Showing 465 items

matching bates

-

Red Cliffs Military Museum

Red Cliffs Military MuseumCushion Cover, Cushion Cover from WW1, (estimated); 1914-1919

John Hughes was Awarded the Military Medal: "for conspicuous good work during operations at/ GIRD TRENCH, near LE SARS, on 14.11.1916./ This N.C.O. was in charge of a party of men engaged in digging a communication trench from/ our jumping off trench to the newly captured GIRD TRENCH. He displayed great courage and coolness under very heavy fire, and his personal efforts were mainly responsible for the completion of the task allotted to his party."// Service number: 3044 Rank: Lance Sergeant Unit: 2nd Pnr Bn Service: Army Conflict: First World War, 1914-1918 Award: Military Medal Date of London Gazette: 22 January 1917 Location in London Gazette: Page 836, position 34 Date of Commonwealth of Australia Gazette: 29 June 1917 Location in Commonwealth of Australia Gazette: Page 1395, position 37A framed embroidered cushion cover from WW1. Sent or brought home by Lt. Jack Hughes. Contained within the same frame is a paper clipping and a photo.1.Cushion cover: from the top down- Egypt.... 1914/ Rising Sun/ scrolls with Australian Commonwealth/ Military Forces/ Aust Div Train/ Palestine Sinai Syria/1919. 2.Newpaper clipping with photo: John Hughes (left) 81, and Hugh Mont/gomery, 87, are the two oldest veterans who/ will be taking part in the Frankston ANZAC/ Day March on Tuesday. Mr Hughes served/ in France and Belgium in WW1 and/ in Darwin in the Second World War. He is a/ holder of the Military Medal./ Mr. Montgomery served with the 29th Bat/talion AIF in France during WW1/ Both men have been residents of the RSL park War Veterans Home for the past eight years.// 3. Photo: Mr. John Hughes.belgium, france, ww1, lt, mm, jack, hughes -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, St. Mary's School, Bedford Road, Ringwood. 1937-38

Written on backing sheet, "St. Mary's School, Bedford Road, Ringwood. 1937-38. Back Row - K. Rodaughan, D. Hannan, ? Ellis, M. Maidment, J. Davern, D. Morphett, ??, J. Kiker, J. Nolan, F. Hardidge, A. Orr, W. Steeth. 3rd Row - B. Bates, W. Smith, K. Hardidge, J. Ryan, B. Byrne, P. Stratton, W. Davern, F. Barro, ??, J. Lindsay, A. Smith, ? Pratt. 2nd Row - Byrne, ??, G. Robinson, J. Grey, ? Brown, ??, G. Robinson, J. Grey, ? Brown, ? Brown, ??, ??, K. Ryan, W. Connell, W. Orr, J. Bowles, B. Grey, ??. Front Row - L. Hardingham, P. Gridley, ??, J. Orr, P. Alford, ??, P. Davern, V. Orr". -

Kew Historical Society Inc

Kew Historical Society IncArchive (series) - Subject File, Artists I (Kew), 1958-present

Various PartiesReference, Research, InformationKHS OrderInformation file including a collection, largely compiled of newspaper articles/cuttings, relating to artists born or practising in Kew. In addition to the cuttings, there is a catalogue of an exhibition at the Town Hall Gallery - Louis Kahan: Art, theatre and fashion (curated by Laura Jokic, 2016), and biographical entries from various publications including the ADB. There is also an invitation (undated) from the Mayor of Kew, Cr. Kaye Cole, to an exhibition of paintings by Gwen Walker and Donald Cameron in the Mayor’s Room. Alice Marion Ellen Bale (1875-1955), Arthur Loureiro (1860-1932), Frances Derham, Eugenia Meldrum, Max Meldrum, Louis Buvelot, Kitchen Dimensions High Street Kew, Ron Walker, Melissa Peacock, Isobel Davies 6 A'Beckett Street, Hertha Kluge-Pott, Debra Luccio, Elise Martinson, Carole Milton, Louise Minahan, Miranda Millane, Sonja Kan, Holly Walton, Q Art Gallery, Archibald Colquhoun, Amalie Colquhoun, John Perry, Pamela Pretty, Christopher Shelton, Amanda Tuohy, Margot Westhorpe, Ian Wood, James O’Brien, Gaby Jung, Rupert Gray, Ray Gee - 3 Fernhurst Grove, Louis Foletta, Thomas King (Tim) Fitchett, Wendy Fantasia, Marion Cravino, Brett Coelho, Eileen Cambell, Helen Carnage, Erin Carnage, John Bates, Nina Bennett, Donald Cameron, Gwen Walker -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Ringwood State School - Grade 5A, 1963

Black and white photograph - Grade 5A, 1963."Attached to photograph" Back Row- L to R: Russell Borke, John Snellders, Craig Austin, Barbara Donald, Janet Conlon, Diana Rankin, Debbie Lawrence, Russell Paine, Neil Ratray, Gavin Philips. 2nd Row- L to R: Tommy Colston, Greg Peters, Leslie Reed, Jeffrey Taylor, Gary McCubbin, Gary Davies, ?, John Moon, Barry McDonald, Malcolm Pearson, ?. 3rd Row- L to R: Stephen Gross, Neil Dawe, Jeffrey Fielding, David Kennely, Ian (?), Philip Bates, Jeffrey Ratten, David Kimberly, Robyn Hagar, Malcolm Williams. Front Row- L to R: Karen Williams, Debbie Monk, Elizabeth Clarke, Judy Parker, Linda (?), Jan Thompson, Sally Shaw, Cheryl O'Brien, Rosaland Wiggle, Julie Cook, Rhonda McLeod. On Ground: Michael Craddock, David Connell. Teacher: -

Federation University Historical Collection

Federation University Historical CollectionMagazine - Booklet, Ballarat School of Mines Students' Magazine, 1944, 1944

List of Full Course Students' 1944, Editorial, News and Notes, Obituary, The Literary Society, Fumes from the Lab, Our Sojourn in Port Pirie, Arts & Crafts Gossip, Sport, Commercial Notes, The Junior Techs, List of Junior Technical School Students' 1944White, blue, green and gold soft covered magazine of 66 pages including advertisements. Artworks Mr Heseltine - By Ruth Mole Mack - By Beryl Grinter Frederick - By Beryl Grinter Stan - By Ruth Mole Scotty - By Joan Walter Jenko - By Ruth Mole Dagwood - By Ruth Mole Along the track - By Neville Reeve Kanga - By Ruth Mole Nev - By Ruth Mole Charlie - By Joan Walter Shergold - By Joan Walter Very friendly people at this beach, everyone's waving at me - By John Procter At the crest of the hill - By Joan Walter Joyce - By Beryl Grinter Mr Procter - By Ruth Mole Phyllis - By Neville Reeve Gwen - By Beryl Grinter Doreen - By William Bates Laurel - By Joan Walter Lorna - By Ruth Mole Ah! an important discovery! wireless poles on Mars - By Frank Daykin Barbara - By Joan Walter Winsome - By Beryl Grinter Kath - By Joan Walter Lola - By Ruth Mole Amy - By Beryl Grinter Laurel - By Beryl Grinter Gwen - By Beryl Grinter June - By Beryl Grinter Peggy - By Beatrice Burgess Winifred - By Ruth Mole Elaine - By M.D Iris - By Ruth Mole Iris - By Ruth Mole Isobel - By Joan Walter Betty - By Joan Walter Nancy - By Neville Reeve Charlie - By Ruth Mole Harold - By Joan Walter Sammy - By Joan Walter Brokie - By Ruth Mole Dick - By Joan Walter Mac - By Ruth Mole Mac - By Beryl Grinter Willie - By Beryl Grinter Deany - By Beryl Grinter Ducky - By Ruth Mole Fitzy - By Joan Walter ballarat school of mines, magazine, percival d. fisher, neville reeve, gwen spiers, p. marxsen, stanley c. sharp, john c. shergold, beatrice e. burgess, john g. procter, alan m. scott, w. reid, elsie coombs, laurence j. george, d. wise, robert j. mckenzie, marian a. beckwith, geoffrey biddington, thelma ellsworth, maxwell a. richards, norma eltringham, k. saunders, john a. mckenzie, beryl grinter, frank d. daykin, dawn wilson, ernest j. poppins, dr pound, mr mein, mr f. g. procter, joan t. walter, peter j. wilson, ruth mole, ian cooper, jack lannen, jack henderson, james duncan, alan wilson, j. baird, ian mclachlan, maxwell lawrence, ken palmer, joy martin, patricia allan, graham lawrie, kevin mclachlan, marion pearce, dimsey, vaughan, wilson, callister, max webster, stan lawrie, eric goon, m. collins, alan paganetti, robert tasman pound, william symons, f. neville. reeve, lester w. roffey, kevin j. whiter, john m. blainey, john middlin, roy e. mawby, phillip p. coulson, john w. jolly, kingsley r. bremmer, basil j. marshall, james s. owen, raymond g. mccahon, lindsay g. pattenden, david t. coburn, bruce j. linklater, muriel coultham, g. harrison, mr cornell, b. brookman, john l. lewis, valerie vickers, robert j. mcmenzie, betty law, miss king, mrs mcilvena, valerie ballinger, grace lawry, mina gallie, eloise prowse, lois strick, kenneth j. lindsay, r. eggleton, w. redfern, w. blundell, l. clifton, w. parker, r. fitzclarence, r. sargent, d. mclachlan, c. mouser, w. trevethan, d. hart, r. bennett, j. beecroft, r. ingleton, k. dean, w. young, b. holloway, w. coad, a. clark, k. innes, k. george, r. willian, j. heys, a. coad, l. dennis, p. banfield, g. pyke, j. humphrey, h. george, f. jacobson, f. savage, c. eltringham, i. scott, a. hughes, h. fumberger, a. smith, m. grinham, c. hoffman, r. swales, joan walter, william bates -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Ringwood State School - Grade 6C, 1964

Black and white photograph - Grade 6C, 1964."Attached to photograph" Back Row- L to R: Greg Peters, David Pumpa, Norman Pearson, Liz Allen, Robyn Henry, Grace King, Deb Lawrence, Jenny Johnson, Linda Chegwiden, Erica Seffers. 2nd Row- L to R: Chris Eastwood, Graham Haglan, Gary Ladegashes, Gary Morgan, ?, Paul Wilson, Wayne Walton, Stephen Foster, Gavin Philips, Barry McDonald. 3rd Row- L to R: Philip Bates, Michael Craddock, Michael Williams, Stephen Cross, Ron Saines, Neil Dawe, ?, Bruce Barber, Robin Hagar, Paul Martin. Front Row- L to R: Lynette German, Lorraine Tann, Linda Willis, Debby Silvy, Judy Parker, Pam Williams, Julie Cook, Glenda Cooper, Jenny Buchanan, Ann Dowling, Sally Shaw. On Ground: Robert Silvie, ?, Graeme Cleator, David Kennely, Dale Ryan. Teacher: Miss Norman -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Ringwood State School - Grade 4A, 1962

Black and white photograph - Grade 4A, 1962"Attached to photograph" Back Row- L to R: Russell Bourke, Robert Taylor, Malcolm Pearson, Russell Paine, Gavin Phillips, Neil Rattray, Gary Davies, ?, Barry McDonald, Craig Austin, Gary McCubbin, John Moon. 2nd Row- L to R: Julie Cook, Jan Thompson, Leslie Gray, Leanne Thorpe, Laurie Simpson,, Debbie Lawrence, Elizabeth Clarke, Roslyn wiggle, Diana Rankin, Wilemina Cook, Janet Conlon. 3rd Row- L to R: Tommy Colston, Stephen Cross, Jeffrey Ratten, Roslyn (?), Sally Shaw, Debbie Monk, Rhonda McLeod, Karen Williams, Ian Jones, Leslie Reed, David Connell. Front Row- L to R: Robin Hagar, Greg Peters, Malcolm Williams, Phillip Bates, David Kimberley, Michael Craddock, David Kennely, Neil Dawe, Jeffrey Fields. Teacher: Mr Delacca -

Federation University Historical Collection

Federation University Historical CollectionAward - Trophy, Six Metre Henk Miller Line Special, 1981

Silver cup with handles relating to the Gippsland Advanced Institute EducationSix metre Henk Miller Line Special The GAIE Annual Raft Perpetual Trophy Hazelwood Pondage 1981 F Golly, S Corlett, G Honeychurch, M Jongerius, P Llewellyn, D Patching, D Wagner 1982 S Corlett, G Honeychurch, P Llewellyn, D Wagner, M Jongerius, D Patching, 1983 C Blowers, A Casser, P Coultox, I Namiltox, A Hassak, S Kallbacka, R Lestin, R Shellcot, T Stevens 1984 D Patching, P Llewellyn, G Honeychurch, N Bates, R Dathan 1985 G Honeychurch, P Llewellyn, G Martin, A Lonneveid, P newman 1986 James (Pas) Bennet Lindsay Fawell 1975 Meredith Annand, Ken Jeanes Tim Gallacher, Jeff Goodchild 1976 Ken Ken Jason, Chris Westaway, Karen Pearce, Charlie Wheelan 1977 Jeff Leamon, Chris Hobson 1978 Jeff Leamon, Ken Jeanes, Greg Vines, Vicki Whitesidef golly, s corlett, g honeychurch, m jongerius, p llewellyn, d patching, d wagner, s corlett, g honeychurch, p llewellyn, d wagner, m jongerius, d patching,, c blowers, a casser, p coultox, i namiltox, a hassak, s kallbacka, r lestin, r shellcot, t stevens, d patching, p llewellyn, g honeychurch, n bates, r dathan, g honeychurch, p llewellyn, g martin, a lonneveid, p newman, james (pas) bennet, lindsay fawell, meredith annand, ken jeanes, tim gallacher, jeff goodchild, ken jason, chris westaway, karen pearce, charlie wheelan, jeff leamon, chris hobson, jeff leamon, ken jeanes, greg vines, vicki whiteside, giae, gippsland institute of advanced education, churchill campus -

Melbourne Tram Museum

Melbourne Tram MuseumMagazine, Yarra Trams, "The Wire", 5/2011 to 1/2015

0 - No 9 - 1/4/2011 - Rhinos on skateboards, Did you know, Spencer St works, .1 - No. 11 of 3/5/2011 with the revised Yarra trams logo, traffic priority, work over Easter in Spencer St at Bourke and Collins St, Good Friday appeal, safety, passenger feedback and future works. .2 - No. 13 - 31/5/2011 - new uniform, cleaning, CEPR, trackwork - Fitzroy St, Northcote, Rhino, Carlton Control. .3 - No. 14 - 15/6/2011 - Haymarket Roundabout, accessibility, maintenance, CSE. .4 - No. 17 - 2/8/2011 - High St Westgarth trackwork, Swanston St, IMF CEO visit .5 - No. 18 - 16/8/2011 - Performance benchmarks met, Preston Workshops, repairs to 3018, tram signal priority. .6 - No . 19 - 30/8/2011 - New E class trams, routes "a" or "d", TramTracker in shelters, police, fare evasion .7 - No. 20 - 15/9/2011 - Football trams, Superstops, Bridge Road, Rhinos. .8 - No. 21 - 27/9/2011 - CEO's journey to work, accessibility, increased patronage, E class. .8a - No. 22 - 11/10/2011 - Minister Mulder visit, E class, Customer experience, Elizabeth Kerdelhue Corporate Affairs Director, flood indicator in Wellington Parade, Keolis - Orleans and PTV coming your way. .9 - No. 23 - 25/10/2011 - forthcoming royal visit, opening for Footscray Road extension, Rhinos, Stockholm .10 - No. 24 - 8/11/2011- Royal visit, photos, Z3 158, route 86 works in High St. (see htd5043i21 for a image from an unknown newspaper of the actual event - features Z3 158.) .11 - No. 25 - 22/11/2011 - new staff guide, Gold Coast tram line, Macarthur St, overhead, fund raising, route numbering update. .12 - No. 26 - 6/12/2011 - Swanston St Superstops, Newmarket bridge strikes, rhinos. .13 - No. 27 - 20/12/2011 - Christmas carnival, Lenny Bates, portable crossover, uniforms. .14 - No. 28 - 17/1/2012 - Passing of Len Bates, Myki, Gardiner railway station. .15 - No. 30 - 15/2/2012 - visit of Keolis, SNCF people, list of Executive leadership team with photos, Swanston St works, Myki introduction. .16 - No. 31 - 29/2/2012 - patronage up, tram postage stamps, Myki, rhinos. .17 - No. 32 - 14/3/2012 - St Kilda Rd trackwork, fund raising, Southbank Depot extensions, Myki, driving conditions, grand prix. .18 - No. 33 - 30/3/2012 - introduction of the PTV, end of MetLink and Transport Ticketing Authority, changes in management structure, trackwork, Gold Coast tramway and Keolis. .19 - No. 34 - Dr Jake - Royal children's Hospital super stop, route 96 - Premium line. .20 - No. 35, 2/5/2012 - Revision of Rules, trackwork in St Kilda Road and Elizabeth St, Myki, safety - Zero Harm. .21 - No. 69 - 25/9/2013 - Passengers paying their way, E class update, Mal Ashworth retires, progress report, feedback, new chime on trams. .22 - No. 70 - 9/10/2013 - Art comes alive, tram 925, driver simulator at Preston Workshops, E class project, 90th Glen Huntly. .23 - No. 83 - 23/4/2014 - Screen time for trams, new PIDs on B class, assistance animals, Operations Centre, Preston Workshops, Electrical log sheets to SLV. .24 - No. 89 - 23/7/2014 - punctuality, refresh of network map (fold-out map), women drivers. .25 - No. 97 - 19/11/2014 - Revitalising route 96, Keolis news, free tram zone, guide dogs. .26 - No. 99 - 17/12/2014 - Accessibility week, new uniform top for CSE's, free tram zone, world trade centre stop upgrade, heat stress, Art tram 158. .27 - No. 100 - 14/1/2015 - Route 96 complete, New Years eve free travel, fare compliance, patronage down, Demonstrates Yarra trams staff newsletters.Set of 22 Yarra Trams internal newsletter "The Wire", All A4, printed in full colour. All four pages unless noted otherwise, full colour, performance snapshot on front cover.trams, tramways, yarra trams, traffic control, trackwork, spencer st, fund raising, operations, rhinos, carlton control, high st, haymarket, preston workshops, e class, route numbers, bridge road, wellington parade, ptv, royal visit, footscray road, new tramway, gold coast, macarthur st, swanston st, superstops, newmarket, gardiner, burke road, level crossings, railway squares, myki, metlink, tickets, route 96, rules, st kilda road, elizabeth st, tram 158, tram 925, glen huntly depot, simulator, b class, opeations centre, art trams, patronage -

Federation University Historical Collection

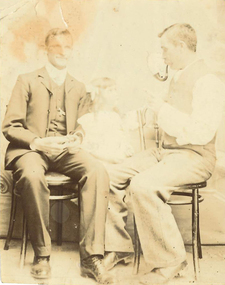

Federation University Historical CollectionPhotograph, James (Jim) Smith of Happy Valley

James (Jim) Smith, (died 03/08/1974, aged 93 years) established an orchard growing snow apples in Happy Valley after returning from mining activities in South Africa. The orchard was called "Springdallah" and was beside the Linton/Happy Valley Road across from the old Happy Valley railway station. Jim was the son of George Henry Smith (18/12/1840 - 26/11/1903) and Emma Keys Smith born Keys (07/08/1842 - 28/08/1888). George and Emma left Liverpool with other unassisted immigrants on the "Bates Family" with baby Clara on 08/06/1863 arriving in Melbourne on 08/06/1863. George and Emma emigrated to Australia on the invitation of Emma's brother Edward Keys who owned a property near the school at Happy Valley on which there were two houses. Teddy offered George and Emma the smaller one to live in. When "Teddy" decided to go into hotel keeping George took over the 200 acres of his property and made it a pleasant orchard and garden called "Cress Green Gardens". George had various secretarial jobs - rate collector; paymaster at the mines; until he became Shire Secretary for the Shire of Grenville, whose centre was Linton and Government Auditor for Western Victoria (1894-1903), the means of transport being horse and buggy. Another son followed his father as Shire Secretary. George and Emma had 14 children, Emma dying giving birth to Emma Keys who lived for 16 months. George later married Annie Bolte with 2 more children being born. Annie later sold the property. The land was used for grazing and the two houses fell into disrepair. In 1995 George's grandson Ernest (Alf) Alfred Watson visited the site and reported a wrought iron gate at the site and a mulberry tree near the site of his grandmother's family home. Bluestone blocks can still be seen in the paddocks from the roadside. Jim Smith was the brother of Clara Emma Yung nee Smith.Sepia photo of two men and a girl. One of them is Jim Smith who established on orchard at Happy Valley. He also went to South Africa - mining activities. The orchard is now part of Clarkesdale Bird Sanctuary located at 360 Linton-Piggoreet Rd, Linton, Vic. 3360. Verso: Jim Smith South Africa (Mining) Established orchard halfway between Yendon and Happy Valley. Clara Emma's brother. [ Orchard established near Linton at Happy Valley.]jim smith, james smith, clara emma smith, happy valley, yendon, piggoreet, south africa, mining, orchard, edward keys, george henry smith, emma keys smith, clara emma yung, annie bolte, shire of grenville, clarkesdale bird sanctury -

National Wool Museum

National Wool MuseumTextile - Quilt, Rosemary A.O. Cameron, Celebration Quilt, 1990

From Rosemary Cameron - This quilt has been made in 100% wool to celebrate the diversity, durability and beauty of pure wool, especially the lightweight cool wools. The woollen patches were kindly donated by Mr. David Jones, managing Director of Fletcher Jones and Staff which were pre-cut samples of European Fabrics in various weights, textures and colours. I had the task of creating a design around the fabrics available, some of which I only had to sample. I chose to surround my design with dark shades to encompass at the top of the quilt, the lightness of the sky and the trees, in the middle the warmth of summer, the dryness of central Australia and at the bottom the rick tones of Opals, our mineral wealth and the internal heart of earth. To add excitement and texture to this design I chose 31 Australian Wildflowers including all the Australian Floral Emblems, some unusual wildflowers and favourite small wildflowers. Twice life size, these flowers have been made of silk wool and cotton, embroidered, painted and beaded by our creative and talented Hamilton Quilters, their results are fantastic! The brilliance and timeless quality of these Australian Wildflowers intensify and complement the colours of the Wool Quilt. The Quilt was hand pieced and hand quilted at quilting bees. It has a woollen batting, binding and backing which was a delight to work with and very easy to quilt. The flowers were assembled and attached in small working bees. To the fifty-two Hamilton Quilters who have worked on this quilt for six months thank you for you hard work and creativity especially Joan H. Lyons for her time, enthusiasm and knowledge when difficulties arose. Joan M. Lyons has worked with me on various stages of this Quilt, her help and support has been tremendous. To my family who have tolerated scraps of wool and silk, photographs, wildflower books and specimens and drawings which have at times almost taken over our house, a year from ideas to completion, thank you for your support and help in many ways.Multi coloured patchwork quilt with native flowers protruding from centre in a diamond shape.Embroidered on back - "The Celebration Quilt" Made in 1990 by The Hamilton Quilters, Designed by Rosemary A.O. Cameron. Made of Pure Wool. Beryl Anderson, Joan Askew, Bett Basham, Marilyn Baulch, Rau Blaby, Pauline Boyd, Aileen Beckwith, Dorothy Beveridge, Ros Brommell, Rosemary Cameron, Gwen Cook, Anne Cordner, Kaylene Cowland, Elaine Denby, Barbara Dolman, Rosalie Duffield, Helen Fry, Glennys Gardner, Nola Gunning, Margaret Irvine, Bev Jeffrey, Emma Jensen, Betty Lacy, Helen Lampard, Joan H. Lyons, Joan M. Lyons, Elaine McDonald, Carole McEwan, Joy McLeod, Joyce McLeod, Mary May, Joan Mallinson, Susan Mason, Anne Menzel, Val Mills, Betty O’Brien, Di Pettigrew, Therese Read, Sherry Robertson, Lee Rowland, Irene Saddler, Nanette Templeton, Glenys Tindall, Liz Wallis, Ruth Walter, Marion Warburton. Alison Waterman, Pat Wilmot, Nola Malcolm, Ann Nicholls, Margaret Rowe, Jill Hillier.celebration, flowers, hamilton quilters, quilt, native flowers -

National Wool Museum

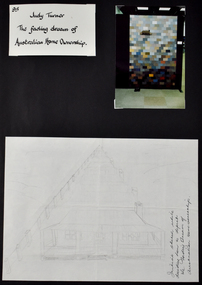

National Wool MuseumDocument - The Fading Dream of Australian Home Ownership, Design and Photograph, Judy Turner, 1989

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Folio page depicting three items attached to a black card background. One item is a title written in black ink on white background, another is a photograph of a quilt, the third shows a hand drawn sketch of a house with a verandah.Front: [handwritten] 95 / Judy Turner / The fading dream of / Australian Home Ownership. / Initial sketch while / deciding how to depict / the Fading Dream of / Australian Home Ownership.quilt, wagga, home, house, housing affordability, design -

National Wool Museum

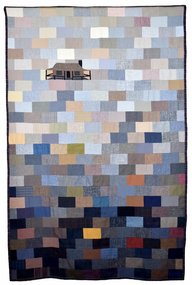

National Wool MuseumTextile - Quilt, Judy Turner, The Fading Dream of Australian Home Ownership, 1989

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Quilt featuring block pieces in tones of grey, blue, tan and brown, graduating in light to dark tones from top to bottom. The top third features a house with a verandah.quilt, wagga, home, house, housing affordability, design -

National Wool Museum

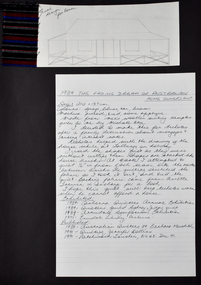

National Wool MuseumDocument - The Fading Dream of Australian Home Ownership, Design and Fabric Sample, Judy Turner, 1989

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Folio page depicting three items attached to a black card background. One item is a red, blue, black and white textile sample, another is a hand drawn sketch of a house, the third shows hand written text on lined paper in black ink.Front: [handwritten] Final / design / for housequilt, wagga, home, house, housing affordability, design -

National Wool Museum

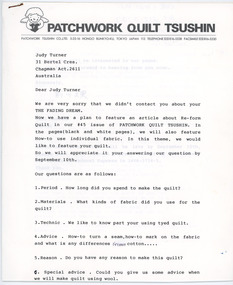

National Wool MuseumDocument - The Fading Dream of Australian Home Ownership, Letters, Judy Turner et al, 1991

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Two typed letters held together with a staple. The first letter has a grey printed letter head which includes a logo of a person with wings holding a heart.[printed] PATCHWORK QUILT TSUSHINquilt, wagga, home, house, housing affordability, design -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros