Showing 176 items matching "handling manual"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageKnife Cleaner, 1877-1916

Knife cleaner, round wooden manual machine with 4 holes in top, each surrounded by metal fitting, handle attached to side of barrel, decorative metal stand with holes for fixing to banch. Black brush bristles are fitted inside, surrounding each hole (some bristles have been worn away. Inscribed "DAVIES PATENT EXCELSIOR LONDON", manufactured by Davis's Excelsior Knife Cleaning Company. Ltd, London. c.1877-1916Inscribed "DAVIES PATENT EXCELSIOR LONDON",flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, knife cleaner, knife cleaning machine, davis's knife cleaning machine co., domestic equipment, butchery, cleaning equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Orbost & District Historical Society

Orbost & District Historical Societyelectric massager, PIFCO Ltd, 1947 - 1948

Lottie Bulmer (wife of Mr Frank Bulmer, Orbost) originally owned the massager. It was given to Di Cunningham by her sister Barbara who married Les Bulmer, Lottie and Frank's son,. After Les died, Barbara gave it to Di Cunningham, her sister, Di kept it for about a year. Pifco manufactured personal massaging equipment between 1948 and about 1968 (the first appeared about 1935).These devices were promoted as being able deal with all kinds of complaints, from headaches, pain relief and flatulence to hair loss and gout. It is an example of an early electrical appliance.3081.1 is an orange and white cardboard box - in black print on top is "PIFCO Electric Massager". It is the original container. Inside is an electric appliance with three attachable massage red coloured caps. There is an electric cord with a plug. The handle has ridges for gripping. There is a special control knob - possibly bakelite. There is a 15 pp instruction manual - 3081.3. Reg. no 852269massager pifco electrical-appliance bulmer -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyGrinder/Mincer - Meat

Old farm kitchen tool used for mincing meat manually.Used at Tawonga, in the Kiewa Valley, by resident Des WartonCast iron with dull smooth surface consisting of a tap to screw it onto a table, a barrel enclosing the auger that turns when the handle is wound around and forces the meat to spill out of a circular grinder. The hand crank is curved with a wooden knob . The outlet is oval shaped.Embossed on barrel: "Universal" Embossed on outlet "2" Embossed on handle "L.F. & c - New Britain Conn U.S.A."household tool, kitchen, meat mincer, grinder, universal no. 2 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySieve - Flour

Manual appliance for sifting flour used in the kitchen.Tin cylinder covered with white, ingrained flour. Top rim is sloped with a handle coming out on the lower side. On one side is a handle for winding two tin rings at right angles to each other. These rings turn and touch a wire net to push the flour through. Both handles are wooden.Embossed in a shield near the top is a shield shaped logo on the side "Kande (within a shape of Australia) / Reg.d 3996 / Made in Australia."kitchen, flour sieve, manual appliance -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine

Sewing machines were used by some ladies to mend and make clothes for the family as shops were some distance away and bought clothes were much more expensive. The sewing machines were also used to sew items for fund raising e.g.. Church and School fetes.Used in the Kiewa Valley.The machine has a brown wood veneer base and a lid with a metal handle in the centre of the top. There is a long screw that fits in a hole at the top of the lid. The screw can be lifted out and used to open and take off the lid. Inside there is a black metal machine which is fitted onto the wooden base. There is a compartment in the base, right of the wheel of the machine, which holds an instruction manual and a tube of ""Singer" lubricant for electric machines". The light, above the needle is covered by bakelite. A leather belt runs around the wheel on the right to enable the machine to run. There is a foot pedal and an electric cord attached."Singer Manufacturing Company" - gold embossed "No. EL 249 355" - oval disc "99K" - disc "Singer Manfg. Co. - discsewing machine; singer manufacturing company; kiewa valley -

Warrnambool and District Historical Society Inc.

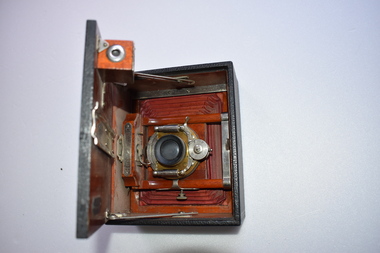

Warrnambool and District Historical Society Inc.Camera, Brownie small, C 1930

The Box brownie camera was invented by Frank A Brownell in 1900 and further improved from 1901. Because it was easy to use, cheap and portable it became very popular. It was used by soldiers in the first World War and other models were marketed to groups such as the Boy Scouts.Many family photos recor It was further modified until the 1950's and have been used until recent times This camera has significance as a very popular model which was used by a wide cross section of people over many decades. It is one of the cameras which made photography accessible to many who would otherwise not have been able to use them. .1 Rectangular black box camera with leather handle attached with silver studs. There is a latch at the top and a winder at the back. There are three circular cutouts on the top and two rectangular ones on the sides.There is a logo imprinted in the base of the camera and a film is inside .2 Small 38 page manual with light card cover. Mainly printed instructions with some diagrams showing aspects of operation. for Nos. 2 A 2C and 3 Brownie cameras..1'Brownie " on the handle.The logo on the bottom reads as follows, " No 2 Brownie Use film No 120 Made in USA by Eastmann Kodak Rochester NY." .2 Published by Eastmann Kodak Rochester NY. box brownie, warrnambool,, kodak cameras, brownie instruction manual -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tool - Hedgetrimmer, 1949

This is a manual hedge trimmer which has a push pull action. It is not a very common garden tool possibly a lot slower to use than clippers. It dates from mid 20th century.This is quite a rare tool.This tool is consists of a metal bar with a row of prongs attached . A blade on one end is moved along the length of the metal bar thereby trimming the bush. There is a wooden handle attached to the metal bar and a wooden ball and spring on the righthand side.Code Half Time. Made in England Pat App No 16418/49warrnambool, tool, hedgetrimmer, code halftime -

J. Ward Museum Complex

J. Ward Museum ComplexInstrument - Electrocardiograph Machine - Cardiotrace Heat Mark II, circa 1920

With the advent of electricity, so to came the invention of the Electrocardiograph Machine. This piece of medical equipment gave nursing staff and doctors a more precise indication of a patients heart beat and was used extensively across Victoria's medical institutions. The equipment is significant because it is a fully intact example of diagnostic equipment used in a mental health hospital in Victoria Australia.Cardiotrace Electrocardiograph Machine in blue plastic case with black handle. Contains: Electric cord Cords to link electrodes Graph paper to measure heart beats Instruments on panel marked 'stylus heat', 'off', 'run', 'position', 'test', 'record', '1', '2', '3', 'aVR', 'aVL', 'aVP', 'V', '1/2V', 'lmV', marker.Manufacturer: Medical Instrument Co. Pty. Ltd. Distributor: Watson Victor Limited Serial No: 3362 Cardiotrace Heat Mark III Electrocardiograph/Voltage 220-240 A/C /Frequency 50 cycles per second/Watts 45 serial 3362/Caution: Refer to Manual for full detail.electrocardiograph machine, medical instrument, medicine, health, mental health, ararat mental hospital, j ward -

Flagstaff Hill Maritime Museum and Village

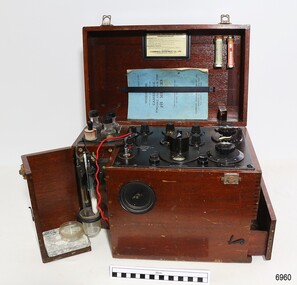

Flagstaff Hill Maritime Museum and VillageInstrument - Cambridge pH Meter, Cambridge Scientific Instrument Co. Ltd, 9-6-1946

This pH meter was made in 1946 by Cambridge Scientific Instrument Co. Ltd. in London. The company was founded in 1881 and the owner eventually became Horace Darwin, the youngest son of the famous scientist Charles Darwin. It is a portable version that can be used on-site in many different situations. A similar instrument was used by the Chemistry Department of what is now the University of Cambridge. The science of pH measurement began in the 1910s and was further developed in 1926. The pH meter is an electronic scientific instrument used to determine the pH measurements of a solution accurately; the amount of acid and alkaline in it This measurement can have many other applications helping to maintain the appropriate balance for a particular result. For example, it can measure the pH of pharmaceutical medications, soil, swimming pool water and hair shampoos. This Cambridge portable electronic pH instrument was made in 1946 by a company specialising in scientific instruments. It is an early example of much smaller devices used today in many different fields including medicine, and the preservation and conservation of shipwreck artefacts. Flagstaff Hill Maritime Museum and Village's Curator uses a pH meter today in the conservation process of a historic cannon that was recovered from the 1839 wreck of the vessel 'Children'.Scientific instrument, electric Cambridge Portable pH Meter in a polished wooden box with compartments, fold-out doors, and leather carry handle. Includes blue covered Instruction manual with a 'Certificate of Test' inside, and chemicals. Electrodes mounted in compartment. The lid is separate from the base, attached by pins and hinges. A plate inside the lid gives instructions for 'Preparation for Use'. Made by the Cambridge Instrument Company, London, in 1946.Printed on plate: "Cambridge Instrument Co. Ltd, 13 Grosvenor Place, London, S.W.1' Certificate dated: "6-3- 46" (1946)flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ph meter, cambridge scientific instrument co. ltd, horace darwin, cambridge university, ph balance, scientific instrument, ph measurement -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, Cut-throat razor ‘Sinfonie’, c1900 -1930

Gebrüder Stoll, Central-Stahlwarenfabrik Founded in 1889 . Solingen-Foche in 1900- 1930. Names: ‘Gallop’, ‘Pedecor’ (Dedecor?), ‘Sinfonie’, ‘Stoll’, ‘Stoll Brothers’. The parts of a straight razor and their function are described as follows: The narrow end of the blade rotates on a pin called the pivot, between two protective pieces called the scales or handle. The upward curved metal end of the narrow part of the blade beyond the pivot is called the tang and acts as a lever to help raise the blade from the handle. One or two fingers resting on the tang also help stabilize the blade while shaving. The narrow support piece between the tang and the main blade is called the shank, but this reference is often avoided because it can be confusing. The shank sometimes features decorations and the stamp of the country of origin. The top side and the underside of the shank can sometimes exhibit indentations known as fluting, or jimps for a more secure grip. The curved lower part of the main blade from the shank to the cutting edge is called the shoulder. The point where the shoulder joins the cutting edge is called the heel. A thick strip of metal running transversely at the junction where the main blade attaches to the shank is called the stabiliser. Although straight razors were once the principal method of manual shaving, they have been largely overshadowed by the safety razor, which incorporates a disposable blade. Electric razors of various types have also been an available alternative, especially since the 1950s. Straight razors require considerable skill to hone and strop, and require more care during shaving A man's cut-throat razor that folds to protect blade inside handle. with a caseon blade 'SINFONIE' on case; Stahlwaron / Fabrikcut-throat razors, straight razors, shaving equipment, steel blades, stoll gebruder ltd., solingen germany, cutlers, steel manufacturers, ‘sinfonie’ trade mark, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBooklet (2 copies), Manual of Land Warfare Part 2 Infantry Training Vol 4 Pam 5: 7.62 mm Self Loading Rifle L1A1 & Automatic Rifle 7.62 mm L2A1, 1983

A soft covered booklet aimed at providing the soldier with the necessary information for him to develop the confidence and knowledge to efficiently handle and maintain these weapons.DSN 7610-66-107-1254rifle slr 7.62, automatic rifle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyConsole Telephone 10 shutter, circa early 1900s

This manual telephone exchange console is an important piece of equipment which provided the most efficient method of long distance communications in the 1950's to the 1980's. Communications were critical, not only for the regional Hospital, but also for large construction sites i.e. the Kiewa Hydro Scheme, especially if they are in dense rugged mountainous regions. The degree of Occupation Health and Welfare on industrial sites were at a bare minimum compared to the work scene after the 1980's.This telephone exchange console is highly significant to both the Kiewa Valley and Mount Beauty region because it was so important in the communications field relating to operational safety and work related controls. The success of any large undertaken relies heavily upon good communications. In the hospital this method of communications is still used i.e. patient to ward station. This flag system link a patient's room to the controlling nursing station. Identification of the patient needing help is crucial for swift action from the available medical staff. Similarly in large construction sites such as the Kiewa Hydro Scheme, successful instant communications was also essential. This switchboard required a 50 volt supply to successfully operate and was in use when both telecommunications and postal were under the one Federal Government carrier i.e. The Post Master General. A benefit with a line communication system (such as the one that fed this console was that interference from atmospheric conditions did not impede the connection.This console telephone switchboard (manual) unit has a shutter operation (precursor to the light indicator) to identify the caller to the telephone switchboard operator. This switchboard has a ten point indication shutter system allowing the operator to clearly identify where the caller is located. The console has a 44 connection point holes with their configurations in a triangular shape. The shutters are held closed by a small lever at the top which is opened by a small electrical charge from the incoming call. The operator uses a wind up handle to power a magneto connector(handle on the console's right side). The telephone hand set is located on the left side of the console. sec vic kiewa hydro scheme, alternate energy supplies, alpine population growth and communications -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBooklet, Australian Army Manual of Land Warfare Part 2 Infantry Vol 4 Pam 9 5.56 mm Austeyr Individual Weapon Family F88,F88C, F88S & Grenade Launcher, 1997

A hard covered loose leaf booklet providing instructors with material to teach the maintenance, handling and shooting skills of the 5.56 mm Austeyr Individual Weapons Familysteyr -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyChurn Butter - Wooden

This type of butter churn was used around the early to mid 20 century by household and small farms of the Kiewa Valley who kept cows for Milk. The buy product of the milk was cream and butter. Once the cows had been milked, often by hand, women would place the milk in shallow dish, and next morning the cream would be separated from the milk. Or a cream separator machine would be used. The cream would then be churned by the paddles in the butter churner until it formed in butter clumps. Butter Pats would be used to take the butter out and press into triangle butter blocksThis butter churner is significant due to its historical value which explains how butter was made by hand before this process became mechanistically made. Many houses or small farms in the Kiewa Valley had these butter churns to make their own butter for their household or to sell. This has very good interpretation significance as it adds to the history of dairy industry in the Kiewa Valley. Wooden box with a metal handle for turning the blades /paddles /slats inside the box.These blades churn the cream when the handle is turned. There is also a wooden handle and a wooden lid.butter, dairy, milk, manual, domestic, item, food, preparation, dairying, technology -

Cheese World Museum

Cheese World MuseumCentrifuge, manual, c1890

The Uebergang family came from Silesia to Australia in 1848 and were early settlers in the Allansford area. The sons and other descendants also purchased farms in the area. The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992 after which the property was sold. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. The collection of items from their property was put into store for a number of years before being given into the care of the Cheese World Museum. The family often re-used, recycled and repaired items and examples can be seen in the museum. This Babcock tester is part of the collection of items given into the care of the Cheese World Museum. The Babcock tester was used to determine the butter fat content in milk. Prior to the use of the Babcock test farmers were paid on volume and milk was sometimes watered down to increase the supply to the factory. Once the Babcock test was introduced it provided a consistent means of paying farmers for milk supplied to the factory. The Babcock tester is significant as a scientific means of testing fat content of milk and the subsequent consistent payment mechanism to farmers. This test also provided a means for farmers to identify poor performing cows and upgrade the quality of their herd and subsequent milk supply to the factory.Four tipping metal testing tubes which revolve on a brass base. A winding handle has a wooden grip. The base and arms holding the metal tubes is painted red.OFFICIAL BABCOCK TESTERallansford, dairy farming, dairy industry, dairy processors, babcock test -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Hand Barrow, 1860s

This hand barrow, sometimes called a Welsh hand barrow, was used to transport a load of marine rescue equipment from the beach cart to the rescue site, particularly over hilly, uneven or rough terrain. Hand barrows were in common use in the 19th century. Saving lives in Warrnambool – The coastline of South West Victoria is the site of over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. Victoria’s Government responded to the need for lifesaving equipment and, in 1858, the provision of rocket and mortar apparatus was approved for the lifeboat stations. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built for it on the Tramway Jetty, followed by a rocket house in 1864 to safely store the rocket rescue equipment. In 1878 the buildings were moved to the Breakwater (constructed from 1874-1890), and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost a hundred years the lifesaving and rescue crews, mostly local volunteers, trained regularly to rehearse and maintain their rescue skills. They were summoned when needed by alarms, gunshots, ringing bells and foghorns. In July 1873 a brass bell was erected at Flagstaff Hill specifically to call the rescue crew upon news of a shipwreck. Some crew members became local heroes but all served an important role. Rocket apparatus was used as recently as the 1950s. Rocket Rescue Method - Rocket rescue became the preferred lifesaving method of the rescue crews, being much safer that using a lifeboat in rough seas and poor conditions. The Government of Victoria adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain. It authorised the first line-throwing rescue system in 1858. Captain Manby’s mortar powered a projectile connected to rope, invented in 1808. The equipment was updated to John Dennett’s 8-foot shaft and rocket method that had a longer range of about 250 yards. From the 1860s the breeches buoy and traveller block rocket rescue apparatus was in use. It was suspended on a hawser line and manually pulled to and from the distressed vessel carrying passengers and items. In the early 1870s Colonel Boxer’s rocket rescue method became the standard in Victoria. His two-stage rockets, charged by a gunpowder composition, could fire the line up to 500-600 yards, although 1000 yards range was possible. Boxer’s rocket carried the light line, which was faked, or coiled, in a particular way between pegs in a faking box to prevent twists and tangles when fired. The angle of firing the rocket to the vessel in distress was measured by a quadrant-type instrument on the side of the rocket machine. Decades later, in about 1920, Schermuly invented the line-throwing pistol that used a small cartridge to fire the rocket. . The British Board of Trade regularly published instructions for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle, determined by the Head of the crew and measured by the quadrant, inserting a rocket that had a light-weight line threaded through its shaft, and then firing it across the stranded vessel, the line issuing freely from the faking board. A continuous whip line was then sent out to the ship’s crew, who hauled it in then followed the instructions – in four languages - on the attached tally board. The survivors would haul on the line to bring out the heavier, continuous whip line with a tail block connected to it. They then secured the block to the mast or other strong part the ship. The rescue crew on shore then hauled out a stronger hawser line, which the survivors fixed above the whip’s tail block. The hawser was then tightened by the crew pulling on it, or by using the hooked block on the shore end of the whip and attaching it to a sand anchor. The breeches buoy was attached to the traveller block on the hawser, and the shore crew then used the whip line to haul the breeches buoy to and from the vessel, rescuing the stranded crew one at a time. The rescue crew wore scarlet, numbered armbands and worked on a numerical rotation system, swapping members out to rest them. This hand barrow is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.Hand barrow; a transporting device carried between two people walking one in front of the other. A wooden ladder-like frame with two handles at each end, blue painted body with unpainted handles. Seven equal-length slats are joined at equal distance between two parallel poles, and two longer slats are attached diagonally between the first and last slats as a brace. flagstaff hill maritime museum and village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, lady bay, warrnambool harbour, port of warrnambool, tramway jetty, breakwater, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, rocket crew, lifeboat men, beach rescue, line rescue, rescue equipment, rocket firing equipment, rocket rescue equipment, maritime accidents, shipwreck victim, rocket equipment, marine technology, rescue boat, lifeboat, volunteer lifesavers, volunteer crew, life saving rescue crew, lifesaving rescue crew, rocket apparatus, rocket rescue method, shore to ship, rocket apparatus rescue, stranded vessel, line throwing mortar, mortar, rocket rescue apparatus, line thrower, line throwing, lifeboat warrnambool, hand barrow, manual transport, welsh hand barrow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Late 19th to early 20th century

A butter churn is a device used to convert cream into butter. This is done through a mechanical process, frequently via a pole inserted through the lid of the churn, or via a crank used to turn a rotating device inside the churn. The use of butter is mentioned in biblical works and the earliest butter churn vessels belonging to Beersheba culture in Israel were found in Bir Abu Matar going back to Chalcolithic period between 6500–5500 BC. The butter churn in Europe may have existed as early as the 6th century AD, In the European tradition, the butter churn was primarily a device used by women, and the churning of butter was an essential responsibility along with other household chores. In earlier traditions of butter making, nomadic cultures placed milk in skin bags and produced butter either by shaking the bag manually, or possibly by attaching the bag to a pack animal, and producing butter simply through the movement of the animal. An item used to make butter in a domestic situation by turning a handle until the cream inside has turned to butter.Butter churn, wooden, lid pieces screwed or nailed together. Brass bearing on side with iron turning handle.Handle marked 28204 no other marks to indicate manufacturer or date of productionflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, churn, butter churn, wooden churn, butter making, food, dairy, kitchen utensil -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, early 20th century

Sewing machine, portable, hand operated, with Premier logo. Has folding crank handle, body painted black with floral design, wooden base and separate wooden cover with lock. Base has compartment with accessories, covered by curved ended, sliding wooden panel. Decorative linework on side, carvings on each corner. Wooden handle on cover is carved in rings, folds down. Below handle is decorative inlaid pattern. Serial number on plate at back of machine. Accessories include 13 attachments, key (broken), screwdriver, sewing machine needle, razor blades (2) and buttons. Attached to inside of case is a square of paper with a number on it. Instruction book for Singer Sewing Machines is included. Also with machine are white tailor's chalk and a cut out, fabric pocket with tissue paper pattern pinned to it.Serial number "579200" is stamped into plate at back of machine. Brand on transfer on front of machine is "Premier". Paper inside case has hand written number "334A". Instruction book "Instructions for using Singer Sewing Machines No. 66 - Oscillating hook for family use" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile -

Federation University Historical Collection

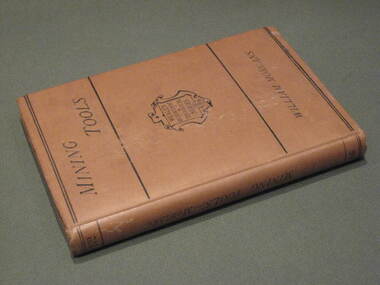

Federation University Historical CollectionBook, Manual of Mining Tools, 1871, 1871

... , hammers, sledges, picks, shovels, spades, saws, helves and handles ...The author, William Morgans, was a lecturer on mining at the Bristol School of Mines. The owner of the book, William Baragwanath, was a former student of the Ballarat School of Mines who held the following positions: Department of Mines (1897-1922); director of the geological survey (1922-24); chief mining surveyor (1924-32); secretary for mines (1932-34); chief mining surveyor (1934-43); consultant to the Department of Mines (1943-50); President, Royal Society of Victoria (1943-44), councillor of the Ballarat School of Mines (1916-50).Hard cover book of 207 pages with buff cloth cover. The books covers materials andf processes used in the manufacture of tools, special uses, qualities and efficiciency. It includes 235 wood engravings of mining tools drawn to scale. Tools include borers, hammers, sledges, picks, shovels, spades, saws, helves and handles.Title page handwritten in ink 'W.B.' [William Baragwanath]mining, tools, ballarat school of mines, geology, bristol school of mines, government geologist, william baragwanath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Foghorn, Late 19th century

... diaphone used on pleasure or sailing craft. By manually turning... diaphone used on pleasure or sailing craft. By manually turning ...A foghorn is a device that uses sound to warn of navigational hazards like rocky coastlines, or boats of the presence of other vessels, in foggy conditions. The term is most often used with marine transport. When visual navigation aids such as lighthouses are obscured, foghorns provide an audible warning of rocky outcrops, shoals, headlands, or other dangers to shipping. An early form of fog signal was to use a bell, gong, explosive signal or firing a cannon to alert shipping. From the early 20th century an improved device called the diaphone was used in place of these other devices, The diaphone horn was based directly on the organ stop of the same name invented by Robert Hope-Jones, creator of the Wurlitzer organ. Hope-Jones' design was based on a piston that was closed only at its bottom end and had slots, perpendicular to its axis, cut through its sides, the slotted piston moved within a similarly slotted cylinder. Outside of the cylinder was a reservoir of high-pressure air. Initially, this air would be admitted behind the piston, pushing it forward. When the slots of the piston aligned with those of the cylinder, air passed into the piston, making a sound and pushing the piston back to its starting position, whence the cycle would be repeated. This method of producing a low audible sound was further developed as a fog signal by John Northey of Toronto and these diaphones were powered by compressed air produced by an electric motor or other mechanical means that admitted extremely powerful low-frequency notes. The example in the Flagstaff collection is an early cased and portable diaphone used on pleasure or sailing craft. By manually turning the crank handle air is produced and fed into valves that direct air across vibrating metal reeds to produce the required sound. in foggy weather, fog horns are used to pinpoint a vessels position and to indicate how the vessel is sailing in foggy conditions. One blast, when sailing on starboard tack and two blasts, when sailing on a port tack and three dots, when with wind is behind the vessel. Since the automation of lighthouses became common in the 1960s and 1970s, most older foghorn marine installations have been removed to avoid the need to run the complex machinery associated with them, and have been replaced with an electrically powered diaphragm or compressed air horns. The example in the collection is significant as it was used in the early 19th century for sailing vessels was important but these portable crank fog horns have also been superseded by modern electric varieties. Therefore the item has a historical connection with sailing and maritime pursuits from our past.English Rotary Norwegian Pattern nautical foghorn within a boxed pine varnished case with exposed corner dovetailing, original leather carrying strap, brass side crank, and original copper trumped horn. Card accessory with Directions for Use in both English and French.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, foghorn, maritime technology, maritime communication, marine warning signal, portable foghorn, bellows foghorn, crank handle, robert hope-jones, john northey -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early industrial manufacturing became established in Australia.Rectangular manual butter churn, footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Label in block transfer Manufactured by Cherry & Sons Pty Ltd Gisborne, Victoria Size "00"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, cherry and sons, wooden butter churn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Butter Churn

Butter churn wooden manually operated with rotating lever curved plywood basin and parallel cross beamed horizontally spoked churning apparatus inside. Wooden lid with raised handle and two hand made rectangular wooden butter pats with flat handles grooved along one face. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn -

Red Cliffs Military Museum

Red Cliffs Military MuseumTorch Pump Action, Untitled

A manually powered torch, made from die cast metal. The torch is powered by means of a lever action handle which is operated by squeezing with a spring return. It has a magnify in lens and the handle can be locked down when not in use.Japanses markings and Arabic Numerals. Possibly patent numbers 178061/188192/203357 -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers' Equipment, hair clippers 'BURMAN", c1950

Hair clippers are specialized implements used to cut human head hair. They work on the same principle as scissors, but are distinct from scissors and razors. :Hair clippers comprise a pair of sharpened comb-like blades in close contact one above the other which slide sideways relative to each other, a mechanism which may be manual or electrical to make the blades oscillate from side to side, and a handle. The clipper is moved so that hair is positioned between the teeth of the comb, and cut with a scissor action when one blade slides sideways relative to the other. Friction between the blades needs to be as low as possible, which is attained by choice of material and finish, and frequent lubrication. Hair clippers are operated by a pair of handles that are alternately squeezed together and released. Barbers used them to cut hair close and fast. The hair was picked up in locks and the head was rapidly depilated. Mid 20thC such haircuts became popular among boys, and young men in the military and in prisons. Burman & Sons Ltd, of Ryland Road, Birmingham, West Midlands, manufactured Burman-Douglas steering gear. Their recirculating worm and ball design of steering gear was fitted to pre-war vehicles such as the Ford Eight and the Ford Prefect, the Bedford CA, plus heavy trucks and off-road vehicles - both pre and post-war. In its day, Burman-Douglas steering-gear was regarded as.... a "quality" feature of a car chassis specification, but the worm and ball design was eventually surpassed by the cheaper rack and pinion design that dominates today. The company also manufactured motorcycle gearboxes, horse clippers and barbers’ clippers. 1871 Company founded. 1897 Private company. 1930s Gearbox for Ariel Square-four motorcycle. (Exhibit at Birmingham Thinktank museum) 1933 Burman and Sons Limited, manufacturers of horse and barbers' clippers, sheep shearers, motor cycle gear boxes and steering gears, Ryland road, Edgebaston 1953 S. F. Burman, M.B.E., Managing Director, Burman and Sons, Ltd 1955 Acquired by Vono Industrial Products. 1961 Manufacturers of motor and motorcycle accessories. 1,500 employees. 1968 Supplied rack and pinion steering units to Ford 1978 Adwest Group acquired Burman and Sons, the steering gear part of Duport. 1986 Major reduction in staffing at Burman due to fall in demand for its products and delivery problems. A set of hand held barbers’ hair clippers with an adjustable screw, from Burman and Sons Ltd of Birmingham, England. Chrome plated, in good condition, c1950. On left arm ; BURMAN On right arm ; MADE IN ENGLANDbarbers, hairdressing, hair clippers, grooming, horse clippers, cars, motor cycles, gear boxes, rack and pinion , worm and ball, steering gears, steel manufacture, birmingham england, burman and sons ltd, moorabbin, bentleigh, ormond, cheltenham, market gardeners, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Barbers’ Equipment, hair clippers steel, c1950

Hair clippers are specialized implements used to cut human head hair. They work on the same principle as scissors, but are distinct from scissors and razors. :Hair clippers comprise a pair of sharpened comb-like blades in close contact one above the other which slide sideways relative to each other, a mechanism which may be manual or electrical to make the blades oscillate from side to side, and a handle. The clipper is moved so that hair is positioned between the teeth of the comb, and cut with a scissor action when one blade slides sideways relative to the other. Friction between the blades needs to be as low as possible, which is attained by choice of material and finish, and frequent lubrication. Hair clippers are operated by a pair of handles that are alternately squeezed together and released. Barbers used them to cut hair close and fast. The hair was picked up in locks and the head was rapidly depilated. Mid 20thC such haircuts became popular among boys, and young men in the military and in prisons. A set of hand held barbers’ hair clippers with an adjustable screw. Chrome plated, in good condition, c1950 barbers, hairdressing, hair clippers, grooming, horse clippers, steel manufacture, moorabbin, bentleigh, ormond, cheltenham, market gardeners, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Barbers’ Equipment, hair clippers steel 'Brown & Sharpe", c1940

1833 Brown & Sharpe was founded in Providence, Rhode Island by David Brown and his son Joseph R. Brown. David Brown retired in 1841 and Joseph Brown formed a partnership with Lucian Sharpe in 1853. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators ) and helped establish: The American wire gauge (AWG) standards for wire; The Brown & Sharpe taper in machine tool spindle tapers; and The Brown & Sharpe worm threadform for worm gears. .Like most machine tool builders, Brown & Sharpe rode a business cycle roller coaster during 1920- 40. After being kept very busy during World War I, builders suffered a slump in the post–World War I recession and depression of 1920–21. The Roaring Twenties brought renewed sales, but then the Great Depression slashed them. The armament-build-up period of 1936 to 1940 again renewed machine tool activity, and then the World War II materiel effort exploded demand, pushing it to record heights and employed 11,000 workers. Brown and Sharpe machine tools were a mainstay of American metal manufacturing until the late 20th Century and could be found in most machine shops and factories that worked with metal. Brown and Sharpe made callipers and micrometers that were essential to products built to fine tolerances. Shortly after World War II, Henry D. Sharpe, Jr. succeeded his father as president of Brown & Sharpe Manufacturing Company, at which point it evolved into a new and modern company built, or at least designed, to last. The firm stopped producing its old stalwarts: sewing machines, hair clippers, and certain categories of machine tools and employment dropped to 3,500 in 1976. Due to industrial disputes in the 1980’s B&S started focusing more on developing Coordinate-Measuring Machines. The company began to lose money as it shifted production away from machine tools and toward advanced metrology equipment, losing $14.6 million in 1990 and employed only 700. In 1994 Brown & Sharpe acquired DEA of Italy, an established manufacturer of CMMs. In 2001, substantially all of the assets of the Brown & Sharpe Manufacturing Company, including the intellectual property, designs, trademarks, facilities and inventory, were acquired by Hexagon AB, Switzerland, without the acquisition of the Brown & Sharpe Manufacturing Company itself. A set of manual barbers’ hair clippers with an adjustable wing screw, from Brown and Sharpe, Manufacturing Company Ltd., Providence, Rhode Island, USA. Chrome plated, in fair condition, c1940on Right handle; MADE BY BROWN & SHARPE MFG. CO. POV. R.I. / PAT'D IN GREAT BRITAIN, EN FRANCE, S.G.D.G. / U.S.A. PATENTS JULY 1-79, JUNE 3-84, AUG 23- 92 on top blade ; BRESSANT / TRADEMARK on base of lower blade ; No. 2* barbers, hairdressers, hair clippers, brown and sharpe manufacturing company, providence rhode island, hexagon ab, switzerland, great britain, france, ww1 1914-1918, ww11 1939-1945, great depression 1930, micrometers, tools, precision instruments, brown david, brown joseph r , sharpe lucian, sharpe henry d jnr, american wire gauge standard, sewing machines, metrological tools, worm gears, spindle tapers, screw machines, moorabbin, bentleigh, cheltenham, city of moorabbin industries,