Showing 670 items

matching jewellery

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

The Beechworth Burke Museum

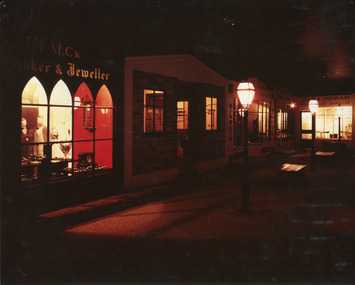

The Beechworth Burke MuseumPhotograph, 1990s--estimated

Taken in 1990, this photograph depicts a row of shops in Beechworth, with the shopfront of watchmaker and jewellers, William Turner and C.F. Falck, in the foreground, and newsagent and bookseller James Ingram's shop in the background.This photograph is of social significance to the Beechworth community in depicting the Street of Shops, the creation of curator, Roy Harvey, which opened in 1979 at Burke Museum. According to the Indigo Shire Council webpage for Burke Museum, this addition 'began a new period of collecting with Roy Harvey calling to the community for donations. The response resulted in an influx of material adding to the town history/ development and local identities collections. The Shops and their contents reflect another period in museology.' The historic shopfronts in this image portray those of local settlers, William Turner and CF Falck's Watchmaker and Jeweller store, and James Ingram's news agency and bookshop. William Turner was originally a goldfields official who became a commissioner on the Ovens goldfield, and later a resident warden, at times performing magisterial duties and chairing the Local Court. Charles Frederick Falck, born in Korlin, Germany, in 1833, a skilled watchmaker and jeweller, ran the jewellery business from 1862. Along with William Turner and Melbourne barrister, George Milner Stephen, he prepared a dazzling display of gems and jewellery from Beechworth for the Royal Society's Exhibition in Melbourne in 1865. This act signposted Beechworth's progress as a nineteenth-century gold rush town with a population of around 3000. In the mid-1850s, newsagent James Ingram established a newsagency and supplied papers and stationary to the goldfields. He and bookseller R.T. Vale stocked a wide range of literary, historical and religious works, textbooks, periodicals and newspapers, as well as hosting a reading and writing room on Camp Street{?}. James Ingram was a 'devoted instigator and supporter of the town's welfare institutions', who raised funds for to establish a hospital, primary school and benevolent asylum, and assisted people who'd fallen on hard times with his wife. He was also a mainstay of the early Baptist church, holding meetings in his house. He died in 1928, six weeks short of his 100th birthday. Ingram's Rock, north-west of Beechworth near where he lived in later life, was named after him. Colour rectangular photograph printed on matte photographic paper.Obverse: FALCK 1880 / maker & Jeweller/ WARDENS OFFICE/COACHING OFFICE/ EST. ??55/ ????ON HOUSE/ JAMES INGRAM/ NEWS?????? AND BOOKSELLER/ TOYS visible above shopfront in left foreground. Reverse: Catalogue item number 3305 pencilled in top right-hand corner.beechworth, beechworth historic shops, william turner, cf falck, james ingram, turner and falck watchmaker and jeweller, james ingram newsagent and bookseller, burke museum, promoting settlement, marketing and retailing, living in country towns, making regional centres, preserving traditions and commemorating, beechworth founders, victorian gold rush towns, beechworth pioneers, ingram's rock, 1860s beechworth, street of shops, roy harvey -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Malachite, Unknown

Malachite is typically found as crystalline aggregates or crusts, often banded in appearance, like agates. It is also often found as botryoidal clusters of radiating crystals, and as mammillary aggregates as well. Single crystals and clusters of distinguishable crystals are uncommon, but when found they are typically acicular to prismatic. It is also frequently found as a pseudomorph after Azurite crystals, which are generally more tabular in shape. This particular specimen was recovered from the Burra Burra Copper Mine in Burra, South Australia. Otherwise known as the 'Monster Mine', the Burra Burra Copper Mine was first established in 1848 upon the discovery of copper deposits in 1845. Within a few short years, people from around the world migrated to Burra to lay their claim in the copper economy. By April 1848 the mine was employing over 567 people and supporting a population of 1,500 in the local township. Up until 1860, the mine was the largest metals mine in Australia, producing approximately 50,000 tonnes of copper between 1845 to its closure in 1877. The Burra Burra Mine was also famous for a number of other specimens, including; crystalline azurite, cuprite, and botryoidal and malachite. Malachite is considered a rare gemstone in that the original deposits for the stones have been depleted leaving behind very few sources. In addition, the use of Malachite as gemstones and sculptural materials remains just as popular today as they were throughout history. It is quite common to cut the stone into beads for jewellery. The fact that Malachite has such a rich colour and one that does not fade with time or when exposed to light makes it particularly rare. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study. A solid hand-sized copper carbonate hydroxide mineral with shades of blue and light green throughout. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, burra, burra burra mine, south australia, malachite, malachite specimen -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Malachite, Unknown

Malachite is a green copper carbonate hydroxide mineral and was one of the first ores used to make copper metal. Malachite has been utilised as a gemstone and sculptural material in the past as its distinctive green color does not fade when exposed to light or after long periods of time. Malachite is formed at shallow depths in the ground, in the oxidizing zone above copper deposits. The material has also been used as a pigment for painting throughout history. This particular specimen was recovered from the Burra Burra Copper Mine in Burra, South Australia. Otherwise known as the 'Monster Mine', the Burra Burra Copper Mine was first established in 1848 upon the discovery of copper deposits in 1845. Within a few short years, people from around the world migrated to Burra to lay their claim in the copper economy. By April 1848 the mine was employing over 567 people and supporting a population of 1,500 in the local township. Up until 1860, the mine was the largest metals mine in Australia, producing approximately 50,000 tonnes of copper between 1845 to its closure in 1877. The Burra Burra Mine was also famous for a number of other specimens, including; crystalline azurite, cuprite, and botryoidal and malachite.Malachite is considered a rare gemstone in that the original deposits for the stones have been depleted leaving behind very few sources. In addition, the use of Malachite as gemstones and sculptural materials remains just as popular today as they were throughout history. It is quite common to cut the stone into beads for jewellery. The fact that Malachite has such a rich colour and one that does not fade with time or when exposed to light makes it particularly rare. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study. A solid hand-sized copper carbonate hydroxide mineral with shades of yellow, blue, and light green throughout.geological, geological specimen, burke museum, indigo shire, malachite, malachite specimen, burra burra mine, burra, south australia, australian mines, mines, monster mine -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Actionlite and Pyrite

Actinolite is usually found in metamorphic rocks, such as contact aureoles surrounding cooled intrusive igneous rocks. It also occurs as a product of the metamorphism of magnesium-rich limestones. Pyrite is usually found with other sulfides or oxides in quartz veins, sedimentary rock, and metamorphic rock, as well coal beds, and as a replacement mineral in fossils. Actinolite is an amphibole silicate mineral. It is named after the Greek word "aktinos" meaning “ray” in allusion to the mineral's fibrous nature. Fibrous actinolite is a type of asbestos and was once mined along Jones Creek at Gundagai, New South Wales. Pyrite or "Fool's Gold" is the most common sulfide mineral. It is named after the Greek "pyr" meaning "fire" because it can be used to create sparks needed for a fire if struck against metal or a hard surface. Due to its gold colour, pyrite can be mistaken for gold and often forms alongside it, causing small amounts of gold to be present in rocks containing pyrite. Most importantly, pyrite is an ore of gold. Pyrite is sometimes used as a gemstone but is not great for jewellery as it easily tarnishes. In some fossils of ammonites – shelled cephalopods that died ~66 million years ago – pyrite also replaces the shell. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study. A small-medium-sized solid specimen with the minerals actinolite (dark green fibrous) and pyrite (brassy) with shades of brown, black/grey, and white. Actinolite is an amphibole mineral in the tremolite-actinolite series of calcium, magnesium, and iron silicates. Pyrite is an iron disulfide mineral.geological specimen, geology, geology collection, burke museum, beechworth, indigo shire, geological, mineralogy, pyrite, actinolite, victoria, sewyln, alfred selwyn -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Greenstone, Hokitika Jade Company, unknown

New Zealand Greenstone, also called Pounamu is found on New Zealand’s South Island in riverbeds and boulders, and colours vary depending on the source, but always include green tones. It is a form of the mineral nephrite, also known as jade, and is a tough stone with a crystalline structure, made up of calcium magnesium and iron silicate. Its hardness means it is ideal for carving, and has been used for this purpose throughout history, especially by the Maori people of New Zealand. Greenstone features heavily in Maori mythology, and the traditional name for the South Island, Te-Wai-Pounamu, literally translates to waters of greenstone. Wearing of Greenstone pendants with different carvings is practiced by Maori to represent connection to land and ancestors, or to endow the wearer with certain attributes. The sticker on the base of the specimen identifies it as a product of Hokitika Jade Company. The company, which was active in the 1970s, sold jade and greenstone specimens and ornaments. Hokitika, which started life as an 1860s gold rush town, is the origin of most nephrite found in New Zealand, and the centre of the Greenstone carving industry. The object has scientific and research potential as part of the Burke Museum's Geology Collection, and as and example of New Zealand Greenstone. It also has spiritual significance for it's role in Maori beliefs and communities, where it is both traditionally worn and features in mythology. As a valuable stone regularly used in carving and jewellery, it has aesthetic significance. Sticker on base: "N.Z. Greenstone/ a product of/ Hokitika Jade Coy."geological specimen, geology, geology collection, burke museum, beechworth, new zealand, greenstone, hokitika, nephrite, jade -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Malachite, Unknown

This specimen is a copper-carbonate malachite mineral. It is often found as crystalline aggregates or crusts, which have a banded agate-like appearance while also commonly found as botryoidal clusters of radiating crystals. Malachite is often bright green in colour, with dark green and blackish blooms or stripes/bands throughout the mineral. This particular specimen was recovered from the Burra Burra Copper Mine located Burra, South Australia. By the 1860's, South Australia was known as the "Copper Kingdom" due to its large amount of copper mines and huge success in the copper mining industry. Burra Burra was no exception to this phenomena, as this mining company was greatly famous and successful, being nicknamed the "Monster Mine". It was first established in 1848 and was the largest metal mine in Australia up until 1860. This specimen is significant as it highlights the historic use and value of malachite and the rarity of the mineral. Malachite is a rare gemstone which has been used in various ways historically. It has been cut and sculpted into beads for jewellery use as its rich colour and distinct yet unique patterns have made it a well sought after gemstone. Its' continued use over time only heightens the value and significance of this mineral.A hand-sized solid copper-carbonate hydroxide mineral specimen in shades of blue, green and copper tones throughout.MALACHITE / (Copper carbonite) / Locality: Burra, South Aust. | Malachite / Burra Burra / South Australia / (good specimen) / needs a wash / BBburke museum, burke museum collection, beechworth museum, beechworth, geological specimen, geological, mineral, mineraology, copper carbonate, malachite, burra burra mine, copper mining -

Orbost & District Historical Society

Orbost & District Historical Societycuff links, Late 19th/early 20th century

A pair of small round bronze coloured metal cuff links or studs. There is a gold coloured circle inset on each.studs cufflinks accessories jewellery -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - F Gill Jewellers Ring Box

A ring box used by a Warrnambool Jeweller in the mid 20th century This ring box was used by the Warrnambool business of F J Gill & Co which operated in Liebig Street in the period 1920-1960. Frederick James Gill (1881-1961) was a consulting optician in 1919 and operated a business in Liebig Street. In the 1950's the jewellery business also operated in Terang and Camperdown. Cream hinged bakelite ring box with velvet cushions to hold a ring. The satin material inside the lid has a small brown sticker. There is a small metal clasp to assist with keeping the box closedBrown Sticker: Jeweller & Optician Warrnambool ring box, f j gill, liebig street, warrnambool, jeweller, optician, watchmaker -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Administrative record - Account cards, 1920s and 30s

These cards have been used as an accounting system by the Warrnambool firm of J. Mainland and Co. This firm of watchmakers, opticians and manufacturing jewellers was established in Liebig Street in the late 1890s and continued on into the 20th century at 166 Timor Street. The cards date from the 1920s and 30s. It is noted that in 1932 one customer purchased a Clarice Cliff ash tray for six shillings and sixpenceThese cards are of considerable interest firstly they give us some details of the many customers of the Warrnambool jewellery firm of J. Mainland and Co and secondly because they provide us with much information on a great number of residents of Warrnambool and district in the 1920s and 30s (addresses etc)This is a collection of paper invoices, some original, some copied, with some in alphabetical order and some in number order. The invoices are separated by pieces of cardboard with either numbers or letters on the front. The collection is only portion of a larger set of cards. The invoices were originally held together by small pins.warrnambool jewellery stores -

Bendigo Military Museum

Bendigo Military MuseumAccessory - BOX, JEWELLRY, 1) 7.2.44

.1) Box, cardboard, brown colour for 9 mm cartridges. Box holds 40 cartridges. .2) Necklace made from small shells, colours soft white, brown & grey. .3) Bracelet made from same shells as .2). .4) Bracelet made from same shells as .2). .5) Bracelet made from same shells as .2)..1) “7 Feb 1944”costume accessories - jewellery, arms - accessories -

Bendigo Military Museum

Bendigo Military MuseumMemorabilia - PURSE & CONTENTS

Items collected by Horace Eli Hambly No 794 AIF. Refer 2325.2 for his service history..1) Pouch, black leather containing 18 foreign coins. .2) & .3) Pair of metal cuff links. .4) Small key for winding a clock or machine. .5) Image of WWI digger fashioned from a 6d (sixpence) & brass set of bars.personal effects - money containers, numismatics - coins - french / german, costume accessories - male jewellery, military history - trench art -

Bendigo Military Museum

Bendigo Military MuseumMemorabilia - BROOCHES, C.1939 - 45

Items in the collection re J.C.W. LEDEUX, refer Cat No 2378 for his service details. These items are classed as Trench Art WW2..1) Perspex map of Australia with Australian coat of arms in metal in centre. Has shape of colour patch in centre. Australian Armoured Division. .2) Perspex bar with Rising Sun badge suspended beneath on chain. .3) Mother of pearl Rising Sun with metal Rising Sun badge in brass in centre. costume accessories - jewellery, military history - souvenirs, numismatics, trench art -

Bendigo Military Museum

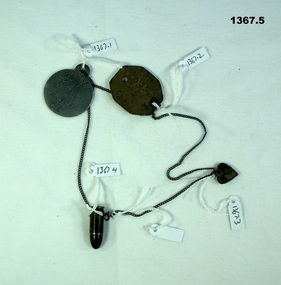

Bendigo Military MuseumAccessory - IDENTITY DISCS & CHAINSET, C.WW1

Edwin James Jones No 3511 AIF enlisted on 15.11.1916 in 9th reinforcements 46th Batt age 18 years 5 months. Embarked for England 11.5.1917, embark for France 2.11.1917, hospital 6.6.1918, records appear to have Influenza and PUO, return to unit 2.8.1918, WIA 25.8.1918 Gassed, mustard severe, returns to Australia classed Gas poisoning, discharged from the AIF 10.3.1919. Refer 1377 re his brothers service..1) Identity disc, aluminium, round re E.J Jones. .2) Identity disc Cardboard material, 8 sided re E.J Jones .3) Pendant, heart shape, metal, attached to 1367.5 (chain) .4) Round brass complete 9mm? has hole drilled through for attachment to 1367.5 (chain) .5) Chain , metal, very small attached to all above .1) “Jones E.J 3511, 46BTN , AIF, C.E” .2) “3511 E.J Jones 46 Batt, C.E” .4) “ - 17, DWN”military equipment - identity, costume accessories - jewellery, jones -

Bendigo Military Museum

Bendigo Military MuseumAccessory - BROOCH, c.1945

Brooch sent home by Roy Hilton Taylor NX94268, enlisted 2.4.1942, age 29 years. On discharge from the 2nd AIF on 17.1.1946 he was a Gunner in 2/1st Field Regt. Blue heart shaped brooch with pin clasp. Island scene in black.On front of brooch in gold: Edna & below a shining sun On rear of brooch: Love from Roy On pin clasp: New Guinea 1945metalcraft, costume accessories - jewellery -

Bendigo Military Museum

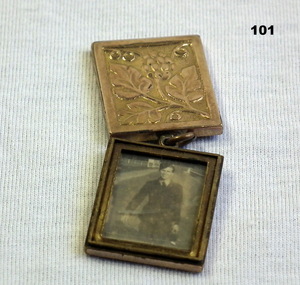

Bendigo Military MuseumAccessory - LOCKET, Handley, c.WWII

Gold locket with grapes & vines on front, containing photograph of man in an Air Force uniform with helmet in hand.Stamped on the back: “HANDLEY 1-109CT, GOLD FILLED”costume accessories - jewellery, photography-photographs, metalcraft-gold -

Greensborough Historical Society

Greensborough Historical SocietyBook, Peter Cuffley, Chandeliers and billy tea: a catalogue of Australian life 1880-1940, by Peter Cuffley, 1984

This book is a catalogue of items used in Australian homes from 1880-1940. Includes items as diverse as jewellery to household furnishings and farm equipment.224 p., Black and white illustrations.non-fictionThis book is a catalogue of items used in Australian homes from 1880-1940. Includes items as diverse as jewellery to household furnishings and farm equipment.catalogues, household equipment, farm implements -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, wooden chinese decorated box, 20thC

Chinese and Japanese artwork was fashionable c1900 and early settlers made decorated boxes to store special items Early settlers in Moorabbin Shire c1900 used decorated boxes to store jewellery, and special items.A wooden box with blue velvet lined lid and with Chinese decorationcraftwork, woodwork, chinese decoration, containers, bentleigh, cheltenham, early settlers, moorabbin -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotos - King Family Collection

The King family lived in Tawonga South where my older brother and sister went to school. We lived over the road from Wally Madison's farm. Later when a house became available, we moved into Valley Avenue, Mt Beauty. This is when I turned 5 and started my schooling. It was a long walk for a 5 year old as I remember. Then later we moved to 50 Lakeside Ave. I remember we loved living there as it was close to the school, footy ground and kindergarten. My father, Ted King, wad a carpenter and was involved in the building of many houses in Mt Beauty which was the home for the workers on the Kiewa Electric Scheme. So as they are part of the history of Mt Beauty I thought they may be useful to you as part of the history. The tennis photos, I vaguely remember Lou Hoad and Ken Rosewell giving exhibition matches in Mt Beauty. I may stand corrected on this, but I do remember my parents who were keen tennis players themselves were most excited at seeing these famous tennis players. As I was only 9 when we left Mt Beauty to live in Dimboola I still remember the shock of leaving a beautiful mountainous county side and arriving in a flat farming land next to a desert and seeing windmills One thing I do remember from school is, once a week (or fortnight) the teacher used to come around with a jar of little white pills, of which we were all to take. I really don't know what they were?? or for?? I also remember being taught to swim in the freezing cold river by a Mrs Smith who wore black bathers and wore her hair in a bun...... ...I am now in my 70s My father used to also carve intricate trays and jewellery boxes in his spare time. I think they were used for tennis trophies. by Diane Werner.x33 photos of small black and white photos of the Tawonga, Tawonga South and Mt Beauty - Photos not labelled but described as follows. See each photo for a possible label. A. Tawonga? B. Mt Beauty taken on the road to Bogong ? C. SEC Works D. Industrial buildings with mountains in the background E. Building site with wooden frame and 3 men F. Buildings with power poles G. Building site with lots of huts H. Buildings under construction I. Group of houses in the distance J. Group of houses in the distance K. Group of people in front of a building L. Group of 8 men sitting on timber planks, corrugated iron at back. M.& N. Building site with floor and upright timbers O. Mountain view with camp site in foreground P.& Q. Buiding site, several houses R.5 men at a building site S. portable building on trailer T & U. Mountain view V. Building site W. Group of men, car and mountains in background X. Cows Y. Pigs Z. 2 men standing next to cars. AA. Football players BB. Man painting a corrugated iron building CC. Football DD. Men in front of a building EE Buildings with mountains in background FF & GG Tennis payersHH & II. Electricity infrastructure -

Orbost & District Historical Society

Orbost & District Historical SocietyDecorative object - Brooch

These items are from the Temple estate. George Temple (1832-1916) started Temple's store opposite Orbost Post Office. Packed stores to Bendoc area gold fields, also had a store in Cann River. This item is an example of a popular piece of jewelry worn by women in the early 20th century. These brooches were sold in a local store and could have been purchased for a local funeral.Black, bakelite brooch - three small sections form centre of brooch, one is a hexagonal cone-shape with hexagonal dome attached by link to smaller circular polygon attached by link to a smaller flat pentagon. Black mesh in the shape of wings form the backing featuring eight bakelite stars of varying sizes (two smaller stars missing from the assembly). A metal pin is attached to the rear in the form of a clasp.1900s jewellery, bakelite, mourning brooch, george temple, orbost store -

Orbost & District Historical Society

Orbost & District Historical Societyfob chain

A pocket watch (or fob watch) is a watch that is made to be carried in a pocket. Watches were also mounted on a short leather strap or fob, when a long chain would have been cumbersome or likely to catch on things. This fob could also provide a protective flap over their face. Watch chains were introduced about 100 years after pocket watches first appeared in the 16th century. This item is an example of a popular piece of men's jewellery often considered to be a symbol of importance.Man's double, silver fob chain with key for watch.On fob chain - GILTchain silver fob-chain jewelry costume-accessories- male -

Orbost & District Historical Society

Orbost & District Historical Societyjewelry, Early 20th century

These are from the Temple estate.. George Temple(1832-1918) started Temple's Store opposite the Post Office and packed stores to Bendoc. Donor was grand-daughter of Dr Kerr, first doctor in Orbost.These items are examples of common jewellery items worn by by women in the early 20th century.Assorted bead chokers and cuffs. Four cuffs and four chokers.jewelry beading costume-accessories temple-family -

Orbost & District Historical Society

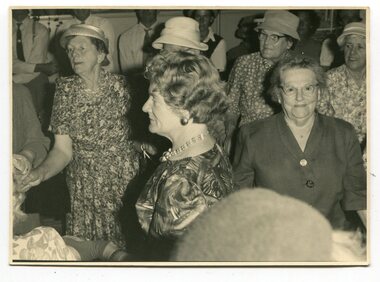

Orbost & District Historical Societyblack and white photograph, mid 20th century

Those identified in this photograph are: Grace Cameron - back row second right and Effie Wait on the left. (Smooker? Firth?)This photograph is a pictorial record of typical women's fashion in the mid 20th century when women's dresses were were modest, revealing very little skin, compared to today’s fashion. Squared shoulders, narrow hips, and skirts that ended just below the knee were the height of fashion. Tailored suits were also quite popular. Generally older women wore hats, gloves and jewellery. The women in the photograph are associated with Orbost.A black / white photograph of a group of women most wearing hats and jewelry. on back- "left Effie Wait Grace Cameron back second row right"cameron-grace wait-effie orbost-social-gathering -mid 20th -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Trinket Box, Johann A. Landmann, 1853

This trinket box was made by Johann Landmann during his journey on the sailing ship Wilhelmsburg and was donated to Flagstaff Hill by the wife of Landmann's great-grandson. Landmann (or Landman, also known as August Landmann) was born in 1826 in Ganhor, Silesia, Prussia. At the age of 20, he travelled through Europe, working from town to town as a cabinet maker. At 26 years old he returned to Germany, married Anna Rosina in Wahlstatt, Prussia, and on the same day sailed for Australia on the Wilhelmsburg in 1853, the year the ship was registered. The Wilhelmsburg was a three-masted, square-rigged sailing ship built at Reiherstieg, Hamburg, and registered in Hamburg on 27th April 1853. On her maiden voyage in 1853, the ship sailed from Hamburg, Germany, to Australia with 510 passengers on board, including emigrants under the Bounty Scheme. Johan Landmann was one of the passengers. The Wilhelmsburg arrived in Hobson’s Bay, Melbourne after sailing for 100 days. Johann spent a week in Melbourne then travelled to Warrnambool aboard the Merry Kitty, arriving fourteen days later. Johann had landed in Melbourne with only 16 shillings in his pocket and by the time he arrived in Warrnambool, he only had one shilling and sixpence left. He also had very limited ability to speak English. He settled in the Allansford area, near Warrnambool, together with other families from Germany and went on to play a significant role in the history of Warrnambool. Johann worked as a cabinet maker in Warrnambool, making the first coffin in the Warrnambool cemetery. He also worked as a general merchant. He built many of the earliest shops in Warrnambool, and the first paddle boat used on the local Hopkins River. He made models of Warrnambool’s Ozone Hotel and Presbyterian Church; the model of the Hotel is now in the Warrnambool Art Gallery, and the model of the Presbyterian Church has been in the care of the Warrnambool & District Historical Society since around 2017. One of Landmann's residences was a two-storey building in Henna Street Warrnambool where he, lived upstairs and operated his business downstairs. After he retired Landmann built a ‘handsome stone residence’ at 30 Mickle Street, Warrnambool, where he lived until his death in June 1920; he was aged ninety-five. “Landmann Street” in Warrnambool has been named after Johann and appears on a map in 1872. He has also been honoured on Warrnambool’s Pioneer Memorial Board which is displayed at the Warrnambool and District Historical Society. Landmann's son Adolph Fritz Landmann (Fritz Landmann) born in 1861, was a Councillor from 1905 to 1915, and Mayor of Warrnambool from 1912 to 1915. The Wilhelmsburg sailed from Hamburg in 1863 heading for Queensland, Australia, but in December the vessel was wrecked off the coast of Holland during storms, with the loss of 247 lives.The trinket box is significant as an early Warrnambool historical artefact with a connection to the maiden voyage of the ship Wilhelmsburg a vessel that holds the record for the number of passengers carried in one journey on a small vessel. Johann Landmann is regarded as a significant and historical figure in the development of Warrnambool as one of the earliest pioneers, not only as a businessman but the civic duties he undertook. First as a councilman and later the mayor of Warrnambool. Trinket box, wooden, with inlaid timber patterns and images. The design includes a mirror with a hidden compartment inside the hinged lid, a removable inner tray divided into compartments, and a fitted brass lock. The trim around the base is angled to widen the base. Images on the lid and three sides represent sailing vessels and a building. The lid and corners have a rope-edge design. Panels of the top and three sides have an intricate inlaid pattern featuring various wood grains. Images are framed by lines etched into the wood. The inside corners of the frames have inlaid quarter-circles of contrasting woods, resembling photograph corners.shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwrecked artefact, warrnambool, trinket box, inlaid woodwork box, wilhelmsburg, landmann, johann landmann, augustus landmann, landman, fritz landmann (warrnambool mayor), presbyterian church warrnambool, 30 mickle st warrnambool, ozone hotel warrnambool, johann carl augustus landmann, jewellery box -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Newsletter, CMHS Moorabbin Mirror Issue 12 October 2017, CMHS Moorabbin Mirror Newsletter Issue 12 October 2017, 2017

This is Issue 12 of the Moorabbin Mirror produced by CMHS members Fran & Holger Bader , Geoffrey Paterson, October 2017 Topics; August Rietman Exhibition Roving Curator Program; OHM; Le Page family Travel Trunk; The Moorabbin Mirror reflects the history and heritage of the former City of Moorabbin — derived from Mooroobin, ‘a resting place’ in the Bunurrung spoken language. In 1994, the City of Moorabbin was integrated into the Cities of Bayside, Glen Eira, Kingston and Monash. This is Issue 12 of the Moorabbin Mirror, Newsletter of CMHS October 2017A4 x 2 paper folded to A5 x 4pp with B/W photographs. Moorabbin / Mirror / Newsletter City of Moorabbin Historical Society Inc. A0020547E (CMHS) / operating Box Cottage Museum (BCM) / OCTOBER 2017 ISSUE 12moorabbin mirror, bader fran, bader holger, patterson geoffrey, rietman august, rennick stefanie, rietman william, le page everest; open house melbourne 2017, world war 1 memorials, lone digger memorials, resin jewellery, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Jewellery, lady's brooche, c1900

A lady's small metal brooch with coloured glass bead inserts, a central larger pale blue glass insert and a pin clasp at back. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Blowtorch 'Sievert', 20thC

A blowtorch or blowlamp is a fuel-burning tool used for applying flame and heat to various applications, usually metalworking. Early blowlamps used liquid fuel, carried in a refillable reservoir attached to the lamp. Modern blowtorches are mostly gas-fuelled. The blowlamp is of ancient origin and was used as a tool by gold and silversmiths. They began literally as a "blown lamp", a wick oil lamp with a mouth-blown tube alongside the flame. This type of lamp, with spirit fuel, continued to be in use for such small tasks into the late 20th century. In 1882, a new vaporizing technique was developed by Carl Richard Nyberg in Sweden, and the year after, the production of the Nyberg blow lamp started. It was quickly copied or licensed by many other manufacturers. Carl Richard Nyberg (May 28, 1858, – 1939) was the founder of Max Sievert’s Lödlampfabrik, then one of the largest industries in Sundbyberg, Sweden. After school he started working for a jeweller and later he moved to Stockholm and worked with various metalworks. 1882 and set up a workshop at Luntmakargatan in Stockholm making blowtorches. However the business didn't work well because it took too long to both manufacture and sell them. In 1886 he met Max Sievert (1849 - 1913) at a country fair and Sievert became interested in Nyberg's blowtorch and started selling it. In 1922 the company was sold to Max Sievert who continued to own it until 1964 when it was bought by Esso. The blowtorch is commonly used where a diffuse high temperature naked flame heat is required but not so hot as to cause combustion or welding: soldering, brazing, softening paint for removal, melting roof tar, or pre-heating large castings before welding such as for repairing. It is also common for use in weed control by controlled burn methods, melting snow and ice from pavements and driveways in cold climate areas, road repair crews may use a blowtorch to heat asphalt or bitumen for repairing cracks in preventive maintenance. It is also used in cooking; one common use is for the creation of the layer of hard caramelised sugar in a crème brûlée. A brass blowtorch, 'Sievert' with a wooden handleSIEVERTtools, blow torches, blow lamps, welding, brazing, jewellery, cookery, soldering, nyberg carl, sievert max, stockholm, sweden, spirit fuel, kerosene, gas fuel, moorabbin, bentleigh, cheltenham, market gardeners, pioneers, early settlers, plumbing, carpenters, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Jewellery, Man's Cufflinks x 2 pair in a velvet box, c1960

Cufflinks were worn to fasten the sleeves of dress shirts worn as part of the formal suit for men in City of Moorabbin c 1960. These cufflinks are typical of the fashion c1960 and are stored in a brown velvet spring lock hinged box These Cufflinks are typical of the fashion worn with formal wear by men in City of Moorabbin c1960 2 pair of Cufflinks in a brown velvet spring loaded hinged box. a) pewter b) silver gold with glass a) Jorge Jenson / Danish Pewter clothing, formal wear, dress shirt, tuxedo, waistcoat, drees scarf, cufflinks, bow ties maynard dennis, city of moorabbin, freemasons lodge, city of moorabbin historical society, early settlers, market gardeners, bentleigh, cheltenham, moorabbin, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Object, Torch small, bakelite, 'Zeiler' Germany, 20thC

This small bakelite torch made by 'Zeiler' Germany was used by Gladys Reed late 20thC Gladys Reed was a member of the Ormond Choral Society c 1950. who performed plays and musicals the City of Moorabbin Gladys Reed was a member of the Ormond Choral Society c 1950. who performed plays and musicals the City of Moorabbin and she used this small bakelite torch. Man.Obj. Torch small, bakelite, 'Zeiler' Germany tools, flashlight, reed gladys, reed george, clark judy, blow torches, blow lamps, welding, brazing, jewellery, cookery, soldering, nyberg carl, sievert max, stockholm, sweden, spirit fuel, kerosene, gas fuel, moorabbin, bentleigh, cheltenham, market gardeners, pioneers, early settlers, plumbing, carpenters,