Showing 59 items matching "post drill"

-

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Post Drill Set

... Post Drill Set...A post mounted drill stand with a gearing arrangement... (on both sides of main casting) A post mounted drill stand ...Used by donor's father, John Palmer, on his parents dairy farm at Mupunga East and later on his own dairy farm at Allansford. From 1966 until 1992 used in Mitcham and Blackburn.A post mounted drill stand with a gearing arrangement driven by a handle. The depth of drill is adjusted by a large red wheel which raises or lowers the drill. There are other adjusting devices on the drill.Buffalo Forge Co, Buffalo N.Y. No 151 (on both sides of main casting)trades, tools, metalworking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

... post drill.... The Dawn Ball-bearing Post Drill no. 611 is described...Dawn Ball-bearing Post Drill no. 611, made by Dawn... for many miles around. The Dawn Ball-bearing Post Drill no. 611 ...This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

... dawn post drill...This post drill press has been made by Melbourne business...Post type drill press machine with gear driven flywheel... Warrnambool great-ocean-road This post drill press has been made ...This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Civic structures, Port Melbourne, Ron LAING, Ron Laing, 1986 - 1999

... Post Office, 1860 Post Office and Naval Drill Hall... Hall Freemasons Hall Fire Station Post Office Naval Drill Hall ...Part of Ron Laing's collection of photographs recording Port Melbourne over a thirteen year period. Donated to the PMH&PS by the photographer.A set of 37 colour photographs of Port Melbourne civic stuctures, 1990s, including the Town Hall, Liardet Community Centre, Freemasons' Hall, RSL Club (Excelsior Hall), old fire station, 1910 Post Office, 1860 Post Office and Naval Drill Hall, Metropolitan Fire Station, Police quarters, Police Station and Court House, Nott Street State School, Graham Street State School, St Joseph's Primary School and Rotunda in Beach Streetbuilt environment - civic, ron laing, nott street state school, graham street state school, port melbourne primary school, port melbourne town hall, liardet community centre, excelsior hall, freemasons hall, fire station, post office, naval drill hall, police station, st josephs catholic primary school, band rotunda -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDrill

... drill, blacksmiths post... of Australia. drill, blacksmiths post Drill ...This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.drill, blacksmiths post -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBench

... raised post, one drill hole for fid; end of bench enclosed... wooden trestle leg style sail maker's bench with one raised post ...Bench wooden trestle leg style sail maker's bench with one raised post, one drill hole for fid; end of bench enclosed by wood to form tray to prevent tools from rolling off. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Sign - Public Works Office

... quarters, the Post Office and drill Hall , all in the same vicinity... quarters, the Post Office and drill Hall , all in the same vicinity ...This sign points has two different messages. The first states Public Works Office, which was operational in Victoria between 1855 and 1987 dealt with many aspects of the states infrastructure. It had many different reponsibilities and roles from building government accommodation and fit out of buildings, licences for unused roads and water ways, main roads and bridges, ports and harbour,and water supplies. Much of this work was managed through local offices such as the one at Warrnambool. The sign on the reverse which states Witnesses Waiting Room relates to the court house which is where this sign originated.The Warrnambool court house was built in 1870-71 by the Victorian Public Works department and it is possible that this sign relates to that period.It is one of a number of public buildings built in the period 1870-1890 including the Police station and stables and police quarters, the Post Office and drill Hall , all in the same vicinity. This building reflects the growth of the town and also the importance it held at the time from a state level. The building while no longer used as a court house is a building of significance to Warrnambool as well as to the state of Victoria, being one of six around the state which were built in free classical style. This sign denotes the waiting room for witnesses which was situated on the western side of the building.A tangible link which provides historical and social significance to Warrnambool.Rectangular wooden sign with rounded corners. There is text on both sides painted in gold paint with shadow in black. One side is a darker brown stain . There are screw holes in each corner.and one hole on left middle of sign. Rounded edge on one side.Side 1:Witnesses Waiting Room Side 2:Public Works Office.warrnambool, warrnambool court house, public works department warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... probably been used in Australia on a farm for drilling fence posts ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - PHOTOGRAPH, 38th BATTALION FORMAL DINNER, 38 Bn, 38 Bn was the Northern Victorian Regiment, c1945-1962

38 Bn, raised March 1916. Post War it was the Bendigo CMF Unit until 1962. then shut down.1. B & W photo of group of officers and senior NCO's talking and laughing. They are wearing formal mess dress with ribbons WW2. At top right can be seen a photo of a group in front of 38 Bn Banner. 2. B & W photo of four men, 2 officers, 2 Snr NCO's. They are wearing formal mess dress. Photo taken in the Officer/Sgts mess, Drill hall, Mollison St, Bendigo. 3. A formal Army dinner. Held in Officers Mess at the Mollison St Drill Hall. An Officer is standing addressing the group. The group is composed of officers and snr NCO's. The table is set with flowers, cutlery and drinks.38 bn, staff, officers, bendigo -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - PHOTOGRAPHS of AUSTRALIAN SOLDIERS, 38 Bn, c1950-1960

38 Bn was raised in Bendigo in 1916. Post WW2 it was the CMF unit until 1962. The Mollison Street Drill hall was first used in Jan 1916.1. Group Portrait of OFFICER AND SENIOR NCO'S ON AN INSTRUCTORS COURSE. The course is titled " School of Infantry 10/55 CMF (All Arms) CW Instructors Course 3 Oct - 14 Oct 55. 2. Group Portrait of OFFICER AND SENIOR NCO'S . 3 rows of men in battle dress & berets. They are in front of Army tents. 3. Group Portrait of OFFICER AND SENIOR NCO'S in front of 38 Bn banner. They are all wearing "Battle dress Ceremonial" . Medals are being worn.1. On rear is stamped 3 Oct 1955 (missing data) Seymour, Vic. 2. On rear is written, Scrub Hill, Puckapunyal. 20 Oct 1957. Stamped - photo studio K. Milvain (?) is 30 Emily St, Seymour, Vic. 3. On rear is written " Freedom of City"- "Honorary Colonel" .photographs, 38 bn, puckapunyal -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - PHOTOGRAPHS OF SOLDIERS, 38th BATTALION, 38 Bn, c1950-1962

38 Bn was raised in Bendigo in 1916. Post War it was the CMF Unit until 1967. The Mollison St Drill Hall was built by Contractor Mr. Midgley. First used Jan 1916. Shut down Circa 2002. The 38 Bn Colours are held within the RSL Military Museum, Bendigo.1. Photo of 4 Senior NCO's in battle dress in front of the Mollison Street Drill Hall. 38 Bn Northern Victorian Regiment. The four soldiers have .303 rifles. WO Burrell has the red sash of a Colour Sgt. His MM can be seen. 2. Photo of Regiment Colours 38 Northern Vic Regiment in front of Mollison St Drill Hall. Two Officers, Capt. Emonde holding Queens Colours - 4 Snr NCO's have rifles at the slope with ceremonial tips on their bayonets.1. On rear is written - Cenotaph party/ Warrant Officer 3 sets Guards. 2. On rear is written - '" ANZAC DAY" .38 bn, mollison st, drill hall, photographs -

Frankston RSL Sub Branch

Frankston RSL Sub BranchCap, Beret, Beret Mnfrs

A type of beret known as a Balmoral Cap worn by Australian Scottish military units in the post WW2 period. It is made of khaki coloured felt with a khaki coloured 'pom pom'. the beret is lined with a black heavy drill fabric. The beret has been moth eaten.It was an inner label with REGIMENTAL No. 3/772077 and NAME 'DREW' -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... probably been used in Australia on a farm for drilling fence posts ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ridgway & sons, wood boring tool, carpenters tools, coopers tools, marine tools -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaLetter - Correspondence, 14/02/1951

In this letter to his mother Allan writes that this year Norway has had "...one of the heaviest falls of snow ever and just two miles from the post office there is nine feet of it." He has a job in a factory "...operating an electric drill boring holes in brass taps." He plans to return to London in September to attend the photography school.Quinn CollectionA self-folding letter written in green ink (0859.a) headed Oslo and dated 14/02/51. Letter is addressed to Mrs K Hayes, 14 Fitzroy Street, St Kilda, Victoria, Australia. The return address is Allan Quinn, G.P.O. Osloletters-from-abroad, allan quinn, norway, oslo -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBooklet, Infantry Training Vol I2 Infantry Heavy Weapons Pam 26, The 81mm Mortar, 1970

A soft covered booklet for instructors covering handling,, aiming, drills and practices and command post procedureDSN 7610-66-035-341781 mm mortar -

Kiewa Valley Historical Society

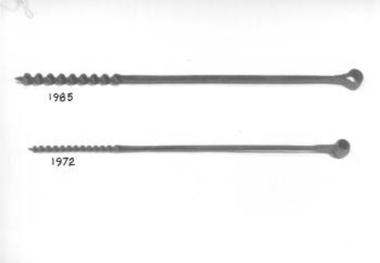

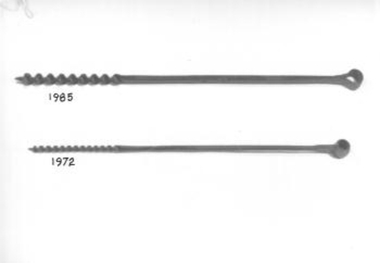

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Federation University Historical Collection

Federation University Historical CollectionBook, New York Post, The School of Mine Quarterly: A Journal of Applied Science, 1889-1809

The School of Mines Quarterly was a jpournal of Applied Science from Columbia College, New York City.The Index to the School of Mines Quarterlu Volumes X1-XX (1900) and 32 green covered journals school of mines, new york, columbia college, schools of mines, columbia school of mines, witwatersrand goldfield, inter-continental railway, mine ropes, harbor improvememnts on the pacific coast, glycerine and artificial butter industry, transit factors for teh columbia college observatory, tables for the reducation of transit observations, ancienct methods for dividing and recoording time in japan, assay of tin, john strong newberry, standards of linnear measure, comparison of costs of electric lighting, huanchaca mine bolivia, el callao gold mine venezuela, john magnus adams, ores in saxony, hartz and rhenish prussia, hofmann apparatus, adjustment of trangulation, determination of carbonic acid in white lead, lower coals in western clearfield county pennsylvania, old telegraph mine ningham canon utah, mechanical preparation of ores, modern waterworks construction, curdling of milk, french regenerative gas furnace, irrication canals, peruvian salt mine, collection of metallurgic dust and fume, permeability of iron and steel, assay of silver, explosion in a zinc fume condenser, teaching archtectural history, liquid air, between the mine and the smelter, ballistic galvonometer, assay of telluride ores, analytical chemistry, theory and design of the masonry arch, silver pick mine wilson colorado, telegraphy and telephoney, mineralogy, morse code, michigan mining practices, titaniferous magnetites, paradox of the pantheon, rocks from wyoming, witwatersrand goldfields, gaseous sun, alternating current distribution, engineering tests on direct current electrical machinery, thomas egleston, ore dressing, frederick morgan watson, camp bird gold mine and mills, magnetic properties of iron and steel, morphology of organic compounds, antimony, structure of the starch molecule, cerrillos hills new mexico, geology, rossie lead veins, practical electrochemistry, lines of graphic statics, anistic acid by the ozidation of anniseed oil, bromate method for antimony, john krom rees, trust company of america building, helion lamp, frederick arthur goetze, mine surveying, pine wood oils, malleable cast iron, electrolytic treatment of galena, turpentine and pine oils, bluestone, ashokan dam bluestone, road resistances, oxy-gas blowtorch, mine dumps, segregation of steel ingots, masonry dam formulas, putnam county magnetic belts, gases, continuity of education, hydraulic diagrams, standardistion of potassium permanganate, sewerage discharge into sea water, modern waterworks, true column formula, slags from lead furnaces, missouri river, tempreture of gases, rocks, architectural history, modern dome, oil machine, undulations in railway tracks, irrigation engineering, cleps-tachymeters, electrical engineering, new york shales, fan pump, sucrose, isaac newton, french school of anstronomers, electrolytic polarization, benjamin bowden lawrence, diamond drilling, new york ciy water front, engineering profession ethics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... probably been used in Australia on a farm for drilling fence posts ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

... probably been used in Australia on a farm for drilling fence posts ...William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Ring Auger, Double Twist with Lead Screw, square shaft (which has had a welded repair), socket set at right angle. Broad arrow mark Ridgway Sheffield and DO stamped. warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Reference photographs, Port Melbourne, 1900 - 1999

... - Naval drill hall .15 - Post Office (original) .16 - Bay St... of photos. .01- the Naval drill hall .02 - Naval drill hall East ...Set of 14 reference photographs plus negatives of Government plans for Port Melbourne buildings and four photos of photos. .01- the Naval drill hall .02 - Naval drill hall East elevation .03 - West elevation .04- Front elevation .05 & .06- Court of Petty Sessions .07 &.08 - Watchhouse .09 - Drill Hall inner elevation .10 & .11 - Graham St School remodel .12 - Remodelling School 1427 .13 Naval offices front elevation .14 - Naval drill hall .15 - Post Office (original) .16 - Bay St shops Nettleton .17 - National Bank, Scott's, Nettleton .18 - Nott St School .19 - set of negatives (.19 at A06.03.B10) >15 to .18 are poor record photosbuilt environment - civic, national trust of victoria, royal navy of australasia -

Clunes Museum

Clunes MuseumTool - FENCING AUGER

.1 Metal auger for drilling holes in timber or fence posts,, 80 cm long with wooden handle. .2 METAL AUGER FOR DRILLING HOLES IN TIMBER OF FENCE POSTS - SHAPED AS BRACE AND BIT, WIRE WOUND HANDLE AND CENTRE OF BRACENilhand tool, auger -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Auger Bit

Long steel rod twisted into a corkscrew shape at one end and a round hole at the other. A rod is inserted into the round hole and is turned to drill a hole in a fence post.rural industry, fencing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Auger Bit

... to turn the drill. Used for drilling hole in fence post.... for drilling hole in fence post. Tool Auger Bit ...Long steel shaft half of which is twisted into a corkscrew shape and sharpened to make a hole in wood. The other end has been formed into a round hole so that a handle may be inserted to turn the drill. Used for drilling hole in fence post.rural industry, fencing -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph, Clare Gervasoni, Former Geelong Drill Hall, 2016

A colour photograph of a weatherbaord Drill Hall at Geelong, Victoria. royal victoria regiment infantry, 87h/7th battalion, geelong, geelong ranger barracks -

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionPhotograph - Neale 8/13 VMR

The 8th/13th Victorian Mounted Rifles was raised as a regiment of the Royal Australian Armoured Corps on 1 May 1948 with Headquarters in Melbourne and squadrons in Sale, Benalla/Wangaratta and Albury. In 1955 Regimental Headquarters moved to Wangaratta and a second squadron was located at Albury. The Sale squadron transferred to 4th/19th Prince of Wales’s Light Horse. In 1977 8/13 VMR Regiment was reduced to an independent squadron A Squadron 8th/13th Victorian Mounted Rifles and in 1991 was linked with 4th/19th Prince of Wales’s Light Horse forming the VMR Squadron of that regiment. Following RAN service in WWII John Neale joined 8th/13th Victorian Mounted Rifles in 1948. He progressed through the ranks and postings in the regiment becoming Commanding Officer 1969-76, and later served as Honorary Colonel. Unique collection of photographs showing the first years of an armoured regiment of the post-Second World War era Citizen Military Forces showing equipment, uniforms, training and social activity and some personalities.Black and white photograph of soldier in khaki drill shirt. One of a collection of photographs of 8th/13th Victorian Mounted Rifles Regiment between 1948 and 1951.Sgt. J. Neale neale, 8/13, vmr, cmf -

8th/13th Victorian Mounted Rifles Regimental Collection

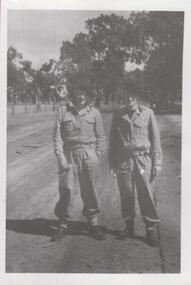

8th/13th Victorian Mounted Rifles Regimental CollectionPhotograph

The 8th/13th Victorian Mounted Rifles was raised as a regiment of the Royal Australian Armoured Corps on 1 May 1948 with Headquarters in Melbourne and squadrons in Sale, Benalla/Wangaratta and Albury. In 1955 Regimental Headquarters moved to Wangaratta and a second squadron was located at Albury. The Sale squadron transferred to 4th/19th Prince of Wales’s Light Horse. In 1977 8/13 VMR Regiment was reduced to an independent squadron A Squadron 8th/13th Victorian Mounted Rifles and in 1991 was linked with 4th/19th Prince of Wales’s Light Horse forming the VMR Squadron of that regiment. Following WWII service in RAAF and RAN respectively, Lieutenant Ian McKay and Sergeant John Neale served in 8th/13th Victorian Mounted Rifles.Unique collection of photographs showing the first years of an armoured regiment of the post-Second World War era Citizen Military Forces showing equipment, uniforms, training and social activity and some personalities.Black ands white photograph of two soldiers in khaki drill uniforms, boots, web anklets and berets. One of a collection of photographs of 8th/13th Victorian Mounted Rifles Regiment between 1948 and 1951." Lt. McKay. Sgt. Neale :mckay ian, neale john