Showing 21 items matching "wood boring tool"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

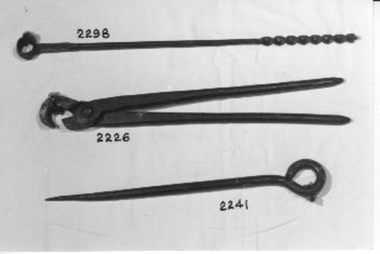

... Wood Boring Tool..., manufacturers of augers, bits, wood-boring, and motorising tools...-maritime-village Ridgway & Sons Wood Boring Tool Carpenters Tools ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ridgway & sons, wood boring tool, carpenters tools, coopers tools, marine tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... Wood Boring Tool..., manufacturers of augers, bits, wood-boring, and motorising tools...-maritime-village Wood Boring Tool Scotch Auger Carpenters Tools ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... Wood Boring Tool..., manufacturers of augers, bits, wood-boring, and motorising tools...-maritime-village Wood Boring Tool Scotch Auger Carpenters Tools ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Ring Auger, Double Twist with Lead Screw, square shaft (which has had a welded repair), socket set at right angle. Broad arrow mark Ridgway Sheffield and DO stamped. warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger Bit, William A Ives, 1860-1950

... and was a prolific inventor of braces and other wood boring tools between... boring tools between 1868 and 1884, when he received a dozen ...William A Ives worked in New Haven, Connecticut, and surrounding towns of Wallingford and Hamden from 1868 to 1917 and was a prolific inventor of braces and other wood boring tools between 1868 and 1884, when he received a dozen patents for these devices. William A. Ives lived in the New Haven CT area, and his first auger-making activity took place in the town of Hamden. At first in association with the Churchill family who had been manufacturing tools in the area at least as early as 1863. That firm's works had created "Augerville" in Hamden, starting earlier, possibly as early as 1830. Ives became active as part of the Hamden Manufacturing Co. until 1875 (it is thought he may also have started his own business in the interim), and the William A. Ives & amp; Co. was established by 1877. This continued, until William's death in 1888, when The Hamden Mfg. Company became its successor. Ives also registered the name "Mephisto" trademark name with the US patent office that was to be used in connection with augers, auger bits, machine bits as of June 1st, 1909, appearing on items up until at least 1922. It also appears that the trademark was licensed by the Mephisto Tool Co of Hudson New York who continued to manufacture tools under this trademark. Item is significant because its maker was the inventor of the wood auger boring bit and his patent has been used ever since on many different types of bits with little change to the original design.Auger wood screw bit W A Ives Patent Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... , manufacturers of augers, bits, wood-boring, and motorising tools... of Sheffield, manufacturers of augers, bits, wood-boring ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bung borer, Prior to 1950

Bung borer are a class of tools that bore a tapered hole in a wooden barrel, cask or flask, the tool makes a graduated tapered hole called a bung hole. The bung that goes into the hole can be made from wood, rubber or cork to make a tight seal or a tap is used to dispense the liquid inside the barrel. Often two holes would be made the first in the middle of the barrel and its highest location when laying on its side, this is use to fill the barrel. The second one, with the barrel now standing up, would be bored on one side of the head, near the rim, opposite the filling bung. That would be the one that would receive a tapered wooden or metal tap for dispensing liquid. There have been many models of bung borer used, the age old pattern is of a simple tapered spoon, later more sophisticated models would appear to do the same job and over the years numerous types of design have been patented.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Bung borer threaded with wooden handle. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, barrel bung hole borer, barrels, coopers tools -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Brace and Bit hand drill, 20thC

Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes. Chucks were patented as vigorously as the braces themselves The braces themselves also evolved for particular trades, from furniture makers to surgeons. The operator holds the ‘head’ in one hand, positions the drill in the wood , applies pressure and rotates the ‘centre piece’ to cause the drill to pierce the wood. A steel revolving hand tool for boring and screw-driving with wood handles * pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBraces for Hand Drilling x4

... are used to make them.The brace is a hand operated tool for boring... to make them.The brace is a hand operated tool for boring holes ...Very old. Ref. Pages 6 and 7 Tools for all Trades Catalogue. The braces vary in quality (strength) depending on what materials are used to make them.The brace is a hand operated tool for boring holes in wood, consisting of a crank-shaped turning device. The brace that grips and rotates the hole-cutting tool, the bit.Used by woodworkers in the Kiewa Valley.Vintage hand drill braces. All different and not all complete. Made of cast iron, steel with wooden handles. The drills fit into one end of the brace which is turned to make a drilling motion. A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. Pressure is applied to the top while the handle is rotated.brace and bit, woodwork, hand drilling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBench

Bench wooden trestle leg style modern replica of a sail maker's bench. Holes bored into bench to hold fids and/or spool holders, end of bench enclosed by wood to form tray to prevent tools from rolling off. Wooden fid in place, drawer at side.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bench, sail makers, fid -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Late 19th Century

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools. Archimedean drill with Rosewood hand, brass bearings, steel twist and wooden grip. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, archimedean drill with wooden hand, drilling tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Drill Brace, 1800s

The subject item is an early Victorian Scotch Brace with a 10-inch sweep. They were also known as a six penny or "gentleman's" brace and were designed to accept tapered square shank bits, early designs have a thumb screw to help secure the bit. Later designs had a catch to secure drilling bits. This type of brace was used in wagon making for boring & drilling holes into the wood for a variety of purposes, including driving screws. The subject item is unmarked but could have been made in Glasgow Scotland by John Fray in the 1800s, early drill braces of this type were often unmarked by their makers. A significant early example of a drill brace made in the UK during the 1800s demonstrates the evolution of this type of tool from this time that today is a rare and collectable example of woodworking tools.Brace metal with wooden handle. Has a screw in the holding socket item also has an auger bit. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brace, carpenders wheel brace, cabinet makers tools, drilling tool, wagon makers drill -

Federation University Historical Collection

Federation University Historical CollectionNewspaper, The Machinery Market, 02/12/1889

It's assumed that this journal was read at the Ballarat School of MinesA small illustrated journal with advertisements and pictures. pages 328-356 (and 26 pages of illustrated advertisements). Illustrations include machinery, corn crushers, condensers, chlorination plants. stea, hammers, steam engines, steam pumps, lamps, saw bench, leather belting, casks, barrels, machinery, boiler, cohran and co, birkenhead, stern, cowles syndicate company, electric smelting works, aluminium manufacturing, w t glover and co, rope machine, steam travelling crane, webster wood fibre machine, automatic govenor expansion gear, international exhibition edinburgh, beacon light, air propeller, well boring tools and pumps, cochran and co.'s launch, tug and boat building yard, s.s. jeanette, cochran boiler, cochran and co's boiler shop, stern wheel steamer, s.s. esperanca, cowles syndicate co, milton, w.t. glover & co.'s patent compound rope making machine, bendh drilling machine, steam launch, bicycle, well-boring tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedes Drill, 1900 to 1930s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool that has been nickel plated with brass fitting and easier to sterilise. The item therefore could have been used in the medical profession as a bone drill during surgery. Weighted Archimedes drill all metal construction, nickel plated with brass handles centrifugal typeNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, tool, drilling tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Drill Brace, 1800s

The subject item is an early Victorian Scotch Brace with a 10-inch sweep. They were also known as a six penny or "gentleman's" brace and were designed to accept tapered square shank bits, early designs have a thumb screw to help secure the bit. Later designs had a catch to secure drilling bits. This type of brace was used in wagon making for boring & drilling holes into the wood for a variety of purposes, including driving screws. The subject item is unmarked but could have been made in Glasgow Scotland by John Fray in the 1800s A significant early example of a drill brace made in the UK during the 1800s demonstrates the evolution of this type of tool from this time that today is a rare and collectable example of woodworking tools.Drill Brace metal with socket and thumbscrew, varnished wooden head and handleNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brace, carpenders wheel brace, cabinet makers tools, drilling tool, wagon makers drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Mid to late 1800s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools.Archimedean drill with wooden grip and butterfly nut on chuck.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, fretwork tools, wood working tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Late 19th Century

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool, the item therefore could have been used in various industries or professions where precise drilling is required. Archimedean drill with Rosewood hand, brass grip and fittings Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Brace & Bit, John S Fray, 1883 - 1906

Context: A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. The pressure is applied to the top and the tool is rotated with a U-shaped grip. Bits used to come in a variety of types but today the more commonly used Ridgeway and Irwin pattern bits also rely on a snail point (called the snail), which is a tapered screw point shaped the same as a wood screw thread, which helps to pull the bit into the wood as the user turns the brace handle and applies pressure. The designs used today come from an original idea and pattern invented by John S Fray. Company History: John S. Fray (1833 ) immigrated to Bridgeport Connecticut USA from England in the 1850s and established a working relationship with Nelson Spofford, who held an 1858 patent for a bit brace (the tool could be augured in a continuous circular motion by hand). He established the John S. Fray Co. around the same time and immediately began producing the Spofford bit brace. Fray himself held at least two patents: one awarded in 1869 for a boring brace attachment, and another awarded in 1883 for a tool handle. By 1889, the firm was located at the industrial complex that sits between the former International Silver Company and the former Bridgeport Chain Company on Crescent Avenue and is identified on the Sanborn Insurance Atlas as a manufacturer of Spofford bit braces, hollow handle awl, and toolsets. The company was in competition with Peck Stow and Wilcox Co. of Southington, and in 1898 was enjoined from making a ratchet bit brace for which the latter company held a patent. By the 1920s, the factory had been purchased by the Stanley Company of New Britain and leased to the American Tube and Stamping Company, a manufacturer of brass, copper, seamless, and bicycle tubing, which also ran a rolling mill to the south on Stafford Avenue (now demolished). The Stanley Company bought both mills in 1926, perhaps as a strategic move to be located along the Bridgeport Harbour, through which much of the raw material used in its operations throughout the state came. By the 1950s, the Crescent Avenue operations had been moved to other sites in Connecticut, and Stanley again leased the building to a company called Cornwall and Patterson, a manufacturer of piano hardware. Today the building appears to be vacant. An early carpenters tool made by a well known early manufacturer from America who instigated many innovations to the making of tools. His early pattern for the improvement of a tool that could be used for the boring of holes in wood was a significant step forward. His design for a boring brace attachment and later a specific handle is still in use today and his original brace and bit is now sought after by collectors of antique tools. Spofford Carpenter's Bit Brace metal has bit attached. Wing nut holds bit in place but nut missing. holds bit in place. 285mm long x 160mm Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, 2x Gimlet, boring screw, c1900

A gimlet is a hand tool for drilling small holes, mainly in wood, without splitting. A gimlet is always a small tool made of a piece of steel of a semi-cylindrical form, hollow on one side, having a cross handle at one end and a worm or screw at the other. A similar tool of larger size is called an auger. Early settlers in Moorabbin Shire had to be self reliant as they established their farms and built their homes using tools like this gimlet. 2 x small hand tool with a screw point, grooved shank, and cross handle for boring holes early settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools, blacksmiths -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bung borer, Prior to 1950

Bung borer are a class of tools that bore a tapered hole in a wooden barrel, cask or flask, the tool makes a graduated tapered hole called a bung hole. The bung that goes into the hole can be made from wood, rubber or cork to make a tight seal or a tap is used to dispense the liquid inside the barrel. Often two holes would be made the first in the middle of the barrel and its highest location when laying on its side, this is use to fill the barrel. The second one, with the barrel now standing up, would be bored on one side of the head, near the rim, opposite the filling bung. That would be the one that would receive a tapered wooden or metal tap for dispensing liquid. There have been many models of bung borer used, the age old pattern is of a simple tapered spoon, later more sophisticated models would appear to do the same job and over the years numerous types of design have been patented.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Bung borer threaded with wooden handle. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, barrel bung hole borer, barrels, coopers tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wood Auger, c1920

... Hand forged steel, used for boring holes through timber. Tool ...Hand forged steel, used for boring holes through timber.rural industry, farm machinery, trades, carpentry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Sovereign of the Seas, Made between 1930-1955

This meticulously hand crafted ship model is one of the most intricate and challenging projects for a ship modeller to create. Jim Williams took up the challenge, choosing to make all of the components by hand, following a plan of the ship rather than purchasing a pre-made kit. He even made his own tools specifically for working with this model. The “Sovereign of the Seas” 1637-1697 - The magnificent ship “Sovereign of the Seas” was ordered by Charles I of England, who desired a giant Great Ship to be built. It was built by Peter Pett under the guidance of his father Phineas, the King's master shipwright, and launched with 102-guns at Woolwich Dockyard on 13th October 1637, as the Navy’s second three-decker first-rate ship. It was the most extravagantly decorated warship in the Royal Navy, bought with the help of a special 'Ship Money' tax imposed by the King. Soon afterwards the ship was remodelled and cut down to a safer and faster ship. Over the ship’s lifetime it was renamed “Commonwealth”, then in 1650 it became simply “Sovereign” then again after a rebuild in 1660 it was named “Royal Sovereign”. By 1642 the ship’s armament had been reduced to 90 guns. In 1651 Sovereign was made more manoeuvrable by reducing the upper works. It served throughout the wars of the Commonwealth and became the flagship of General Robert Blake. It was involved in all of the great English naval conflicts fought against the United Provinces and France and was referred to as 'The Golden Devil' by the Dutch. By 1660 the armament was changed attain to 100 guns. After the English Restoration, it was rebuilt as a first-rate ship of the line, with flatter gun decks and 100 guns, and most of the carvings were removed. During the First Anglo-Dutch War, in a secret session on 21 October 1652, the States-General of the Netherlands announced reward money for the crews of fire ships that succeeded in destroying enemy vessels; the Sovereign was singled out with an extra prize of 3000 guilders to sink or ruin it. Although repeatedly occupied by the Dutch, the Sovereign was retaken every time by the British and remained in service for nearly sixty years as the best ship in the English fleet. The Sovereign was in regular service during the three Anglo-Dutch Wars, surviving the Raid on the Medway in 1667. After a second rebuild in 1685 the Sovereign was relaunched as a first-rate ship of 100 guns, before taking part in the outset of the War of the Grand Alliance against Louis XIV of France, venturing into the Irish Sea, and later participating in the Battle of Beachy Head in 1690 and the Battle of La Hougue. At this time she was more than fifty years old. It was the first ship in history to fly ‘royals’ above the topgallant sails and a top gallant sail on the jigger-mast. The Sovereign eventually became leaky and defective with age and was laid up at Chatham when, on 27th January 1697, the famous ship caught fire, burning to the waterline. Jim Williams, the model’s maker - Jim (James Bernard) Williams was born in 1888 at The Forth in Scotland. He lived in Tasmania for some time and enlisted to fight in France in WW1. After the war he moved to Warrnambool, Victoria, where he worked at the Cramond & Dickson clothing store until the Great Depression in the 1930’s. He was later employed at Fletcher Jones Menswear, where he worked for 27 years until just before his death in 1959. Jim was a passionate ship model builder. He worked on his model ships between 1930 and 1955, including The Endeavour and The Sovereign of the Seas, which was one of the most intricate historic ship models to build. He had a table set up in a bay window and worked on them on and off using a jeweller's eye glass on the finer pieces. Jim’s long-time employer, Fletcher Jones, knew of Jim’s hobby and skill as a ship model builder and requested Jim to describe the model, Sovereign of the Seas, with the view of putting it on display. When the model was finished there was a full article and photo in The Standard newspaper. Jim described his work on the ship mode “Sovereign of the Seas” in correspondence to his then employer, Fletcher Jones. The document gives us an insight into his skill, patience, and regard for replicating the details of the original ship. Some of the details are: "In making the model the time taken to make certain items might be of interest. For instance "The Great Lantern" on the stern, four weeks, a similar time for the figurehead of St George & the Dragon. "The lower shrouds three to each side about six weeks & the rigging as whole several months. There are nearly 300 blocks and pulleys ranging from nearly 1 / 16 inch in diameter. Dead eyes were bored with 3 to 5 holes. To do this needles of different sizes, set in handles & ground to wedge ends were used. Glass cut and ground to shape were used windows. All gun-port covers (74) hinged. "All guns and anchors made of wood. Nothing for the model was purchased ready-made; everything hand made." Jim’s family donated the ship model along with many associated tools, accessories and papers. The model represents the Sovereign of the Seas. The Royal Navy ship of the line launched in 1637 has a significant British maritime heritage. These days the Sovereign of the Seas still remains one of the most intricate historic ship models to build, representing to the model enthusiast a true challenge to the art of model shipbuilding. The model of Sovereign of the Seas in Flagstaff Hill's collection is an exemplary example of a ship model built and hand crafted from a plan with the making of every item on the model, not a model kit with prefabricated parts. It was made by a local Warrnambool man Jim Williams as a leisure activity in the mid 20th century. The hobby and craft of ship model making has resulted in visual representations of the changes in maritime technology and advances in world-wide navigation. Ship model of HMS Sovereign of the Seas, a 17th century British warship. The handmade model is in wooden framed, airtight glass case. All components were hand crafted. Many of the tools used were made by the model maker, Jim Williams. An inscribed plaque is within the case. Inscribed on plaque "SOVEREIGN OF THE SEAS / 102 GUNS - 1634"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, model ship, vessel sovereign of the seas, jim williams, james bernard williams, the forth tasmania, freda williams, heather williams, phyllis bowditch, fletcher jones staff 1936, 17th century sailing ship, cramond and dickson, sovereign of the seas, royal sovereign, sovereign, charles 1, ship model