Showing 15 items matching "timekeeping"

-

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Memo, State Electricity Commission of Victoria (SECV), "Timekeeping procedure - weekly time sheets", 3/1/1961

... "Timekeeping procedure - weekly time sheets" ...Memo on SEC Electricity Supply Dept. letterhead from the Branch Manager to other managers, dated 3/1/1961, regarding "Timekeeping procedure - weekly time sheets" - giving an example sheet for a shed man at the depot and a blank form. Memo notes that this form did not apply to the Traffic staff. Signed by H Linaker, Manager. Branch timekeeper N L Pearson.Yields information about the process for recording working hours by SECV personnel.Document - half-foolscap typed sheet, carbon copy and two sample Weekly time sheets. Was pinned in the top left hand corner.In red type "Works Superintendent"tramways, secv, depot, works foreman -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClocks, 1950

In 1865 James Jones Elliott of 156 Cheapside in the City of London, was apprenticed to a clockmaker"Bateman" of 82 St John Street, Smithfield, London., to learn the art of clock making. Initially, J J Elliott specialized in producing pinions and balance shafts for clocks. He eventually progressed to making, and patenting, a weight-driven movement which had chimes on tubes. This clock was very successful and resulted in considerable trade with America. James Elliott's son, Frank Westcombe Elliott, when he was 17 years old, went into business with his father after his father had bought a partnership with a jeweler called “Walden” of Brompton Road, London. In 1904, JJ Elliott died and Frank succeeded his father in clock making business. In 1909 company of JJ Elliott amalgamated with Grimshaw Baxter, and the factory moved to Grays Inn Lane, London, in 1911, followed by a further move, in 1917, to larger premises in St Ann’s Road, Tottenham, London. In 1921 the partnership with Grimshaw Baxter was dissolved and Frank Elliott joined a well-known firm of Bell Founders and Clockmakers, Gillett and Johnson Ltd, in Croydon. In 1923, two years later, he took over their clock factory and formed the famous company of F.W. Elliott Ltd. He was joined by his two sons, Leonard and Horace Elliott, who had served their apprenticeships in the trade. The third son, Ronald, joined the company in 1929. Elliott's started to produce clocks for the armed forces when war was declared in 1939, together with test gear and apparatus for the Rolls Royce engines used in the RAF planes. In 1944, Frank Elliott died at the age of 69 and Horace Elliott assumed the role of Managing Director. Whilst Horace controlled sales from a showroom in Hatton Garden. In 1952, Horace Elliott was elected Chairman of the British Horological Institute in the same year as Tony, one of Horace's sons, joined the company after he had completed training as a cabinet maker. Ronald Elliott died suddenly in 1966, at the age of 54, his son Peter continued to manage the company until 1998 when it ceased trading. An item that is now regarded as vintage, sought by horology collector’s worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by a well-known British clock manufacture. Its provenance is well established as the serial numbers on the clock indicate it was made in 1950. Production by F.W Elliott for this design of ships clock ceased in 1959. Clock has a gold color case with a 150 mm white painted dial and Roman numerals. The movement has a balance wheel escapement and a slow-fast timekeeping adjuster to the top of the dial. The back of the clock is stamped “made by F W Elliott Ltd of Croydon” and a serial number 21B/829, an additional number 994 is also stamped on the back casing. Thsi model clock finished production in 1959. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, f w elliott, maritime clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Watch Glasses, early to mid 20th century

... timekeeping ...Watches and wristwatches have a glass over the watch face to protect the internal parts, the face and the moving hands from damage. The watch glasses are made in a range of diameters and heights according to the individual watch. A jeweler usually keeps a wide range of glass sizes and sometimes different materials depending on the purpose of the watch e.g. as a fashion accessory or a robust timekeeping piece. The glasses in these boxes have tissue paper between them and most have a label identifying their sizes.These watch glasses are an example of the stock items a watchmaker or jeweler would need to have on hand to service his customer's timepieces. Today's jewelers follow this example to be able to quickly attend to their customer's needs.Three boxes of watch glasses. The collection of circular, slightly domed, clear thin glasses includes different sizes to suit different watches and wristwatches. Many of the glasses have a protective paper on them that also has a printed size. (.1) small glasses in a "Country Life" cigarette tin (.2) medium glasses in a "Jewelex" cardboard box and (.3) large glasses in an open faded blue cardboard box.Protective papers with various sizes and codesflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jewelex, watch face, watch glasses, wristwatch glasses, clear watch glasses, jewellery, accessory, timepiece, timekeeping, early to mid 20th century -

Mont De Lancey

Mont De LanceyFunctional object - Wall Clock

The invention of the pendulum clock in the 17th century marked a significant milestone in the evolution of wall clocks. The pendulum clock was more precise and dependable than previous clock designs, and it became the standard for timekeeping for many years. In the 19th century, the production of wall clocks became more industrialized, and they were mass-produced for the first time. This made wall clocks more affordable and accessible to the general public, allowing more people to have access to accurate timekeeping devices in their homes and businesses.The brass plaque notes - 'This clock was presented to the MDL Museum to mark the 90th birthday of Mr. Neville Lord Gift from Mrs Annette Lord 22:1:1995'.A brown wooden wall clock with a white round clock face, with roman numerals, and a brass pendulum enclosed in a glass faced compartment. It has a brass presentation plaque below the clock, on the wooden pole.'Gerber' 'Quartz' is printed on the clock face. 'Regulator' is printed in gold lettering on the glass encasing the pendulum. On the brass plaque is written - 'This clock was presented to the MDL Museum to mark the 90th birthday of Mr. Neville Lord Gift from Mrs Annette Lord 22:1:1995'.wall clocks, plaques, timepieces, clocks -

Melbourne Tram Museum

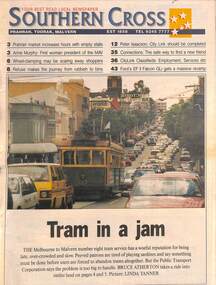

Melbourne Tram MuseumNewspaper, Southern Cross, "Tram in a jam", 18/10/1995 12:00:00 AM

Newspaper clipping - set of three cuttings - from the Southern Cross, 18/10/1995 titled "Tram in a jam" with a photo of W6 983 outbound in Toorak Road. Looks at the performance of the tram route and the issues of timekeeping, over crowding and traffic. Story by Bruce Atherton, photo Linda Tanner. Quotes Peter Batchelor Opposition transport spokesman, MLA Robert Doyle, and Transport and PTC Spokesman Ray Wilson. Also has quotes from five tram patrons.trams, tramways, route 8, toorak rd, passengers, traffic control, timetables -

Melbourne Tram Museum

Melbourne Tram MuseumDocument, Swanston Trams, "The Operational Performance Regime", 1999

Document dated 15-11-1999, titled "The Operational Performance Regime", prepared by Swanston Trams for Malvern Depot, training drivers about the DOI proposed tram monitoring system in relation to timetables, cancelled trams, short shunts, late running and early or late running monitored by the AVM system. Details the role of drivers, explains timing points, location of the points for each route, penalties, running times, and the importance of timekeeping. Part of the tram performance reporting system that was provided to passengers and possible ticket refunds. See item 8834 for a M>Tram version.Demonstrates the training paper provided to drivers to make them aware of the new monitoring system and the penalties that would apply to Swanston St for late running etc at the time of privatisation.Document - 9 A4 pages stapled in top left hand corner photocopied.tramways, swanston trams, malvern depot, instructions, performance, avm, drivers -

Melbourne Tram Museum

Melbourne Tram MuseumDocument, M>Tram, "M>Tram operational performance regime (OPR) training manual, c2002

Document titled "M>Tram operational performance regime (OPR) training manual" - undated, c2002 with a photo of B2 2078 on the front cover. Prepared for the training of fleet operations staff about the tram monitoring system in relation to timetables, cancelled trams, short shunts, late running and early or late running monitored by the AVM system. Details the role of staff, explains timing points, location of the points for each route, penalties, running times, and the importance of timekeeping. Part of the tram performance reporting system that was provided to passengers and possible ticket refunds. See item 8711 for a 1999 version.Demonstrates the training paper provided to fleet operations staff about the monitoring of tram services and the timing points used for each M>Tram route.Document - 14 A4 sheets stapled in top left hand corner.trams, tramways, the met, timetables, passenger services, instructions, avm, m>tram, fleet operations centre -

Orbost & District Historical Society

Orbost & District Historical Societywall clock, c. late 19th century

The clock was the original clock located over the bar in the Orbost Club Hotel. In 1884 J.A. Petterson built the first Orbost Club Hotel with the licence in the name of Thomas Maguire (his stepson). This hotel was the first in the area and cost 1,400 pounds to build (ref. In Times Gone By - Deborah Hall) and was actually built before Orbost was proclaimed a township - April 17 1885 The R A on the pendulum stands for: retard/advance. It is a common pendulum bob, used by many manufacturers, worldwide. Regulator clocks, sometimes referred to as pendulum clocks, were invented in the late 18th century in a quest for greater timekeeping accuracy. They were weight-driven devices. The pendulum on this clock appears to be German made. .The Orbost Club Hotel was the first hotel built in the Orbost district and was an important hub for the township with many whole town meetings held there.A wall clock with Roman numerals inside a dark brown wooden case. It has a brass pendulum and the key is inside the case.R A on the pendulum.wall-clock orbost-club-hotel -

Merri-bek City Council

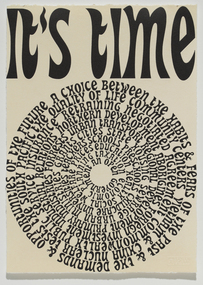

Merri-bek City CouncilRelief etching printed in 1 colour from 1 copper plate over lithograph printed in 1 colour from 1 aluminium plate, Emily Floyd, It’s Time (Again), 2007

Emily Floyd is a Melbourne-based artist who works across sculpture, printmaking and public installation. In It’s Time (Again), Floyd graphically presents Gough Whitlam’s election speech, delivered before he became Prime Minster in 1972. Floyd’s training as a graphic designer is evident in the way in which the text’s presentation ties form to meaning. For example, the circular arrangement of the words resembles a vinyl record to be played again and again, implying the speech is worth revisiting. The circular arrangement also references other forms of timekeeping, such as the growth rings of a tree; the face of a clock; the cyclical nature of time, with its diurnal, lunar, seasonal and annual cycles. Floyd's work implies that social and political issues are cyclical in nature. It emphasises the necessity, once again, for proactive measures to ensure a quality, human-centered existence for everyone. -

Flagstaff Hill Maritime Museum and Village

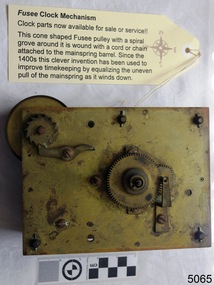

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clock, late 1900s early 20th Century

In 1850 the Ansonia Clock Company was formed as a subsidiary of the Ansonia Brass Company by Phelps and two Bristol Connecticut clock makers, Theodore Terry and Franklin C. Andrews. Terry & Andrews were the largest clock manufacturers in Bristol at the time with more than 50 employees using 58 tons of brass in the production of about 25,000 clocks in 1849. Phelps decided to get into the clock making business to expand the market for his brass, while Terry and Andrews got access to better quality brass at better prices. They had then sold 50% of their business to Phelps and moved the business to Ansonia, Connecticut. In 1877 the clock company purchased a factory in New York and moved most of its production thereafter being spun off from the brass company. Henry J. Davies of Brooklyn, himself a clock maker, inventor and case designer, joined the newly reconstituted company as one of its founders. As President, he is thought to have been largely responsible for the figurine clocks, swing clocks and other unusual and desirable novelties for which the Ansonia firm became known. By 1879, a second factory was opened in Brooklyn, New York and by June 1880 employed 360 workers, while the Connecticut factory continued producing clocks as well with a workforce of 100 men and 25 women. Hence, clocks marked "Connecticut" were generally produced before 1879, while those marked "New York" were all produced after 1880 After the New York factory burnt down in 1880 the company rebuilt the factory on the same site, and reopened the expanded factory in 1881, with a capacity to exceed that of the Connecticut factory which by 1883 had closed. By 1886, the company had sales offices in New York, Chicago and London, with more than 225 different clock models being manufactured. In 1899, Phelps' grandson William Earle Dodge Stokes commissioned architect Duboy to build the "greatest and grandest hotel in Manhattan, New York” which became the city's first air-conditioned building. In 1929 the majority of the timekeeping machinery and tooling was sold to the Soviet government's US trading company Amtorg, just before the stock market crash. The parts, machinery and key skilled workers were shipped out of the USA to form the basis, along with the remains of a watch company purchased a year later, of the clock and watch industry in Moscow such as Poljot and Sekonda. In 1969, the rights to the use of the name, trademarks, and goodwill were transferred to Ansonia Clock Co., Inc., Lynnwood, Washington. The item marks the beginning of mass produced clocks in the United States, cheaply priced and available to all. The company had many innervation's during it’s life regards clock and later wrist watch making that led the way for other companies in many different countries to emulate.Clock, pendulum mantle model. Carved scallop "Ginger bread house" cottage clock. Oak case, white enamel face, floral etched glass door. Clock has an hour bell chime. Glass front opens to allow rewinding. Made by Ansonia Clock Co, New York. Marked "Manufactured by Ansonia Clock Co. New York, USA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, mantle clock, clock, pendulum clock, time keeper, horology, ansonia, ansonia clock co, america -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1867

Langlands Company History: Langlands foundry was Melbourne's first foundry and iron shipbuilder established in 1842, only 8 years after the founding of the Victorian colony by two Scottish immigrants, Robert Langlands and Thomas Fulton, who had formed a partnership before emigrating (1813–1859). The business was known as the 'Langlands Foundry Co'. Henry Langlands (1794-1863), left Scotland in 1846 with his wife Christian, née Thoms, and five surviving children to join his brother Robert. By the time he arrived in early January of 1847 the partnership of Robert Langlands and Fulton had dissolved as Fulton had gone off to establish his own works. It was at this time that the two brothers took over ownership of Langlands foundry. Several years later Robert retired and Henry became sole the proprietor. The foundry was originally located on Flinders Lane between King and Spencer streets. Their sole machine tool, when they commenced as a business, was a small slide rest lathe turned by foot. In about 1865 they moved to the south side of the Yarra River, to the Yarra bank near the Spencer Street Bridge and then in about 1886 they moved to Grant Street, South Melbourne. The works employed as many as 350 workers manufacturing a wide range of marine, mining, civil engineering, railway and general manufacturing components including engines and boilers. The foundry prospered despite high wages and the lack of raw materials. It became known for high-quality products that competed successfully with any imported articles. By the time Henry retired, the foundry was one of the largest employers in Victoria and was responsible for casting the first bell and lamp-posts in the colony. The business was carried on by his sons after Henry's death. The company was responsible for fabricating the boiler for the first railway locomotive to operate in Australia, built-in 1854 by Robertson, Martin & Smith for the Melbourne and Hobson's Bay Railway Company. Also in the 1860s, they commenced manufacture of cast iron pipes for the Board of Works, which was then laying the first reticulated water supply system in Melbourne. Langlands was well known for its gold mining equipment, being the first company in Victoria to take up the manufacture of mining machinery, and it played an important role in equipping Victoria's and Australia's first mineral boom in the 1850s and 1860s. Langlands Foundry was an incubator for several engineers including Herbert Austin (1866–1941) who worked as a fitter at Langlands and went on to work on the Wolesely Shearing machine. He also founded the Austin Motor Company in 1905. Around the 1890s Langlands Foundry Co. declined and was bought up by the Austral Otis Co. in about 1893. History for Grimoldi: John Baptist Grimoldi was born in London UK. His Father was Domeneck Grimoldi, who was born in Amsterdam with an Italian Father and Dutch mother. Domeneck was also a scientific instrument maker. John B Grimoldi had served his apprenticeship to his older brother Henry Grimoldi in Brooke Street, Holburn, London and had emigrated from England to Australia to start his own meteorological and scientific instrument makers business at 81 Queens St Melbourne. He operated his business in 1862 until 1883 when it was brought by William Samuel and Charles Frederick, also well known scientific instrument makers who had emigrated to Melbourne in 1875. John Grimoldi became successful and made a number of high quality measuring instruments for the Meteorological Observatory in Melbourne. The barometer was installed at Warrnambool's old jetty and then the Breakwater as part of the Victorian Government's insistence that barometers be placed at all major Victorian ports. This coastal barometer is representative of barometers that were installed through this government scheme that began in 1866. The collecting of meteorological data was an important aspect of the Melbourne Observatory's work from its inception. Just as astronomy had an important practical role to play in navigation, timekeeping and surveying, so the meteorological service provided up to date weather information and forecasts that were essential for shipping and agriculture. As a result, instruments made by the early instrument makers of Australia was of significant importance to the development and safe trading of companies operating during the Victorian colonies early days. The provenance of this artefact is well documented and demonstrates, in particular, the importance of the barometer to the local fishermen and mariners of Warrnambool. This barometer is historically significant for its association with Langlands’ Foundry which pioneered technology in the developing colony by establishing the first ironworks in Melbourne founded in 1842. Also, it is significant for its connection to John B Grimoldi who made the barometer and thermometer housed in the cast iron case. Grimoldi, a successful meteorological and scientific instrument maker, arrived in the colony from England and established his business in 1862 becoming an instrument maker to the Melbourne Observatory. Additional significance is its completeness and for its rarity, as it is believed to be one of only two extant barometers of this type and in 1986 it was moved to Flagstaff Hill Maritime Village as part of its museum collection. Coast Barometer No. 8 is a tall, red painted cast iron pillar containing a vertical combined barometer and thermometer. Half way down in the cast iron framed glass door is a keyhole. Inside is a wooden case containing a mercury barometer at the top with a thermometer attached underneath, each with a separate glass window and a silver coloured metal backing plate. Just below the barometer, on the right-hand side, is a brass disc with a hole for a gauge key in the centre. The barometer has a silvered tin backing plate with a scale, in inches, of "27 to 31" on the right side and includes a Vernier with finer markings, which is set by turning the gauge key. The thermometer has a silvered tin backing plate with a scale on the left side of "30 to 140". Each of the scales has markings showing the units between the numbers.Inscription at the top front of the pillar reads "COAST BAROMETER" Inscribed on the bottom of the pillar is "No 8". and "LANGLANDS BROS & CO ENGINEERS MELBOURNE " The barometer backing plate is inscribed "COAST BAROMETER NO. 8, VICTORIA" and printed on the left of the scale, has "J GRIMOLDI" on the top and left of the scale, inscribed "Maker, MELBOURNE". There is an inscription on the bottom right-hand side of the thermometer scale, just above the 30 mark "FREEZING" Etched into the timber inside the case are the Roman numerals "VIII" (the number 8)flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, warrnambool breakwater, coast barometer, coastal barometer, barometer, weather warning, ports and harbours, fishery barometer, sea coast barometer, austral otis co, coast barometer no. 8, henry grimoldi, henry langlands, john baptist grimoldi, langlands foundry co, meteorological instrument maker, robert langlands, scientific instrument maker, thermometer, thomas fulton -

Parks Victoria - Wilsons Promontory Lightstation

Parks Victoria - Wilsons Promontory LightstationClock

The brass wall clock retains its key. It was provided by the Department of Shipping and Transport in about 1900 and is original to the lightstation. It was mounted in the watchroom, a small extension at the front of the lighthouse (later radar station), where lightkeepers completed many of their reports and recorded radio schedules, weather observations, distress calls and other data. Good, reliable clocks were also essential for maintaining a strict roster of hours for winding the clockwork mechanism that kept the lens active. The name of the clock’s manufacturer has not been determined. More specifically it was used for logging radio schedules that were made at five minutes to midday, everyday, and for recording the times of weather observations, distress and any other calls that came in. AMSA notes that ‘Lightkeepers who used this clock were said to have polished and wound it every week while it was in use until the 1990s when its otherwise impeccable time keeping mechanisms finally became inaccurate’.The brass clock at Wilsons Promontory illustrates the importance of timekeeping in a nineteenth century lighthouse. Despite its slightly chipped face, the timepiece has first level contributory significance for its historic association with the watch room and confirmed provenance. The significance of this clock also lies with its complete provenance..1. Brass clock with a circular white face and black roman numerals. Three brackets at back to attach to wall. Face of clock is covered by a hinged glass cover with a fastener. .2. key. Roman numerals on face of main clock. "1-12" On inner dial "10-20-30-40-50-60" -

Flagstaff Hill Maritime Museum and Village

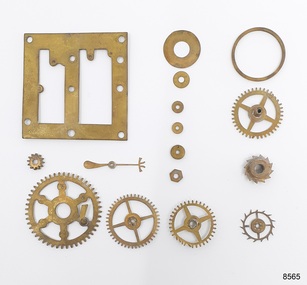

Flagstaff Hill Maritime Museum and VillageInstrument - Clock Parts, Bef. 01-06-1878

The clock parts were discovered in 1980 by Julie Wilkins, a Victorian scuba diver who had already experienced more than 500 dives in Australia and overseas. She was holidaying in Peterborough, Victoria, and looking forward to discovering more about the famous Loch Ard ship, wrecked in June 1878 at Mutton Bird Island. The fast Glasgow-built clipper ship was only five years old when the tragedy occurred. There were 54 people on board the vessel and only two survived Julie's holiday photograph of Boat Bay reminds her of her most memorable dive. Submerged in the calm, flat sea, she was carefully scanning around the remains of the old wreck when, to her amazement, a gold coin and a small gold cross suddenly came up towards her. She excitedly cupped them in her hands and then stowed the treasures safely in her wetsuit and continued her dive. She soon discovered a group of brass carriage clock parts and some bottles of champagne. It was a day full of surprises. The items were easily recognisable, without any build-up of encrustations or concretion. Julie secretly enjoyed her treasures for twenty-four years then packed them up for the early morning train trip to Warrnambool. After a short walk to Flagstaff Hill Maritime Museum and Village, her photograph was taken as she handed over her precious find. She told her story to a local newspaper reporter, lunched a café in town then took the late afternoon train home. Her generous donation is now part of a vast collection of Loch Ard shipwreck artefacts, including the gold watch and the Minton Majolica model peacock. This group of brass clockwork parts is incomplete. The pieces were in the ocean for over 100 years before Julie recovered them from the Loch Ard wreck. Their size would suit the works of a carriage clock, with a mainspring and weight to power the clock movement, a pendulum to measure the clock's speed, arbours, posts, pillars and at least one other plate. They would have been mounted inside a protective case with a small door to easily access the clock face for setting the time and accessing the key's winding hole. The clock cases were usually made from decorative gilt brass with a glass front and a carrying handle. The parts include a weighted second hand with a decorative four-pronged finish at one end, a rounded weight at the other, and a hole for attaching it to the clock face. The gear teeth profiles are ‘cycloidal’, an arch shape with vertical sides, which is common for antique clocks. Modern clockworks have ‘involute’ teeth with sloping sides and a squared-off top. The brass carriage clock parts are an example of a mechanical clock produced in the 1870s. The clock's design is a part of the chain of technological improvements in methods for timekeeping. Its cycloidal gear teeth were the forerunner of the more modern involute gears. The group of clock parts includes a weighted hand or arm for signifying the seconds. This feature was uncommon in portable Victorian-era clocks. The clock parts are also significant for their association with the ill-fated sailing ship Loch Ard, wrecked in 1878. The travelling clock or officer’s clock may have been part of the cargo destined for the 1880 Melbourne Exhibition, or the personal possession of one of the people on board the vessel. Brass clockwork parts from a mechanical clock, sixteen pieces. Parts comprise a plate, large gears or wheels, small pinions or wheels with fine teeth, wheels with cogs, and a weighted second hand. The parts were from a carriage clock ca. 1878. They were recovered from the wreck of the sailing ship Loch Ard.flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, loch ard, wreck of the loch ard, 1878, mutton bird island, peterborough, scuba diver, 1980s, shipwreck artefact, relic, clock, mechanical, clock parts, time, timekeeper, horology, chronometry, cogs, time keeping device, scientific instrument, chronometer, john harrison, longitude, carriage clock, coach clock, portable clock, travelling clock, travel clock, traveller’s clock, officer’s clock, weighted second hand, victorian era, cycloidal gear teeth, brass clock, julie wilkins -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Quartz veining in Breccia Conglomerate, Unknown

Quartz is one of the most common minerals in the world. It is formed by a 3d structure of silicon and oxygen. While it is a simple mineral, it can come in a variety of shapes and colours. When quartz is pure it is colourless, transparent and can appear glass-like. Better known and more rare variations of quartz include amethyst and smoky quartz. This specimen is a vein of quartz in Breccia Conglomerate. Breccia is coarse-grained clastic rock which is made up of broken rock fragments and held together by mineral cement. The locality of this specimen is unknown. While quartz is a very common mineral and does not have rarity, it is an important material in industrial settings. One of it's physical and chemical properties is that it is piezoelectric, which means it can be used to generate an electric charge. This has made it useful in the manufacturing of timekeeping devices. This specimen was donated to the Burke Museum between 1868-1880 among a larger collection of geological specimens. It was collected as part of the Geological Survey of Victoria which begun in 1852 as a response to the Gold Rush. Collections were distributed to organisations across Australia to encourage the further study of the scientific makeup of the Earth. A solid egg-shaped rock with a mineral vein forming a ring around the rock in shades of brown and beige.burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, 1852 geological survey of victoria, mineralogy, quartz, breccia, breccia conglomerate, conglomerate