Showing 2150 items matching "machinery"

-

National Wool Museum

National Wool MuseumPhotograph

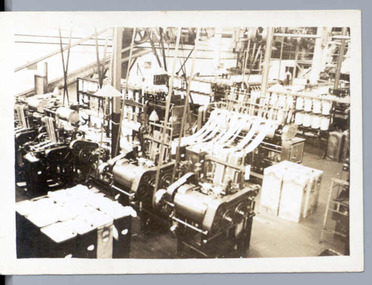

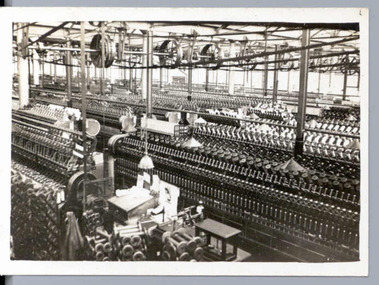

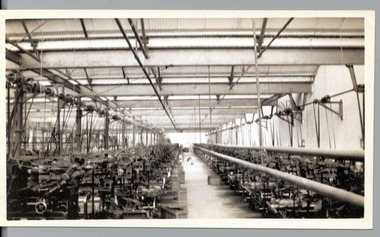

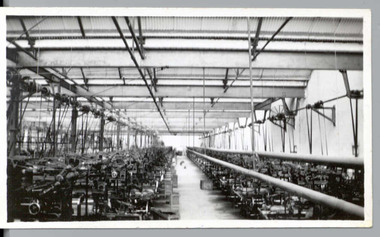

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

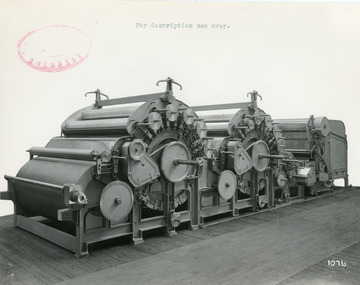

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

Tarnagulla History Archive

Tarnagulla History ArchiveTwo sections of Flat Wire Rope used in Tarnagulla mines c.1886

David Gordon Collection. These are an interested relic from the 1880s when the Prince of Wales and Old Poverty Company converted their winding machinery from flat wire rope to round wire rope. The old rope of some hundreds of metres in length was simply dragged clear of the mine and discarded in the surrounding bushland. This style of rope succeeded the old Indian hemp flat rope, and was in turn superseded by the round wire rope. These segments are most instructive and quite rare relics. The smaller segment measures approximately 40 x 10cm. The longer segment measures approximately 96 by 10cm -

Sunbury Family History and Heritage Society Inc.

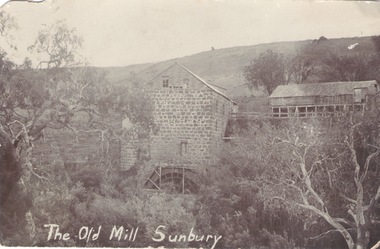

Sunbury Family History and Heritage Society Inc.Photograph, The Old Mill Sunbury

Scottish miller and immigrant, John Eadie established his water-driven flour mill on Jacksons Creek in Sunbury in 1861.To make of a sufficient water supply to operate the mill, he built a weir and a water-race to drive it. Some of these can be seen today. The machinery for the mill was bought from Scotland and transported here. The mill continued to operate until 1914. At that time the 20 ton metal wheel and the iron roofing removed to aid the war effort.This mill is one of a number that were built along the water courses in the Sunbury-Bulla area to process the wheat grown in the area.A non-digital black and white photograph in post card format of a an old bluestone mill building sited on the bank of a watercourse in a deep valley with bare hills in the background. The remains of the water wheel are at the rear of the building. A New Year greeting dated 24th Dec. 1907 has been written on the back from H.H in Bulla to his aunt, Miss M.A.Ripon who was staying with Mrs. Tricks in Canterbury at the time.The Old Mill Sunburyjohn eadie, the old mill, milling, jacksons creek -

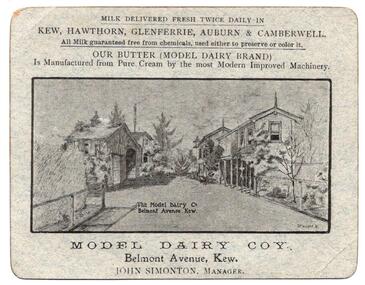

Kew Historical Society Inc

Kew Historical Society IncCard - Model Dairy Coy: Belmont Avenue, Kew, c.1907

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Digital copy of a business card advertising the Model Dairy in Belmont Avenue, Kew, managed by John Simonton. (The card was donated by John Harvey Simonton in 2021,)"Milk delivered fresh twice daily in / Kew, Hawthorn & Camberwell / All Milk guaranteed free from chemicals, used either to preserve or colour it / Our butter (Model Dairy Brand) / I Manufactured from Pure Cream by the most improved Machinery / [DRAWING] The Model Dairy Co Belmont Avenue Kew / Model Dairy Co / Belmont Avenue, Kew / John Simonton, Manager"model dairy -- kew (vic.), john simonton, belmont avenue -- kew (vic.), dairies -- kew (vic.) -

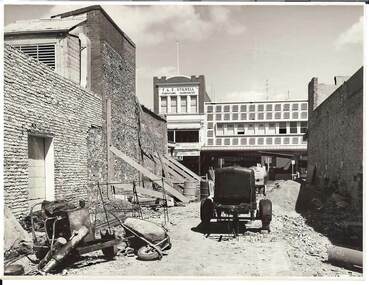

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - BENDIGO ARCADE, c1950

Black and white photograph. Demolition site, taken from Old Bennett's Arcade. Brick walls each side, wheelbarrows and machinery on site. Opposite 2 & 3 storey buildings with shops and offices. In image F & E Stillwell, Furniture Warehouse. On windows 'Pitson Bros', GH? Pitson, GJ? Pitson, Public Accountants, Estate Agents, Travel Agents, Sister McKenzie, Chiropodist. Identified by James Lerk as a Alan Doney photo.Alan Doney Photoplace, arcade, bendigo arcade -

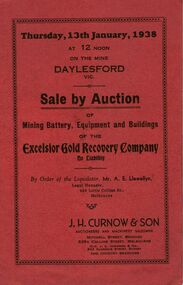

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - EXCELSIOR GOLD RECOVERY COMPANY

Auction catalogue with an orange cover for a sale on 13th January, 1938 of Mining Battery, Equipment and buildings of the Excelsior Gold Recovery Company No Liability, By Order of the Liquidator, Mr. A. E. Llewellyn, Legal Manager. J. H. Curnow & Son were the auctioneers. Catalogue has a column down the right side of the page to write in the price of each lot. Contains a description of some of the machinery. Bolton Bros. Pty. Ltd. Were the printers of the catalogue.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - excelsior gold recovery company no liability, mr a e llewellyn, j h curnow & son, j l jamieson & co, bolton bros pty ltd -

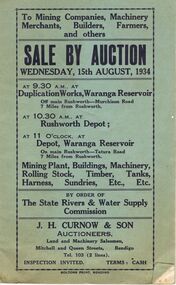

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - WARANGA RESERVOIR

Two pale green auction catalogue with black printing on the cover for a sale on the 15th August, 1934 at the Duplication Works, Waranga Reservoir, Rushworth Depot and the Depot, Waranga Reservoir, by order of The State Rivers & Water Supply Commission. For sale is Mining Plant, Buildings, Machinery, Rolling Stock, Timber, Tanks, Harness Sundries, etc. Some notes and prices written in one catalogue. Catalogues have columns on the right of the page for £, S & D to be noted.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - waranga reservoir, the state rivers & water supply commission, j h curnow & son, boltons print bendigo -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - NEW GLENFINE GOLD MINING CO

Blue covered Auction Catalogue for a sale held on 17th December 1940 at the New Glenfine Gold Mining Co. N. L. at Pitfield Plains (Vic.)Front page has a black and white photo of a Ruston Diesel Electric Generating Set - Similar to Lot 129. For sale was Electrical & Steam Mining Machinery, Plant, Buildings & Extensive Equipment. There are descriptions of many lots and where they are situated. J. H. Curnow & Son were the Auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - new glenfine gold mining co n l, a e llewellyn, j h curnow & son, j l jamieson, the cambridge press -

Bendigo Historical Society Inc.

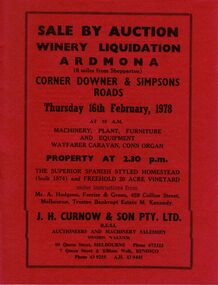

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - WINERY LIQUIDATION - ARDMONA

Two red covered auction catalogue with black printing for a sale on 16th February 1978 for a Winery Liquidation, Ardmona, under instructions from Mr. A. Hodgson, Ferrier & Green, Trustee Bankrupt Estate M. Kennedy. For sale was a Spanish styled homestead (built 1974) and Freehold 20 acre vineyard. Also tools, wine making equipment, Water Right, machinery and furniture. J. H. Curnow & Son Pty. Ltd. Were the auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - winery liquidation - ardmona, mr a hodgson ferrier & green, estate m kennedy, j h curnow & son pty ltd, f c dyett, i m dyett, bolton bros print -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - QUESTION 5 ON VICTORIA HILL

Handwritten notes and carbon copy titled Question 5. Notes refer to Victoria Hill being opened up by Theodore Ballerstedt and his son early in 1854. Theodore Ballerstedt left for Germany having sold his home, crushing battery and mine to Mr. Geo Lansell. He called the mine the '180'. Next mine north to the '180' was the Victoria Quartz. Also contains notes on machinery, geological formations and earning from the mines.document, gold, victoria hill, victoria hill, question 5 on victoria hill, theodore ballerstedt, mr geo lansell, fortuna villa, commonwealth survey regiment, the 180, ballerstedt's original open cut, bendigo south rotary club, john wybrandt, north old chum coy, victoria quartz, victoria reef quartz company, mr william rae, a roberts & sons united ironworks, australian mining standard special edition 1899, bendigo advertiser 10/2/1897, a harkness & coy, bendigo advertiser 30/6/1910 page 5, rae's open cut, e j dunn, bendigo saddle reefs, wittscheibe's 'jeweller's shop', roberts & frost, ashley noy & coy, grant & co, woodward & son, couth allen and co, taylor gould and co, crawshaw & co, roberts & co -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Label, Rosebrook Cheese and Butter Factory, Early 20th century

The Rosebrook Cheese and Butter Factory was opened in November 1888 by Messrs Lydiard &T F Rutledge & was a cooperative factory managed by Mr. Goldie. It operated out of the former Rosebrook Flour Mill which was built on the banks of the Moyne River near the Rosebrook bridge in the late 1840s. In 1896 the factory commenced the production of the condensation of milk. The company closed in 1911. The building and machinery were sold in 1917. Rosebrook is situated about 20 kilometres from Warrnambool on the Princes Highway. This label is of some local significance as the Rosebrook Cheese and Butter factory operated for 30 years Rectangular dark blue and white label featuring text and a trade mark. The latter is circular with three cows pictured. There are decorations of flowers and leaves. The central area of the label is white with three lines. The label is adhered to a piece of pink card.FROM THE Rosebrook Cheese & Butter Factory Company Limited, MANUFACTURERS OF "PURUS BRAND CONCENTRATED MILK Rosebrook, Port Fairy. "PURUS" TRADE MARK FOR CONCENTRATED MILKrosebrook, cheese and butter, concentrated milk, lydiard, rosebrook butter factory -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBlacksmith's Bellows

In the Middle Ages double-acting bellows was introduced. It had 2 parts, one operated by hand or foot, the other took air from it and was weighted so it forced air out while the part was filling. Blacksmithing is the shaping of hot iron and steel, usually by hammering. Very hot fires were produced by 1.a hot air blast. 2. burning charcoal (not wood). Bellows were used to make tools, fix equipment including machinery, drays, carriages, harnesses etc. Farmers in the Kiewa Valley often had their blacksmith forge. They made their own tools, were able to mend equipment, drays etc., gates, and most items that were made of iron and steel.Large Double Acting bellow with wooden top and bottom, shaped like a 'water drop' - narrow at one end and broad at the other. The wood is held by strips of wood and leather bound and placed around the perimeter. The wood on the top side has inscriptions (illegible). The wood on the bottom side has a rectangular hole. The narrow end feeds into a pipe to enable the fire to receive a hot blast of air. When the bellow is squeezed it allows both pieces of wood to be pushed together.Illegibleblackmiths, bellows, double acting bellow -

Orbost & District Historical Society

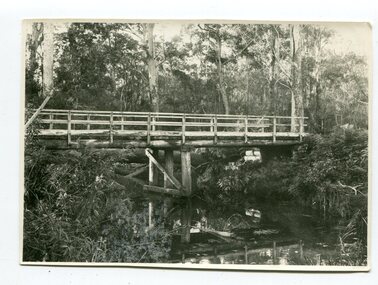

Orbost & District Historical Societyblack and white photograph, June 1897

This photograph was taken at what is now the Young’s Creek picnic area which is located on the site of an old sawmill, once owned and operated by L.E. & H. Williams, dating back to the early 1920’s. The mill was eventually sold, dismantled, and the machinery transferred to a sawmill at Cabbage Tree Creek. there are still some items of old sawmill debris. The old steam engine at the edge of the car park is the remains of the mill’s former power plant. This portable steam engine was constructed in Leiston, Suffolk, in England.This is a pictorial record of a popular recreational area in the Orbost district in the late 19th century.A black / white photograph of a wooden bridge over a creek in forest setting. There is a second copy.on back - handwritten "the Young's Creek Bridge June 1897"young's-creek-orbost bridge-young's-creek -

Federation University Historical Collection

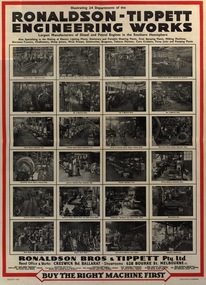

Federation University Historical CollectionPoster - Poster - Advertisement, ZILLES COLLECTION: Posters advertising Ronaldson and Tippett Engineering, Ballarat

Zilles Printers was begun by Lewis Zilles in the early 1930s. It was in McKenzie Street Ballarat. His son Jeffrey also became a printer - letterpress, offset and screen printer. The business became Zilles Printers/Graphics and was in Armstrong Street and later Bell Street Ballarat. Ronaldson Bros and Tippett began in Creswick Road Ballarat 1905. They were manufacturers of agricultural machinery and oil engines. In the 1930s they began production of tractors. The company was taken over in 1970 and closed. Framed copies of these posters are in the collection.Large posters - one with red border, one with blue border. zilles printers, ronaldson and tippett, ballarat, agricultural machinery, oil engines, tractors -

National Wool Museum

National Wool MuseumPhotograph

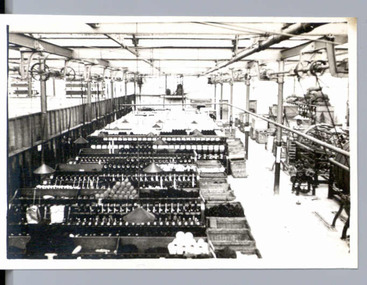

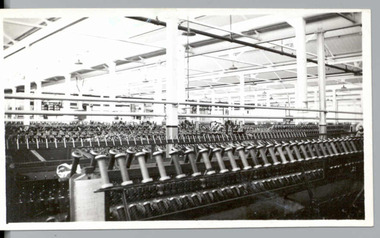

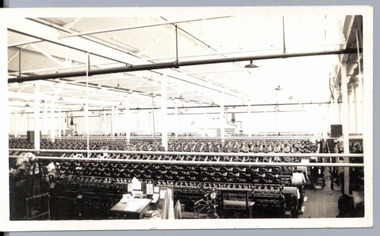

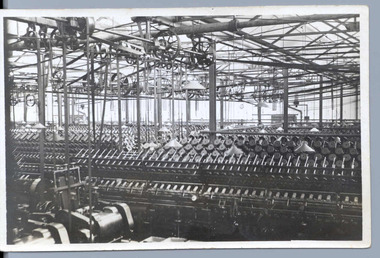

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

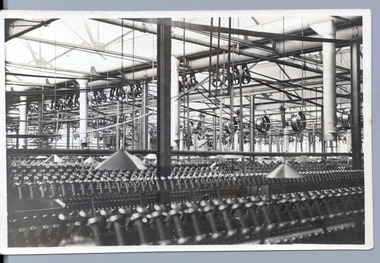

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

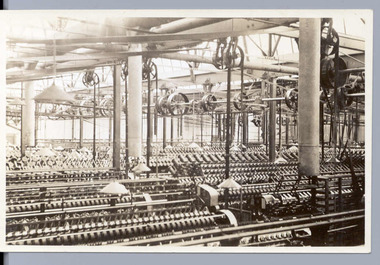

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

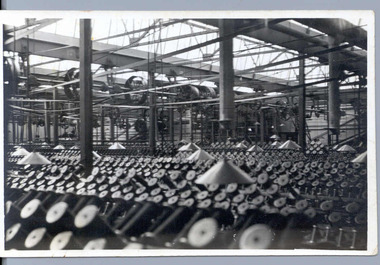

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

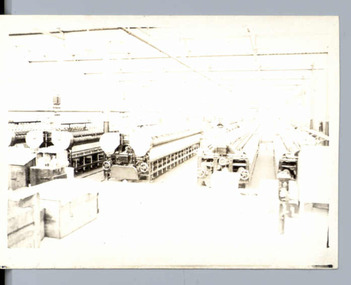

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

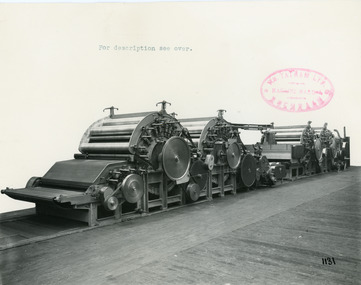

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

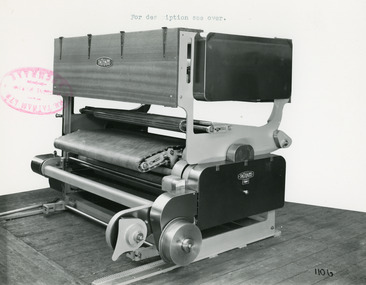

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

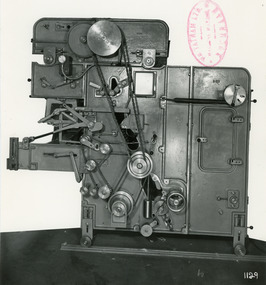

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool