Showing 350 items

matching worsteds

-

National Wool Museum

National Wool MuseumPamphlet, Worsted Card for Man-Made Fibres Type CS-2

"Worsted Card for Man-Made Fibres, Type CS-2" - Befama Bielska Fabryka Maszyn Wlokienniczych; sole exporters: Metalexport, Warsaw, Poland, c.1950.textile machinery, metalexport bielsko textile machinery works, carding, yarn - worsted -

National Wool Museum

National Wool MuseumBook, Finishing Machinery

"Finishing Machinery" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926. Catalogue of machinery for fulling, scouring, carbonising, dyeing and finishing woollen and worsted and other types of textiles.Catalogue of textile finishing machinery from James Bailey, textile machine maker, Huddersfield, c.1926.textile machinery textile finishing, james bailey, textile machine maker, milling, scouring, carbonising, dyeing, raising, textile machinery, textile finishing -

National Wool Museum

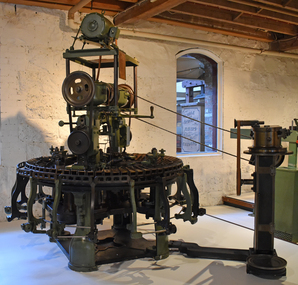

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

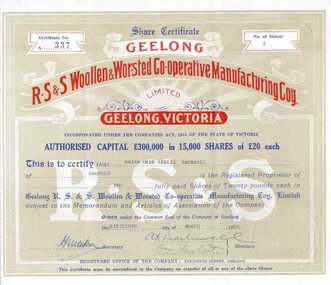

National Wool MuseumShare Certificate

Share certificate from R.S. & S. Woollen and Worsted Co-operative Manufacturing Coy. Limited Geelong, Victoria dated 16 March 1964 in the name of Brian Owen Leslie Backwell of Leopold. Share certificate no. A 337.RSS Mill share certificate, 1964.textile mills management, textile mills, returned soldiers and sailors mill, textile mills - management -

National Wool Museum

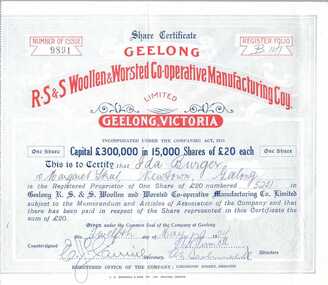

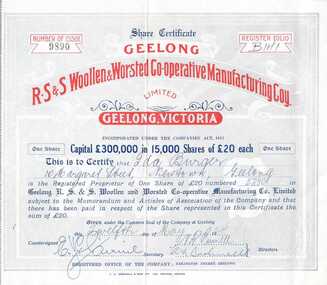

National Wool MuseumShare Certificate

R.S. & S. Woollen and Worsted Co-operative Manufacturing Coy. Ltd share certificate No. 9891 for Ida Burger, 12/5/1954. Share worth 20 pounds. Signed by RSS Mill company secretary E.J. Fairnie.RSS Mill share certificate, 1954.textile mills management, textile mills, returned soldiers and sailors mill, fairnie, mr edward john - returned soldiers and sailors mill, textile mills - management -

National Wool Museum

National Wool MuseumShare Certificate

R.S. & S. Woollen and Worsted Co-operative Manufacturing Coy. Ltd share certificate No. 9891 for Ida Burger, 12/5/1954. Share worth 20 pounds. Signed by RSS Mill company secretary E.J. Fairnie.RSS Mill share certificate, 1954.textile mills management, textile mills, returned soldiers and sailors mill, fairnie, mr edward john - returned soldiers and sailors mill, textile mills - management -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's Bombasine jacket, c1900

This lady's jacket would have been worn for special occasions by an early settler of the Moorabbin Shire c1900. Bombasine material was usually black and worn during the mourning time. It has a dull, twilled surface with a silk warp and worsted wool weftA lady's shiny black Bombasine dress jacket with embroidery at buttonsclothing, brighton, moorabbin, pioneers, sewing, dendy henry, early settlers, craftwork, jackets -

National Wool Museum

National Wool MuseumBook, I.C.S. Reference Library no. 92

"I.C.S. Reference Library no. 92: glossary of weaves, elementary textile designing, analysis of cotton fabrics, analysis of woolen and worsted fabrics, twill weaves and derivatives, satin and other weaves, combination weaves, construction of spot weaves, weaves for backed cotton fabrics, woolen and worsted ply weaves, leno weaves, pile weaves, color in textile designing, designing in general" International Correspondence Schools Ltd, 1921. There is a fine ex libris plate (designed by W.L. Trigg) on the inside of the front cover depicting the Anzac statue from the RSS Mill. This book is from the library of V.J. Schofield, son of Albert Schofield, the first managing director of the RSS Mill.EX LIBRIS / V.J. SCHOFIELD / W.L. TRIGGweaving textile design cotton textile mills, international correspondence schools ltd returned soldiers and sailors mill, cloth - woollen, cloth - worsted, twill, trigg, w. l., weaving, textile design, cotton, textile mills -

National Wool Museum

National Wool MuseumBook, I.C.S Reference Library No. 106

"I.C.S Reference Library no. 106: arithmetic, logarithms, mensuration, woollen and worsted yarn calculations, mechanical definitions, mechanical calculations, reading textile drawings, wool, wool washing, wool drying, burring and carbonising, wool oils and oiling" International Correspondence Schools Ltd, 1923.textile production wool processing, international correspondence schools ltd, cloth - woollen, cloth - worsted, carbonising, burring, textile production, wool processing -

National Wool Museum

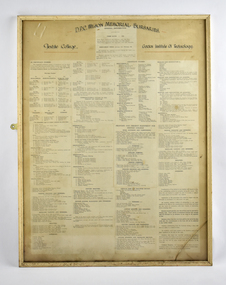

National Wool MuseumPhotograph - Framed Printed Coursework, Gordon Institute of Technology, Textile College, 1950

Framed papers outlining the courses and coursework for the Textile College at the Gordon Institute of Technology in 1950. The courses include Woolcombing, Worsted Spinning, Woollen Yarn Manufacture, Designing, Weaving and Turning and Finishing. A digital copy of this item was made for the National Wool Museum Collection, with the original remaining with the donor. Digital TIFF file, 100 MB, showing image of framed printed paper.D.P.C. WILSON MEMORIAL BURSARIES. / Textile College / Gordon Institute of Technology. / GENERAL INFORMATION / TERM DATES 1950 ...courses, gordon institute of technology, textile college, geelong, woolclassing, weaving, spinning, coursework, 1950 -

National Wool Museum

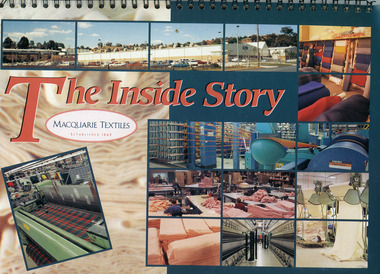

National Wool MuseumBooklet - Binder, The Inside Story, 1995

Binder begins by discussing the history of Macquarie Textiles before expanding into explaining the operations of the company and how they produce their different finished worsted and woollen textiles. The information is dated to 1995 and makes for interesting reading into the past, especially the information in regards to computers and how they were begin to be introduced into the work place.A4 sized binder with 8 individual pages containing information on both front and back. Coloured ink with attached samples make up the contents of these pages. All pages have the same image of wool in the backgroundmacquarie textile, wool processing -

Federation University Historical Collection

Federation University Historical CollectionBook, The Year Book and Diary 1914, 1914

... worsteds ...Sixtth year of issueBlack hard covered book of 592 pageswool, carding, weaving, spinning, sizing, dyeing, worsteds, waterproofing, factory, trade, associations, unions -

National Wool Museum

National Wool MuseumBook - Textile Industry (Woollen and Worsted Section) Award 1963, Australian Textile Workers’ Union, 1963

Thirty six page booklet with printed black and white text. Front and back cover grey with printed black text. Blue pencil marks are shown on the front. front: [printed] Textile Industry / (Woollen and Worsted Section) / Award, 1963 / Issued for use of members by:- / VICTORIAN CHAMBER OF MANUFACTURERS / CHAMBER OF MANUFACTURERS OF NEW SOUTH WALES / SOUTH AUSTRALIAN CHAMBER OF MANUFACTURERES / INCORPORATED / TASMANIAN CHAMBER OF MANUFACTURERSunions, textile workers union, award, legal document, textile industry, woollen, worsted -

National Wool Museum

National Wool MuseumBook, Scouring and Milling

"The Science and Practice of Scouring and Milling in the Worsted and Woollen Industries" - John Schofield, 1921. There is a fine ex libris plate (designed by W.L. Trigg) on the inside of the front cover depicting the Anzac statue from the RSS Mill. This book is from the library of V.J. Schofield, son of Albert Schofield, the first managing director of the RSS Mill.EX LIBRIS / V.J. SCHOFIELD / W.L. TRIGGtextile mills, returned soldiers and sailors mill, scouring, milling, cloth - woollen, cloth - worsted, trigg, w. l. -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Packaging, W'bool Woollen Mill, between 1983 and 1994

The Warrnambool Woollen Mill was established in South Warrnambool in 1909 and was officially opened in 1910 with John Bennett as the first manager. In 1968 the mill was sold to the Dunlop company and in 1982 Dunlop sold the mill to Onkaparinga Woollen Company. In 1983 Onkaparinga was taken over by Macquarie Worsteds and traded in Warrnambool as Warrnambool Textiles. This arrangement ceased in 1994. In 2000 the mill closed after 90 years of operations.This is not a very significant item but it is interesting as it is connected to one of the major industries operating in Warrnambool for 90 years (1910-2000). It highlights also one aspect of the mill’s history- the years 1983-1994 when the mill operated as Warrnambool Textiles. This is a plastic shopping bag from the Warrnambool Woollen Mill shop. It has red printing on the front and back.‘Bargains Galore at the Woollen Mill Shop, Located at the Mill, Warrnambool Textiles, Harris Street, South Warrnambool, 3280, Phone: (055) 64 0044’warrnambool woollen mill -

National Wool Museum

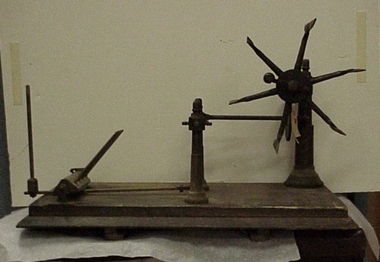

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Packaging, Blanket Box, 1990s

This item has been made to package a ‘Dream Sleep’ underblanket. This item was produced by the Warrnambool Textiles factory in the 1990s. In 1910 the Warrnambool Woollen Mill was established and it produced blankets, rugs etc with a staff of over 700 in the 1940s. In 1958 the Mill became the first in Australia to manufacture electric blankets. In 1968 the business was sold to Dunlop and in 1982 Dunlop sold the Mill to Onkaparinga Woollen Company. In 1983 Onkaparinga was taken over by Macquarie Worsteds and the Warrnambool Woollen Mill then traded as Warrnambool Textiles. In 2000 the Mill closed. This packaging is of some interest as a memento of the old Warrnambool Woollen Mill which operated in Warrnambool for 90 years and was a major industry in the town/city and a major employer of local residents. It is still remembered fondly by many local people today. This is a cardboard sheet for packaging an underblanket for Warrnambool Textiles. It has white printing on a dark blue background on one side and is white and unmarked on the other. It has an image of a sheep, three symbols for ‘Pure New Wool’, a symbol for ‘Naturally Flame Resistant’ and one for ‘Moth-Resist Treated’. The sheet is designed to be folded in four places to cover an underblanket. This is a cardboard sheet for packaging an underblanket for Warrnambool Textiles. It has white printing on a dark blue background on one side and is white and unmarked on the other. It has an image of a sheep, three symbols for ‘Pure New Wool’, a symbol for ‘Naturally Flame Resistant’ and one for ‘Moth-Resist Treated’. The sheet is designed to be folded in four places to cover an underblanket. warrnambool woollen mill, warrnambool textiles, onkaparinga woollen company -

Warrnambool and District Historical Society Inc.

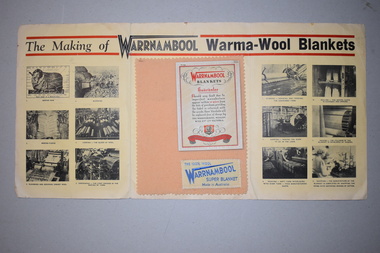

Warrnambool and District Historical Society Inc.Brochure, The Warrnambool Woollen Mill Co Ltd, c.1950

This is an advertising leaflet issued by the Warrnambool Woollen Mill Co. This mill was established in South Warrnambool in 1910 with John Bennett the first Manager. The mill’s production increased during both World Wars with government contracts and wartime demands. In the 1940s the mill employed over 700 people. In 1968 the mill was sold to the multinational company Dunlop which in turn sold the business in 1982 to Onkaparinga Woollen Mill. In 1983 Onkaparinga was taken over by Macquarie Worsteds and in 1994 this group pulled out of Warrnambool. The Warrnambool Woollen Mill closed in 2000 after 90 years of operation. This leaflet is of interest as an example of the advertising mechanisms produced by the Warrnambool Woollen Mill when it was a locally run large-scale business in the city. The business was a dominant one in Warrnambool for many decades, employing many local people. The factory itself was a well-known landmark in the city. This is a sheet of buff-coloured thick paper folded in two places to make a six-page leaflet. The front page has an aerial black and white photograph of the Warrnambool Woollen Mill, two of the inside pages have 12 black and white photographs showing the processes in making woollen blankets and two other pages have advertisements for Warrnambool blankets and dress suiting material. Inside the folder is a sample piece of pink blanket with a card in red and cream colouring showing the factory’s guarantee. The sample has been glued to the paper. There is evidence of silverfish damage on both the blanket sample and the paper. ‘With the Compliments of the Warrnambool Woollen Mill Co. Ltd.’warrnambool woollen mill -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Lady's nightdress crepe de chine, floral c1950, c1950

Gladys Reed was a member of the Ormond Choral Society c 1950. who performed plays and musicals in the City of Moorabbin and she made this nightdress c1950 Crepe de Chine, also spelled Crêpe De Chine, (French: “crepe of China”), light and fine plain woven dress fabric in silk, wool, or synthetic fibre fabric with a distinctively crisp, crimped appearance produced either with all-silk warp and weft or else with a silk warp and hard-spun worsted weft. This material was easy to sew, wash and dry and required no ironing . . This crepe de chine nightdress is an example of the popular style worn by women in the post World War 11 Estates in the City of Moorabbin c1950 A lady's floral crepe de chine, full length, nightdress with shoulder straps and waist ties clothing, nightdress, crepe de chine, theatrical props, craftwork, sequins, beading, early settlers, moorabbin shire, mechanics institute cheltenham, ormond choral society, postworld war 11 settlers, housing estates moorabbin 1950, bentleigh, ormond, moorabbin, cheltenham, drama societies, musical society cheltenham, clark judy, reed gladys, reed george -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Book, Charles Hurst, Valves and Valve-Gearing, 1907

This is a technical book regarding valves and their maintenance in machinery.This is a book of 258 pages plus 86 pages of advertisements. The cover is dark red with an embossed shield on the front cover and gold printing on the spine. The pages contain a black and white photograph, many illustrations and diagrams and several pages of fold-out sketches. non-fictionThis is a technical book regarding valves and their maintenance in machinery. henry family, warrnambool woollen mill, valves and valve gearing -

National Wool Museum

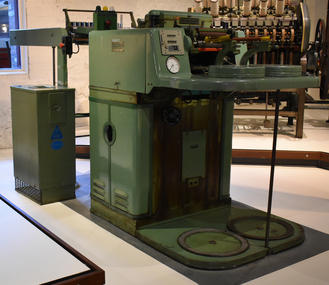

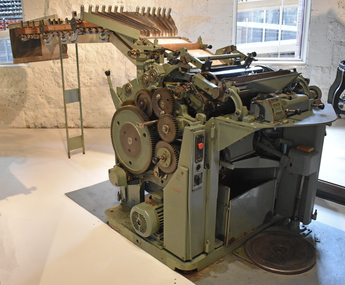

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

National Wool MuseumCertificate, South Australian Chamber of Manufactures Centennial Exhibition, 1936

Certificate awarded to the Geelong RSS Mill for winning the gold medal for the most attractive still grouped exhibit at the South Australian Chamber of Manufactures Centennial Exhibition in 1936.Certificate awarded to the RSS Mill for the most attractive still grouped exhibit at the South Australian Chamber of Manufactures Centennial Exhibition, 1936.South Australian Chamber of Manufactures / INCORPORATED. / Centennial Exhibition / MARCH 20th to MAY 16th, 1936. / GOLD MEDAL / AWARDED TO / GEELONG RETURNED SAILORS' & SOLDIERS' / WOOLLEN & WORSTED MANUFACTURING CO. LTD. / Most Attractive Still Grouped Exhibit. / Section A. / H.E. WINTERBOTTOM, Secretary. / Modern Printing Company, Chancery Lane, Adelaide. Phone, Central 283.woollen mills history, textile mills, returned soldiers and sailors mill, 1918: australians in france - exhibition (19/02/2000 - 30/04/2000), woollen mills - history -

National Wool Museum

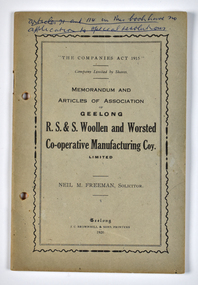

National Wool MuseumBooklet, Neil M Freeman, Memorandum an Articles of Association of Geelong R. S. & S. Woollen and Worsted Co-operative Manufacturing Coy. Limited, 1920

Legal document52 page booklet with typed text and some additional typed text pasted in over the top of some sections.cover: [handwritten] articles 71 and 114 in this book have no / application to special resolutions cover: [printed] "THE COMPANIES ACT 1915" / Company Limited by Shares / MEMORANDUM AND / ARTICLES OF ASSOCIATION / OF / GEELONG / R. S. & S. Woollen and Worsted / Co-operative Manufacturing Coy. / LIMITED / NEIL M. FREEMAN, SOLICITOR. / Geelong / J. C. BROWNHILL & SONS, PRINTERS / 1920 -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Folder, Warrnambool Woollen Mill Co Ltd, Warrnambool Woollen Mill, 1950s

This folder contains photographs, advertisements and a sample of a piece of blanket from the Warrnambool Woollen Mill. This mill was officially opened in South Warrnambool in 1910 following the establishment of a local public company. The first manager was John Bennett from Yorkshire, England. The operations of the mill expanded with new buildings enabling the business to double in size by 1915. In the 1940s the factory was employing 700 people. In 1968 the factory was sold to Dunlop Australia but was sold again in 1982 to Onkaparinga Woollen Company. In 1983 Mcquarie Worsteds took over the factory with the business then known as Warrnambool Textiles. In 2000 the mill closed and most of the buildings were later demolished for a housing estate. This item is an attractive and informative memento of one of Warrnambool’s most important businesses of the past. The Warrnambool Woollen Mill operated for 90 years and employed many local people. The photographs are of particular interest.This is a rectangular-shaped sheet of buff-coloured lightweight cardboard. It has been folded twice to create six pages in a folder. Three pages contain black and white photographs of the woollen mill operations and two pages contain advertising material with black and white images. One page has a cream blanket piece of material attached to the page by two staples and this has the brand name stitched onto the right hand corner This piece of blanket also has a paper guarantee card attached by staples. The Warrnambool Woollen Mill Co. Ltd. South Warrnambool The 100% Wool Warrnambool Super Blanket Made in Australia warrnambool woollen mill, history of warrnambool -

Federation University Historical Collection

Federation University Historical CollectionBooklet, N.L. Harvey Photographers, All that Glitters ... :The Growth of Ballarat Victoria, c1966

Red, blue and gold soft covered booklet. Images include the Ballarat Town Hall, The Eureka Monument, Begonia house, Ballarat Botanic Gardens,M.B. John, Sebastopol Technical School, reservoirs, Ballarat Base Hospital, Calembeen Park, Ballarat Industrial Estate, Lal Lal Falls, Buninyong Golf Course, Mayne Nickless, Firth Cleveland Plant, Bendix Mintex, Bunge, (Aust.) Pty Ltd, Martin's Stoneware, Sunshine biscuits, Timken, M.B. John and Hattersley Limited, Ballarat Gas Company, Ballarat Paper Mills, Ballarat Woollen and Worsted Mills, Eclipse Motors, E. Lucas and Co, Milk Processors Pty Ltd, Eureka Valves, Paddle Bros., George Farmer Pty Ltd, Sebastopol technical School, Burrumbeet and Windermere Co-Operative Society Ltd .greater ballarat association, develop victoria council, ballarat, begonia queens, yvonne arstall, carol penrose, wendy longmore, lal lal falls, ballarat town hall, the eureka monument, begonia house, ballarat botanic gardens, m.b. john, sebastopol technical school, reservoirs, ballarat base hospital, calembeen park, ballarat industrial estate, buninyong golf course, mayne nickless, firth cleveland plant, bendix mintex, bunge, martin's stoneware, sunshine biscuits, timken, m.b. john and hattersley limited, ballarat gas company, ballarat paper mills, ballarat woollen and worsted mills, eclipse motors, e. lucas and co, milk processors pty ltd, eureka valves, paddle bros., george farmer pty ltd, yvonne arsrtall, wendouree, shire of wendouree, guncotton factory, regina glass fibre -

National Wool Museum

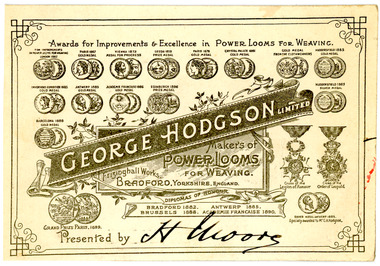

National Wool MuseumAdministrative record - Business Card, George Hodgson Limited Business Card, Unknown

George Hodgson Limited Business Card, a British loom manufacture based in Bradford England. The card showcases the awards the company as won as well as a description of one of their looms.Cream business card printed with the black ink. The front of the card lists the awards and medals the company had one in the background with an image of each award. The company logo is placed in the center. The back of the card has a drawing of a loom with a decorative border.Front top edge - Awards for Improvements & Excellence in Power Looms for Weaving. Front middle - George Hodgson Limited Makers of Power Looms for Weaving. Bradford, Yorkshire, England Front bottom edge - Presented by J T Elioors (?) Back bottom edge - One shaft heavy underpick worsted and woollen cloth loom, with 4 holed drop box on each side, fitted with positive wheel dobby.textile machinery, wool manufacture, wool, loom, george hodgson limited -

Glen Eira Historical Society

Glen Eira Historical SocietyDocument - Classic Retirement Village, Brighton

Four documents about the history of this site pre Classic Retirement Village: 1/A copy of a description of the sale process of the Gascor site, cnr Nepean Highway and Thomas Street, to Becton Corporation in 1997 And 1998. Printed on 31/07/2010 from the Victorian Auditor General’s Department website with aerial photograph 2/A copy of page one of the Gleneira Planning Scheme dated 19/01/2006 which mentions the Gascor site. 3/Research note by Andrew Frederick dated August 2010 listing occupiers of the site in the 1960 and the 1970 Sands and Mc Dougall Directories. 4/Research note by Claire Barton dated May 2010 containing Ian Swan’s recollections of working at Daylesford Worsted Woollen, occupier of the site, in the 1960s.thomas street, brewer road, bentleigh, gascor, becton corporation pty ltd, virginia park, gas and fuel, hughesdale dairy, east boundary road, moorabin, east bentleigh, hooblerstone, clairmont avenue, glen eira, daylesford centenary woollen and worsted mills pty ltd., nepean highway, f and j industries australia plastic and rubber division., swan ian, korman stanley, mills, wool industry, weaving mills, textile factories, textile manufacturing, manufacturing industry -

National Wool Museum

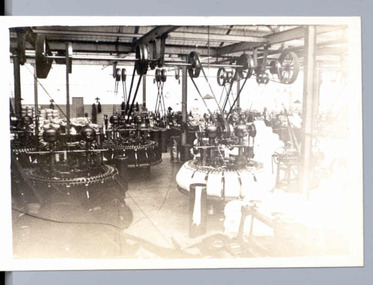

National Wool MuseumPhotograph - Noble Combs, Valley Worsted Mill, 1923

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs. "These 12 machines ended their working life in 1981 when the mill switched from the Bradford system of wool combing to the Continental system, the reason being was that the cost of maintaining them became too high, also the replacement rectilinear combs production rate was far greater and achieved higher yields although it could be argued that the Noble combs quality was superior". - Greg AldridgeBlack and white image showing the interior of a textile mill with machinery. Slightly overexposed on the right side.valley worsted mill, combing, noble comb, geelong -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

National Wool Museum

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres