Showing 588 items matching " bakelite"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGestetner Machine, c. 1922 - 1929

This Gestetner Cyclostyle duplicating machine was invented and manufactured by David Gestetner. He claimed in 1922, once he had released several models, that if a Gestetner Durotype stencil was used together with his Cyclostyle machine, then 10,000 copies could be made from the one Durotype stencil, an amazing claim for office technology of that era. David Gestetner (1854-1939), was born in Csoma, Hungary. He has been called the “founder of the worldwide office copying and duplicator industry.). He moved to London and in 1879 filed his first copying patent. In 1881 he patented the Cyclostyle stylus (or pen), which was used in conjunction with his Cyclograph device for copying text and images, He established the Gestetner Cyclograph Company in England at this time (1881) to protect his inventions and to produce his products; stencils, stylos (stylus or pen) and ink rollers. HIs inventions included nail-clipper and the ball-point pen (although the latter is more commonly associated with Laszlo Biro). Gestetner’s patented Cyclograph duplicator was used with his Cyclostyle Stylus or pen to write or draw on special thin wax-coated stencil paper (originally used for kite making paper) in the following way; 1. The Cyclostyle stencil was placed on a lower, framed metal plate of the Cyclograph 2. An upper frame was clipped over the top 3. The Cyclostyle pen, with its tip being a small metal-spiked or toothed wheel, was used to write or draw on the stencil, punched small holes into the paper and removed the wax coating in those places 4. The upper frame and stencil was then removed and a piece of blank paper was placed onto the metal plate in the lower frame and the upper frame with stencil was replaced 5. A roller was given an even distribution of Cyclostyle ink and rolled by hand over the stencil in the frame. This forced the ink through the holes in the stencil to and made a copy of the stencil on the paper 6. The upper frame was raised, the printed paper removed and another blank sheet was put into place. The whole process was repeated until enough copies were made. Gestetner’s invention developed further in 1894, with a stencil that could be placed on a screen on a revolving drum. The drum was manually rotated, the stencil then wrapped around another drum and was fed between cloth-covered rollers on which ink was evenly spread. Each revolution of the drum forced ink through the holes in the stencil and transferred the ink onto paper that had been fed between rollers and pressed against the drum. The process was repeated for each page. The paper was still fed and removed manually in this earlier invention but became more automatic in later models. In 1902 Gestetner duplicator model 6 was put onto the market. This model included the improvement of an automatic paper feed that synchronised with the rotation of the stencil. The Gestetner machine was the first office printing machine. It was easily installed and it made exact copies of the sane document quickly, effectively and inexpensively. This changed the way offices operated, making information easily available to many more users. The machines were commonly used in small businesses, schools, churches, clubs and other organisations for the wide distribution of a wide variety of information in the form of worksheets, newsletters and more. In 1906 the Gestetner Works were opened in Tottenham Hale, North London, and thousands of people were employed there up until the 1970’s. Due to the fast growing success of the Gestetner Duplicator machines many international branches for sales and service centres were established. David Gestetner was succeeded by his son Sigmund, followed by his grandson’s David and Jonathan. Further advancement was made by using a manual typewriter with specifically designed stencils. The end product was a printed, typewritten copy similar to the print from newspapers and booklets. In the next few years there were further developments of this revolutionary invention. The Gestetner Cyclostyle duplicator in our Collection is dated c.1922 - 1929 and it uses Gestetner Durotype stencils The 1922 British Industries Fair’s catalogue contained advertising for the Gestetner Rotary Cyclostyle “The World’s Premier Duplicator”, demonstrated at Stand K 86.” A Notice at the foot of the advertisement’s page boasts "Important - D Gestetner's latest invention, the "Durotype" Stencil, enables you to obtain 10,000 copies from one original if desired. It contains no wax of any description, is indestructible, can be stored indefinitely and printed from as required” In 1929 the look of the Gestetner machines changed; American designer Raymond Loewy was invited by Gestetner to improve the look of his duplicators, resulting in a very streamlined appearance. Eventually, around 1960’s, offices replaced their Gestetner with small photocopying machines and printers. Gestetner took over ownership of other office machine companies over time, including Nashua, Rex Rotary, Hanimex and Savin and eventually all came under the holding company name of NRG (Nashuatech, Rex Rotary and Gestetner). In 1996 Ricoh acquired the Gestetner Company, and it was renamed the NRG Group. REFERENCES Cyclostyle, Stencil Duplicating Machines, antique Copying Machines, Early Office Museum, http://www.officemuseum.com/copy_machines.htm Duplicating machines, Wikipedia Duplicator, Collection online, Canada Science and Technology Museums Corporation http://techno-science.ca/en/collection-research/collection-item.php?id=1989.0229.001 Gestetner duplicators, Totterham-Summerhillroad.com http://tottenham-summerhillroad.com/gestetner_duplicators_tottenham.htm Gestetner Duplicator, V&A Museum http://collections.vam.ac.uk/item/O322014/gestetner-duplicator-duplicator-loewy-raymond-fernand/ Gestetner, Grace’s Guide to British Industrial History, http://www.gracesguide.co.uk/Gestetner Duplicating machines such as this one revolutionalised access to copies of printed material, changing the way that educational bodies, offices, small businesses and community clubs and charities operated.Duplicating machine, Gestetner Cyclostyle Durotype, a stencil-method duplicating machine with two rotating drums plus rollers. Hand operated, tabletop office machine. Front has folding Bakelite handle, oil filling hole, calibrating gauge with scale, and copy counting meter. Right side has printed manufacturer’s plate that slides out as a paper output tray. Left side has metal plate with protrusions and perforations, plus another similar plate that is detached. It also has a metal frame attached [that would have been used to hold a paper input board, adjusted for various sizes of paper]. Cover, metal, with folding wooden handle on top, attaches to base with metal clips. Inscriptions printed on machine, mostly in gold-coloured paint. Round metal manufacturing plate is stamped with Serial Number 95759. Made by D. Gestetner, London, c.1922-1929Maker’s plate “MANUFACTURED / BY / D. GESTETNER LTD, / No. 95759 / CYCLOSTYLE WORKS / TOTTENHAM HALE / LONDON, N” Copy counting meter shows “1 4 6 4 8 [space]“ copies. Calibrating gauge has divisions with numbers “0 1 2“, labelled “← [left arrow] “TO PRINT LOWER” and “→ [right arrow], TO PRINT HIGHER”. “The Gestetner”, “Cyclostyle”, “Gestetner” (Trade Mark), Right side print of manufacturing details includes “The / Gestetner / TRADE MARK” And “THE FOLLOWING TRAFE MARKS / - - - OF INK, STENCILS / - - - AND GUARANTEE OF PERFECT / - - - BOTH - - - AND MACHINE” and “CYCLOSTYLE / DUROTYPE / GESTETNER” and “D. Gestetner” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, office machine, copying machine, gestetner machine, duplicating machine, duplicator, stencil machine, gestetner cyclograph company, cyclograph, cyclostyle, d. gestetner ltd, gestetner durotype stencils, gestetner cyclostyle, printing machine, office technology, durotype stencils, david gestetner, raymond loewy, roneo, rotary duplicatorten, mimeo, mimeograph machine, roneograph copier -

Wangaratta RSL Sub Branch

Wangaratta RSL Sub BranchEquipment - WW2 Telephone Set, Standard Telephone and Cables Pty Ltd, 1942

An example of a Telephone Set D Mk V which was used by Australian forces during the Second World War for verbal and Morse code communications over short distances via a telephone line.An example of a Telephone Set D Mk V which was used by Australian forces during the Second World War for verbal and Morse code communications over short distances via a telephone line. Rectangular aluminum green painted box with broad canvas webbing strap secured to the side of the body through metal loops. Two vertical webbing loops are attached to the rear of the body. Stencilled in black on top TELE. SET. D. MK. V.'. The housing opens by a hinged fold back lid that is secured by a hook and eye closure. Attached to the inside of the lid are two metal plates. The first is a circuitry diagram, the second is the instructions for use of the set. The interior contains the phone assembly and is divided by a metal shelf. On the left is a bell with two screw terminal in front. At the center is the telegraph key and behind that is the battery box with a small metal plate with, 'TELEPHONE SET. D.MK.V To the right is metal box with two terminals in frontAttached to the bottom of the shelf is a slide out metal key Below the shelf is a compartment in which is stowed a black metal headset with provision for a bakelite handset with attached cord and four-prong plug.Tele Set stamped on outside of unit. Inside lid plaque - Telephone Set D MK V -

Geelong Naval and Maritime Museum

Geelong Naval and Maritime MuseumDitty Box, John Kidd's Ditty Box, c.1915-1930

There is a single record with the RAN for a John Kidd, who commenced service in 1909 and left in 1912. Kidd was born in 1885 in Sydney and his mother lived in Queenscliff. He served on the HMAS Parramatta from 1911-1912. There is no evidence of him having served on the HMAS Melbourne. Kidd served from 1911-1912 on the HMAS Parramatta, the first ship launched for the Royal Australian Navy (RAN).A wooden box with mortise and tenon joins, brass fittings, circular handles, silver hinges and a name plate on the front. The box has a lift out section creating compartments. On the inside lid of the box is a postcard of the HMAS Melbourne surrounded by small rope decoration. A number of keepsakes are inside including a fidd for splicing ropes, a Capstan Wills tobacco tin, 3 postcards, a "Bengall Imperial" cut throat razor (T.R. Cadman & Sons, Sheffield England), black and white bakelite buttons with embossed crown and anchor and brass shank (either for war time or junior officers), gold naval buttons with embossed naval anchor and 2 piece shank (from a coat and cuffs), a bullet casing (Webley '45), a petty officers cloth badge (crossed anchors with a Crown), 4 shells, a good conduct badge (black with gold embroidery) and a red/brown vulcanized asbestos fibre fireproof dog- tag with rope attached."John Kidd" on front of box. "20171" stamped on edge of box. Tobacco tin: "Medium/"Capstan"/Registered/Ready Rubbed Fine Cut Tobacco/-1 oz net weight when packed/W.D. & H.O. Wills/(Australia) Ltd., Sydney. Postcard: Main Street, Samarai. Postcard: Sydney from Lavender Bay Kerry (Copyright) Sydney. Postcard: "Docks showing cathedral, Bristol BL 193. Copyright Lilywhite (1932) Ltd, Sowerby Bridge". Buttons: "AUSTRALIA/Y6-298", "Buttons Ltd B'HAM mark trade" "AUSTRALIA Stokes & Son Melbourne". Bullet casing "WEB WRA 45". Dog-Tag may read "L/Ford" written in ink?ditty box, john kidd, dog-tag, wwi identification tag, lilywhite ltd, w.d & h.o wills, stokes & son melbourne, naval buttons, hmas melbourne -

Orbost & District Historical Society

Orbost & District Historical Societyglass containers, first half 20th century

These items were used at the pharmacies in Orbost. Chemists who worked in Orbost included Henry Cottman; James Alfred Dubois Williams; Harry Arthur Murray; Miss P.E .Mason (Phyllis Estelle?); Miss Sybil Monica Buzza; Thomas James Frazer; Australia Shaw; James David Torley; John William Zimmer; Dalkeith William Steele; William Thomas Hollingsworth; E.E. Cohen; R.S. Anderson; Frances John Perry Faith Everard Pardew and Charles Anthony Wurf. Castor oil and Eichorn's Remedy were home based remedies for non life threatening injuries. The practices of early pharmacists are revealed through these glass containers. The items have a clear association with Orbost and indicate that many rural households had first-aid sources. .Six glass containers. 3210.7 is a deep blue coloured glass bottle. It has a narrow neck and a screw on lid. It has an embossed manufacturer's name, logo and contents (Castor Oil) on one side and identification marks embossed on the underside. 3210.8 is a small clear glass flat bottle with a metal top.It is labelled "SIGMA JUNIPER BACC'. It contains pale brown liquid 3210.9 is a a small moulded clear glass flat bottle with a white bakelite cap.It is labelled "EICHORNS REMEDY 100 ml HELP IN EVERY DROP". 3210.10 is a clear glass bottle with no lid.It has embossed manufacturer's stamp on base. 3210.11 isa clear glass beaker with a label on the front of two concentric green circles inside of which is "PYREX Made in England" with 200 ml below this. 3210.12 is a lear glass jar / bottle with a black lid. The front and sides are ridged with part of a label - "CAL". This bottle contains some pink powder.3210.7 - "Rolfes Medicinal Tasteles Castor Oil - Rolfe & Co King St Melbourne. Contents 5oz" 3210.8 - "SIGMA JUNIPER BACC SIGMA COMPANY LIMITED, Melbourne" 3210.9 - "EICHORNS REMEDY 100 mm Help in Every Drop" 3210.10 - on base -"J983 / M 2 " 3210.11 - "PYREX Made in England 200 ml" 3210.12 - "CAL"glass-containers pharmacies-orbost medicines chemists-orboet -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchWW2 Field Telephone/Communication Instrument; German

Used in WW2. Basically of german origin and manufacture but 'English' handset suggests capture and use by Australian forces possibly in Middle East Desert warfare.Black Rectangular Metal Box with Lid. Total Height 215mm (with lid closed), Body Height 140mm. Lid Height 75mm.Lid attached by full length Hinge on rear and locking Clip at front.Depth 90mm. Length 275mm. Lid Outside: has overlapping lip to body when closed.Reinforcing metal attachment on left side rolls over to inside of lid and is attached by two screws. Front locking clip is spring loaded and attached to lid by 3 screws. Lid Inside: Flexible metal plate to clip on handset. 2 inscription plates on left and right ends and telephone handset described separately Body Outside:Front: 2 Jack plug points, vertically aligned 85mm from left, 25mm apart either side of mid point of height of bodyprotedted by protective pivot plate. Air vent plate attached with 2 screws adjacent to Jack plug holes (same on Back). Left side at top; metal plate for carry strap (same on right side). carry strap not with item.Right side; hole covered by protective cover plate centred 70mm from base , Wind-Up handle attached (described seoarately. Body Inside: 2/3 filled with visible metal and bakelite components in separate compartment containing unseen working parts. Left side contains morse code key in canvas bag (described separately). Contents Inside Lid. Two schematics of wiring layouts attached to left and right ends. Removable Bakelite handset clipped into postion for carrying, attached cable has 4-pronged attachment connected to main section in body. Contents Inside Body. Most working parts hidden inside metal container. White plastic button 'Pruttaste' is a test button; threaded screws on top for attachments not present.Two pieces of loose wire purpose unknown. Canvas Bag with zip, labelled DD with arrow between (Department of Defence) containing Morse Code Key; wire with large jackplug attachment connected to MC Key through the bag. Jackplug connects via front of body of object. The whole of this item is stored in left inside of body.underside of handset says PRESS KEY WHILE SPEAKING and in smaller font size TELE HD NO 2 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Match Safe, after 1830's

This match safe was amongst various items collected from a sea dive in Port Phillip Bay. The diver was the caretaker of the Port Lonsdale Lighthouse, who dived on various wrecks in the bay during the 1960's. After the caretaker's death, his son sold off many of the shipwreck artefacts. The match safe was purchased from the caretaker's son in the 1990's by a previous owner of the Marine Shop, Queenscliff, Victoria. Pocket match safes or match safes were small portable boxes, or containers made in a great variety of forms and shapes, each with lids or covers to contain matches and retain their quality. Matches came into use around the 1830's and were produced extensively between the years 1890 and 1920. During this period everyone carried strike anywhere matches, so they could ignite stoves, lanterns and other devices. Early matches were unreliable and prone to ignite from rubbing on one another or spontaneously. Accordingly, most people carried a match safe to house their matches. Wealthy people had ‘match safes made of gold or silver, while common folk had ones made of tin or brass. They were made throughout the world including the United Kingdom, in the U.S.A., continental Europe and Australia. Significant English makers of cases were, Sampson Mordan and Asprey & Co. Significant American manufacturers of match safes include Wm. B. Kerr, Gorham, Unger Brothers, Battin, Blackington , Whiting, George Scheibler and Shreve & Co. Different patterns and types run into thousands as well as plain and decorative examples. They were also made in a wide range of materials, including pressed brass, pressed tin, gunmetal, nickel silver, gold, bone, ivory, the wood of varying types, early plastics like tortoiseshell and Bakelite, and ceramics. A distinguishing characteristic of match safes is that they have a ribbed surface, usually on the bottom, for lighting the matches. The item gives a snapshot into the social development through it's application in every day use match safes were used at a time when there were no safety matches and the early use of matches was a dangerous affair given they were easily combustive if rubbed together in a pocket for example. The item is also an example of the shipwreck artefacts gathered along the southwest coast of Victoria.Match Safe; hollow brass cylinder with ribbed match striker texture on base and screw thread around top. Fitted brass lid has an internal screw thread, and the top's flat surface has concentric circles design, with a twisted rope pattern grip around the edge. flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, shipwreck artefact, port phillip bay, port lonsdale lighthouse, wreck, 1960’s diver, queenscliff marine shop, match container, match safe, matches, fire lighter, fire safety, heat, fire, portable match safe, 19th century -

Mont De Lancey

Mont De LanceyDomestic object - Four Medicinal Bottles, Sigma, Unknown

These medicinal products were used in the 1900's. Eucalyptus oil was used both externally for Lumbago, Rheumatism, Sciatica, Sprains, Cuts, Bruises and Burns and for all Throat and Cough disorders. McKean's Camphorated Oil was to be used carefully and under strict Accordance with the instructions. Adults to rub briskly on part affected, Infant use to be massaged gently. McKean's were in operation from 1890's - c1960's. The company appeared to have ceased in 2012. Friars Balsam similarly was used externally for Cuts, Wounds, etc. Could be taken internally for Coughs, Colds, Bronchitis, etc. 10 drops to one teaspoonful. The Bosisto bottle probably contained eucalyptus oil.Four glass medicinal bottles: 1. A small clear glass McKean's "Helping Hand' Eucalyptus Oil bottle, with a faded paper label with Trade Mark surrounding a hand illustration with leaves. Unadulterated is printed at the bottom of this label. Pure Eucalyptus Oil with its uses is included. On the back is a paper label with further instructions for use. The screw top bakelite lid is broken. 2. An angular shaped small brown SIGMA Camphorated Oil bottle with a stained paper label of the manufacturer details and uses. It has 'NOT TO BE TAKEN' stamped into one of the edges on the side of the bottle. Two other sides have three rows of crosses as a pattern. The metal screwtop lid is rusted. F1071 is stamped on the base. 3. A very small round brown Rolfe's Friars Balsam bottle with a broken cork stopper. It has a faded paper label with uses and the manufacturer's details. 4. A small blue tinted clear glass J. Bosisto medicine bottle with rounded corners and flattened sides on the front and back surfaces.The flat lip at he opening could have been sealed with a stopper. The sides of the bottle have a vertical joining line.1. 'McKean's 'Helping Hand' Eucalyptus Oil'. It has a faded paper label with 'Trade Mark (Registered) surrounding a hand illustration with leaves. Pure Eucalyptus Oil' 2. 'SIGMA Camphorated Oil SIGMA CO. LTD Melbourne'. 3. 'Rolfe's FRIARS BALSAM Rolfe & Co. Ltd. Melbourne'. 4. 'J. Bosisto Richmond' is stamped on front side of the front. On the base is stamped ' "English Bottles" '.medicines, medicine bottles, medicinal containers -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchGreat Coat, Bradley's Industries N.S.W, 1951

Long khaki coloured heavy coat. Thick, sharp angled collars. Right collar has a hook and eye attached in the lapel split. Collar has zig zag stitching and two plastic buttons on each the left and right sides. Each shoulder has a lapel that is fastened with a plastic button. The coat is double breasted. Three buttons on the right side, held in place by metal loops on the interior rather than stiches; mirrored on the left side. Left interior has oval shaped fabric buttoned to the interior with two brown (possibly bakelite) buttons. A larger brown button sits atop the smaller as a means of closing the jacket from the inside. There are two pockets on the front that are angled with the highest point near the centre and the lowest point near the hips. The arms, underarm and upper back section contains an inside khaki coloured lining of thinner, most likely cotton fabric. Above this there is a thin strip of fabric attached at either short end to use for hanging the coat on a hook. At the back of the coat there is a single pleat stretching from the base of the neck to the base of the coat. Approximately half way down the pleat there is a split in the fabric that is fastened with two plastic buttons. At the waist there are two fabric flaps that fasten together at the back with three buttons, also held in place with metal loops on the reverse.Label on interior back lining reads "REGIMENTAL No./NAME" Label on interior of the right "GREATCOATS. G.S. 1946 Patt/SIZE 1/HEIGHT 5'3"/CHEST 34"-36"/BRADLEY'S INDUSTRIES N.S.W./1951" Handwritten on label, "M J Davis"post war, army uniform, great coat, inter war, uniform, military uniform, wool, greatcoats, bradley's industries -

Bendigo Military Museum

Bendigo Military MuseumUniform - SERVICE DRESS, RAMC, BRITISH, unknown

R.A.M.C. = Royal Army Medical Corps - British. Uniform issued to Captain McKenzie. refer Cat No. 7875.5 and 7876.2.1. Jacket - black and crimson colour wool velvet type fabric. Crimson colour fabric on collar and sleeve cuffs with gold braid edging. Mandarin collar with two gold and silver metal collar badges - crown, snake on pole, laurel wreath and ribbon scroll with lettering - "ROYAL ARMY MEDICAL CORPS" - British - Tailor made uniform. Shoulder epaulettes - gold colour twisted braid with two gold, blue and green metal rank pips = Lieutenant. on right epaulette. Gold colour metal buttons with shank, raised emblem and lettering - (same as collar badges). Lining - combination top gold colour, lower black colour silk fabric. Sleeve - white colour cotton fabric. At waist red leather lining strip. Brass colour metal belt hooks. Manufacturers label on white cotton fabric, inside on collar. 2. Trousers - stirrup pant style, black colour wool fabric, six button fly. Crimson colour, wool fabric. Three 1.5 cm strip down each side. Black colour bakelite buttons. White colour cotton fabric lining to waistband. At ankles - black leather straps with metal buckle. Manufacturers label on white cotton fabric label with black ink print and handwritten details - back, inside below waistband lining.1. & 2. Black ink print "HOLT & SON/ Military Tailors/ 20 Sackville Street, PICCADILLY, W". Handwritten black ink pen "T.F.C. McKENZIE/RAMC"uniform, ramc, british, ww1, service dress, mckenzie -

Stawell Historical Society Inc

Stawell Historical Society IncInstrument - Realia, Engineering Instruments from Northern Grampians Shire

1: Small cardboard box with lid containing Silver distance Measurer. This was used for Measuring distances on plans.(Planimeter) 2: Cardboard Box without lid containing three plumbobs: One large turned brass: one small turned metal. One circular silver coloured metal complete with string and winding board. These were used to locate survey equipment above a fixed point. 3: Timber ( Vic Ash?) dovetailed box with brass hinged lid and brass swing catches containing plywood templates called railway curves, used for drawing curves on plans. 4: Cardboard box with lid containing Allbrit panimeter in Bakelite/plastic box with silver metal hinges and catches "Shire of Kara Kara" inscribed on the box. The box contains the original Instructions. The Planimeter was used for calculating areas of Irregular shapes and used for estimating quantities from plans of cut and fill projects, as one example. 5: Timber Box with brass hinges and swing catches wand leather carry Strap containing one set of self adjusting level made by E.R. Watts and Son, London England. Paper label on the inside "Shire of Stawell". Also had paper instructions pasted to the inner lid. The level was used for taking Ground Levels. The first 3 have been in use up until the 1990's, when computer drafting took over the role of these instruments with greater speed and accuracy. The dumpy level would have been superseded in the 1980's when automatic levels became cheaper, and were more accurate. stawell -

Bendigo Military Museum

Bendigo Military MuseumUniform - MESS DRESS, RAMC, BRITISH, unknown

R.A.M.C. - Royal Army Medical Corps - British. Uniform issued to "Captain McKenzie". Refer Cat No. 7874.2 and 7876.2.1. Jacket - Mess Dress style. Black and crimson colour wool fabric. Crimson colour fabric on rolled collar and sleeve cuffs. On collar are two gold and silver metal collar badges - crown, snake on pole, laurel wreath and ribbon scroll with lettering "ROYAL ARMY MEDICAL CORPS" British - Tailor made. Shoulder epaulettes - fabric with three tarnished gold, blue and green metal rank pips = Captain. Gold colour buttons with shank, raised emblem and lettering (same as collar badges). Lining - crimson colour body of jacket with concealed internal pocket. Sleeves - white colour cotton fabric. Manufacturers label on white colour cotton fabric, back, inside collar. 2. Vest - crimson colour wool fabric, front two inset pockets and four buttons (as above). Back - crimson colour cotton sateen fabric with strap and brass metal buckle for size adjustment. Lining - cream colour cotton fabric. 3. Trousers - black colour wool fabric with five button fly, fob pocket cream colour cotton lining to waistband and fob pocket. Black colour Bakelite buttons. Two silver colour metal buttons at back. Manufacturers label on white colour cotton label with black ink print and handwritten details - back, inside below waistband lining. 4. & 5. Part of crimson colour wool fabric three 1.5 cm strips on black colour wool fabric backing. These have been removed from a garment.Manufacturers information. 1. & 3. Black ink print 'HOLT 7 SON/Military Tailors/ 20 Sackville Street, PICCADILLY W." Black ink pen, handwritten "T.F.C.. McKenzie/RAMC".captain mckenzie, uniform, ramc, british, ww1, mess dress -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePen Nibs, 1920's

The two cards of nibs are retail display cards of the dip pen nibs that William Mitchell Calligraphy produced, dating back to around the 1920’s, which was the time of the Great Exhibition in the UK. At that time dip pens with steel nibs were the main writing instruments. British Pens Ltd. had recently formed as a company and its subsidiaries included the the company William Mitchell, which is why British Pens Ltd. is named on the cards as well. One card (1) has the Round Hand nib, which is widely used today for calligraphy scripts. The other card (2) has the Script nib that has round upturned points for monocline or unshaded lettering that is also used for calligraphy. The nibs also have a detachable reservoir. The pen nibs are shaped to fit into a slot in the base of a wooden or Bakelite pen holder. The hole at the front of the nib is for collecting ink from a well, which is then stored in a reservoir at the back of the nib. The nibsare stamped with their nib size and Pedigree (what type of nib it is) and maker’s details. William Mitchell Calligraphy still makes these nibs today with a slightly difference finish. (ref: Sales and Marketing Director of William Mitchell Calligraphy in 2016). HISTORY of the Ink Pen Quills and ink were common writing tools until the early 19th century when the pen trade began mass producing steel nibs and pens. The steel nibs each have a hole in the middle that acts like a well for the ink. When the nib is dipped into the ink well the writer needs to ensure that it is dipped to only just past that well. India Ink was one of the most popular inks used with the nib pens, notable for its satin-like smooth flow. This ink is composed of a particularly fine carbon mixed with water; it can also be obtained as a dry stick that is then crushed and mixed with water as required. The Jewellery Quarter of Birmingham had the largest concentration of independent jewellers in Europe. Birmingham became the centre of the world’s pen trade for many years -, during the 1800’s over 100 factories, employing 1000s of skilled workers, manufactured the ‘Birmingham Pen’. ABOUT WILLIAM MITCHELL CALLIGRAPHY LTD.* (*The following text is quoted from the William Mitchell Calligraphy website) British based William Mitchell Calligraphy has been designing and manufacturing exceptional pens for almost 200 years. The William Mitchell heritage in making pen nibs began whilst working with his brother John Mitchell in the early 1820s. William Mitchell established his own business in 1825 to become one of the leading nib manufacturers and famous for lettering pens. Almost 100 years later William Mitchell merged with Hinks, Wells & Co, another pen manufacturer, to form British Pens, employing around 1000 people in the Bearwood Road area of Birmingham. During the early 1960s British Pens acquired the pen business of other pen manufacturers Perry & Co and John Mitchell, once again reuniting the two brothers. Joseph Gillott, who were famous for their artist drawing and mapping nibs, amalgamated with British pens in 1969. William Mitchell and Joseph Gillott established in Birmingham during the early part of the nineteenth century and [their products] are still proudly made here. British Pens were subsequently purchased by its current owner Byron Head, the owner of William Mitchell (Sinkers) in 1982, and was subsequently renamed William Mitchell (calligraphy) Ltd. Established in 1827 Joseph Gillott was one of the pioneers of mass steel pen nib manufacturing. The company was particularly strong in the American market, prompting Elihu Burrit, the American consul, to write “In ten thousand school houses across the American continent between two oceans, a million children are as familiarly acquainted with Joseph Gillott as with Noah Webster” (The compiler of the famous American dictionary). The company consequently received visits from many notable Americans, including president Ulysses S Grant. The early 19th century invention and mass production of pen nibs such these in our collection had a large impact on education and literacy because the nibs could be produced in great numbers and affordable prices.Pen nibs; 2 cards of steel dip pen nibs from the 1920’s. The steel nibs are attached to cards by 2 rows of entwined cotton cord. Reverse sides of cards have some hand written marks. Manufacturer; William Mitchell, Birmingham, England. Card issued by British Pens Ltd. Nibs have shaped ends, a hole in the centre with a well on the underside, and the tops are shaped approximately quarter circle. Inscriptions are pressed into each nib. The script pens have detachable reservoirs made of a metal different to the nib. (Card 1) Round Hand Pens, 11 nibs remain from card of 12. Printed on card “Round Hand Pens for Beautiful Writing, Twelve degrees of point, Square points. William Mitchell, Birmingham, England. This card is issued by British Pens Ltd. MADE IN ENGLAND” Also printed on top left of card is a pen drawing of a person writing at a desk, background of decorative 3-paned window in brick wall. (Card 2) Script Pens; 11 nibs remain from card of 12. “Script pens fitted with detachable reservoir. William Mitchell, Birmingham, England. This card is issued by British Pens Ltd. MADE IN ENGLAND” Also printed on top right of card is a pen drawing of a person writing at a desk, background of decorative 3-paned window in brick wall. On Card 1, - each nib is stamped with its size, and “Wm MITCHELLS / PEDIGREE / ROUND HAND / ENGLAND” - hand written on front bottom of card in ball point pen “Lettering 5 times size of nib” - hand drawn on back of card in red and blue ball point pen are scribbled lines On Card 2 - each nib is stamped with its size, and “WILLIAM / MITCHELLS / SCRIPT PEN / ENGLAND” - a black circle corresponding to the nib is printed on the card above each nib. - hand written on back of card in black felt tip pen are numerals - hand drawn on back, 4 parallel lines in red ball point pen with the numbers “10” between 2 of the lines flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, william mitchell calligraphy ltd, british pens ltd., pen nib, writing implement, dip pen, round hand nib, script nib, birmingham manufacturer, communication in writing, mass produced pen nibs -

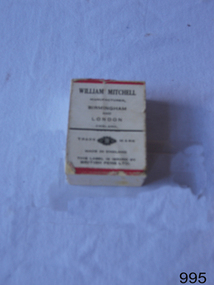

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageNibs & box, late 19th to early 20th century

Box of dip pen nibs made by William Mitchell Calligraphy dating back to late 19th or early 20th century when dip pens with steel nibs were the main writing instruments. The pen nibs are shaped to fit into a slot in the base of a wooden or Bakelite pen holder. The hole at the front of the nib is for collecting ink from a well, which is then stored in a reservoir at the back of the nib. The nibs are stamped with their nib size and Pedigree (what type of nib it is) and maker’s details. William Mitchell Calligraphy still makes these nibs today with a slightly difference finish. (ref: Sales and Marketing Director of William Mitchell Calligraphy in 2016). HISTORY of the Ink Pen Quills and ink were common writing tools until the early 19th century when the pen trade began mass producing steel nibs and pens. The steel nibs each have a hole in the middle that acts like a well for the ink. When the nib is dipped into the ink well the writer needs to ensure that it is dipped to only just past that well. India Ink was one of the most popular inks used with the nib pens, notable for its satin-like smooth flow. This ink is composed of a particularly fine carbon mixed with water; it can also be obtained as a dry stick that is then crushed and mixed with water as required. The Jewellery Quarter of Birmingham had the largest concentration of independent jewellers in Europe. Birmingham became the centre of the world’s pen trade for many years -, during the 1800’s over 100 factories, employing 1000s of skilled workers, manufactured the ‘Birmingham Pen’. ABOUT WILLIAM MITCHELL CALLIGRAPHY LTD.* (*The following text is quoted from the William Mitchell Calligraphy website) British based William Mitchell Calligraphy has been designing and manufacturing exceptional pens for almost 200 years. The William Mitchell heritage in making pen nibs began whilst working with his brother John Mitchell in the early 1820s. William Mitchell established his own business in 1825 to become one of the leading nib manufacturers and famous for lettering pens. Almost 100 years later William Mitchell merged with Hinks, Wells & Co, another pen manufacturer, to form British Pens, employing around 1000 people in the Bearwood Road area of Birmingham. During the early 1960s British Pens acquired the pen business of other pen manufacturers Perry & Co and John Mitchell, once again reuniting the two brothers. Joseph Gillott, who were famous for their artist drawing and mapping nibs, amalgamated with British pens in 1969. William Mitchell and Joseph Gillott established in Birmingham during the early part of the nineteenth century and [their products] are still proudly made here. British Pens were subsequently purchased by its current owner Byron Head, the owner of William Mitchell (Sinkers) in 1982, and was subsequently renamed William Mitchell (calligraphy) Ltd. Established in 1827 Joseph Gillott was one of the pioneers of mass steel pen nib manufacturing. The company was particularly strong in the American market, prompting Elihu Burrit, the American consul, to write “In ten thousand school houses across the American continent between two oceans, a million children are as familiarly acquainted with Joseph Gillott as with Noah Webster” (The compiler of the famous American dictionary). The company consequently received visits from many notable Americans, including president Ulysses S Grant. Email on file, from Mike Chappell, Sales and Marketing Manager, William Mitchell Calligraphy, “20161122 - William Mitchell re pen nibs” How to use a dip pen to create modern calligraphy, https://thepostmansknock.com/how-to-use-a-dip-pen-to-create-modern-calligraphy/ India Ink, Wikipedia https://en.wikipedia.org/wiki/India_ink birmingham Pen Trade, Wikipedia, https://en.wikipedia.org/wiki/Birmingham_pen_trade The Pen Museum, http://penmuseum.org.uk/ The early 19th century invention and later mass production of pen nibs such these in our collection had a large impact on education and literacy because the nibs could be produced in great numbers and affordable prices.Box of patent Mitchell nibs containing 48 "Pedigree" nibs. Box depicts picture of William Mitchell on lid, and picture of nib pen on lid and side. Made in Birmingham, England. Nib “0505 Wm MITCHELLS PEDIGREE ENGLAND” Box “PEDIGREE / MAINFOLD SLIP”, “WILLIAM MITCHELL / BIRM - - - - - - LOND” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, william mitchell calligraphy ltd, pen nib, writing implement, writing accessories, dip pen, birmingham manufacturer, communication in writing, mass produced pen nibs -

Federation University Historical Collection

Federation University Historical CollectionObject, Synchronome Co. Ltd, Synchronome Frequency Checking Master Clock No. 2191, c1930

Information from Norman F. Dalton: Ballarat had a reticulated DC supply in the early part of last century and in 1905 had sufficient generating capacity to enable the trams to be changed from horse drawn to DC electricity. The use of electricity increased with the main power station located on Wendouree Parade, near Webster Street, under the ownership of The Electric Supply Company of Victoria. AC generating plant was installed in 1925 and conversion to AC proceeded. In 1934 the company was taken over by the State Electricity Commission Victoria (SECV) and more AC generation was installed and the changeover of customers was accelerated. This is around the time that the Synchronome Frequency Checking Mast Clock was installed at the Wendouree Parade Power Station. The SECV Annual Report of 1921 states: ::Section 11 of the act directed the COmmission to enquire into the question of securing the adoption of such standards of plant and equipment of a system, frequency and pressure for the generation and distribution of electricity as will admit of the efficient interconnection of undertakings throughout the State. In 1934 when the SECV took over the Ballarat operations the question of linking with the State grid had been a planned operation for some years but due to financial considerations had hindered it and in fact would continue to do so for a further 10 years. So while the need for close frequency control for interconnection was hardly an issue, the need to keep electric clocks correct was important, particularly as this item was a frequent sales point to cover the inconvenience and sometimes expense of converting from DC to AC. The clock is a very accurate pendulum clock with provision for varying effective length during operation for precise time regulation. There are two normal time dials and one is controlled by the pendulum and the other is operated by the system frequency. When the clock was in use it was installed by the MEter and Tests Laboratory and the time was checked daily by radio time signals. The two dials were repeated in the operators control panel in the Power Station. A maximum deviation between the two dials was set in the operating instructions (eg 5 seconds) and the operator would correct this when necessary by remote manual alteration of the turbine governor set point. The clock was used to drive and regulate a system of "slave" clocks which were used to display the time in various locations around the power station. A slave clock is a simple clock which is driven by a small electric motor, its accuracy is regulated by the master clock every 30 seconds to ensure that it and all the other slave clocks in the station are on exactly the right time; slave clocks were placed in various locations, from common rooms to workshops. A master clock could potentially run thousands of slave clocks at one plant. The clock also contains a rectifier. A rectifier is a device that is used to convert AC power to more stable DC current.Two clocks in a timber case. Both are electric, one is powered by the main pendulum mechanism, the other is a self contained electric clock. The main mechanism is of the gravity arm and roller type, which sends an impulse to the slave clocks every 30 seconds. The This Synchronome Frequency Checking Master Clock was used at the Ballarat Power Station. Below the main section of the case is a smaller cabinet containing a rectifier to provide consistent DC power for the clock. The rectifier was made by the Victorian company Hilco, which was located in Burwood. There is a high chance this is not the original rectifier from this clock as there appears to be brackets to hold a larger device in the space the rectifier occupies.Front below main clock face on front of case: "Patented Sychronome Brisbane" Lower left-hand clock face: "Frequency time" Lower right-hand clock face: "Standard Seconds" Synchronous electric clock mechanism on door (Frequency time clock): >200/250 V. 50~ >"Synchronomains" Made in England >Direction indicator for clock starting switch >"To start move lever in direction of arrow and release" >"Patent applied for" Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for main clock face: >"English Made" >"Patented" >Serial number "8751" >0 above right-hand pillar on front-plate Inside case, back panel, top enamel plate: >Seconds Battery + Pos. > Battery Common or - Neg. >1/2 min dials Inside case, back panel, bottom enamel plate: external seconds dial Inside case, right hand side, electrical knobs: two switches, both "A.C. mains" Pendulum rod, below suspension spring: Serial number (?) 0000005 Rectifier in bottom cabinet: >"Hilco Rectifier" >"A.C. Volts 230/240" >"Model 1060/S" >"A.C. Amperes" >"Serial No. 1060/S >"Phases 1" >"D.C. Volts 6" >"C.P.S. 50" >"D.C. Amperes 1" >"Made in Australia by Hilco Transformers McIntyre St., Burwood, Victoria." Bakelite electrical plug: makers mark Lower cabinet, RH side panel, pressed tin plate: "AC" (upside down) Brass speed adjustment, outer right RH side: "S" and "F" Ivory and wood pendulum beat ruler: >Ruler, with 0 in centre and numbers 1-5 in ascending order from centre on left and right. > "Synchronome Patent." Steel plate, back panel, inside case, right hand side: >N R A" (descending) >"2191" serial number/part number Face of main clock: "Synchronome Electric" synchronome frequency checking master clock, electricity, state electricity commission, wendouree parade power station, secv, clock, time, pendulum, electric supply company of victoria, norman f. dalton, ballarat power station, rectifier, slave clock -

Nhill Aviation Heritage Centre

Nhill Aviation Heritage CentreMemorabilia - aircraft identification models, c1940

Models originated at the Nhill Air School during the war. These models were used for instructional purposes.Bakerlite model identification planes, Kittyhawk, Grumman F6F Hellcat, Tony (Kawasaki Ki61)116.1 Curtis p 40E Kittyhawk E9-2183, 116.2 F6F Hellcat E9-3810, 116.3 "Tony" E9-3309bakelite model, model plan, identification model, len pilmore -

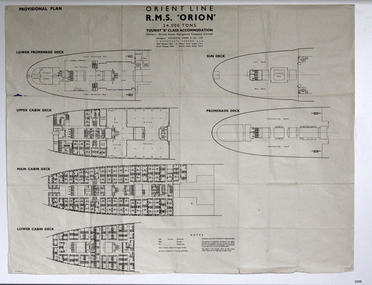

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlan - Ship Plan, Orient Steam Navigation Company, Orient Line, RMS Orion, ca. 1934

The Orient Steam Navigation Company Limited launched the Ocean Liner RMS Orion in 1934 and it remained in operation until 1963. The twin screw steamship was built to carry first class and tourist class passengers, over 1100 in all, plus almost 500 crew from Europe to Australia in comfort. The ship had a single funnel and a single mast. During WWII the vessel served as a troop carrier. The ventilation system noted on the plan, Punkah Louvre System, was designed for heating fresh air ventilation in buildings, ships and railroads. The system originated from Thermotank in Glasgow, Scotland. The ship plan for the RMS Orion is significant for its connection with the vessel. The ship was a leader, with several 'firsts'; the first Orient Line ship to be built with a single funnel since 1902, and the first to be painted in the Orient Line's livery, with a corn-coloured hull. It was the first liner to use chromium and bakelite materials for the surfaces throughout the ship, which provided greater resistance to the sea. It was also the first British ship to be fitted with air conditioning.Plan: printed provisional line drawing of the Orient line vessel "R.M.S. Orion". Inscriptions are printed on the plan. There are diagrams of six decks included in the plan. The ship is built for tourist "B" accommodation. The plan's Notices include details of the cabins including wardrobes, drawers, hinged seats, mattresses and bunk numbers. It also notes that there is a Punkah-Louvre System of Ventilation.Printed on the plan: "PROVISIONAL PLAN" "LOWER PROMENADE DECK" "UPPER CABIN DECK" "MAIN CABIN DECK" "LOWER CABIN DECK" "SUN DECK" "PROMENADE DECK" "ORIENT LINE / R.M.S. "ORION" / 24,000 TONS / TOURIST "B" CLASS ACCOMMODATION" "Owners: Orient Steam Navigation Company Limited"' "Managers : ANDERSON, GREEN & CO. LTD" "7 BISHOPS GATE, LONDON, E.C.2" "Chief Passenger Office : 14 Cockspur Street, London, S.W.1" "Branch Passenger Office : 1 Australia House, Strand, W.C.2" "notices"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, rms orion, plan, ship plan, provisional plan, orient line, orient ship, vissel orion, class b passenger accommodation, punkah louvre system of ventilation, deck plan, ship ventilation, ship floor plan, orient steam navigation company limited, anderson green & co ltd, steamship, ocean liner, war ship, troop carrier -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Lamp fitting double holders, Middy's Aust, c 1930

Made in Australia by Middy's Used by a pioneer family in Moorabbin. Manufactured by Middy's: Arriving in Australia at age 19 by ship at Port Melbourne, Dutch immigrant Petrus Cornelis Nicolaas Middendorp (1891-1963) settled in Melbourne to apply his trade as a cigar maker for the British American Tobacco Co. Retiring from the cigar industry and following his work as an honorary orderly tending WW1 Australian casualties in Paris and Melbourne, Petrus began selling Dutch manufactured light globes, vacuum cleaners and other electrical products imported from Holland and England. Warehousing and sales of the goods were undertaken from 1928 by the ‘Middendorp Goods Supply Company’ initially located in Flinders Lane in Melbourne’s CBD, then moving to McKillop Street, followed by a basement store at 148 Queen Street. During the 1940s a manufacturing plant known as ‘Middendorp and Sons’ was established in the Melbourne suburb of Preston, where Petrus’ three teenage sons Peter, Nick and Hugh joined him. Peter and Hugh worked with a small team of staff to produce rubber plug tops, extension sockets, double adaptors and a small range of bakelite accessories, whilst Nick became the first sales rep calling on customers and construction sites. The products were sold under the brand name of ‘Middy’. A name change of the distribution business took place in the late 40s and Middendorp Electric Company Pty Ltd was officially registered in 1948. The manufacturing operation ceased during the late 50s due to the introduction and acceptance of plastic and injection moulding. However, the Middendorp family had positioned itself to further establish its electrical wholesale business with the first branch and Head Office opening in 1956, located at 520 Latrobe Street, Melbourne. By 1962 there were five trading branches, growing to 25 in 1986 and 101 by 2018 Australia wide. Middendorp Electric, more commonly known as Middy’s and readily identified by its trademark colour of Middy’s pink, has developed into the largest privately owned Electrical Wholesaler in Australia. In 2015 Middy’s acquired Mekolec lifts fire and electrical adding presence and sector expertise in Melbourne’s inner south. In Sep 2018 Middy's acquired Salmon Brothers Electrical, with 5 Branches in Sydney's Metro region and in 2019 they acquired Goulburn Electrical Wholesalers greatly adding to Middy's location coverage in NSW and providing Middy’s the ability to better service NSW contractors. Bakerlite electrical fittingMiddy - Made in Australiamiddy's, moorabbin pioneers, electrical, bakerlite -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumButton - bakelite

Part of local man Ren Smith, ex RAAF, WW2 serviceman's memorabilia.Small round black shank button featuring crown and eagle.To - 283ren smith, raaf uniform accessories, bakelite buttons