Showing 102 items matching "metal testing"

-

Stawell Historical Society Inc

Stawell Historical Society IncInstrument - Realia, Textile Fabric Pilling Testing Machine, c1950

Used at Norwellan for testing cloth North Western Woolen Mills became Norwellan Textiles then AUNDEWood and iron Instrument with handle that drags metal pin repeatedly over a cloth sample.Peg Load Checked at 2 lbs 20.11.69manufacture -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumClothes Wringer

Made by Good Housekeeping InstituteClothes mangle [wringer].Wooden metal Turning Handle ,Ratchet,screws and nuts .2 Top screws for pressure B/N Rollers - photo 0027Trade "Acme" British +Bets Serial No. 165 --Tested and approved.wringer, mangle, washing, clothes -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Equipment - Natural Gas Conversion Testing Kit

... 1. Gas testing kit in green metal box, with silver handle... H.V.Allen MSA 1. Gas testing kit in green metal box, with silver ...All items belonged to Harold Victor Allen who worked for Colonial Gas Association Ltd. Firstly at Footscray and then Box Hill in the 1960's. Retired in 1971. Born in Ballarat in 1906. Apprenticed and worked there till 1945, then moved to Footscray. Eileen, his wife, worked with Harold, helping with the Natural Gas Conversion during Harold's Box Hill time.Change over in Victoria from Gas fired gas supply to Natural Gas supply to Victoria from about 1965 -1. Gas testing kit in green metal box, with silver handle and clasp (silver colour)|2. Suction ball and pump body.|3. Detector tubes of glass capillary. 4. Instruction Manual. 5. Sealing cap ( box of 10) All spare parts |6. Natural Gas Conversion Badge.H.V.Allen MSAgas technology, appliances & accessories -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Pioneer Test Tools, Instruments and Equipment Manual, Pioneer Test Tools & Equipment

... Moorabbin melbourne Dark brown hard-cover folder bound with metal ... -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Pioneer Instruments Test Procedures Manual, Pioneer Test Procedures

... Moorabbin melbourne Dark brown hard-cover manual bound with metal ... -

Moorabbin Air Museum

Moorabbin Air MuseumBook (Item) - Australian Institute of Metals - Definitions and Terms used in the Heat Treatment and Testing of Metals

... - Definitions and Terms used in the Heat Treatment and Testing of Metals ... -

Moorabbin Air Museum

Moorabbin Air MuseumBook (Item) - Australian Institute of Metals - Definitions and Terms used in the Heat Treatment and Testing of Metals

... - Definitions and Terms used in the Heat Treatment and Testing of Metals ... -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Instruction Book, Westinghouse Brake Company of Australasia Limited and The Westinghouse Brake & Saxby Signal Co. Ltd. of 82 York Road and Kings Cross London, "Westinghouse Railway Operating Data", 2000

Photocopy of 54 data sheets published by Westinghouse Electric & Manufacturing Company of East Pittsburgh Pa, USA c1920. Consists of plastic cover, header page with Westinghouse logo, contents sheets (2 pages), forward, 67 pages (single side photocopy) and heavy rear card cover bound with a green comb binder. Original material lent by Craig Tooke of the Melbourne Tramcar Preservation Association at Haddon. Photocopied by Warren Doubleday March 2000. List of contents produced 30/6/2000 and then bound. Contains data sheets regarding motors, commutators, brushes, armatures, bearings, field coils, pinions, lubrication, air piping, axle collars, resistance grids, gear cases and other technical information. Westinghouse Railway Operating Data 30/6/2000 List of Contents Page No. Care and repair of commutators 1 Undercutting commutators 2 Railway Motor carbon brushes 3 Brush holders 4 Flashing of railway motors 5 Soldering railway armatures 6 Armature Winding 7 Banding armatures 8 Railway Motor Bearings 9 Lubrication of railway motor bearings 10 How to babbitt motor bearings 11 Oil, grease and waster for motors and gears 12 Saturation of motor bearing waste 13 Testing Polarity of Field Coils 14 Charging of storage batteries on Interurban & street rail cars 15 Precautions to be taken with blower installations on motor cars 16 Putting on Railway Motor Pinions 17 How to take armatures out of box frame motors 18 Dipping and Baking of Railway Motors 19 War time dipping and baking outfits 20 Dipping and baking railway motors will decrease troubles 21 Protection of Motor Bearings from Dust 25 Winter Operation of Railway Motor equipments 26 Installation of Air piping to prevent freezing 27 Maintenance of Traction Brake Equipment 28 Maintenance of controller fingers and contacts 29 Hand operated circuit breakers 30 Railway Motor Testing I 31 Railway Motor Testing II 33 Railway Motor Testing III 35 Railway Motor Testing IV 36 Railway Motor Testing V 37 Removing and replacing railway motor armature shaft 39 Mounting and Maintenance of car resistors 40 Lubrication of control apparatus 41 Maintenance of fuse boxes for railway service 42 Does it pay to dip and bake armatures 43 Dipping and Baking as a financial asset 44 Shop Organisation 45 Tinning Malleable Iron Bearing shells 46 Life of armature bearings or railway motors 47 The assembly of complete sets of commutator segments 48 Electric welding as a factor in reclamation 50 Metal to Metal press, shrink and clamping fit allowances 52 Life of railway motor carbon brushes 54 General information of grid resistance design for the operating man 56 Stopping a car by braking with the motors 57 Railway Motor shafts and their maintenance 58 Axle collars 59 Gear cases 60 Ventilated railway motors 62 Revamping Loose armature bearings 64 Life of axle bearings of railway motors 65 Heat-treated bolts for railway service 66 Document imaged over 7 parts 7-9-2016 - see hi res files. trams, tramways, westinghouse, motors, data sheets, technical information -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Trolley Wire Sample, Metal Manufacturers - Kemba Wire and Rod of Port Kembla NSW, Oct. 1996

Sample length (260mm long) of 107mm2 trolley wire supplied by Metal Manufacturers (Port Kembla Wire and Rod) - November 1996, Used in ceremony of 26/11/1996 when Victorian Minister of Transport, Alan Brown handed over the Trolley Wire (2km) to Museum. Sample supplied ex Test lab - had been tested for hardness. Wire type known as HC - high conductivity. Images added 3-12-2016 See Courier p6 of 27/11/1996 - see Reg. Item No. 503. trolley wire, btm -

Moorabbin Air Museum

Moorabbin Air MuseumDocument - T.Q.R.39 Performance Tests on DHAx3cDrover Fitted with Fairey Fixed Pitch Metal Propellers, De Havilland Aircraft Australia

-

Moorabbin Air Museum

Moorabbin Air MuseumDocument - Performance Tests on DHA-3 Drover Fitted with Fairey Fixed Pitch Metal Propellers, De Havilland Aircraft Australia

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - Definitions of Terms Used in the Heat Treatment & Testing of Metals, The Australian Institute of Metals

... Definitions of Terms Used in the Heat Treatment & Testing of Metals ... -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Rolls-Royce Nene Engine Assembly and Test Notes, 'Nene' Asembly and Test Notes: Notes on Dynamic Balancing

Written by F. C. Kimberley -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Technical Data for Bell 206B-1 Helicopters, Avionics Test Specification

... Moorabbin melbourne White soft-cover manual bound with metal clasps ... -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, British Engineering Standards Association, "Electrical Machinery excluding motors for traction purposes", 1927-1939

.1 - Book - 56 pages + grey covers, side stapled, issued by the British Engineering Standards Committee "Electrical Machinery excluding motors for traction purposes", No. 72-1917, September 1917. Has "Commonwealth Engineer" label along the bottom edge. .2 - Book 28 pages - light grey covers, side stapled, issued by the British Engineering Standards Association, "Insulating oils for use in Transformers, oil switches and circuit breakers" No. 148-1923, April 1923. Has a Tait Book Co. stamp along the bottom edge and ESCo date stamp 1 Oct. 1925. Printed by Gaylard & Sons London. .3 - Book 72 pages - light grey covers, side stapled, issued by the British Engineering Standards Association, "Tungsten Filament Electric Lamps" No. 161-1925, August 1927. Has a Tait Book Co. stamp along the bottom edge and ESCo date stamp 15 Feb. 1928. Printed by Waterlow & Sons London. .4 - Book 48 pages - light grey covers, side stapled, issued by the British Standards Institution, "Metal Sheathed paper insulated plain annealed copper conductors for electricity supply including voltage tests" No.1 48-1933, March 1933. Has a Tait Book Co. stamp along the bottom edge and ESCo date stamp 15 Feb. 1928. Printed by Waterlow & Sons London. trams, tramways, power station, standards, materials, electrical systems -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Geelong No. 7, 1912

The photograph shows Geelong 7 as built, understood to be a test tram prior to the opening of the system. Photo taken in the then Corio Terrace, now Brougham Street Geelong 1912. Has a number of men on board the tram - depot workers for the photograph? See Item 4314 for another photo looking the other way. Printed by the donor from a negative held by the Museum of Victoria, Science Works. Shows Geelong tram No. 7 as built.Metal framed photograph with card backing, and hanging cord.geelong, trams, tramways, tramcars, tram 7, corio terrace, opening -

Tennis Australia

Tennis AustraliaTrophy, 1982

... International Tennis Test. Materials: Wood, Metal, Plastic, Glue..., featuring two cast metal racquet sculptures, adhered with glue ...A wooden panel trophy, featuring two cast metal racquet sculptures, adhered with glue. Presented to winner of 1982 Robina International Tennis Test. Materials: Wood, Metal, Plastic, Gluetennis -

Kew Historical Society Inc

Kew Historical Society IncEquipment, ACME, The ACME British Made Wringer, 1920-1929

A large device for drying laundry consisting of two rollers between which the wet laundry is squeezed (or wrung); a mangle. American English uses the term 'wringer' whereas UK English uses the term 'mangle'. Later devices were typically electrified.Intact item of household (laundry) equipment.Domestic laundry equipment. Wringer of Mangle. Two rollers in Metal frame. Hand operated."ACME M 14 A WRINGER / ROLLS 14" / ROLLS 14" "THE ACME BRITISH MADE WRINGER / THE WRINGER WITH THE FIVE YEARS GUARANTEE" "USE THIS BOARD FOR MANGLING ONLY / IT FITS ON THE OTHER SIDE OF THE WRINGER / CLOTHES SHOULD BE FOLDED CAREFULLY AND MANGLED SLIGHTLY DAMP. EVEN IF YOU ARE GOING TO IRON IT WILL SAVE HALF THE LABOUR IF YOU MANGLE FIRST." "TESTED AND APPROVED SERIAL No.166 / GOOD HOUSEKEEPING INSTITUTE LONDON / Conducted By GOOD HOUSEKEEPING INSTITUTE MAGAZINE." acme wringer, mangle, laundry equipment -

Brighton Historical Society

Brighton Historical SocietyUniform, Girl Guide uniform, circa 1952-1953

This uniform was worn by Sandra "Sally" Allmand circa 1953-57 as a member of the 3rd St Andrews Girl Guides company in Brighton. Sally Allmand went on to serve on the Brighton Council from 1977 to 1983 and was mayor in 1981.1950s Girl Guides uniform consisting of a dress, belt and beret. Blue cotton dress with long sleeves and high collared neck. Various patches sewn onto sleeves and front breast. Three front pockets fastening with black plastic buttons featuring Girl Guides trefoil logo. Breast pocket has two vertical white stripes. Brown leather belt with silver metal buckle with embossed Girl Guides logo and the text "Girl Guides Association / Be Prepared". Navy blue felt beret with two sewn-on patches. Included with the dress are a Girl Guides 'test card' dated 1953 and a rectangular De Reszke cigarette tin containing a collection of Girl Guide ribbons, patches and buttons. .1 - Dress .2 - Belt .3 - Beret .4 - Test card .5 - Box of patches and ribbonsDress label: "The Guide Shop / STATE HEADQUARTERS / RUN BY GUIDES / FOR GUIDES".girl guides, sally allmand, 1950s -

National Wool Museum

National Wool MuseumFunctional object - Yarn Spinner and Accessories, John Nesbitt, 19th Century

Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design.Custom made wooden hinged box with a hook latch. Brass yarn spinner, attached to a mahogany wood plinth base, which spins fibre into cord/yarn/thread. It has dials to set the rate that it spins. Metal plaque with black inlaid enamel lettering. Small cork inlay. Brass rod with hinge and wingnut, and ball at end. Ball at end has an adjustment mechanism. Rod also has an adjustable circular collar. Pair of curved tweezers. Circular magnifying glass on long thin handle. Glass has two concave lenses. Weaving sample in shades of blue, green and brown. Twill weave. Alternate pattern samples separated by red thread.Brass plaque on base of spinner: 42 MARKET St / John Nesbitt / REGd TRADE MARK / LIMd / MANCHESTER Underside of wooden plinth: 4976apparatus, textile, testing, spinning, nino corda, magnifyer, tools, brass, mahogany, tweezers, yarn, spinner, design, john nesbitt, manchester, england, 19th century, engineering, manufacturing -

National Wool Museum

National Wool MuseumFunctional object - Magnifying Lens, c.1930s

This item was inherited from the donor's father, René Dupuche. John Dupuche, writes: This magnifying glass was used to remove the burrs and thorns that wool-buyers tended to get in their fingers when examining bales of wool. The open end was placed on the finger since the thorn was sometimes buried under the skin. The buyer looked through the magnifying glass and with tweezers or a pin removed the thorn which had rendered the finger inoperative. The wool-buyers needed the sensitivity of their fingers to appraise the suitability of the wool, as buyers had for centuries past, measuring the length of the staple, feeling and counting the crimps in the fibre, its finesse, softness, elasticity and strength, assessing the colour, watching for extraneous matter such as dust or seeds which would not be welcome by manufacturers half-way across the world. Their skills took years to acquire. Knowledgeable buyers were invaluable to their employers, since they were able to evaluate to the last percentage the yield of a bale. My father, René Dupuche, was the ‘principal buyer’ from 1927-1966 in Victoria, South Australia and Tasmania for the international wool company ‘Masurel Fils’ which was one of the largest wool businesses in Europe. It was based in the north of France, in Tourcoing, one of the major wool centres of the world. He was sent to Australia as a young man at the age of 23 and took part in the ‘golden era’ of wool in Australia, and the eventual replacement of hands-on appraisal by ‘core-testing’. Masurel Fils was one of the dozens of French and Belgian firms operating in Australia. These men from Flanders enjoyed a cosmopolitan society augmented by diplomats, European bankers and shipping-line executives for various countries and a handful of scientists and academics.Small black metal magnifying lens with three fold design and two hinges. One panel contains a circular glass lens, the centre panel has a circular hole, and the third panel has a square hole with three lines on each side.wool buyer, magnifying glass, magnifying lens, burrs, rené dupuche, john dupuche, migrants, masurel fils, french, belgian, flanders, working life, sheep industry, wool industry, agriculture -

Mont De Lancey

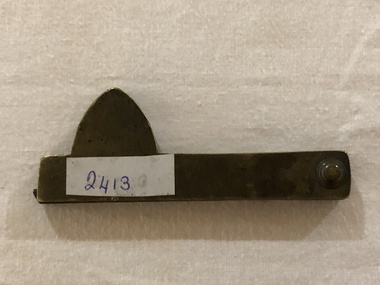

Mont De LanceyTool

Tool used for bleeding horses for testing.Folding metal Veterinary tool, used for bleeding horses for testing.Joseph Roger & Sonsveterinary equipment -

Falls Creek Historical Society

Falls Creek Historical SocietySki Lift Test Ticket 1995

SKI TICKETS Before tows and lifts were introduced at Falls Creek, it could take skiers 20 minutes to climb to the Summit … but only TWO minutes to go back to the bottom. The arrival of tows, then chairlifts and T-bars changed the face of skiing forever. The first rope tow was constructed by Toni St. Elmo for the 1951 winter season. Bob Hymans installed a smaller tow for his guests at Skyline Lodge. Tows were still quite slow, so in 1956 Bob Hymans created his single chairlift. In 1958 the Village rope tow, designed by Albury engineer Jock Wilson, opened. It was financed by shareholders including Bill Griffith (Bowna Ski Club) and the Bridgford family (St. Trinian’s Ski Club). Several other tows followed including the Summit T-bar in 1961, built by Ron McCallum and operated by Alpine Developments Pty. Ltd. which was a company formed by C. H. (Bill) Bridgford. By 1982 Falls Creek was served by 16 different lifts or T-bars, all owned and operated by Alpine Developments (Holdings) Pty. Ltd. During the development of Falls Creek, different methods have been used to pay for the use of tows, lifts and T-bars … including metal tokens, single tickets, strips of tickets and season passes. The Falls Creek Historical Society Collection includes many examples of these items.This ticket is significant because they represent a stage in the progression of chair lifts and management at Falls Creek Tourist Village.A test ticket produced prior to the full run of tickets being created for the 1995 season.falls creek passes, falls creek ski lifts, falls creek tourism -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Student Microscope, 1960s

This microscope was made in the mid 1960s as an introductory microscope for students. As indicated by the brand plate on the front, it could be set to 3 different magnification settings of 75x, 300x or 600x. When originally produced these microscopes came as part of a kit including microscope slides and testing samples.This item is representative of a range of scientific tools available to engage young people in scientific discovery in the 1960s.Small green and silver metal microscope with adjustable focus dial. It includes a mirror and clamp arms to hold slides and plastic knobs to adjust focus.On metal plate: "tasco/ 75x - 300x - 600x/ 600x/ REG-NO-GE 6'00" Underneath rubber base:"PAT. PEND. NO. 026004/ JAPANtasco, student microscope, microscope -

Falls Creek Historical Society

Falls Creek Historical SocietyEquipment - Blasting Equipment

In the early 1970s the rope tows at Falls Creek were replaced by T Bars, after which they were replaced by chairlifts. When the snow thawed, the mountains reverberated from the sounds of blasting as new pylons were constructed for these chairlifts.Blasting equipment from the early 1970s in three parts, including a rectangle metal box with black with white text on top and six connectors, a rectangle yellow 'Blostometer 80' and a rectangle box with red knobs at end and enclosed in a black-brown leather case. 'EXPLODER TESTING RHEOSTAT' 'Blastometer 80' 'Nissan Blasting Machine - ICI - 30 shot condenser'falls creek, construction, blasting, explosives, snow, snow fields -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Delayed Action Incendiary Device (DAID), Bryant and May - Richmond, Large double ended match

The Forests Commission developed the use of helicopters for aerial ignition from the mid 1960s. Bryant and May at Richmond worked with the Commission to develop a Delayed Action Incendiary Device. DAIDs as the were known, had an overall length of 180 mm, striker end length - 10 mm. Ignition end length - 80 mm, then a layer of high melting point wax (to prevent accidental ignition when rubbing together in transit). Both ends coated with a modified match head compound with safety fuse exposed length between coated match ends. There was a 17-second delay from when the small end was struck to an intense flaming of the large end, which lasted for 40 seconds. DAIDs were dangerous so were stored in a metal box outside the helicopter along with a disposable striker patch attached with a quick release pin to a special half-door. The first test was with a Bell 47G on 4 October 1967 and the first use, anywhere in the world, of DAIDs to backburn a large bushfire was undertaken in north eastern Victoria in February 1968. There was a crash of an FCV helicopter conducting aerial ignition near Wandiligong on 19 April 1978 with the tragic death of two forest officers and their pilot. The crash led to the immediate end of the use of DAIDs and the adoption of the safer Premo ping-pong ball incendiary machine which originally came from Canada but was modified at the Altona workshops. Overall, the development of aerial ignition techniques by the Forests Commission from the mid-1960s resulted in a steady climb in the area burnt each year…. peaking at 477,000 ha in 1980-81 and with an impressive 10-year rolling average of 220,000 ha around the time of 1983 Ash Wednesday Bushfires.Developed in Victoria for aerial ignitionLarge double ended match used for aerial ignition and back burning by dropping from a helicopterbushfire, forests commission victoria (fcv) -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, British Army, Royal Engineers Supplementary Pocket Book, No. 5E: Quarries And Gravel Pits 1959, 1959

A faded blue coloured cardboard cover with black information. There is a code near the top which reads WO COde No. 9552. Under the main test of the cover there is a rummber stamp mark which reads HQ 6 Const Gp, Library Copy No: and beside this is the number 57 written in red texta. There are two metal staples and two punch holes down the left hand side of the booklet,british armed forces - service manuals, royal engineers, pocket book, quarries and gravel pits -

Melbourne Tram Museum

Melbourne Tram MuseumSign, "Danger - Tram Testing in Progress - Keep Clear", undated

... Trams tramways Yarra Trams Signs Testing Metal based sign ...Metal based sign with two large holes at the top edge with printed plastic adhesive overlays on either side rounded edges with the words - "Danger - Tram Testing in Progress - Keep Clear" in capital letters. Sign has been damaged. No manufacturer details. Was used at Malvern Tram depot until damaged.trams, tramways, yarra trams, signs, testing -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionDelayed Action Incendiary Device (DAID)

The Forests Commission developed the use of helicopters for aerial ignition from the mid 1960s. Bryant and May at Richmond worked with the Commission to develop a Delayed Action Incendiary Device. DAIDs as the were known, had an overall length of 180 mm, striker end length - 10 mm. Ignition end length - 80 mm, then a layer of high melting point wax (to prevent accidental ignition when rubbing together in transit). Both ends coated with a modified match head compound with safety fuse exposed length between coated match ends. There was a 17-second delay from when the small end was struck to an intense flaming of the large end, which lasted for 40 seconds. DAIDs were dangerous so were stored in a metal box outside the helicopter along with a disposable striker patch attached with a quick release pin to a special half-door. The first test was with a Bell 47G on 4 October 1967 and the first use, anywhere in the world, of DAIDs to backburn a large bushfire was undertaken in north eastern Victoria in February 1968. There was a crash of an FCV helicopter conducting aerial ignition near Wandiligong on 19 April 1978 with the tragic death of two forest officers and their pilot. The crash led to the immediate end of the use of DAIDs and the adoption of the safer Premo ping-pong ball incendiary machine which originally came from Canada but was modified at the Altona workshops. Overall, the development of aerial ignition techniques by the Forests Commission from the mid-1960s resulted in a steady climb in the area burnt each year…. peaking at 477,000 ha in 1980-81 and with an impressive 10-year rolling average of 220,000 ha around the time of 1983 Ash Wednesday Bushfires.Developed in Victoria for aerial ignition by the FCV and Byant & MayLarge double ended match used for aerial ignition and back burning by dropping from a helicopterforests commission victoria (fcv), bushfire, planned burning