Showing 83 items

matching shipwrights

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlant specimen - Wood Sample, Herbst, 1759-1765

The piece of oak wood sample inside the case was obtained from Mr. H Cooper during the time he served as a shipwright for the British Royal Navy on Nelson’s flagship, HMS Victory, in 1891. By that time the H.M.S. Victory was around 100 years old having been built in 1765 and was currently in dry dock undergoing restoration. Cooper’s skills as a shipwright would have been well employed during this period. HMS Victory was and still does undergoing continuous restoration to preserve her for display as a museum ship, due to the vessel's significant naval history. It was during that time of early restoration that Cooper obtained the piece of Oak from HMS Victory believed to be from the ships hull. Cooper was in Australia in September 1891 serving on the HMS Wallaroo, a British Auxiliary Squadron commissioned to serve as part of the British Royal Navy contingent, tasked to operate in Australian waters. The photograph included with the donation of the wood sample is a portrait of Mr H Cooper taken in 1895 in Sydney. The inscription on the photograph describes him as a skilled shipwright from the H.M.S. Wallaroo, depicting Cooper as a young man in Royal Navy uniform, with the emblem of a petty officer third class. While Cooper was stationed on the H.M.S. Wallaroo in Sydney he presented the display case, containing the wood sample from H.M.S. Victory, as well as the exhibit labels to Charles Harding, ("Chas") late of the Royal Australian Navy. Harding had been based at the H M Naval Torpedo Depot at Williamstown, Victoria. Although not mentioned, it is believed the two men met whilst serving together in Australia in their respective assignments. It could have been a retirement gift from Cooper to Harding with the photograph of Cooper likely included with the case, and gifted to Harding in 1895, as the date on the photograph indicates. One of the exhibits labels indicates that Harding had the item on display whilst serving at the Naval Torpedo Depot in Williamstown. The label indicates: "This piece of Oak is part of the hull of H.M.S. “Victory” Lord Nelson’s renowned Flag Ship, which took such a prominent part in the Battle of Trafalgar. 21st October 1805. Exhibited by Charles Harding, H.M.V. Naval Torpedo Depot, Williamstown.” After Charles Harding died in 1931 the case containing the sample of oak from H.M.S. Victory was donated by his son Reg Harding to Mr. Murphy in 1962. The display case has since become a treasured item at Flagstaff Hill. A newspaper article dated 1905 included with the donation mentions that the city of Hamilton in Victoria was shortly expecting a mounted piece of the H.M.S. Victory, to be included in the city’s commemoration of the centenary of the "Battle of Trafalgar". Battle of Trafalgar: On October 21, 1805, twenty-seven British ships of the line led by Admiral Lord Nelson aboard HMS Victory defeated thirty-three French and Spanish ships of the line under French Admiral Villeneuve. The battle took place in the Atlantic Ocean off the southwest coast of Spain, just west of Cape Trafalgar, near the town of Los Caños de Meca. The victory confirmed the naval supremacy Britain had established during the course of the eighteenth century and it was achieved in part through Nelson's departure from the prevailing naval tactical orthodoxy of the day. Conventional practice at the time was for opposing fleets to engage each other in single parallel lines, in order to facilitate signalling and disengagement, and to maximise fields of fire and target areas. Nelson instead arranged his ships into two columns to sail perpendicularly into the enemy fleet's line. During the battle, Nelson was shot by a French musketeer and he died shortly before the battle ended. Villeneuve was captured, along with his ship Bucentaure. He later attended Nelson's funeral while a captive on parole in Britain. Admiral Federico Gravina, the senior Spanish flag officer, escaped with the remnant of the fleet. He died five months later from wounds sustained during the battle. It was prior to this battle that Nelson had issued his now-famous final orders to his ships in 12 separate flag-hoists “England expects that every man will do his duty”. This wood sample is historically significant for its association with Admiral Lord Nelson the Battle of Trafalgar. Through Nelson’s leadership and unorthodox battle tactics, he secured not only a victory against the French and Spanish but reaffirmed Britain's naval supremacy opening the way for Britain to continuing the policy of colonisation of many countries including Australia.Wood sample adhered to the base of a hinged wood and glass display case. Wood is a sample of oak taken from the hull of Vice-Admiral Lord Nelson's flagship, the HMS Victory, built in 1765. The case also contain two exhibit labels pinned above the wood sample. Other items donated with the display case, and relating to the wood sample: an 1895 photograph, a 1905 newspaper clipping, a 1962 donor's letter (two pages), and a handwritten exhibit label with a border of red lines. Photograph Front: printed- "Herbst" "28 Oxford Street, Hyde Park, Sydney", handwritten - "Mr Cooper", "see back". Back: handwritten - "Mr H Cooper, skilled shipwright, H.M.S. Wallaroo 1895" Exhibit labels still in the case: Left: handwritten- “PIECE OF OAK FROM THE HULL OF H.M.S. VICTORY”, Right: typewritten- “This piece of Oak was originally obtained by Mr. H. Cooper, skilled shipwright on H.M.S. “Victory” & afterwards on H.M.S. “Wallaroo” on the Australian Station in 1895, when he presented this exhibit to me. Chas. Harding, Late Victorian Navy.”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, oak, hms victory, vice-admiral lord nelson, horatio nelson, lord nelson, oak piece, piece of oaknelson, battle of trafalgar, maritime technology, ship relics, 18th century warship, british royal navy, h cooper shipwright, hms wallaroo, herbst hyde park sydney, charles harding, hmv naval orpedo depot williamstown, sir home popham’s telegraphic code, admiralty official day signal book -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumTool - Mallet, wooden

Shipwright toolsWooden Serving Malletmallet, shipwright wooden tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCaulking Box

Shipwrights Caulking Tool Box has some caulk material inside box. Box has no tools. Box has eye bolt and iron ring on front. Length 17" Width 8" Height 12½"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRibbon

Purple and gold cloth badge (.1). Ribbon, blue cloth with gold writing. Has metal braiding on the bottom. Depicts three "8" interlocked with word "Hours". Also depicts a steamship encircled by a rope. Produced by the Port Phillip Ship Constructive & Shipwrights Association. (.2)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ribbon, port phillip ship constructive & shipwrights association. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMallet

Mallet Shipwrights caulking mallet. The slots were cut in to give the malleta certain amount of spring to prevent jarring of the users wrist. It also gave the mallet a characteristic ring when striking the caulking iron Handle separates from head. 330mmL x 80mmW head. 410mmL handle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMallet

Owner of tools Jim Gillespie Clayton VictoriaMallet Shipwrights caulking mallet. The slots were cut in to give the malleta certain amount of spring to prevent jarring of the users wrist. It also gave the mallet a characteristic ring when striking the caulking iron Handle separates from head. 365mmL x 70mmW head. 475mmL handle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship's Wheel, 20th century

This large, ten-spoked wheel is an example of a ship's wheel used to steer a large sailing ship. Wheels such as this would usually be handcrafted by a shipwright.This large, heavy wooden ship's wheel is an example of a wheel used used in past centuries at the helm to steer large sailing ships. The design continues to be used on sailing vessels today. This whieel has been on display for decades to demonstrate the perspective of size of equipment on a sailing ship.Ship's wheel: wood and brass. Ten spokes. Brass hub and trim around circumference of wheel. Column-like spokes, with usual rounded handles around the outside of the wheel. Heavy wooden centrepiece with metal backing and shaft.flagstaff hill maritime museum and village, maritime museum, maritime village, great ocean road, shipwreck coast, ship's wheel, 10-spoked ship's wheel, wooden ship's wheel, navigation, ship's steering, ship's steering wheel, maring technology, ship's fitting, navigational equipment, sailing ship's wheel, handcraft, shipwright -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipwrights Caulkins Tools

100 plus years old, original owner Hughie H BothnaughtThirteen tools and two textiles displayed on two pieces of white backing board hinged together.'SHIPWRIGHT CAULKING TOOLS,' Individual labels are also included (from top) Oakum, Shipwrights caulking mallet, caulking cotton, raking tool, No.1.5 off set caulking iron, busting iron, no. 2 off set caulking iro(n). (Bottom board from left) Caulking iron no.3, Feeding iron, caulking iron no1 off set, caulking iron no1.5, caulking iron no.2.5, feeding iron, caulking iron no.2, feeding iron. -

Bendigo Military Museum

Bendigo Military MuseumCraft - MODEL & BASE, HMS KASHMIR

Model of HMS Kashmir built by Shipwright Charles Axiak. He originally trained and worked in British dockyards during WW2. Emigrated to Australia in 1955 and finished working in Williamstown dockyards building the River Class Destroyers K Class Destroyers built in UK in 1930's.1. Model of K-class Destroyer UK. Grey in colour above water line and brown below water line with black stripe dividing. Model has complete details of deck, guns and screws. 2. Wooden stand tailor made to hold the model of the ship. Brown in colour with long flat board. Small individual pieces of wood glued to the top to form the cradle for the boat. Also 4 felt footings at bottom of cradle.G.12 painted on side.ships model, hms kashmir -

Bendigo Military Museum

Bendigo Military MuseumCraft - MODEL & BASE, HMAS SWAN

Model of HMAS Swan built by Shipwright Charles Axiak. Original ship construction in Melbourne and entered service 1970. Was a River Class Destroyer. Model maker worked in British Dockyards during WW2 and emigrated to Australia in 1955. He worked in Williamstown dockyards involved with construction of the Swan,1. Model of River Class Destroyer. green in colour from water line. Black line and brown at bottom. Small Australian flag at front and naval flag at back. 2. Wooden stand, tailor made to hold the model of the 'Swan'. Brown in colour with long flat board and separate pieces of wood embedded in the base to make the cradle. High points of cradle covered by some white felt to protect boat. Bottom of stand has felt studs."50" painted at front of boat.ships model, hmas swan -

The Paynesville Maritime Museum

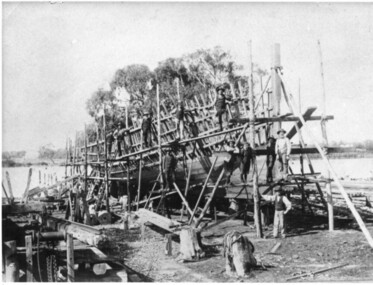

The Paynesville Maritime MuseumPhotograph - The S.S. Gippsland during construction

Peter Tierney built the SS Gippsland for the ,Dahlsen Company of Bairnsdale, at the Paynesville Slip to the design of Victor Gotch in 1908. Photo shows the shipwrights standing on the scaffold in front of the ship. The S.S. Gippsland maintained an important trade and passenger link between Cunninghame and Bairnsdale before being sold in 1937 and leaving the Gippsland Lakes. Photograph of SS Gippsland in build. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking mallet, Mid 19th to early 20th centuries

The subject item is a vintage Nautical Shipwrights Ship Boat Caulking Hammer Mallet, Unusual Small Size. These mallets were routinely used in the 1800s when ships were made of wood. This mallet was used with caulking irons to drive the oakum (caulk) between the ship's bottom planking to seal them up. The mallet has slots to dampen the vibration of the mallet blows on the user's elbows. The head is made of a very hard wood, possibly Lignum Vitae or another dark tropical wood. The item seems to be of a very early design with the two preened-over metal rods for reinforcing the head. Item appears to be of early manufacture by an unknown maker from the mid to late 19th century and is significant as tools of this era are quite rare. This tool is also significant as it gives an insight into how ships made of wooden planks were made sea-worthy by inserting caulking material between the boards thereby making the vessel watertight. Caulking Mallet Wooden with iron ferrules on each end. Wooden head with two large bolts passing through body. Stamped W Milne. James S Steele tool box.Stamped W Milne & James S Steele tool box.mallet, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking mallet, caulking, james steele, shipwrights tools -

Port of Echuca

Port of EchucaFunctional object - Paddlesteamer, George Linklater, P.S. Adelaide, 1866

Built in 1866 in Echuca, the PS Adelaide is the oldest wooden hulled paddle steamer still operating as a passenger vessel in the world. Engines made in Melbourne by Fulton and Shaw. JG Grassie was the original owner who was looking for a wool carrying boat as a commercial venture with the arrival of the rail at the Port of Echuca making the future look bright. Seutonius and Charles Officer of Murray Downs Station joined Grassie in financing the venture and they used the boat for 6 years before David Blair and partners (Echuca sawmillers) bought the Adelaide in July of 1872 and she began her long working life as a logging boat providing a shuttle service between the forests around Barmah and the mill, usually towing up to 3 or 4 barges. The paddle boxes were rebuilt from round to a square configuration in approximately 1924 by Charles Felshaw, local Echuca shipwright. The Adelaide had unusual strength for her size. Her career ended in the mid 1950s where she lay idle tied up near the mill at Echuca wharf. For a short time she was sold to Mildura but fortunately the Apex Club raised funds to buy her back to be a reminder of the riverboat days at the Port. She was lifted out for safekeeping into Hopwood Gardens where she remained on show for nearly 25 years. After restoration by Port shipwright Keven Hutchinson OAM, she returned to the waters of the Murray River on Sunday March 4th 1984 at 5.20pm. After further restoration, in 1985 the Prince and Princess of Wales re-commissioned PS ADELAIDE in a ceremony on their tour of the region. The world's oldest wooden hulled paddle steamer still operating as a passenger vessel today built in Echuca in 1866. It is often considered the flagship of the operational fleet of the Port of Echuca given its age and known provenance to Echuca. The Adelaide is an iconic symbol of the riverboat timber and cargo trade that worked on the Murray River from the mid 1800s. Remarkably, PS ADELAIDE still operates with its original Fulton and Shaw engines.Composite hull, side wheeler with two single cylinder steam engines, producing a total of 36hp. Currently cream and burgundy moored at the Echuca Wharf. 49 passenger capacity.P.S. Adelaide signage on wheelhouse and port and starboard bow.p.s. adelaide, paddle steamers, echuca boat builders, charles felshaw -

Port of Echuca

Port of EchucaFunctional object - Paddlesteamer, P.S. Alexander Arbuthnot

The P.S. Alexander Arbuthnot was the last of the paddle steamers built at Koondrook, for the river trade in 1923. Owned by the Arbuthnot Sawmills. She was used to bring timber in from the forest to the sawmills to be processed from logs to timber. She was later owned by Evans Bros and then Barmah Charcoal Ltd. She sank at Yeilima, re-floated in 1973, placed on a low loader and taken to Shepparton for preservation. Echuca city council bought her for the Port of Echuca in April 1989. She was bought to Echuca in December 1991 to complete her restoration by shipwright Kevin Hutchinson. She is now used as a passenger vessel and is licensed to carry 47 passengers. The P.S. Alexander Arbuthnot is a reminder of the past life on the river. Being the last paddle steamer built for the river trade in 1923, the Alexander Arbuthnot is a reminder of the past life on the river. Licensed to now carry 47 passengers, she was used by the saw mills to bring timber in from the forests to the sawmills. A timber planked, monohull, side wheeled paddlesteamer with a 8hp horizontal Ruston Hornby steam engine. It has a flat bottom and mutiple decks. Currently painted cream with burgandy trim.Alexander Arbuthnot signage on wheelhouse and port and starboard bowp.s. alexander arbuthnot -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumVehicle - Workboat ex Wyuna

In 1974, this 18 foot (5.5 meter) diesel-powered workboat was one of the last boats built to operate from the pilot cutter Wyuna. These boats were used to transfer pilots from the Wyuna to the ship being serviced or vice versa. Until 1946 they were propelled by two oars then simplex two-stroke petrol engines were fitted followed by diesel engines. The Pilot Service Shipwrights built the boats in a shed which stood on the site of the present Pilot Station, Tobin Drive, North of Shortland Bluff. The design is based on a Gig and was developed by the Pilots as suitable for the severe conditions at the entrance to Port Phillip. To understand how these boats were used view the film "Through The Rip" on the video in the Exhibition Hall.Close association with QueenscliffTimber Workboat used to transfer pilots between Wyuna and ship requiring servicepilot service, wyuna, workboat, boat buiding, port phillip sea piots -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Fountain Head Brewery at Armstrong 1866

Fountain Head Brewery Armstrong's. Part of a collection of Photographs by Mr. O.G. Armstrong as commissioned by the Shire of Stawell for the Inter-colonial and Paris Exhibition in Melbourne in 1866. The brewery, a three-storey high building, was established close to two streams which joined the Concongella Creek near Armstrong, although the water required to run the brewery was obtained from a natural underground spring which is still visible. Further findings of Gold in Victoria around 1859-1860 brought a large rush of miners to the area. Some stayed on to become merchants, farmers, etc. Jens Kofoed, a shipwright from the Netherlands, was one who came to the area at this time. He and his family move to Armstrong in 1860, establishing the Fountain Head Brewery, which employed quite a number of people for about 40 years. stawell industry -

Orbost & District Historical Society

Orbost & District Historical Societynewspaper, PS Curlip, November 2008

This inset was published to commemorate the Curlip Festival on 28/30 November 2008 and the P.S. Curlip 11 launch. The Snowy River Mail is an East Gippsland Newspaper. The original PS Curlip was a paddle steamer built in a Tabbara sawmill in 1889 by Samuel Richardson and his sons. It was operated along the Snowy River in Australia's Gippsland region between 1890 and 1919, before being washed out to sea, and broken on Marlo beach, by a flash flood. The Orbost and district community started a project in 2002 to construct a live steam powered replica, albeit somewhat larger than the original to meet safety regulations and carry additional passengers for commercial reasons, the Paddle Steamer Curlip II with the assistance of grants from the Federal and Victorian State Governments.Construction was started in earnest by shipwright, Bill Jones, in August 2006, and with the assistance of roughly 200 volunteers (a core group of 10 performing the majority of the work), she was finally completed and launched on the Snowy River in late November 2008. The construction of P.S.Curlip 11 was a community project which began as a project to re-engage the timber-working community of Orbost. The construction and launch was a major community event. The local newspaper, The Snowy River Mail, documented its progress on a regular basis.An insert from the Snowy River Mail newspaper dated November 2008. On the front cover is a coloured photograph of the Paddle Steamer Curlip 11. It contains photographs, information on the history of P.S. Curlip and the construction of Curlip 11. There are details of the Curlip Festival and advertisements.newspaper p.s.curlip -

Port of Echuca

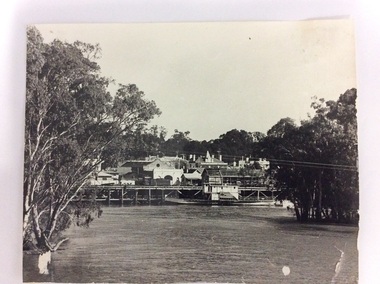

Port of EchucaBlack and white photograph, 1973 or 1974

The P.S Pevensey was built in 1910 in Moama by the Permewan Wright Co. Initially she was a barge, called the Mascotte, but by May 1911 she had been converted into the P.S.Pevensey. Initially the P.S.Pevensey was used as for transporting wool from the Murrumbidgee River Stations. In 1932 the P.S Pevensey carried the largest load of wool ever from the Murrumbidgee River. This record was 2600 bales of wool. She was destroyed by fire at Koraleigh Landing later in 1932, but was soon rebuilt.By 1939 she was running a regular service between Morgan and Mildura. By 1958 it was reported that she was moored above Renmark and not working. In 1967 she was sunk by vandals. In 1968 she was bought by Bill and Norm Collins. They refloated her, restored her and moored her at Mildura. The City of Echuca bought the P.S. Pevensey from the Collins Family in 1973, for $20,000. The P.S. Pevensey came to Echuca Wharf in July 1973 along with Kevin Hutchinson OA., a shipwright who stayed with the P.S. Pevensey for the rest of his life. The P.S Pevensey currently works as a Tourist paddle steamer taking cruises from the Echuca Wharf every day. (Ref. Parsons, R. "Ships of the Inland Rivers. P. 116.)This photograph is significant because it shows the wharf in 1973, being converted into a Tourist precinct. The roof of the cargo shed is being repaired. The P.S Pevensey is tied up to the wharf and looks as if it needs more repairs. The buildings in the background are still used as business venues. The Shamrock Hotel can be seen in High Street. A train can also be seen parked on the wharf.A black and white rectangular photograph of the P.S Pevensey tied up at Echuca Wharf during a high river probably taken in 1973 or 1974.On the Bond Store in Murray Esplanade can be seen the words SHACKELL. On the front of the building can be seen the words "Panel & Paint."p.s pevensey, echuca wharf, hutchinson, kevin, collins, norm, collins, bill, city of echuca -

Port of Echuca

Port of EchucaColoured Photograph, 04/03/1984

The P.S Adelaide was launched on 21st July 1866. It was owned by J.G.Grassie from Poon Boon Station and the Officer Family of Murray Downs Station Swan Hill. The Adelaide was named after the niece of the Officer Bros, Adelaide Blackwood. The shipwright who built her was George Linklater. The Adelaide brought wool and passengers from the wool stations on the Murray and Darling Rivers down to the Echuca Wharf. In 1872 she was sold to David Blair & Sons. She was used to bring timber from the Barmah Forest to the Echuca Wharf. She did this work for the next 80 years. In 1953 she was tied up near the Mill and left. In 1958 she went to Paringa South Australia to work in the sawmill industry again. In 1960 the Echuca Apex Club and The Echuca Historical Society raised enough funds to buy the P.S. Adelaide and return her to Echuca. In November 1963 she was lifted out of the water and placed in Hopwood Gardens as this was thought to be a way of preserving her. In 1984 it was decided to return her to the water to resume work as a passenger vessel. In that time the Port of Echuca and the Echuca Wharf had been restored as a Tourist Precinct. This photograph shows the beginning of the task to return her to the river. It took several weeks in March 1984.The P.S Adelaide is extremely significant as it it the oldest known wooden hulled paddle steamers in the world. She was built in Echuca in 1866 and still operates on the Murray River today. She has worked in the Wool Industry, the Timber Industry and the Tourist Industry.This is a coloured square photograph of an orange front end loader clearing a track from Hopwood Gardens down to the river. The track was used to bring the P.S Adelaide from the gardens back into the river. The P.S Adelaide is in the background. The paddle steamer appears to be up on a trailer of some sort and is surrounded but plastic orange temporary fencing. There are small mounds of soil in the foreground.On the orange front end loader are the numbers "5900" and the word "case." p.s. adelaide, grassie, j.g, port of echuca, linklater, george, poon boon station, blair, david, murray river, darling river, logging industry, officer brothers., barmah forest, fulton & shaw, hutchinson, kevin, murray downs station, blackwood, adelaide -

Port of Echuca

Port of EchucaPhotograph, 1984

The P.S Adelaide was launched on 21st July 1866. It was owned by J.G.Grassie from Poon Boon Station and the Officer Family of Murray Downs Station Swan Hill. The Adelaide was named after the niece of the Officer Bros, Adelaide Blackwood. The shipwright who built her was George Linklater. The Adelaide brought wool and passengers from the wool stations on the Murray and Darling Rivers down to the Echuca Wharf. In 1872 she was sold to David Blair & Sons. She was used to bring timber from the Barmah Forest to the Echuca Wharf. She did this work for the next 80 years. In 1953 she was tied up near the Mill and left. In 1958 she went to Paringa South Australia to work in the sawmill industry again. In 1960 the Echuca Apex Club and The Echuca Historical Society raised enough funds to buy the P.S. Adelaide and return her to Echuca. In November 1963 she was lifted out of the water and placed in Hopwood Gardens as this was thought to be a way of preserving her. In 1984 it was decided to return her to the water to resume work as a passenger vessel. In that time the Port of Echuca and the Echuca Wharf had been restored as a Tourist Precinct. This photograph shows the beginning of the task to return her to the river. It took several weeks in March and April 1984.The P.S Adelaide is extremely significant as it it the oldest known wooden hulled paddle steamers in the world. She was built in Echuca in 1866 and still operates on the Murray River today. She has worked in the Wool Industry, the Timber Industry and the Tourist Industry.Colour photograph of the P.S Adelaide, having been hauled out and dry-docked. The P.S Adelaide is resting on a log platform with a winch attached to the front.p.s. adelaide, grassie, j.g, port of echuca, linklater, george, poon boon station, blair, david, murray river, darling river, logging industry, officer brothers., barmah forest, fulton & shaw, hutchinson, kevin, murray downs station, blackwood, adelaide, 1866, 1984 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Peter Payne, Early 1930s to 1960s

Half-hull ship models were an important step in the process of building a vessel. Shipwrights or designers would construct a half-hull scale model of a ship before the vessel was built. They used it to ensure that the dimensions would work together and that the ship look balanced. They would often mount the half hull onto a board in their workshop. The half-hull ship models were also used to show prospective buyers how the design would work and look. Given the plywood construction of the model, it is believed to have been made around the 1930s as plywood construction had started in earnest in Queensland around this time and soon became the centre of the industry because of Queensland's attractive rain forest woods used which also included red cedar, silver ash, black bean, Queensland maple and silky oak. It is also believed the model was a design for a clinker-built barge to be built by Peter Payne who operated a boat building works on the Mordialloc Creek, Victoria going out of business in 1973. Records show Peter Paynes' first craft launched in 1962 and the last in 1973 from Mordialloc Creek works. However, he was one of the most prolific builders from the 1930s and produced many more vessels than the records currently show. There is at this point no further record of the subject model or whether a full version was ever built and for whom is not known at this time.A model that demonstrates the boat-building process is believed to have been made by Peter Payne or someone who worked in his yard. P Payne was a very well-known boating personality, vessel captain and boat builder throughout most of the 20th century. Model barge half hull on wooden of plywood laminated construction. Marked "AUXILIARY BARGE 80'x16'x6' 315 TONS 4" - 1 FOOT" "P and H PAYNE?" "22/E/26" flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ship model half hull, ship half model, shipbuilding, shipwright, ship design, peter payne, boat builder victoria, clinker design, barge -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912