineering Profession" which was published in 1940 and revised in 1950. In addition to his academic activities he was generous in his hospitality. Faculty and students alike enjoyed the annual field day and barbecue at his Rancho del Oso, near Santa Cruz. He was widely read and had a lively interest in all the things he encountered. He speculated on the antiquity of man and man's early production processes. To verify an idea regarding flint tools, he studied their shapes and became proficient in making arrow heads. He was also interested in wild life, and was one of the founding members of the Cooper Ornithological Society. (http://engineering.stanford.edu/about/bio-hoover)Blue hard covered book of 547 pages including an index. Contents include mine valuation (sampling, ore deposits, ore reserves, financial provisions, sale of mineral product, metal prices, reports) and Mining Organization (Co-operative effort, Mining Companies, Promoting Mining Enterprises, fluctuations of share prices, valuation of mining shares, fakes and fallacies, the mining Engineer and the law) and Mine Management (Organization of staff, mine manager, efficiency, industrial relations, training and discipline, safety).inside cover 'Charles Bacon Mackay School of Mines'.mining, economics, hoover, stanford, mackay school of mines, mackay, bacon -

Puffing Billy Railway

Puffing Billy RailwayGreenbat Battery Loco, Greenwood & Batley ltd

Greenbat Battery Loco Built by Greenwood & Batley Ltd Builders No. 420363/2 This Greenbat Battery Loco has been loaned to the Museum by the Walhalla Goldfields Railway, who had acquired it in 2013 along with a large quantity of narrow gauge trollies and light rail from Orica’s now closed munitions factory in Melbourne’s western suburbs. The trolley on display was one of two in use from the 1970s. Orica - Deer Park Munitions factory Orica Deer Park in Melbourne’s west has been used since circa 1875 for various forms of manufacturing and storage of chemicals. Although the site is bounded by Ballarat Road, Station Street, Tilburn Road and the Western Ring Road, the current entry point for industrial operations is situated at Gate 6 off Tilburn Road. Operations include: • a specialty chemicals facility producing products for mining services operations • quarry services • other chemical manufacture activities. The Deer Park factory complex is of historical significance as the location of the first plant for the manufacture of high explosives in Australia and has been, for its entire history, the most important, if not only, commercial manufacturer of high explosives in Australia. It commenced operation under the importer Jones Scott and Co, and then the Australian Lithofracteur Company (Krebs Patent), a rival to Nobel's dynamite patent. The factory was producing nitro-glycerine based explosives in Australia only a couple of years after Nobel's Ardeer factory began operating in Scotland. The explosives factories complex is of historical significance for the association with the Australian Lithofracteur Company, Australian Explosives and Chemicals, the Nobel company and later ICIANZ, which grew to become one of the largest explosives, chemical and plastics manufacturers in Australia. It was the pioneer of the industry and retained its dominance through monopolistic practices, taking over most of its competitors in the Australasian region. Substantial parts of the pre-Second World War layout of the site remain which, with a number of significant buildings dating back to the 1920s and '30s, indicate past and present processes of manufacturing, the necessary safety measures required and the integrated nature of the explosives and chemical industry. The narrow gauge tramway, which ran through the explosives section, was a rare survivor of nineteenth century materials-handling methods into the 21st Century. Greenwood & Batley were a large engineering manufacturer with a wide range of products, including armaments, electrical engineering, and printing and milling machinery. They also produced a range of battery-electric railway locomotives under the brand name Greenbat. The works was in Armley, Leeds, UK. Greenbat was the trade name for the railway locomotives built by Greenwood & Batley. The company specialised in electric locomotives, particularly battery-powered types for use in mines and other hazardous environments. Historic - Industrial Narrow Gauge Railway - Battery Locomotive - Orica - Deer Park Munitions factory - Deep park, Victoria, Australia Battery Locomotive - made of iron puffing billy, greenbat battery loco, battery locomotive, industrial narrow gauge railway, orica - deer park munitions factory -

Anglesea and District Historical Society

Anglesea and District Historical SocietySafety Matches, Crown Bryant & May's Safety Matches

Early matches. Brown paper package containing eleven boxes of safety matches. Made in Australia. Product information printed on red and blue and label attached to brown paper.Bryant & May's Crown Made in Australia Safety Matchesbryant & may, matches, crown matches -

Anglesea and District Historical Society

Anglesea and District Historical SocietyCamera - Kodak - Brownie Six-20, Kodak, Estimated 1953-57

Product Identifier: K763.00017. This camera has a black imitation pigskin covered metal body with two finders, two pin flash contacts; shutter safety catch; tripod sockets and a cable release socket. This 1953-57 model has a horizontally striped front, plastic wind knob and release button and a triangular springback catch. (Film winder missing).Front: Brownie SIX-20 CAMERA / Model E / with flash contacts / MADE IN ENGLAND BY KODAK LIMITED. Inside back: Use Kodak 620 films, Shutter Synchronised for Flashbulbs. Class F or M.camera, brownie, kodak -

Unions Ballarat

Unions BallaratKiller Company: James Hardie Exposed, Peacock, Matthew, 2009

Matthew Peacock is an ABC journalist who researched the story of the company, James Hardy, that knowingly continued to sell asbestos products despite serious health risks to its employees and customers. Stories of past employees including the late Bernie Banton who publically crusaded against James Hardy.The book and its stories are significant to workplace health and safety in Australia and consumer safety.Paper; book. Front cover: red and black background; white and red text; photographs of Greg Combet, Bernie Banton and a man holding a banner that reads, "Killed by Asbestos".Front cover: title and author name.btlc, ballarat trades hall, ballarat trades and labour council, banton, bernie, james hardy industries, occupational health and safety, asbestos, workers' compensation, political activists, unions, asbestosis, biography