Showing 2934 items matching "on tin"

-

Bendigo Military Museum

Bendigo Military MuseumMemorabilia - BADGES

Belonged to Fanny Isabella Nicol Staff Nurse AIF. Refer 1795P for service history, 2317.6, 2591.4 paper & circular tin ANZAC day badges (not individually marked) .1) round paper badge "Remembrance " wattle flowers .2) square badge union jack flag and Navy flag (red) .3) round badge "remembrance." ANZAC day (1936) mauve .4) R.S.L remembrance ANZAC day (1940) yellow paper badge. .5) round metal badge ANZAC day purple / yellow .6) round badge metal ANZAC day (1939) purple/ green .7) round badge (metal) ANZAC day (1938) blue/ green with a laurel wreath + bow .8) round metal badge twentieth anniversary (1935) green/ blue .9) round metal badge "Lest we forget." brown /white) soldier with open. badges, remembrance, australian -

Flagstaff Hill Maritime Museum and Village

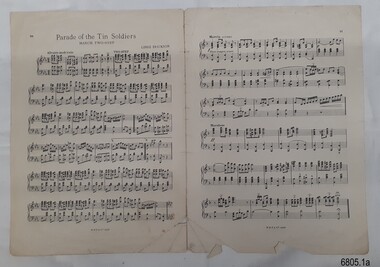

Flagstaff Hill Maritime Museum and VillageDocument - Sheet Music, W H Paling & Co., music publisher, 1900s-1920s

The tunes in the set of sheet music are mostly marches, jaunty and bright songs from the 1910s. The sheet music were published by W H P & Co., which was the company of William Henry Paling, Sydney. Paling was born in the Netherlands in 1825. He was a musician, composer, and violin teacher at the Academy of Rotterdam. In 1853 he arrived in Sydney where he became a piano and violin teacher and a professor of music at a ladies' college. He opened the W H Paling music warehouse around the same time, at 85 Wynyard Square in Sydney. He initiated clubs and groups, was involved in fundraising in the community, and conducted a Philharmonic Society concert. He seized the opportunity to supply the growing demand for pianos and local sheet music, becoming an agency for European manufacturers. He made several trips to Europe to supply his business. In 1875 the firm opened up premises in George Street Sydney. On his 1884-85 trip, he met Pietro Marich, an Austrian musician and businessman who then joined Piling's company and successfully expanded it into large premises with showrooms. In 1886 Piling's brother John joined the firm as partner. In 1883 it became a limited liability company, setting up in other major cities. He had many civic involvements and eventually presented his model farm at Campden for use as a hospital, along with finances to erect buildings on the land. He became ill after a trip to Europe, passing away in 1895, but the company continued in business.The collection of sheet music represents the musical and entertainment taste of the early 20th century. Sheet music was collected from Europe and locally and played in homes and public gatherings for listening to, for dancing and for background music. It was even recorded and played on portable gramophones with wax cylinders.Sheet Music wet; three sheets of printed music, comprising two large sheets with two pages of music printed on each side in black ink, and one small sheet with one page of music printed on one side in red ink. Music on the large sheets is March Music by W H P & Co. no. 1437, which is the same company as the music on the last sheet, The Music on the small sheet is Tango Music by Paling & Co. Ltd, of Sydney, and established by William Henry Paling (W H & P Co). Music Titles on the large sheets are: - - Parade of the Tin Soldiers - Guard of Honour - Irish Guards March - Slope Arms Music title on the small sheet is: - - Caro Mio Tango (My Dear) by Silvo ArnoOn the large sheets: printed "W.H.P. & CO." "1437" and handwritten in pencil "268" On the small sheet: printed "THE LATEST SUCCESS" "Try this on your piano" "Price 1/6 or Post Free 1/7, From all Music Stores, or direct from the Publishers" "PALING & CO. LTD. George-st., SYDNEY."flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sheet music, music, guard of honour, parade of the tin soldiers, irish guards march, caro mio tango (my dear), w h p & co., william henry paling, pietro marich, john piling, jos j kaiser, silvo arno, leon jessel, george street sydney, early 29th century, march music, tango music -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCase for G.P. Multimeter, Circa 1950

This leather case holder for a general purpose Multi-meter( KVHS 0307 (A)) was manufactured after 1950 and used by the SEC Vic (Kiewa Hydro Electricity Scheme) from that date until late 1900's. It was used to measure very small voltages associated with the operation of the various Hydro Generators. The readings were able to be shown by the resistor in use in the current circuit. During this time period, high quality testing instruments were either sourced from Europe or England. This particular carry case was manufactured in the Netherlands. This carry case for an analog General Purpose multi-meter which is quite a large (for a handheld mobile) apparatus.The bag however permits the easy monitoring of electrical variations within the large SEC Victoria Hydro Scheme's electrical generators. These generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro schemes was achieved from the mid 1900's to the 1960's. At this point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This leather case is to provide protection for this mobile G.P. Multimeter, therefore it is made from thick leather. It has a carrying strap from a thick "D" chromed link. This link is fastened to the main cover by a looped leather strip with a black coloured rivet. All the fasteners are either chrome or black coloured rivets. The front, which when opened back exposes fully the inside of the case. It is clip fastened to the lower section of the front piece which also can be pushed back allowing the meter to be removed from the frontal position. There is a strip retaining strap slightly higher from the mid point. This is fasted by a black press stud. There are two "L" shaped tin protrusions allowing the meter to slide only down the case until it rests on these shelves. This provides for an empty space for minimal storage,.On the front bottom and below the clasp is a tag "STATE ELECTRICITY COMMISSION OF VICTORIA TRANSMISSION DEPT."sec vic kiewa hydro scheme, alternate energy supplies, alpine population growth -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: THREE WOOD SPOKEHAVES

Pittock collection: three wood spokeshaves, metal construction * one straight spokeshave, marked 64, 230 mm L x 40 mm W * one rounded spokeshave, marked B, 250 mm L x 60 mm W * one specialised marking/shaping tool, wide guide, marked Stanley No. 66 Pat'd Feb 9.86, 300 mm L x 50 mm W x 55 mm D * variety of shaping tool blades for Stanley tool, 60 mm x 15 mm blades. Stored in Havelock Flake Cut Pure Virginia Tobacco tin, 80 mm L x 55 mm W x 15 mm D Items stored in Pittock coach builder's box, reference 13000.1. -

National Wool Museum

National Wool MuseumGriswold stocking knitting machine, c1890 - 1900

The machine was most recently used by donor's father c2008 to knit socks, but had been used for many years earlier. According to family history, it is believed that the machine came to Australia with donor's grandparents in the early 20th century, and was created c1890-1900. It is still in working order and a demonstration was given by the donor during the acquisition process.Griswold stocking knitter machine. Black steel manual machine which clamps on to the edge of a table and is operated by turning a handle. Centre of machine is a cylinder which can be lined with pins to create the sock/stocking. Two detached parts of the machine include a bobbin holder and yarn feeder. Accompanying items include: 3 examples of incomplete attempted socks made by donor. 4 envelops containing instructions, pattersn, notes and advice on using the machine, created by donor's father and grandfather. 1 bobbin with grey yarn. 2 metal machinery pieces. 2 tins containing pins for the machine. 1 metal yarn feeder cone. 10 weights plus two weight stands. Stocking knitter machine has an identifier plate with patent numbers on the side. -

Kew Historical Society Inc

Kew Historical Society IncBooklet, Arbuckle, Waddell & Fawckner, The Pickwick Portfolio, Vol.1 No.2, 1912

Pickwick Clubs were established around the world in the nineteenth and twentieth centuries, inspired by the first novel of Charles Dickens. A Kew branch was formed in 1897 and lasted until c.1912. Its membership was drawn from a number of notable Kew families. The club published two booklets, the first in 1904 and the second in 1912. In addition to holding meetings, club members performed in productions of Shakespearian plays in the Recreation Hall in Wellington Street Kew. Members of the club adopted pseudonyms based on characters in Dickens' novels.Literary publication of of artistic (literary) significance recording the social and cultural activities of a group of residents of Kew and its environs that operated from 1897 to c.1912. Another copy is held by the State Library of New South WalesContents of The Pickwick Portfolio, Vol.1, No.2 - Frontispiece / Mark Tapley (Alice Bale); Editorial; To Pickwick / John Jarndyce (Mr G. Bell); A sonnet / BarkisThe Pickwick Portfolio being the magazine of The Pickwick Club, Kew, Vol.1, No.2 January 1, 1912 (Mr McCowan); Nikko / Barnaby Rudge (Mr H. Gaze); The lady or the tiger? / Nathaniel Winkle (Mr J.A. Richardson); Why? / Alfred Jingle (Mr H.M. King); The autobiography of Richard Pitt Cobden Slugger / Sam Weller (Mr P Vines); A new natural history; A kerosene tin / Wardle (Mr Veitch); Peter, or butt me no butts / Henrietta Boffin (Mrs J.A. Richardson); Laughter: can it be cured? / Cap'n Cuttle (Mr E. Vines)fictionthe pickwick club - kew, literary clubs, pickwick clubs, charles dickens -

Ringwood and District Historical Society

Ringwood and District Historical SocietyBiography, He heard Dickens, Disraeli, 21-Jul-44

Handwritten article about Captain Edward Thomas Miles 21-Jul-1944, copied from a newspaper.This is a handwritten copy from an unnamed newspaper. Refer also to the Australian Dictionary of Biography.; 21-Jul-1944 - Newspaper.; He heard Dickens, Disraeli; Captain Edward Thomas Miles who died recently at Ringwood where he had lived in retirement for many years, was born in Hobart 1849 and gained Master Mariners Certificate at 21 and his first command two years later. Served in the China, South African and Indian Wars. Was on the China - London tea run.; Pioneered the coastal trade of Tasmania.; was warden of Hobart marine Board, Member for Glamorgan in the Tasmanian House of Assembly for 12 years and also a minister before Federation.; In 1905 got Concession from Siam to form the Tongkah Harbour Tin Dredging Company, which later won 2,000,000 pounds worth of Tin. Sons and Grandsons managed the original company until present war, and one son and three grandsons remained to become prisioners of war.; Met Cecil Rhodes when he went to the Cape with his first sample of diamonds from the Kimberley.; With all other ship's officers was called out as special policeman to quell the Fenian riots in London.; Heard on several occasions Charles Dickens reading his own works. Listened to Disraeli and Gladstone speaking in the House of Commons.; With his partners built the Zeehan to Strahan railway, Tasmania, 29 miles. Was shipwrecked 3 times.; His first memory was that of travelling with his parents to the gold diggings in Victoria by bullock cart in 1852 at the age of three years. +Additional Keywords: Miles, Captain Edward Thomas / Dickens, Charles / Disraeli / Rhodes / Gladstone -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Photo Postcard, Pond near Eltham Park, c.1910

This card depicts the pond near Eltham Park (later Eltham Lower Park) circa 1910. The view is taken from Maria Street (Main Road) opposite Dalton Street looking northwest across the Dalton Street road extension reserve (now Wingrove Park Trail) and Jarrold farm. A haystack is visible. Also visible is a gas streetlight and White Cloud cottage which belonged to the Jarrold family From the same collection as accession no. 00778, (Yarra at Eltham) - sent from Eltham and addressed to "Mr J. L. Brown, "Elthamville", Tinning Street, Brunswick" "with love from Nellie" who was most probably a member of the extended Brown family, and no. 00780 (Eltham, J.H. Clark Photo - dated 20 May 1911). Sending postcards to family and friends including short messages was a common form of communication in the early 20th century. Part of a slide show presentation "Bridges & Waterways of the Shire" by Russell Yeoman to the 13 September 1989 Society meeting. The presentation included slides of historic photos from the Shire of Eltham Pioneers collections as well as several recent views.Sending postcards to family and friends including short messages was a common form of communication in the early 20th century.Sepia postcard in very poor condition which has been removed from an album. Glue residue and album page adhering preventing information being readFront: Pond near Eltham Parkpostcard, eltham, pond, dalton street, duck pond, eltham park, elthamville, gas lamp, haystack, jarrold cottage, jarrold property, main road, maria street, white cloud cottage, wingrove park trail -

Federation University Art Collection

Federation University Art CollectionPainting - Artwork - watercolour, Wes Walters, [Boats] by Wes Walters, 06/1948

Wes WALTERS (06 August 1928 - 19 August 2014) Born Mildura, Victoria From 1940 t0 1945 Wes Walters attended the Ballarat High School. He then studied architecture at the Gordon Institute in Geelong, followed by art at the Ballarat School of Mines (a division of the Ballarat School of Mines). During his time at the Ballarat Technical Art School (later Federation University Australia) Walters studied under Neville Bunning and Taylor Kelloch, and was awarded the Ballarat Ladies Art Association Scholarship in 1948. He next moved to Melbourne to work as a commercial artist with the George Patterson advertising agency. Each evening Walters studied life drawing at the Victoria Artists’ Society and taught himself anatomy. Wes Walters excelled in both abstract and realist art. He won the Art Gallery of Ballarat’s Minnie Crouch Prize for watercolour art in 1953 and 1956. He won the prestigious Archibald Prize in 1879 for his portrait of Phillip Adams, and the sketch was completed tin preparation for that portrait. 2 This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Framed watercolour behind glass depicting moored sailing boats.Signed lower right 'W.R. Walters June 48' Sticker verso "Jaman the Picture Framer 84-88 Lt Collins Street Melbourne Phone Cent 4802"wes walters, watercolour, boats, coastal, sailing, alumni -

![Drawing - Artwork, [Title Unknown] by Wes Walters](/media/collectors/530576742162ef0fa09a2288/items/558384312162f11b8cbfb771/item-media/558384e12162f11b8cbfcf01/item-fit-380x285.jpg) Federation University Art Collection

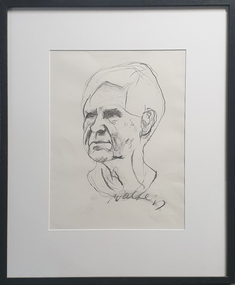

Federation University Art CollectionDrawing - Artwork, [Title Unknown] by Wes Walters

Wes WALTERS (06 August 1928 - 19 August 2014) Born Mildura, Victoria From 1940 t0 1945 Wes Walters attended the Ballarat High School. He then studied architecture at the Gordon Institute in Geelong, followed by art at the Ballarat School of Mines (a division of the Ballarat School of Mines). During his time at the Ballarat Technical Art School (later Federation University Australia) Walters studied under Neville Bunning and Taylor Kelloch, and was awarded the Ballarat Ladies Art Association Scholarship in 1948. He next moved to Melbourne to work as a commercial artist with the George Patterson advertising agency. Each evening Walters studied life drawing at the Victoria Artists’ Society and taught himself anatomy. Wes Walters excelled in both abstract and realist art. He won the Art Gallery of Ballarat’s Minnie Crouch Prize for watercolour art in 1953 and 1956. He won the prestigious Archibald Prize in 1879 for his portrait of Phillip Adams, and the sketch was completed tin preparation for that portrait. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Black and white charcoal drawing in white frame with glass.wes walters, drawing, available, alumni -

Federation University Art Collection

Federation University Art CollectionDrawing, Wes Walters, 'Towards' by Wes Walters, 1991

Wes WALTERS (06 August 1928 - 19 August 2014) Born Mildura, Victoria From 1940 t0 1945 Wes Walters attended the Ballarat High School. He then studied architecture at the Gordon Institute in Geelong, followed by art at the Ballarat School of Mines (a division of the Ballarat School of Mines). During his time at the Ballarat Technical Art School (later Federation University Australia) Walters studied under Neville Bunning and Taylor Kelloch, and was awarded the Ballarat Ladies Art Association Scholarship in 1948. He next moved to Melbourne to work as a commercial artist with the George Patterson advertising agency. Each evening Walters studied life drawing at the Victoria Artists’ Society and taught himself anatomy. Wes Walters excelled in both abstract and realist art. He won the Art Gallery of Ballarat’s Minnie Crouch Prize for watercolour art in 1953 and 1956. He won the prestigious Archibald Prize in 1879 for his portrait of Phillip Adams, and the sketch was completed tin preparation for that portrait. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Framed and mounted abstract artwork wes walters, artist, artwork, drawing, walters, available -

Federation University Art Collection

Federation University Art CollectionDrawing - Pencil on paper, Wes Walters, 'Self Portrait', by Wes Walters, 1980

Wes WALTERS (06 August 1928 - 19 August 2014) Born Mildura, Victoria From 1940 t0 1945 Wes Walters attended the Ballarat High School. He then studied architecture at the Gordon Institute in Geelong, followed by art at the Ballarat School of Mines (a division of the Ballarat School of Mines). During his time at the Ballarat Technical Art School (later Federation University Australia) Walters studied under Neville Bunning and Taylor Kelloch, and was awarded the Ballarat Ladies Art Association Scholarship in 1948. He next moved to Melbourne to work as a commercial artist with the George Patterson advertising agency. Each evening Walters studied life drawing at the Victoria Artists’ Society and taught himself anatomy. Wes Walters excelled in both abstract and realist art. He won the Art Gallery of Ballarat’s Minnie Crouch Prize for watercolour art in 1953 and 1956. He won the prestigious Archibald Prize in 1879 for his portrait of Phillip Adams, and the sketch was completed tin preparation for that portrait. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Framed pencil self portrait by Wes Walters drawn close to the time he completed the Archibald Prize winning portrait of Phillip Adams. Signed and dated lower centre: '1/2/79 Walters' art, artwork, walters, wes walters, portrait, sketch, available -

Federation University Art Collection

Federation University Art CollectionDrawing - Charcoal on paper, Wes Walters, 'Study for Portrait of Arthur Boyd' by Wes Walters, 1982, 1982

Wes WALTERS (06 August 1928 - 19 August 2014) Born Mildura, Victoria From 1940 t0 1945 Wes Walters attended the Ballarat High School. He then studied architecture at the Gordon Institute in Geelong, followed by art at the Ballarat School of Mines (a division of the Ballarat School of Mines). During his time at the Ballarat Technical Art School (later Federation University Australia) Walters studied under Neville Bunning and Taylor Kelloch, and was awarded the Ballarat Ladies Art Association Scholarship in 1948. He next moved to Melbourne to work as a commercial artist with the George Patterson advertising agency. Each evening Walters studied life drawing at the Victoria Artists’ Society and taught himself anatomy. Wes Walters excelled in both abstract and realist art. He won the Art Gallery of Ballarat’s Minnie Crouch Prize for watercolour art in 1953 and 1956. He won the prestigious Archibald Prize in 1879 for his portrait of Phillip Adams, and the sketch was completed tin preparation for that portrait. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Charcoal portrait study of Arthur Boyd on Fabriano paper. This sketch is one of several head studies made for the portrait of Arthur Boyd portrait entered into the 1982 Archibald Prize. The painting is in the collection of the Art Gallery of New South Wales. Signed lower right: 'Walters'art, artwork, walters, wes walters, arthur boyd, portrait, available, archibald prize -

Ringwood and District Historical Society

Ringwood and District Historical SocietyBooks, Ian McKellar Books (4): History of the Family, History of Cape Otway, 14 Radar Station Wilson's Promontory, and Mt Hunter Tin Mine. Published 1989-2010

4 books by Ian C. McKellar; �37 A Year And A Free Passage - A History Of The McKellar Family Of Warrnambool. Published by Ian and Margaret McKellar, Heathmont, 1989. Printed by Globe Press P/L Brunswick - 153 pages.; Defending The Eye Of The Needle - A History Of Cape Otway 1939-1945. Published for Ian McKellar and Morrie Fenton, 2010. Printed by PenFolk Publishing, Blackburn - 195 pages.; History And Memories Of 14 Radar Station Wilsons Promontory. Published by Ian and Margaret McKellar, Heathmont, 2004. Printed by PenFolk Publishing, Blackburn - 103 pages.; The Rise And Fall Of The MtHunter Tin Mine, A History Of Northern Wilsns Promontory. Published by Ian and Margaret McKellar, Heathmont, 1993. Printed by Ringwood Litho Art and Design - 46 pages. +Additional Keywords: McKellar, Ian / McKellar, Margaret / Fenton, Morrie -

Ringwood and District Historical Society

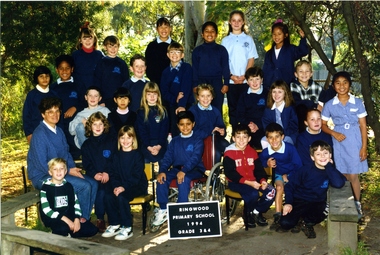

Ringwood and District Historical SocietyPhotograph - Photograph-School, Kuddly Koala School Portraits, Ringwood Primary School 1994 Class Photo Grade 1 and 2, 1994

Grade 1/2 1994. Names taken from typed legend below each photo (via OCR). Photos mounted on Kuddly Koala School Portraits Card. Top Row: (L to R) Timothy Dalton, Sros Sok, Denis Felic, Michael Senton, Rebecca Lewin, Varun Bhatia, Sonya Shafaati 3rd Row: Annie Chen, Diana Stevanovic, Jessica McDonald, Sean Coleman, Mrs. Glenda Winchester. 2nd Row: Teneille Bird, Sharon Legg, Amanda Ashdown, Jane Truong, Nicholas Macklin, Steven Butkovic, Vanny Tin, Christian Santos. 1st Row: Phillip Rouse, Ben Taylor, Aaron Roberts, Kate Hayes, David Doyle, James Davidson, Marie Weaver, Daniel Guy. Teacher: Mr. Jan Michelson. Principal: Mr. Geojf Buzaglo. -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph - Photograph-School, Kuddly Koala School Portraits, Ringwood Primary School 1994 Class Photo Grade 3 and 4, 1994

Grade 3/4 1994. Names taken from typed legend below each photo (via OCR). Photos mounted on Kuddly Koala School Portraits Card. Top Row: (L to R) Jodie Butkovic, Daniel Shaw, Tina Chen, Khushboo Thakkar, Lauren Grigg, Sunley Tin. 3rd Row: Sonia Singh, Luke Puamau, Tom Davidson, Rick Papadimitriou, Rebecca Mollison, Daniel Hadina. 2nd Row: Mrs. Eyck, Matthew Clark, May Lim, Amanda de Vries, Sara Nickson, Kylie McNeil, Sokney Noy. 1st Row: Arran Gray, Erin Smart, Samantha Hayes, Raghav Bhatia, Julian Furzer, Kurt Herdina, Kym Pongho, Brent Senton. Absent: Rebecca Tamme. Teacher: Mrs. Johanna Eyck. Principal: Mr. Geoff Buzaglo. -

Federation University Historical Collection

Federation University Historical CollectionDocument - Documents, James Curtis, Agreement Between University of Melbourne at the Ballarat School of Mines, 1893-1894, 1893, 1885-1887, 1894

.1) Foolscap agreement between the Ballarat School of Mines and the University of Melbourne relating to the affiliation and notice of termination of the affiliation, which was signed by E. a'Beckett, Registrar of the University of Melbourne. A red wax seal is attached to the paper by blue ribbon. The seal is housed in a tin. The seal depicts a woman with wings and the words "VicL ACAD: MELB: SIG: 1853. .2) Document on Cuthbert, Wynne, Morrow nd Must letterhead relating to an affiliation between the Ballarat School of Mines and the University of Melbourne, 1894 .3) Typed notes respecting the proposed affiliation of the Ballaarat School of Mines and the University of Melbourne, 1885 .5) Handwritten notes from Cuthbert and Co regarding the termination of the affiliation between the Ballarat School of Mines and the University of Melbourne .6) Document relating to severing the affiliation between Ballarat School of Mines and the University of Melbourne, 1884e a'beckett, seal, university of melbourne, ballarat school of mines, affiliation, cuthberts, cuthbert, wynne, morrow and must, legal, andrew berry, university seal -

Women's Art Register

Women's Art RegisterWomen's Art Register Bulletin, Women's Art Register, Women's Art Register Bulletin number 43

28 page Magazine photocopy in black and white with following contents where the first figure is the page number and this is followed by the article title then the author.#43 3 News from the Register Gail Stiffe July 2008 25 Nude Margaret Gurney 5 Parallel Dreams Anna Glynn 24 Reflection Helen Clancy and John Bainbridge 13 Success for one of our members Lea Kannar 9 Tin Sheds Gallery, Malmsbury Janet Goodchild-Cuffley and Desiree Radi-Mansbridge 26 Totem Sayraphim Lothian 12 Travelling: Time, Place and Translation: 1 998 – 2008 Noela Stratford 19 Warringah Printmakers Sasha Grishin 21 Water Ghosts Annette Vincent, 15 Women’s Art Library Gail Stiffe and Althea Greenan 7 Words and Images Annette Iggledonmargaret gurney, judy barrass, kate hendry, jan delaney, irina kuzminsky, ramona barry, kevin murray, ellen michel, francesca mataranga -

Brighton Historical Society

Brighton Historical SocietyUniform, Girl Guide uniform, circa 1952-1953

This uniform was worn by Sandra "Sally" Allmand circa 1953-57 as a member of the 3rd St Andrews Girl Guides company in Brighton. Sally Allmand went on to serve on the Brighton Council from 1977 to 1983 and was mayor in 1981.1950s Girl Guides uniform consisting of a dress, belt and beret. Blue cotton dress with long sleeves and high collared neck. Various patches sewn onto sleeves and front breast. Three front pockets fastening with black plastic buttons featuring Girl Guides trefoil logo. Breast pocket has two vertical white stripes. Brown leather belt with silver metal buckle with embossed Girl Guides logo and the text "Girl Guides Association / Be Prepared". Navy blue felt beret with two sewn-on patches. Included with the dress are a Girl Guides 'test card' dated 1953 and a rectangular De Reszke cigarette tin containing a collection of Girl Guide ribbons, patches and buttons. .1 - Dress .2 - Belt .3 - Beret .4 - Test card .5 - Box of patches and ribbonsDress label: "The Guide Shop / STATE HEADQUARTERS / RUN BY GUIDES / FOR GUIDES".girl guides, sally allmand, 1950s -

Mont De Lancey

Mont De LanceyContainer - Cane Sewing Basket, Happy Home, 1950's

The handmade basket has a variety of pieces of vintage sewing items as listed in the detailed Description. These would have been used in the home for repairs as well as pieces sewn. Mrs Pratt owned the sewing basket and it's contents - she lived in Beenak Road, Wandin, Victoria.An open rectangular shaped cane woven sewing basket with three bands of green and tan raffia woven around the sides. It had a lid which is missing but there is one twisted wire loop where the lid would have been attached. Inside are various pieces of vintage sewing items including; large and small cotton reels with cotton thread, very small cotton cardboard reels with thread, plastic container of pins, a handmade wooden darning mushroom, a brightly coloured tin of pins and needles, two short zips, a piece of embroidery material stamped with a pansy pattern to sew, a Birch brand packet of sewing needles, a Delyta brand "Nu-Bras" Brassiere Repair Set, two "Mendex" Cuff Savers for Men's Trousers, a Happy Home Needle Book with a few needles, and a paper pattern for Cross Stitch. See above for the brands and details of the sewing items included in the basket.containers, sewing, baskets, sewing equipment -

Federation University Historical Collection

Federation University Historical CollectionBook, Australasian Institute of Mining Engineers, Transactions of the Australasian Institute of Mining Engineers, Volume X, 1905, 1905

Fabric covered hardcovered book of 367 pages. Includes a number of pullout plans. Contents * Mount Lyell Mining Field Tasmania by Professor J.W. Gregory * Concentration of solver-led ores (with 6 plates) by V.F. Stanley Low * Phosphate Deposites of Ocean and Pleasnt Islands (with 15 plates) by F. Danvers Power * Coal and Coal Mining in New SoPleassant Isuth Wales by Thomas Parton * Method of TImbering at the Mount Rex Tin Mne, Ben Lomand, Tasmania by Mark Ireland * Peck's Centrifugal Elevator by W. Peck * A Portable Assay Furnace by J.J. Gillio * NOtes on Sampling by A.C. Thomas * The Career of the Gold Dredge i n New South Wales by David K. Blair * The Transmission of Power by COmpressed Air in Mines by R.W. Chapman * The Misplacement of Mning Shafts and Adits in Victoria (with 7 figures) * The Indicators of the Daylesford Gold Mines, Victoria * Mining Accounts by R.N. Kirknon-fictionausimm, a.s. kenyon, frank a. moss, mount lyell, j.w. gregory, coal, gold dredge, transmission of power, mining shaft audits, daylesford gold mines, spitzkastens, ocean island banaba, pleasant island nauru, pinnacles on flat reef pleasant island, ocean island, blow hole howe bay, rock phosphate, thomas parton, mark ireland, mount rex tin mine, ngapara dredge, w. peck, w.h. vale, daylesford, jim crow diggings, glenmona gmc, f. danvers power, leigh g. hancock, workers' industrial union of australia (barrier district) -

Kiewa Valley Historical Society

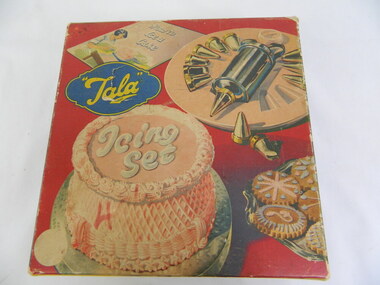

Kiewa Valley Historical SocietyIcing Set

Square cardboard box with a coloured illustrated lid with 'Tala' / Icing Set / How to Ice a cake. On one side of the box - 12 icing tubes in this set; Tala Icing set containing syringe, 12 tubes, turn table, icing book no. 1730, copyright design made in England. On the other 2 sides (opposite to each other.) Let all your kitchen ware be Tala - illustrated. Turning table is tin. 200mm outer stand, circle turntable 140 mm. Book: 'How to decorate a cake booklet' - 130 mm long x 195 mm wide and 5 mm thick; Pink plastic tray indented to hold metal cones 12 cones tubes each with different opening at the point. Icing syringe (nickel silver with brass collars). Plastic icing cone, Tala ware, Made in England 320 mm long, circumference 30 mm at point x 210 mm wideSee description.cooking, baking, icing, cakes, domestic, decorating -

Bayside Gallery - Bayside City Council Art & Heritage Collection

Bayside Gallery - Bayside City Council Art & Heritage CollectionDocument - Certificate, College of Arms, City of Brighton Coat of Arms, 1970

The Coat of Arms, represents Brighton City Council's "growing awareness of the importance of formality and correct symbolism in local government". It replaced the council's crest of a pier and yachting scene and was used as council's seal, and emblem on its flag and letterhead. The new Coat of Arms, drawn up by the College of Arms in England, depicts the progression from a seaside gardening community to a modern residential city. The prominent forms are on the shield-like coat of arms include waves and a Lymphad (a ship, symbolic of the sea); a market gardener; an aboriginal man; two horns plenty with abundant fruit and vegetables (the wealth and plenty) and Elster Creek. It is underscored by the motto 'By their fruits, ye shall know them'. Brighton was first incorporated as a borough on 18 January 1859, it became a town on 18 March 1887 and was proclaimed a city on 12 March 1919.Ink and gouache on parchment with wax seals. Allocates a Coat of Arms to the City of Brighton, by the College of Arms in London on 08/09/1970. The Coat of Arms is located on the upper left quadrant and has the following parts: the crest, the wreath, the helmet and mantle, the shield, the supporters, the compartment and the motto. The crest is two cornucopias with fruits and vegetables, above which sits a seagull. The mantle above the helmet is in green and gold. The shield is also green and gold with a lymphad (ship), and blue and white waves, representing the sea. The market gardener, holding a hoe, and Aboriginal figure, bearing a boomerang, support the shield and stand upon the compartment which is soil with a representation of Elster Creek. A ribbon below contains the motto in 'FRUCTU NOSCITUR'. The certificate text explains the origins of Brighton and the parts of the coat of arms. At the bottom of the folded parchment are three signatures and titles, below which three red wax seals in gold tin containers hang from blue ribbons.coat of arms, certificate, city of brighton, college of arms, market gardener, aboriginal, wax seal, elster creek, lymphad, fructu noscitur, letters patent, armorial bearings, heraldry, seal -

Bendigo Historical Society Inc.

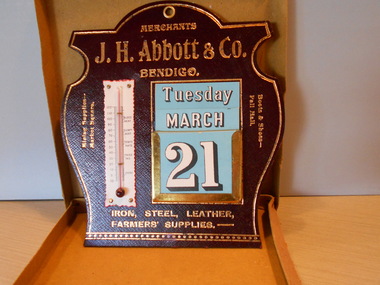

Bendigo Historical Society Inc.Domestic Object - ABBOTT COLLECTION: PERPETUAL CALENDAR

Perpetual Calendar from LH Abbott & Co. Dark Brown Cardboard with stippled finish. Gold Lettering. Symmetrical vase shape with a stand of black cardboard attached on the back. it has a small brass eyelet at the top to hang the item On the left hand side is a thermometer attached by small rivetts (10cm by 3cm) To it's right is a gold coloured tin frame (7cm by 5.5cm) In the frame sits light blue cardboard cards with white and black lettering telling the month, day and date which can be replaced each day. All complete.Sits in a light brown cardboard box (20.5 by 19 cm ) with stappled corners and a label giving directions. " In the event of the spirit becoming divided through inversion, a few sharp jerks will make right." Wording on Calendar. " Merchants. J.H. Abbott & Co. Bendigo. Mining Supplies - Market Square Boots and Shoes - Pall Mall. Iron, Steel, Leather, Farmers' Supplies.- " -

Bendigo Historical Society Inc.

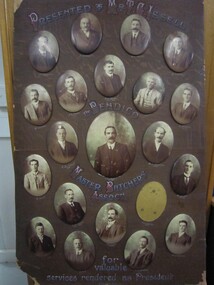

Bendigo Historical Society Inc.Photograph - BENDIGO MASTER BUTCHERS PHOTO MONTAGE

Plaque ( made of brown painted heavy cardboard ) with 21 photos attached. In recognition of services rendered by Mr. T.G. Issell, to the Master Butchers Association: On top ' Presented to Mr. T.G. Issell' In centre ' The Bendigo Masters Butchers Association' On bottom ' for valuable services rendered as President' Photos of 20 male people surrounding larger photo in centre. ( Mr. T. G. Issell ? ) are oval shaped, printed on a tin like material, slightly rounded surface. Names are printed underneath photos. Names on board : E.A. Webster, S. Sprenger, W. Inglefinger, M.S. Dunstan, W. Gittins, J.K. Tarner Comm., A.J. Clarke Vice Pres. S. Hewitt, com. R. Wheaton, Com. M.Mulcare, Auditor, W.S. Dunstan, Com. T.G. Issell, Pres. R.E. Issell Com.W. Issell, E.W. Hands, V.J. Ellis, g. Hill, W. Ewing, B. Newman, W.J. Thomas, E.K. Varcoe, Sec.bendigo master butchers association, bendigo, butchers, master butchers association, issell -

Melbourne Tram Museum

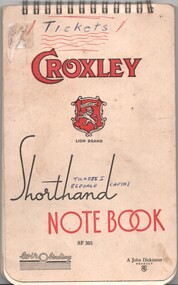

Melbourne Tram MuseumDocument - Notebook, John Dickson, Barry George, "Tickets", 1960's?

Notebook - wire bound - Croxley - shorthand notebook - SF305, a John Dickson Product, mark in ink on the top "Tickets" and "Tickets B George (AETA). About 50 pages. Each page has been cut with diagonal cuts to hold MMTB size paper tickets. Most tickets have been removed, but a pencil mark notes what was their when prepared. Has written heading on top of sheet "Melbourne - Out of Date" Includes description of ticket, revenue tin or container or outfit number and prefix. Includes 10d, 9d, 1/-, ticket machines 7d and 1/3 Melbourne as is now: = 3d, 6d, 6d City Section, 10d, 1/6,. Has pages for Sydney, Hobart, Bendigo, VR Melbourne, Perth, Brisbane Sydney 3d, 6d, 9d, 1/-, 1/6, 1/9/ 1/10, 2/- Melbourne - 3d, 4d, 7d, 9d, 1/2, 10d, 5d, 6d.trams, tramways, tickets, mmtb, aeta -

Bendigo Historical Society Inc.

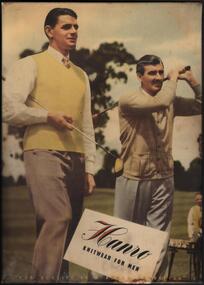

Bendigo Historical Society Inc.Sign - HANRO COLLECTION: HANRO STAND ALONE COUNTER DISPLAY PICTURE

BHS CollectionHanro Stand Alone Counter Display Picture: A coloured picture of two men on the golf course playing golf modelling Hanro knitwear. One has on a beige long sleeve V necked cardigan. The pockets on either side have a pleat in the centre and a band at the top. The garment has a small vertical brown stripe running through out the fabric, it is buttoned up with five brown buttons. The other is a yellow V necked vest. The Vest is knitted in a small cable pattern with knit bands around the neck and arms. At the bottom on the picture is a label with white background and *Hanro in red and black print and Knitwear for men*. The very bottom printed in yellow is *'The Quality Is A Proud Tradition. The material for the front is plastic covered card. The back is green tin. A brown card rectangular strip used for a stand and has two metal holes with string attached. A sticker with Bellesini is stuck on the card stank. Box 116Aphotograph, person, hanro, hanro -

Bendigo Historical Society Inc.

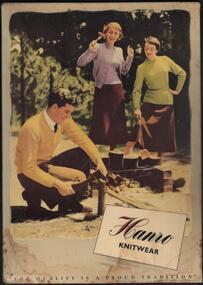

Bendigo Historical Society Inc.Sign - HANRO COLLECTION: HANRO STAND ALONG COUNTER DISPLAY

BHS CollectionHanro Stand Along Counter Display: The picture is of three people at a BBQ scene. The man is chopping kindling and is wearing a yellow V neck lone sleeve jumper that has a vertical pattern. One lady is holding a sausage in a fork and is wearing a mauve twin set. The cardigan is V necked and has four buttons, lone sleeves with cuffs. The jumper has a high neck with a small collar. The twin set has an over all uniform pattern. The second lady is toasting bread on a long fork and is wearing a green jumper with long sleeves and high neck, it is knitted in a ribbed design. At the bottom is rectangular white area with Hanro knitwear printed in red and black ink. At the very bottom is *The Quality is a Proud Tradition* The front has water marks at the bottom. The back is green tin with a brown card piece for a stand and two metal holes with string for hanging if needed. Bellesini is hand written on a small white sticker. Box 116Aphoto, person, hanro, hanro -

Frankston RSL Sub Branch

Frankston RSL Sub BranchRation, Special Flying, Circa 1942 - 1945 for similar packs

A military dark green painted steel container which is empty. This was a sealed container with rations for RAAF aircrew undertaking long duration flights. Khaki painted metal tin which contains rations, for use in aircraft. Printed in black on top of the detachable metal cover, which would have been taped down on top of the ring-pull lid, is; 'D^D / Made in Australia / Packed by MacROBERTSON'S / SPECIAL FLYING RATION / To be consumed by Air Crew carrying / out flights of 4 hour duration or longer. / List of contents on inside of lid / KEEP PACK INTACT / R.A.A.F / A Gadsden Container'. Printed on the top of the ring-pull lid is 'D^D D^D Contents believed to be (obtained from similar "Special Flying Ration") / Nuts. (Shelled) 4 ozs / Barley Sugar 3 ozs / Raisins 4 ozs / Chocolate ozs / Chewing Gum 3 pkts / Fruit Juice 8 ozs'. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Hot water bottle, late 19th - early 20th century

This hot water bottle was designed to lay flat in a bed between the sheets. Its purpose was to warm the bed before use. The bottle was filled with hot water then a stopper was placed in the top to seal it, preventing the water from running out. The inscription on the attached label of this hot water bottle gives both the donor's details and the location of the bottle when it was first displayed at Flagstaff Hill Maritime Village. the "P.M.O." are the initials for the Port Medical Office. The donor's details are also written in pencil on the base of the bottle. In the 16th-century people warmed their beds with the 'bed warmer', which was a long-handled, metal pan filled with hot coals and embers and covered with a lid. The pan was placed between the bedsheets to warm the bed before the person retired to sleep for the night. In the early 19th-century earthenware bed warmers came began to be used for the same purpose. They would be filled with hot water and sealed then often wrapped in fabric. The ceramic material would hold the heat for quite some time, without being too hot for the person in bed to also warm their feet as they went off to sleep. Hot water bottles were later made from glass, copper, brass or tin. Some manufacturers made them into decorative pieces that still had practical use. In 1903 a patent was taken out for the first rubber hot water bottle, invented by Slavoljub Eduard Penkala, a Croatian engineer. This bottle is of historic significance, as an example of personal heating equipment used in the late 19th and early 20th centuries.Hot water bottle, earthenware, pale colour with brown glaze on top over the shoulder and mouth section and clear glaze on the remainder of the sides. The cylindrical bottle tapers to a slightly narrower base. One side of the bottle, about a sixth of the circumference, is flat. The base of the bottle has a handwritten inscription. An inscription was on the paper label originally attached to the bottle. Inscription hand written on base of bottle "Mrs K. Rob _ / Browns Rd / Offic / 3 _ _ 9" Inscription on paper label " "Mrs K Robinson Browns Rd Officer 3809 - Hot water bottle P.M.O." flagstaff hill, warrnambool, shipwrecked-coast, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, domestic item, hot water bottle, heating equipment, ceramic bottle, stoneware bottle, potter, earthenware, personal item, bed warmer, foot warmer, flat-sided hot water bottle, household item, stoneware, clay, ceramic