Showing 53 items matching "butter manufacture"

-

Cheese World Museum

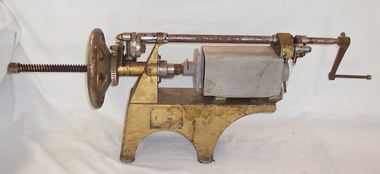

Cheese World MuseumButter cutter

... butter manufacture...-ocean-road No known provenance. butter manufacture butter ...No known provenance.Gold-coloured metal butter cutter on 4 legs with winding handle, a box for butter and a wheel on a threaded spindle. The metal handle is connected to a geared cog and when turned pushes a metal plate in the butter box which forces the butter through a star-shaped hole and the wire drops to cut the shaped slice of butter to the determined size.BUT AP ATTAbutter manufacture, butter cutters, warrnambool cheese and butter factory company ltd -

Warrnambool and District Historical Society Inc.

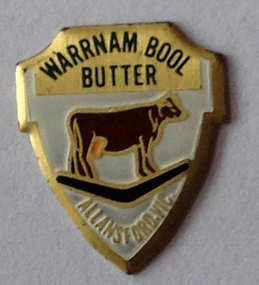

Warrnambool and District Historical Society Inc.Badge, Warrnambool Butter

... Factory at Allansford and promote the butter manufacture... at Allansford and promote the butter manufacture. The Warrnambool Cheese ...These discs come from the Warrnambool Cheese and Butter Factory at Allansford and promote the butter manufacture. The Warrnambool Cheese and Butter Factory was established in 1888 and was one of the first co-operative butter factories in Victoria. Cheese making started at the factory in 1892, with the Kraft Food Company leasing the factory in the 1930s and continuing for many years to operate the cheese production area. These discs are of some interest as ones used by a premier factory in the Warrnambool district. Dairying in the Warrnambool district is of major significance.These metal discs, four in number, are in the shape of a shield and have gold, brown and green enamelling on the front. There is an image of a cow with a boomerang shape underneath. The discs would be used for packaging and promotional material and are intended to be glued on to the material. ‘Warrnambool Butter, Allansford’warrnambool cheese and butter factory, allansford -

Cheese World Museum

Cheese World MuseumBook, laboratory notes

... manufacture and Warrnambool Cheese and Butter Factory for whole milk... manufacture and Warrnambool Cheese and Butter Factory for whole milk ...Kraft Walker commenced cheese processing at Allansford in 1935 under a lease arrangement with Warrnambool Cheese and Butter Factory. This arrangement remained in place until Kraft officially ceased bulk cheese production at Allansford in February 1993. Kraft was responsible for farm collection of milk which was then shared between the two companies -Kraft for bulk cheese manufacture and Warrnambool Cheese and Butter Factory for whole milk, milk powder and butter manufacture. Laboratory technicians tested milk and cheese during the receival and manufacturing processes to ensure a high quality product. Derek Shaw, whose notebook this is, was the first person in charge of the Kraft Allansford laboratory. He kept notes of testing undertaken and recorded results of anything considered unusual. This notebook is one in a series of 33. Les O'Callaghan commenced work in the laboratory as Derek Shaw's assistant and technician in charge following Derek's retirement. He too kept notebooks of test results.Kraft laboratory technician/bio-chemist Les O'Callaghan was responsible for the introduction of a number of quality control measures which are still in use in the dairy industry today. Les was mentored by Derek Shaw. This note book provides an insight into the dairy processing industry at this period.Black exercise book with lined pages; white sticker on front cover showing dates usedLH/ 17/11/1938 / 2/5/1939allansford, dairy industry, dairy processors, cheese making, kraft foods ltd, warrnambool cheese and butter factory company -

Mortlake and District Historical Society

Mortlake and District Historical SocietyMortlake Butter Factory Co. Ltd, Photograph

... and the separated cream was manufactured into butter, some of which... was manufactured into butter, some of which was exported to England ...This local factory was typical of small butter factories in the 1890's in Western Victoria. It was established in 1894 when farmers brought their milk to the factory on horse drawn drays and carts and waited for their cream to be separated. The skimmed milk was mostly used by farmers to feed calves and pigs and the separated cream was manufactured into butter, some of which was exported to England. By 1910 this butter factory had an electricity generating plant called Mortlake Electricity which supplied both the factory and the township with power and this took precedence over the butter production which continued until 1926 when it was sold to the Electricity Commission. By 1930 the Butter Factory had a yearly turnover of 24,000 pounds sterling and in1935 it was producing 6 tons of butter weekly. But in 1936 the factory was sold to Glenormiston Cheese & Butter Factory who ceased operations. The manager's residence still remains in 2011 as does the remnants of the small timber butter factory (charcoal lined) and the double brick cheese room but the bluestone chimney has long gone. This complex is listed by Heritage Victoria Black and White Photograph Nonecheese factory, mortlake, butter factory -

Orbost & District Historical Society

Orbost & District Historical Societyletter book, before 1919

The Orbost Butter and Produce Co. Ltd was registered on June 1st 1893 and was an important source of income to the Orbost district.A greenish-grey hard covered letter book used by the orbost Butter Factory. It contains hand-written letters from the secretary. One glued in typed letter is addressed to the prime minister (Billy Hughes) in Melbourne.On spine - Letter Bookorbost-butter-factory correspondence letter-book agriculture dairy -

Orbost & District Historical Society

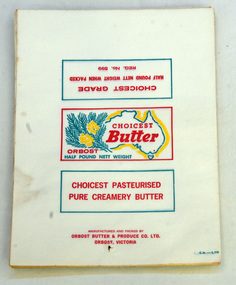

Orbost & District Historical Societywrappers

... -head wrappers butter Manufactured and Packed by C.M. -L/FD ...Used to wrap half pound packs of butter made at the Orbost Butter Factory.The Orbost Butter and Produce Co. Ltd was registered on June 1st 1893 and was an important source of income to the Orbost district. .1 is a bundle of twenty wrappers for Orbost Choicest Butter -Half Pound Nett Weight. They are white, rectangular with yellow,red ang green print . .2 is two blank letter heads for Orbost Butter and Produce Co LtdManufactured and Packed by C.M. -L/FD Orbost Butter & Produce Co Ltd in bottom Orbost Victoria R.H. cornerorbost-butter-factory agriculture farming letter-head wrappers butter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooler

Terra cotta is the perfect medium to manufacture items for keeping foods and liquids cool. When water is added to the base, the terra cotta body absorbs it and the subsequent evaporation creates a cooling effect for the contents. It is particularly effective when used to keep milk, cheese, butter and bottles of wine cool.Terra cotta was one of the first ceramic materials to be used.Terra cotta cooler, with bell shaped lid that is open at the top, but with a rim for holding water. There are ventilation holes around the base of the lid. The top stands inside the base. When water is added to the rim at the top, the terra cotta body absorbs it and creates a cooling effect for the contents. Probably used to keep butter or cheese cool. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, terra cotta, ceramics, coolers, dairy products -

Flagstaff Hill Maritime Museum and Village

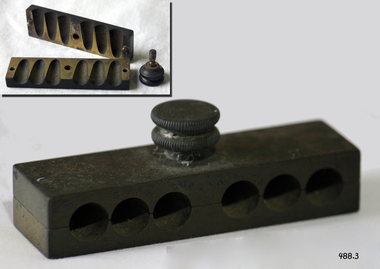

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Bottle, Antarctic Ice Milk Bottle, Early /mid 20th century

Antarctic Ice dairy plant was in Kepler St Warrnambool. It sold to Warrnambool Cheese and Butter and Kraft in the 1940’s and was relabeled as Sungold Dairies. They then purchased Kaye Ryan and relocated to Verdon Street.A common item with links to a local manufacturing business.Round bottle with wide neck and thick rim around top. Logo embossed on front of bottle with writing around bottom of bottle as well.Embossed on bottle as follows: This bottle contains milk bottled for sale by Antarctic Ice Products Pty Ltd Warrnambool. Smaller print at bottom reads “Bottle is the property of the above. It is loaned and cannot be legally used by others. One imperial pint on the back.497 and 842 on bottomantarctic ice pty ltd, sungold dairies warrnambool history -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Souvenir glass, Trufood Employees Reunion 1986, Circa 1986

Trufood factory was established in 1911 at Glen Ormiston producing skim milk powder. Along with the Glenormiston Cheese and Butter factory the employed many people in the district.A link to an early manufacturing plant and the dairy industry in the region.Short based glass with gold lettering and gold rim. Trufood Skim milk Employees reunion 26th January 1986.glenormiston cheese and butter factory, trufood glenormiston -

Frankston RSL Sub Branch

Frankston RSL Sub BranchKnife, Butter

This is a trench art butter knife. The handle is made of a plated spent bullet cartridge and the blade is made from brass. The blade is engraved with a delicate pattern which is quite worn. On one side are the words "Souvenir France". The cartridge is the type used by the German Mauser and is stamped with a manufacturing date of 1918. The blade of this knife is engraved with the words "Souvenir France". The end of the cartridge is stamped ".D. SE 4 18"great war, world war 1, ww1, trench art, bullet, france, sovenir, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant item giving an snapshot into how early industrial manufacturing became established in Australia in the production of domestic and industrial dairy equipment.Butter churn wooden manually operated made by Cherry and Sons with rotating lever curved plywood basin and parallel cross beamed horizontally spoken churning apparatus inside with wooden plug at lower side of churn. Label in block transfer "E CHERRY / MAKER / GISBORN / VICTORIA / 2" "IMPROVED PATENT"warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, wooden butter churn, e cherry & sons, dairy equipment, gisborne, food preparation -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales, Domestic Imperial, ‘Fairway Melbourne’, c1930

Fairway Company Melbourne manufactured this pair of domestic scales with a dish / pan in which objects to be weighed and the weights / masses against which to weigh them are placed. These common kitchen / dairy scales would be used by the householder to weigh flour, sugar, cereal, vegetables, fruit, meats, butter, cheese etc. prior to cooking or storing . Its parts include a fulcrum, a beam that balances on it, two pans at the ends of the beam to hold the materials to be weighed, and counter-balancing weights. A set of domestic scales made by ‘Fairway’ Melbourne c1930. Painted cream steel with 1 metal bowl / pan and Imperial measure weights 2LB, 1LB, 4OZ, 2OZ, 1OZScales ; MADE BY / DOMESTIC SCALES / FAIRWAY / MELBOURNE AUST. Weights ; 2LB, 1LB, 4OZ, 2OZ, 1OZ market gardeners, early settlers, fruit vegetables, farmers, cooking, recipes, scales, weights, measures, brass, balance beam, moorabbin, cheltenham, bentleigh, kitchen scales, dairy products, cereals, wheat flour -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyButter Stamp Block, Circa 1950

... At the time when this shortbread / butter stamp block... dairies and larger properties who manufactured their own butter ...At the time when this shortbread / butter stamp block was used, rural dairies and larger properties who manufactured their own butter used butter stamps blocks for identifying the source of the butter or for decoration.. The patterns stamped into the warmed butter provided for a range of decorative visual enhancement to the "plain" and "boring" straight leveled normal butter surface. Although the wooden surfaces could be hard to keep clean commercial usage would have been limited and eventually replaced by a non porous and hygienically cleaner material. Greater hygiene controls where introduced. from the late 1940s on. These controls were the result of high infectious illnesses due to contaminated milk and dairy handling methods.This shortbread / butter stamp was used by a Kiewa Valley dairy and it presents what the domestic butter beautification processes were available during the mid to latter 1900s was. Their was a pride by rural properties in their produce and its by-products.This shortbread / butter stamp is made from wood, round and fashioned from a flat bed to a dome top. The top has a round moulded hole with screw indentations for fastening a pressure pole. The pattern on the face of the stamp is of an eleven petalled flower pattern around a small circular flower head. Both the head and petals have indentations which are will produce raised points in the pressed butter. Enclosing the flower pattern is a pattern which when pressed against the butter would produce small ridges radiating outward.On the dome stamped in black ink "T. & W. Davies"butter stamp, domestic butter blocks, domestic food preparations., shortbread, stamp, dairy, butter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMould Butter, unknown, post 1967

This butter mould/pat may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce. This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This well crafted circular wooden butter mould could also be used as a butter pat.The handle in the middle of the mould was not added after the crafting but has been fashioned from the initial block of wood when the bowl was crafted. The bowl structure has a rim around the edge.The top of the handle has an ink stamp "T. & W. Dav" on the top line and "Tawonga 3697" underneath.domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950s

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter Pat/Profiler has on its base two patterns. On each end it has horizontal grooves cut into the wood which produce distinct lines onto the surface of the butter. between these grooves there is a section of two double lines crossing in the middle and separated by eleven horizontal lines The base has an elongated rectangular shape. The upper body has been sanded into a smooth convex shaped form where a wooden circular hand grip has been fashioned.On the top of the hand grip is stamped in black print"T. & W. Davies" and under this"TAWONGA 3697"domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter pat is one of two,see KVHS 0071 (A). It has been crafted from wood. One side has grooves running from the handle to the square shaped bottom. These grooves would stop the wet butter from clinging to the pat. The top side of the pat has been bevelled on both sides and the bottom edge. The hand grip is flat and curved to allow for a comfortable hold.domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Cheese World Museum

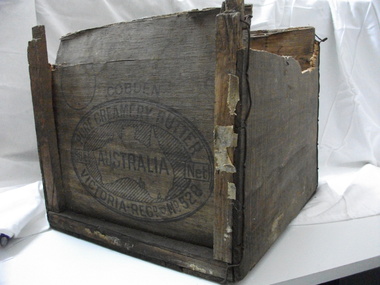

Cheese World MuseumBox, butter

... of these exist. butter dairying dairy manufacturing industry butter boxes ...This butter box belonged to Jack Gore of Warrnambool who used it in his garage to store car parts. It is connected to Warrnambool Cheese and Butter Factory Company Limited through the box manufacturer, Peter John McGennan, who was one of the instigators of the factory. Cobden and Warrnambool factories were the first two co-operative factories to produce butter in Victoria, both commencing in 1888. Warrnambool Cheese and Butter Factory Company Ltd is the only remaining independent butter factory still using its original name. It is an example of the manner in which butter was packed for export from the late 19th century until well into the 20th century. Its innovative design is light but strong, using plywood for the box body and struts 'stitched' to the body with wire. The ply was originally pine imported from New Zealand which did not taint the butter. Following the exclusion of the timber from NZ, plantations of local pine were planted and used. McGennan's box factory supplied butter boxes to the majority of butter factories in Victoria, producing up to half a million boxes per year by 1917.This Cobden butter box is historically significant relating to the butter industry and a rare item. Not many of these exist. Wooden butter box with broken ends and a hole in the bottom.Constructed using thin ply ends, sides and base with square wooden struts tied with wire to strengthen the box. The trade mark on the end of the box is an oval with text around a map of Australia with the word AUSTRALIA printing across the map.COBDEN/PURE CREAMERY BUTTER/56lb Net/VICTORIA/REGD No.528butter, dairying, dairy manufacturing industry, butter boxes, cobden -

Cheese World Museum

Cheese World MuseumTrophy, 2001

Awards for cheese quality have been part of the dairy industry since the 19th century and are designed to maintain and continue improving the quality and flavour of cheeses manufactured in Australia.Wooden trophy in form of cut-out shape of Victoria mounted on a plinth by two gold-coloured rods. Details of the award printed in black on the shaped area and a small plaque noting details of winner attached to the plinth.Rhodia DIAA Dairy Product Awards 2001/Rhodia Australia Award/Highest Scoring Cheddar Cheese - Mild in Class 7 Base plate - Presented to/Warrnambool/Cheese & Butter Factory Ltdallansford, dairy industry, cheese, warrnambool cheese and butter factory ltd, wcb, rhodia, dairy industry association of australia, trophies -

Cheese World Museum

Cheese World MuseumDVD, A Look at our History -Vol.2, 2005

Series of interviews with former employees of Kraft (Allansford) and directors of Warrnambool Cheese and Butter Factory discussing their time and experiences as employees and directors of the factories. Warrnambool Cheese and Butter Company Ltd was established in 1888 and in 1935 developed a relationship with Kraft Foods Australia whereby Kraft leased premises from WCB. The two companies shared the milk collected to make their core products of cheese (Kraft) and butter and milk for domestic use (WCB). This arrangement continued until 1997.Gold DVD in plastic case, B&W cover with colour WCB logo.A Look at our History: Ron Campbell, Steve Heazlewood, Jim Mahony, DJ (Barney) Loganallansford, heazlewood, steve, campbell, ron, mahony, jim, logan, dj (barney), wcb, warrnambool cheese and butter factory company ltd, kraft foods ltd, dairy industry, dairy processors, factories, local history, cairns, peter, cheese manufacture -

Cheese World Museum

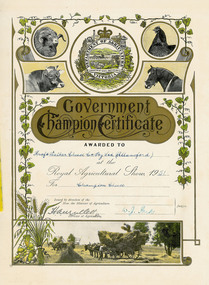

Cheese World MuseumCertificate, Government Champion Certificate, 1951

Kraft-Walker Cheese Company commenced in Allansford in 1935 leasing the factory premises from Warrnambool Cheese and Butter Factory Company. Dairy companies entered competitions organised by the Dairy Industry Association and associated organisations and local agricultural societies to encourage improvement in products. Some of these awards are considered prestigious and highly regarded within the industry. The certificates were passed to Cheese World Museum by the factory management.This certificate was held by the factory management until transfer to Cheese World Museum. The certificate provides an insight into the dairy industry during the 1950s.Cream card certificate from Royal Agricultural Show has a plain line border on left, bottom and right side with inner border of green vine plant on left, top and right side. A sheaf of oats and a scene of haymaking complete the border design. The top of the certificate has the Department of Agriculture Victoria logo flanked by circular images of a sheep and cow on the left and a hen and horse on the right. The centre of the certificate has a gold shape overprinted with black.Government Champion Certificate/ Awarded to Kraft Walker Cheese Co Pty Ltd (Allansford) at the Royal Agricultural Show 1951/ for Champion Cheese/ Issued by direction of/Hon. the Minister for Agriculture/H A Mullett/ Director of Agriculture/ W J Park/ Judgesallansford, kraft walker cheese company, cheese manufacture, dairy awards, product awards, warrnambool cheese and butter factory company, kraft walker pty ltd, royal agricultural show, department of agriculture victoria, cheeses, cheese manufac, warrnambool cheese and butter -

Cheese World Museum

Cheese World MuseumPhotograph, Kraft Walker Cheese Pty Ltd Garvoc Branch factory, c1940

The Kraft Walker Cheese Co Pty Ltd entered into an agreement with Warrnambool Cheese and Butter Factory Company in 1935 whereby the Kraft company leased premises from WCB. This arrangement remained in place until the 1990s. WCB took over the Garvoc factory in the 1920s. It became outdated and was eventually demolished.Black and white photograph showing timbered building with iron roof and turned wooden finial on the gable end. There are three timber ventilation ducts on the roof. The gable end has sign Kraft Walker Cheese Co Pty Ltd Garvoc Branch. A concrete block addition is at the front. A tray truck with milk cans is in between the main factory building and the outbuilding.garvoc, allansford, dairy industry, food manufacture, kraft walker cheese company, factories, cheese, kraft foods ltd, transport, milk cans -

Cheese World Museum

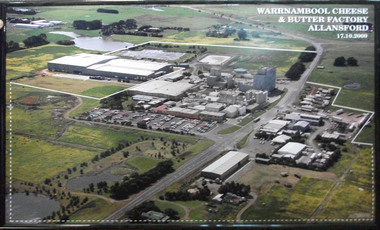

Cheese World MuseumPhotograph, Warrnambool Cheese and Butter Factory Co Ltd site 2000 -aerial view, 2000

... dairyiing dairy manufacturing diary manufacturers cheese butter ...Warrnambool Cheese and Butter Factory Company was formed by a group of Warrnambool business men. The company was registered in May 1888 and commenced commercial production in November 1888. The company retained its independence for more than 125 years until acquired by Canadian firm Saputo. It has operated from the same site since its inception and also has an office in Japan. Milk processing is undertaken by Sungold. Milk powder for export is also produced on-site. Cheese World is a retail arm of the company operates on a connected site selling company products, local food products, wine and cheese tasting. Cheese World Museum operates under the Cheese World umbrella.Aerial colour photograph of Warrnambool Cheese and Butter Factory in wooden frame. Shows buildings and surrounds. Lines indicate factory boundaries, dotted lines indicate property extension. Date is recorded on the image.17.10.2000allansford, warrnambool cheese and butter factory company, saputo, dairyiing, dairy manufacturing, diary manufacturers, cheese, butter -

Cheese World Museum

Cheese World MuseumButter printer, J Bartram & Son, c1900

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This butter cutter is part of the collection of items given into the care of the Cheese World Museum. It was in the early 1900s for hand-use in home dairies or small factories. An example of an early butter packaging machine.Wooden Eureka brand butter printer and weigher with dovetailed corners on the bulk butter box, wooden rollers for moving butter along once cut and wire cutter.Eureka/J Bartram & Son/sole makers Uebergang No. U027butter cutters, uebergang, allansford, dairy manufacture -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Terracotta Cooler Top, Ovens Pottery, c. 1890-1892

The Ovens pottery operated from 1881 to1892 they had taken over H L & E pottery at Beechworth in 1888 but mounting debts forced the Ovens company to close in 1892. During their short ten years of operation they produced stoneware garden urns, vases, cheese dishes, ginger beer bottles, butter coolers, water filters, wine and spirit barrels, bread plates, jugs, teapots, storage jars, pots, tiles, flower pots, spittoons, basins, bowls, demijohns, lidded crocks, pipes and bricks.A significant item made by an early Australian pottery in Beechworth Victoria, this company made many utilitarian items for the Victorian domestic market. It gives us today a snapshot into early Australian companies that were unable to sustain manufacturing their products into the 20th century, due in part to the rising imports of cheaper items from overseas.Red terracotta butter cooler comprising, round base with ridged lip, and bell shaped, domed lid with spherical handle on topMarked "Ovens Pottery, Co Ltd, Patd 1890, Beechworth" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooler, terracotta cooler, utensil, kitchen ware, terracotta, food container, food preservation, butter cooler, ovens pottery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Fred Walker Cresco Foods, 1910

Fred Walker 1884 – 1935 was an Australian businessman and founder of Fred Walker & Co. first in Hong Kong, then in Melbourne as the Fred Walker Company. He also set up Kraft Walker Cheese Co. in partnership with American businessman James L. Kraft in 1926, to market Kraft's patented method of processing cheese in Australia. Fred Walker & Co. is best known for creating Vegemite, a yeast extract-based food spread and Australian cultural icon. Kraft Walker Cheese Co. Is best known for manufacturing a cheese known as Red Coon around 1931, which later became known as Coon cheese. He founded the Fred Walker Company at 54 William Street and later moving to Flinders Street in 1911. This company specialised in canned foods, especially dairy products, exporting them to Asia. It manufactured Red Feather canned foods including butter and cheese from around 1910. He also went on to created Cresco Food Co. for his younger brother, which was the first factory to manufacture "flaked food" or dehydrated food products in Australia.A significant item that catalogues the start of dehydrated food production and sale in Australia was initiated by an Australian businessman and well-known entrepreneur. The history of Fred Walker gives insight into how many food brands in Australia now that we take for granted had his involvement in their early beginnings. Large cylindrical tin with push on lid, painted label on the sides in maroon, black gold and dark fawn colours with text.Palm Flaked Rice manufactured by the Cresco Co. Limited Melbourne Australiaflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, container, food container, kitchen ware, flaked rice, cresco, palm flaked rice, tin, fred walker, dehydrated food