Showing 418 items

matching pourer

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured GLass, test tubes, mixers, 20thC

A test tube, also known as a culture tube or sample tube, is a common piece of laboratory glassware consisting of a finger-like length of glass or clear plastic tubing, open at the top, usually with a rounded U-shaped bottom. Test tubes are widely used by pharmacists to hold, mix, or heat small quantities of solid or liquid chemicals, especially for qualitative experiments and assays. Their round bottom and straight sides minimize mass loss when pouring, make them easier to clean, and allow convenient monitoring of the contents. The long, narrow neck slows down the spreading of vapours and gases to the environment. Test tubes are usually held in special-purpose racks, Test tubes for physics and chemistry are usually made of glass for better resistance to heat and corrosive chemicals and longer life. Tubes made from expansion-resistant glasses, such as borosilicate glass, can be placed directly over a Bunsen burner flame.8 clear glass test tubes of varied capacity with 3 glass mixers sitting in a wooden stand. A 1 metre length of clear plastic tubing is with this setglass manufacturers, test tubes, culture tubes, sample tubes, borosilicate glass, otto schlott, felton grimwade company, melbourne glass bottle works, laboratory glass, pharmacy, moorabbin, bentleigh, cheltenham, spotswood melbourne -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchEquipment - WW2 First Aid Kit. Contents, part of, First Aid Dressing

6 sided brown glass bottle with paper label and black screw capLabel Front: Trade Mark SANAX. FIRST AID DRESSING. Forms an Antiseptic skin over cuts, wounds etc. Label Side: DIRECTIONS. A few drops on the part affected and spread over the injury with the cork. For knuckle joint wounds place on the wound a thin film of absorbent cotton and then pour dressing over freely. Label Side: This bottle must be kept ell corked and away from flames. CAUTION contains 60% ether. The Sanax Co 349-51 Nepean Highway Moorabin , Vic -

City of Ballarat

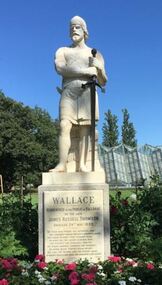

City of BallaratArtwork, other - Public Artwork, Percival Ball, Sir William Wallace by Percival Ball, 1889

The imposing white marble statue of William Wallace by Percival Ball stands approximately 8 feet tall with helmet and sward. The statue is mounted on a granite base with a marble plaque inscribed in praise of William Wallace, the Scottish warrior famous for leading the defeat of English forces at the Battle of Stirling Bridge in 1297. The artwork is located in the Botanic Gardens in Ballarat, Victoria and can be seen upon entry from the main gates. Sculpted by Percival Ball of Melbourne and unveiled in 1889, the statue was funded by a £3000 bequest to the gardens by James Russell Thomson, a Scottish miner who made his fortune during the Victorian gold rush. It was intended as a tribute to Thomson’s Scottish origins. The front the statue bears an inscription from Robert Burns’ 1785 sentimental poem ‘The Cotter’s Saturday Night’, which also lauds Wallace as a noble patriot and hero.The artwork is of historic and aesthetic significance to the people of BallaratWhite marble statue of William Wallace on plinthWALLACE Bequeathed to the public of Ballarat by the late James Russell Thomson unveiled 24th May 1889. "Oh thou! who poured the patriotic tide that streamed through Wallace's undaunted heart, who dared to nobly stem tyrannic pride, Or nobly die, the second glorious part, (The patriot's God, peculiarly thou art. His friend, inspirer, guardian, and reward!) Oh never, never, Scotia's realm desert; But still the patriot, and the patriot bard, in bright succession raise her ornament and guard;" (Burns)sir william wallace, statues, statuary pavillion, botanical gardens, lake wendouree, william wallace statue, charles summer, percival ball -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, early to late 1900's

This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State. In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (H Taylor) and where it originated from. These bottles were recyled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle. This heavy gauged glass ginger beer bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the filling production line. The method of pouring ginger beer into the bottle has been part of the "production line". This bottle has a one and a half pint capacity and is made from "light green" coloured glass(a protection against light penetration). This thick glass bottle, to contain ginger beer, required its thickness because of the extensive handling (man and machine) before final consumption. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck. Ginger beer was a "soft drink" of great demand. On the middle portion of this bottle is a large elongated circle within it and following the spherical line is "H. TAYLOR" ans a star separates this from "MELBOURNE" rounding out the bottom curviture. Within these words are the large initials "T H" . The "T" superimposed onto the "H". On the base and covering the whole bottom is the letter "T". At the opposite side to the manufacturers logo is "THIS BOTTLE CANNOT BE SOLD OR USED BY ANY OTHER PERSON & IS NOT COMPLETE WITHOUT STOPPER" glass bottle, non alcoholic drink, taylor ginger beer bottle, reuseable bottles -

Mont De Lancey

Mont De LanceyBook, Jean-Rodolphe Ostervald, La Nourriture De L'ame, ou Recueil De Prieres which translates to - The Food for the Soul or Collection of Prayers, 1833

Food for the Soul - a collection of prayers for every day of the week and for the main holidays of the week.This is a plain brown book with small diagonal squares pattern on the covers. La Nourriture De L'ame, ou Recueil De Prieres pour les Principales Fetes de L'annee which translates to - The Food for the Soul or Collection of Prayers for the Main Holidays of the Week. The author is Jean- Rodolphe Ostervald, pastor of the French Church of Bale. There is a drawing on the frontispiece of Jesus talking to men. At the back is a Table of Contents. Some pencil markings inside, foxing and tanning. There are two bookmarks included - One has Federal printed on it in red lettering with a rising sun pattern at each end with a French handwritten message written on the front and back. Another paper used as a bookmark has Y Foy and Gibson, Melbourne. 545p.non-fictionFood for the Soul - a collection of prayers for every day of the week and for the main holidays of the week. religion, prayers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Flagstaff Hill Maritime Museum and Village

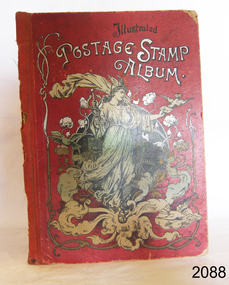

Flagstaff Hill Maritime Museum and VillageBook - Stamp Album, CF Lucke, publisher, Illustrated Postage Stamp Album, ca 1900

The inscription in the book indicates that it once belonged to Edwin J Dale, who may have received it May 13th 1901, the date on the inscription. The album was made in Germany and has English, German, French and Spanish language on the fly page. It has 2000 pockets for holding stamps and is illustrated. The printer, Spottiswoode and Co., was established in 1738 by William Strahan, with premises in New Street Square, London. The growing firm advertised as Printers, Lithographers, Stationers, Electrotypers, Publishers, and Booksellers and by 1914 there were 1,000 employees.The stamp album is of Victorian vintage and shows that at the end of the 19th century people collected stamps. It represents the hobbies and past times of the people of that era.Illustrated Postage Stamp Album. Publisher: Lalso by CF Lucke, Leipzig, Germany Printer: Spottiswoode & Co Ltd, London Date: 1908 Red hardcover, illustrated with a robed figure image and text in English, German, French and Spanish. Book has information, advertising and pages divided into blank squares for attaching stamps. Some pages have cutouts where squares would have been, perhaps holding stamps. An inscription with the name Edwin J Dale, 13 May 1901 is on the first turned page..Inscription: Edwin J Dale, May 13th 1901" Cover: "Illustrated POSTAGE STAMP ALBUM" Inage on cover: "within a floral border, a robed figure wearing a winged helmet, holding a staff with two snakes in one hand, and a sealed letter in the other." Fly: "Registered" "Schaubeks Postage Stamp Album" "Victoria" "Briefmarken"[German - stamps] "Pour Timbres-poste" [French - for postage Stamps] "Para Selloyde Correo" [Spanish - for postage stamps] "With 1070 reduced illustrations, 2200 blank cases for stamps" (also in German, French and Spanish) "Made in Germany"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, illustrated postage stamp album, postage stamp album, stamp album, book, postage stamp, stamp, edwin j dale, may 13th 1901, stamp collecting, german stamp album, spottiswoode & co ltd, germany, cf lucke leipzig, cf lucke, leipzig -

Orbost & District Historical Society

Orbost & District Historical Societywash tub, 1900-1910

This item was bought by George Henry Douglas Russell when he married Hilda Raymond, a parson's daughter, in 1920. This galvanised metal wash tub was manufactured for domestic use prior to household plumbing, running water or waste removal in Australian homes. On farms in the late 19th / early 20th centuries there were no built-in coppers and concrete troughs with reticulated water. Thus the washing for the family of five daughters was done with this tub. .Tubs of this type vary in size and were used for washing dishes (It was the “ kitchen sink”) or for washing smaller items of clothing “the delicates”. This tub could also have been used to bathe the children. The water was heated on a wood fired stove, then carried to the tub. This could be a lengthy and physically demanding exercise. Much more labor intensive than loading the dishwasher. After use the water may have been “recycled”by being poured onto vegetable gardens and fruit trees. Later at harvesting this tub held maize and beans to top up the three bushel bags of the threshing machines. This was before the hand sewing of the top of the bags with needle and twine.This tub is an indication that items for domestic use in the early 20th century were “made to last” and not manufactured for planned obsolescence.A large galvanized iron was tub, circular with the sides tapering slightly to the flat base. It is seamed on both sides, made from two shets of iron. The base has been soldered on. and the top rim is folded. On either side handles are rivetted on.domestic laundry was-tub galvanized-iron -

Parks Victoria - Wilsons Promontory Lightstation

Parks Victoria - Wilsons Promontory LightstationBottles

The catalogue includes twenty-one diverse types of bottles ranging from beer, soft drink and chutney bottles to bottles designed to hold perfume, medicines and poisons. They appear to range in date from the nineteenth to c.mid-twentieth centuries and represent various types of mass-produced consumer goods that were commonly available at the time. The five different types of bottles included in 0156.5 are made of clear glass with tapered necks and narrow openings to facilitate pouring. One can be positively identified as an imported mineral soda water/soft drink bottle because of the marble stopper in the neck and thickness of the glass. The globe-stopper bottle, also known as a ‘Codd’ bottle, was invented by English engineer, Hiram Codd in 1873 for holding gaseous soft drinks. The thick glass could withstand the pressure of the contents as well as repeated bottling by manufacturers. The bottles were probably used by former lightkeeper households. and tapered, narrow necks. The older ‘porter’ has a slightly bulbous neck. The bottles were probably used by former lightkeeper residents. Five glass bottles. Four are clear glass and one has coloured to green. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Bushells, after 1937

Bushells tea and coffee producers started in Brisbane(1883) and expanded to Sydney, Melbourne(1899), Fremantle and finally to Auckland(1937). Like other Pacific Island sourced condiments Tea and coffee were a lot easier to import than British or European goods. Local Australian industries were starting to develop and grow to overcome the long transportation times and the high costs of goods from traditional suppliers. Bushells Pty Ltd is a prime example.This "Bushells" Coffee tin is a good example of Australian "grown" condiment suppliers serving the "whole" of the Australian marketplace. Rural areas were not neglected and the purchase price for goods were a reasonable levels. Kiewa Valley experienced a population growth from the late 1940's and due to the migrant works in the Kiewa Hydro Scheme the greater use of coffee was initiated. Rural areas, on the whole, where the population was more connected to some degree with a British heritage lineage were predominately tea drinkers. The American film productions, however, screened in Australia post 1950's showing a greater degree of coffee drinking "stars" had a long term effect upon the drinking habits of the rural populous. This round tin of coffee with lid is made from pressed steel lid framed top and bottom. Sturdy cylindrical body is made of cardboard. Paper information label is pasted onto the container with promotional and logo information.In large print and on opposite sides are two manufacturers labels.The topprint and on a diagonal slant in gold letters on a dark blue background is "BUSHELLS" underneath this "PURE" and below this on a red background "COFFEE". On one side in smaller print "EASY TO MAKE" and below this "Use one dessert-spoonful for each cup of coffee desired. Place in the pot and pour over it fresh water briskly boiling. Let stand for five minutes, then strain". Below this "1 IB. net" and underneath is a signature "BUSHELLS" below this in small print "Pty. Ltd." Below this, in a vertical row are"SYDNEY MELBOURNE fREMANTLE AUCKLAND"coffee and tea processors and distributors, hot drink suppliers -

Flagstaff Hill Maritime Museum and Village

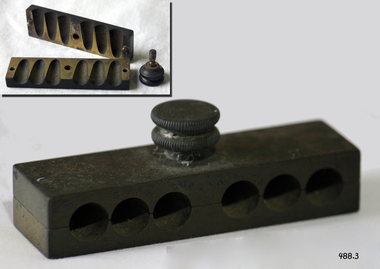

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health -

Eltham District Historical Society Inc

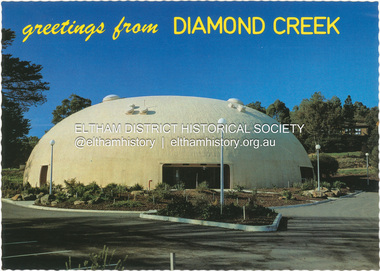

Eltham District Historical Society IncPostcard - Photograph, Nucolorvue Productions Pty Ltd, greetings from Diamond Creek, n.d

Diamond Creek Bini Shell Community venue Built in 1979 in Diamond Creek opposite the hotel using a construction method invented by Dante Bini. A net of flexible steel rods were laid on the building’s circular base, on the top of a fabric bladder. Concrete was poured onto the mesh and a sealed cover laid over the concrete making a sandwich of cover, bladder and mesh. Compressed air was pumped into the bladder and the sandwich slowly began to rise and become a massive self-supporting dome. The inflation of the dome attracted crowds of onlookers many from various technical schools, VIPs and the famous football doctor, Donald Cordner. An opening night dinner was held to celebrate the construction and the Diamond Creek Bini Shell was used as a community venue for over ten years including for the Town Fair. The Shell was closed for safety reasons after a Bini Shell in another State had chunks of concrete fall off the dome due to a construction fault. At the Diamond Creek Town Fair in 1991 the demolition of the Bini Shell was an item on the Town Fair’s program. Information: Kevin Patterson, Nillumbik Historical Societybini shell, diamond creek community centre, nu-color-vue, postcard -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Chadborn modification Schimmelbusch ether inhaler used by Dr Mitchell Henry O'Sullivan

Dr. Curt Schimmelbusch (1860-1895), a German physician, designed his original mask around 1889 while an assistant surgeon. Surgical assistants were often assigned the task of delivering the anesthetic. During anesthesia it was not uncommon for ether and chloroform to get onto the patient’s skin, causing irritation. Chloroform can even cause burn-like reactions. Schimmelbusch designed the rim of his mask so that both sides curve away from the patient’s face to form a kind of trough. He intended the trough-like rim to collect excess anesthetic that would otherwise have trickled onto the patient’s face. To anesthetize a patient, gauze was stretched over the metal bars and fastened in place by the hinge. The mask was placed over the patient’s nose and mouth, and the anesthetic was applied in drops or lightly poured onto the gauze so that the patient breathed in evaporated anesthetic as well as air. This type of mask is sometimes still used today for ether anesthesia in developing countries when other means are not available. (Wood Library Museum of Anesthesiology) This particular object is a modified version of Schimmelbusch's design, known as Chadborn's modification.Oval shaped chromium plated mask with two metal strips linked front to back and side to side to create a dome. An oval shaped mobile wire frame is attached to the lower part of the mask by a hinge at the back, approximately two inches from the lip of the metal handle. A "U" shaped bit of metal is attached to the front of the mask which acts as a clip to fasten the wire frame to the lower section of the mask.anaesthesia -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Ammunition, Before 1878

The objects are a small sample of small gauge lead shot raised by Flagstaff Hill divers from the LOCH ARD shipwreck site in 1976. Companion pieces are in the Maritime Village collection. The three masted, iron hulled, LOCH ARD was wrecked against the tall limestone cliffs of Mutton Bird Island in the early hours of the first of June 1878. Included in her diverse and valuable cargo were 22 tons of lead shot, packed in cloth bags and wooden casks. Bulk quantities of lead shot, uniformly round balls of dull grey metal ranging from 2mm “birdshot” to 8mm “buckshot”, were routinely exported to the Australian colonies. Shot was used mostly as projectiles fired from smooth bored guns to bring down moving targets such as wild ducks and small game. It was also useful as ballast, when a dense, “pourable” weight was required to fill cavities or establish volume within a measuring container. The production of consistently round spheres of lead shot required the pouring of molten metal through a sieve and then a long drop through the atmosphere to a water filled basin for final cooling and collection. This “shot tower” process was first patented by William Watts of Bristol in 1782. His calculation of a 150 feet fall was not only to form evenly spherical droplets through surface tension, but also to provide partial cooling and solidification to each shot before they hit the water below. The value of his innovation was the minimising of indentation and shape distortion, avoiding the expense of re-smelting and re-moulding the lead. Lead shot was already being produced in Australia at the time the LOCH ARD loaded her cargo and left Gravesend on the second of March 1878. James Moir constructed a 157 feet circular stone shot tower near Hobart in 1870, with a peak annual production of 100 tons of lead shot sold in 28 pound linen bags. However colonial demand exceeded this source of local supply. The continued strength of the market for lead shot in the Colony of Victoria prompted substantial investment in additional productive capacity in Melbourne in the next decade. In 1882 Richard Hodgson erected the 160 feet round chimney-shaped Clifton Hill shot tower on Alexandra Parade (VHR H0709) and in 1889 Walter Coop built the 160 feet square tower-shaped Melbourne Central shot tower on La Trobe Street (VHR H0067). At its peak, the Coop Tower produced 6 tons of lead shot per week, or 312 tons per annum. The shipwreck of the LOCH ARD is of State significance – Victorian Heritage Register S417 Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best known shipwrecks in Victoria’s history. A quantity of 2mm and 4mm lead shot ammunition retrieved from the LOCH ARD shipwreck site. They are concreted together by sediment. There are (6) small pieces with some single shot and a larger conglomerate of cemented shot. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, lead shot, colonial industry, melbourne shot towers, victorian metallurgy, colonial imports -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - Non Fiction History, The Kiewa Story, circa 1993

This book provides in chronological order the development of the Kiewa Hydro-electricity scheme from the first concept (1911) to final construction work (1961). It covers the first attempt to utilise the power of the Victorian Alps water system. It started from a private syndicate and developed to the current State Electricity Commission of Victoria. The incentive for the Hydro scheme was to make money and not as an alternative to the carbon producing coal fired power plants. These coal fired power plants were increasing in numbers to service an ever increasing demand made by population expansion, especially in cities and large rural settlements. This demand spiraled up after World War II when there was a tremendous spike in immigration numbers due to refugees and displaced persons in Europe. The ability to utilise the untapped water provided by the winter snow fields, for a higher yield in electricity, was a powerful incentive to overcome the physical hardships in this remote Alpine region. Future power requirements may initiate the re-installation of the other two power stations(Pretty Valley and Big Hill) covered in original Scheme. This publication not only covers the development of the Kiewa Valley region with respect to population (within a socio-economical framework) but also the subtle but yet strong physical changes of a relatively pristine alpine region. The demands that an ever growing regional population places on the environment is clearly documented in print and black and white photographs. The working and living conditions of those who constructed and gave life to this hydro scheme is well documented in this book. It may be viewed as spartan now but was relevantly good at that moment in time, especially for those workers fleeing a devastated European environment. The successful planning and consideration to minimising any intrusion upon the natural alpine forests and high plains can viewed as an example (compared to the Tasmanian Hydro schemes) of how future hydro schemes (an inevitable requirement) will proceed. Most rural towns (in the early 1900s) were built by unencumbered rural based citizens, with the exception of Mount Beauty and Falls Creek. These two settlements were brought into life by a State (Victorian) Authority for a specific function and program. They were a gated community, that is, only open to construction workers involved with the hydro scheme. All facilities within these communities were provided by the State Electricity Commission of Victoria. The impact on the social, financial and individual independency of the community, by the transition from the S.E.C .environment to one of local government (Shire of Bright), had in some cases a severe impact.This hard covered book has a green cover with pictures on the front and back covers. The front cover has a coloured picture of a snow covered Mount Bogong taken from the opposite mountain range. The valley between both ranges has a whisk of mist over it. At the bottom of this picture are three black and white photographs covering the construction of the Kiewa Hydro - Electricity Scheme. On the back cover is a photograph, (black and white) detailing the Bogong village and Junction dam containing lake Guy. The inside front cover is a black and white photograph which details the construction of the West Kiewa tailrace tunnel during April 1951. The inside back cover is a black and white photograph of the concrete pour at the Clover Dam circa 1952. All photographs and sketches are in black and white. The pages are approximately 160 g/m2 and those which have photographs are on gloss paper.Book spine: "The Kiewa Story Graham Napier Geoff Easdown" alongside this is a white framed circle with white spokes radiating out and underneath in white lettering SECkiewa valley, hydro scheme, victorian alpine region, electricity generators, graham napier, geoff easdown -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Cannon Ball, Victorian era

This small cannon ball was found by the donor around 1975 to 1977 when he was digging a trench to install underground cables at the Warrnambool Surfside Caravan Park' Its location is just below both Cannon Hill and the 19th century Fortifications at Flagstaff Hill Maritime Museum and Village. The ball is made of iron. Cannon balls were used as ammunition for a cannon gun and fired at a target. This cannon ball is only 8 cm round, or 4.15 inches, and is likely to have been called a 4-pounder (4-pdr). The ball was made from molten iron was poured into the small opening of a two-piece mould. The seam between the moulds sometimes left a raised ring mark on the ball, as can be seen on this ball. The ridge would have been filed to make the join smooth, sometimes leaving a slightly flat area. Six 4-powder cannons were recovered from Endeavour Reef, Queensland, in 1969. They were from Captain Cook's HMS Endeavour, thrown overboard when the ship struck a reef there in 1770. They are likely to have been mounted on deck cannon carriages on the ship. Similar 4-pounder cannons were mounted on gun carriages and used as field guns. Cannons with cannon balls as ammunition were installed at Warrnambool for protection from possible invasion in the mid-to-late 19th century and early 20th century.Cannon ball, iron, black with a pitted shiny surface. It has three flat areas and evidence of a seam around the circumference. There are remnants of a possible inscription stamped into the iron. The cannon ball is a four-pounder ball. Imperial weight is 71 oz (201.3 gms or 4.44 pounds).Remnants of an indecipherable stamp and / or red text.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, cannon ball, ammunition, cannon, fortifications, military equipment, firearm, weapon, two-piece mould, seam line, four-pounder, 4-pounder, field gun, field ammunition, gun carriage, cast cannon ball -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFreezer, circa 1930's

This ice cream freezer, manufactured in South Australia in the 1930's, was advertised to "keep the contents of the cream compartment frozen for many hours". It was promoted for use at picnics to keep salads cool. Its design is very similar to other freezers of The Frigid name which were made in 1939; those freezers were all one colour whereas this one is blue around the top and bottom of the barrel and cream in the centre with blue/green lettering. The process of making ice cream was to pack the outer chamber full with a combination of 3 parts ice cubes of about 1 inch (2.cm) to one part coarse salt, then pour into the chamber about 1 cup of cold water. After this, the ingredients for ice cream or sorbet were poured into the inner chamber, then attach the lid and turn The Frigid freezer upside down for about 40 minutes or until the right consistency is reached. Advice as given to open the freezer every 20 minutes and stir around the contents that were frozen against the sides of the inner chamber. The ingredients for the ice cream could include cream, sugar, vanilla and eggs. The label on the box of The Frigid shows the address of A Simpson and Son to be at Pirie Street, Adelaide. This address was used as early as 1876 and later catalogues, 1931 - 1960 still show this address. Alfred Simpson and his family emigrated from England, arriving in South Australia in 1849. He had already completed his apprenticeship as a tinplate worker but he tried various other occupations, including trying out the gold mines in Victoria, before he established himself as a tinsmith in 1853. His products included many agricultural items. His son, Alfred Muller Simpson, joined the business when he turned 21. In the 1860 Simpson's products included 'explosion proof' safes. In the late 1880's A Simpson and Son manufactured munitions and mines for the war. At the time of Alfred's death in 1891, A Simpson and Son had the largest metal manufacturing plant in Australia. From 1898 the company's reputation grew from the process of enamel plating with porcelain. During the First World War, Simpsons returned to the manufacture of munitions. Alfred M. Simpson's sons (Alfred Allen, known as Allen, and Fredrick Neighbour) joined the company when they finished their schooling. Allen was also associated with the Royal Geological Society over many years and when the CT Madigan surveyed Central Australia in 1929, the Simpson Desert was named in his honour. Cape Simpson in Antarctica is also named after him due to his assistance to Douglas Mawson. A new factory was opened at Dudley Park in the 1940s and the company began the manufacture of whitegoods. In 1963 A. Simpson and Son merged with Pope Industries to form Simpson Pope Holdings. Alfred Simpson became chairman of the board of Simpson Pope Holdings. The Simpson brand, now owned by Electrolux, continues to produce a variety of household appliances. (Reference: State Library of South Australia) A Simpson and Son was an early colonial business that has lasted well into the 20th century and the name Simpson is still associated with whitegoods. Freezer, 2 quart (1.8 litre) capacity, made by A Simpson and Son Ltd, marked "The Frigid". Cylinder shaped, constructed from enamelled sheet metal, has two catches one on the base and one on top. Inner cylinder for holding contents for freezing. Slightly rusted. Freezer is inside original cardboard box with yellow label showing manufacturer details. Circa 1930'sOutside of freezer is printed in blue"The Frigid". Box includes "THE "FRIGID" FREEZER" and branded "S & S" inside a circle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, a. simpson & son limited, manufacturer, foundry, freezer, 2 quart freezer, portable freezer, kitchen appliance, the frigid, ice cream freezer, ice cream maker 1930's -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bullet Mould, From 1600s to early 19th century

Musket balls are the ammunition used in muskets the weapons used during the English and American Civil Wars. The balls could be made from any metal alloy, but many were made from lead. Lead can be melted at reasonably low temperatures and so lead musket balls could be made over a camp fire. Lead could be readily sourced from such places like church roofs or even coffins, and recast from old musket balls, so it was an easy material to work with while preparing for battle. The soldier would carry a crucible in which to melt the lead, he would put the material into it and place it over the fire until it had formed into a liquid. Musket ball moulds like the subject item, had a small hole above one of the domes where the liquid could be poured into once the two domes were closed together. The soldier would wait until it cooled then opened the mould to reveal a solid lead ball inside. Because these were cast in halves even though pressed together, there would always be a small amount of liquid lead leakage which would form a thin crust around the ball. These needed to be filed off before being used inside a musket, so some soldiers would pop a few in their mouths and roll them around, chewing off the excess until the ball was smooth. The obvious downside to this method is that lead is poisonous. A tool used to make ammunition for black powder firearms either muskets or pistols from the early part of the 18th to mid 19th century. After this time enclosed brass cartridges that held the propellent powder and bullet were starting to come into wide spread use, negating the need for a firearm to first have black powder placed in a barrel then the ball rammed on top and finally the firearm primed with powder or a percussion cap.Musket rifle/ pistol bullet mold. Makes .50 -caliber- round balls with a sprew cutter to cut off excess lead.Marked 50flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shot pliers, lead shot, shot, armoury, firearms, bullet, cast bullet, lead ball, lead shot, scissor mould -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Scale, 1900-1930

The basic balance scale has been around for thousands of years and its accuracy has improved dramatically over the last several centuries, the principle behind this tool remains unchanged. Its parts include a fulcrum, a beam that balances on it, a pan at the end of the beam to hold the materials to be weighed, and a flat platform at the other for the counter-balancing weights. Balance scales that require equal weights on each side of the fulcrum have been used by everyone from apothecaries and assayers to jewellers and postal workers. Known as an unequal arm balance scale, this variety builds the counterweight into the device. Counter scales used in dry-goods stores and domestic kitchens often featured Japanned or (blackened) cast iron with bronze trims. Made by companies such as Howe and Fairbanks, the footed tin pans of these scales were often oblong, some encircled at one end so bulk items could be easily poured into a bag. Seamless pans were typically stamped from brass and given style names like Snuff (the smallest) and Birmingham (the largest). Some counter scales were designed for measuring spices, others for weighing slices of cake. In the 18th century, spring scales began to appear and would use the resistance of spring to calculate weights, which are read automatically on the scale’s face. The ease of use of spring scales over balance scales. These scales are significant as they identify one of the basic preparation items for the weighing of foodstuff in the family kitchen to prepare everyday meals. This item is significant as it gives a snapshot into domestic life within the average home in Australia around the turn of the twentieth century and is, therefore, an item with social relevance. Black cast iron, medium weighing scales, with a fulcrum which the beam that balances on, there is a scoop or large bowl at one end for the material to be weighted and a flat platform at the other end that holds the weights. Around the cast iron base is an embossed strip weight and bowl missing.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Ballarat Heritage Services

Ballarat Heritage ServicesDigital Photograph, Dorothy Wickham, The Cast Courts, 2016, 09/2016

This ornate cross sits at the right hand side of View of Trajan's column, Cast Courts, Room 46a, The West Court, Victoria and Albert Museum, London. Cast Courts: "When the Architectural Courts – or Cast Courts as they are now known – opened in 1873, The Builder magazine compared the experience of seeing them to a first glimpse of Mont Blanc, creating one of those 'impressions that can scarcely be effaced'. Since then, these two enormous rooms and the reproductions they contain have continued to impress and inspire visitors to the Museum. For centuries, antiquarian interest in world architecture and sculpture led to reproductions – or copies – being made of outstanding national monuments and notable sculptures. When the Museum was founded, it collected and displayed reproductions of great art and architecture from across the world in order to offer objects for study and tell a complete story of the history of art and design. Casts are made by placing several plaster moulds upon the surface of the original structure. Once hardened and removed, the moulds are then enclosed in an outer casing, the interior coated with a separating agent and the wet plaster poured in. When set, the pieces are then assembled and the joints and surfaces finished off, to make a complete reproduction of the original work. The finished product – as well as being a formidable technical achievement in its own right – enables admirers to study faithful reproductions of important monuments and works of art." Ref: https://www.vam.ac.uk/articles/history-of-the-cast-courtslondon, victoria and albert museum, cast courts -

City of Warrnambool Rowing Club

City of Warrnambool Rowing ClubDevelopment Plaque, 16 july 2017

The people are L to R: Kathy McMeel (secretary), Annie Blanch (Boat Captain), Joanne Bone (president), James Tait (director of Gwen and Edna Jones and Ray and Joyce Uebergang Foundations, Susan Finnigan (Grants Officer) and Clive Wooster (treasurer). • In February 2017 the club filled the base of the boathouse and poured a new concrete floor. • They had an opening to thank the donors, especially the Gwen and Edna Jones and Ray and Joyce Uebergang Foundations and to celebrate with the community and rowers, past and present • Since 1996 rowers had to wade in foul, ankle to thigh high water to access the boat shed- this was for 3-5 months of every year- our facilities are now accessible and Warrnambool has a sporting venue for rowers that is safe and one the public can be proud of. • The Club thanked Barry Wilson for generously donating the plans and acknowledged the ‘term deposit’ raised over the last 10 years, by past and present members, which allowed the Club to contribute the additional funding required. • In particular The Foundations assistance made the project possible. The two philanthropic Foundations are a treasure for the community as they can step in and fill the gap where other funding sources cannot. In our case they were the major donors and we could not have contemplated this project without their assistance. We are truly grateful for the assistance of The Gwen and Edna Jones and Ray and Joyce Uebergang Foundation. • Mr James Tait, a director of both Foundations to unveiled the commemorative plaque. Color photograph taken at the opening of the Redeveloped City of Warrnambool Rowing Club. Includes a brass plaque. The people are L to R: Kathy McMeel (secretary), Annie Blanch (Boat Captain), Joanne Bone (president), James Tait (director of Gwen and Edna Jones and Ray and Joyce Uebergang Foundations, Susan Finnigan (Grants Officer) and Clive Wooster (treasurer).james tait, warrnambool, city of warrnambool rowing club, warrnambool rowing club, boathouse, boathouse redevelopment, gwen and edna jones foundation, ray and joyce uebergang foundation -

Tarnagulla History Archive

Tarnagulla History ArchiveCodd Bottle - Whittaker & Sons, Lemonade, Dunolly

David Gordon Collection. A Codd-neck bottle is a type of bottle used for carbonated drinks. Hiram Codd, an English engineer invented a successful process that he patented as “Codd’s patented globe stopper bottle” in 1872. This type of bottle has a closing design in which a glass marble is held against a rubber seal, which sits within a recess in the lip. The Codd-neck bottle was designed and manufactured with thick glass to withstand internal pressure, and a chamber to enclose a marble and a rubber washer in the neck. The bottles are filled upside down, and pressure of the gas in the bottle forced the marble against the washer, sealing in the carbonation. The bottle is pinched into a special shape to provide a chamber into which the marble is pushed to open the bottle. This prevents the marble from blocking the neck as the drink is poured. The bottles were regularly produced for many decades, but gradually declined in usage. Since children smashed the bottles to retrieve the marbles, vintage bottles are relatively scarce and have become collector items, particularly in the UK. William Whittaker's son Joseph Whittaker operated a cordial factory at Tarnagulla for many years. It was located at the southern end of Commercial Road, and was the last business premises on the eastern side of the road. Joseph Whittaker was a leading citizen at Tarnagulla for many years, and was a leading supporter of sporting activities including cricket and rifle clubs, as well as a strong patron of the fire brigade. He was known by some as Ginger Beer Joe. -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Cream Separator

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. ALFA-LAVAL SEPARATORS The principal works and head office of Aktiebolaget Separator was established by Gustaf de Laval in Stockholm. The first Laval milk separator was patented in1884. In Australia three old established firms commenced pioneering the Alfa Laval cream separators in about 1885. These were A. W. Sandford & Co. Ltd., in Adelaide, J. Bartram & Son, of Melbourne, who have ever since been the Victorian agents of Aktiebolaget Separator. In New South Wales and Queensland, the pioneering firm was Waugh & Josephson Ltd. J. Bartram & Son, the distributor of the separator in this collection, established their business in Melbourne in 1881. In 1892 Bartram & Son estimated that 1,130 of these machines were operating throughout Victoria. This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is made from cast iron. The cover and vat are made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A name plate featuring the Victorian distributor, J Bartram & Son of Melbourne and a plate outlining patent information are attached to the base by screws.Around edge of wheel "Aktiebolaget Separator Stockholm/ 2236"dairying industry, dairy machinery, milk separators -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - GEORGE AND EDITH LANSELL

Black and white (faded) photograph of Mr George and Mrs Edith Lansell sitting at small table with lace tablecloth. Mrs Lansell is pouring tea from a silver teapot. Mr Lansell reading newspaper. Flowers behind Mrs Lansell and flowers decorating a stand behind Mr Lansell. On back in pencil- 'could be George Lansell and wife (Peg Parsons, Castlemaine)'. 'Is definitely George Lansell and wife (Aunty Ruth Hill)'. 'Is definitely George Lansell and wife' - according to Mr Peter Lansell from Kew (June 1990). He has a similar photograph. The lady is Edith Lansell, the second wife of George Lansell. 1st wife - Bedelia died Sept 1880 at St. Kilda, buried Mill Scu Cem?, (Mrs. Balfour), Geo & Edith Borins? Bgo. Scu Cem. (Children all from Edith). By chapel. Printed on back in blue ink: QC Binks, 99 Rowan St, Bendigo, 3550. Photocopy of photo included with original.Agnes S Morris - Dunollyperson, family, husband and wife