Showing 180 items matching "textile factory"

-

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Colour, Textile Factory at Prato, Italy, 2017

... Textile Factory at Prato, Italy...textile factory... Office goldfields textiles textile factory loom tapestry prato ...textiles, textile factory, loom, tapestry, prato, tagliabue -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Roger de Stoop, 1956

... de Stoop Textile Factory... textile factory which was established in 1950. Bales of ticking... Factory Blackburn North Textiles Prince of Luxembourg Princess ...Roger de Stoop was born in 1912 in Flanders, Belguim. He migrated to Australia and set up a mattress ticking factory in Blackburn North in 1950.The company produced damask ticking. de Stoop sponsored Belgian migrants to work in his factory and built housing for them close to the factory. He sold the business in the 1960's to Smith and Nephew but continued to manage the manage the business until 1966Black and white photograph of Roger de Stoop showing the Prince and Princess of Luxembourg around his Blackburn North textile factory which was established in 1950. Bales of ticking in foreground. Staff standing, guests seated.de stoop, roger, de stoop textile factory, blackburn north, textiles, prince of luxembourg, princess of luxembourg -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Roger de Stoop and Belgian workers, C 1950

... roger. de stoop aust pty ltd. de stoop and best textile... Best, an Australian who wanted to establish a textile factory... textile factory. weaving mills. belgians in australia Black ...Roger de Stoop came to Australia during the Second World War when the de Stoop spinning & weaving factory in Belgium was closed during the German occupation. He had previously met Dick Best, an Australian who wanted to establish a textile factory in Australia and in 1950 they built a factory at Blackburn North importing the weaving looms and many of their skilled workers from Belgium. Housing for the workers was built near the factory.Black and white photograph of Belgian family groups in front of one of the houses erected for the de Stoop workers. Roger de Stoop is in the centre of the photograph in a dark suit and tie.de stoop, roger. de stoop aust pty ltd. de stoop and best textile factory. weaving mills. belgians in australia -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Roger de Stoop

... roger. de stoop and best textile factory. belgians in... and died in Australia on 18th April 1999. The de Stoop textile... textile factory was closed due to German occupation and when Roger ...Roger de Stoop was born in Flanders, Belgium in 1912 and died in Australia on 18th April 1999. The de Stoop textile factory was closed due to German occupation and when Roger de Stoop received an offer from Australian Dick Best to begin a a partnership in similar venture in Australia, he agreed, bringing looms and skilled workers with him. The company was the first to produce Belgian damask ticking in Australia. The firm was sold to the British firm, Smith and Nephew in 1960.One coloured and one black and white head shot of Roger de Stoop wearing a suit and tie.de stoop, roger. de stoop and best textile factory. belgians in australia -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Newspaper - Article, Belgians here to settle, 13/03/1952

... joining Roger de Stoop, proprietor of a textile factory in North... joining Roger de Stoop, proprietor of a textile factory in North ...Photocopy of article on the arrival of the de Stoop family joining Roger de Stoop, proprietor of a textile factory in North Blackburn.de stoop, roger, belgians in australia, weaving mills -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article - Newspaper Clipppings, Worker's paradise factory at Blackburn, 1951 & 1988

... de stoop textile factory... textile factory de stoop roger 'The Belgians in Australia' gives ...'The Belgians in Australia' gives a brief history of Roger, 1950 - 1975.Belgian, Roger de Stoop, plans a spinning and weaving factory at Blackburn. He plans many innovative amenities to keep his staff happy. Also another article - 'The Belgians in Australia' gives a brief history of Roger, 1950 - 1975. 'The Belgians in Australia' gives a brief history of Roger, 1950 - 1975.textiles, de stoop textile factory, de stoop, roger -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: HANDSCHIN AND RONUS, SWITZERLAND FACTORY

... textile factory...Hanro Switzerland Handschin and Ronus textile factory ...Photograph. Black and White Photo of the back of Hanro, Handschin & Ronus in Switzerland. Markings on rear of photo read 'Back of Hanro', Handschin & Ronus.hanro, switzerland, handschin and ronus, textile factory -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - RICHARD KURT GOTZE - HANRO

... textile factory... textile factory black and white copy: (a) Richard Kurt Gotze ...black and white copy: (a) Richard Kurt Gotze, employee of Hanro. Gotze came to Bendigo to support the setting up of Hanro, in the early 1930's. 'He worked in the Hanro Mills with a lady called Adekle Hofmann' (b) Letter attached to photo from Christine Gorman, his daughter.richard kurt gotze, hanro, handschin and ronus, switzerland, textile factory -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Document, Arrivals of Belgian families

... sponsored by him to work in his Blackburn North textile factory... sponsored by him to work in his Blackburn North textile factory ...List by Roger de Stoop of Belgian immigrants 1950 - 1955 sponsored by him to work in his Blackburn North textile factory; with photocopy of photos of houses built for de Stoop employees, factory site and original buildings.belgians in australia, de stoop, roger, weaving mills -

National Wool Museum

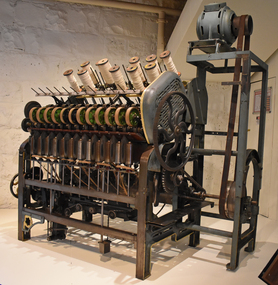

National Wool MuseumMachine - Cap Spinner, 1925

... and knitting. weaving knitting cap spinning cap spinner machine textile ...This cap spinner squeezes the thread under the stationary cap and winds them onto the bobbin. Spinning transforms tops into yarns. The tops are pulled out into fine strands known as rovings. They are then twisted to bind the thread together to give the yarn greater strength. The yarns are wound into differently shaped tools. They are then sent off for weaving and knitting.Cap spinning machine.weaving, knitting, cap spinning, cap spinner, machine, textile industry, factory -

National Wool Museum

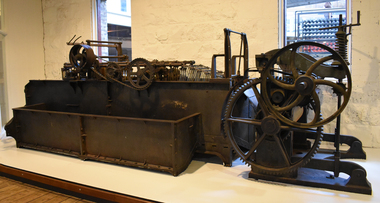

National Wool MuseumMachine - Scouring Bowl, J Dyson & Sons Pty Ltd, c.1890

... processing E. P. Robinson Textile Industry Factory Mill J. Dyson ...Scouring is the process that removes wool wax and other unwanted products from wool. Wool is washed in a hot detergent solution. It moves through a series of scouring bowls and is then rinsed and dried. Careful handling and washing preserves the strength and softness of wool. If the wool contains lots of seeds and other vegetable matter, it must be cabonized. This means it is treated with a solution of sulpheric acid and then baked at high temperature to remove impurities. The disused scouring water left-over from this process was often let drain into rivers and watercourses causing pollution. Many of Geelong's wool scours along the Barwon River were closed due to environmental damage. The race system on this bowl is not the original it has been modified with a variation of the harrow system. Used at E.P. Robinson South Geelong from c.1890-1970.Scouring bowl.J. Dyson & Sons Pty Ltd, Geelongsouring bowl, j dyson & sons, geelong, wool processing, e. p. robinson, textile industry, factory, mill -

National Wool Museum

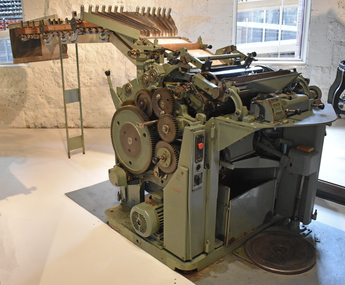

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

... operator always needed to be on duty in the factory to precisely ...Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

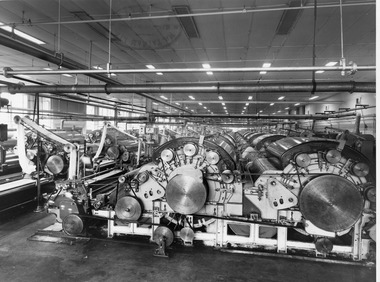

National Wool MuseumPhotograph - Carding Machines

... , to showcase new Carding Machines in a newly developed textile factory... textile factory. The photograph was taken in Glasgow, Scotland ...Sales photograph for William Tatham Ltd. of Rochdale, to showcase new Carding Machines in a newly developed textile factory. The photograph was taken in Glasgow, Scotland.A black and white photo of a room filled with working Carding Machines in a portrait format. A man is working at the end of the closest machine.On rear - top margin - Showing Card Sets in new Card Room. Bottom right corner - Commercial Artists photographers and blockmakers Scottish Studios and Engravers LTD. 196 Clyde st. Glasgow. C C.P.D 6893 Dtextile machinery, wool manufacture, carding, wool, glasgow -

National Wool Museum

National Wool MuseumBook, Australasian Sheep and Wool

... treatise from paddock to loom; from shearing shed to textile... to textile factory" - Alfred Hawkesworth, 6th ed. 1930. Wool ..."Australasian Sheep and Wool: a practical and theoretical treatise from paddock to loom; from shearing shed to textile factory" - Alfred Hawkesworth, 6th ed. 1930.PORT PHILLIP MILLS PTY. LTD. / Morland Street / Footscraywool - history wool growing wool processing, port phillip mills pty ltd, wool - history, wool growing, wool processing -

National Wool Museum

National Wool MuseumBook, Australasian Sheep and Wool

... treatise from paddock to loom; from shearing shed to textile... to textile factory" - Alfred Hawkesworth, 6th ed. 1930. Wool ..."Australasian Sheep and Wool: a practical and theoretical treatise from paddock to loom; from shearing shed to textile factory" - Alfred Hawkesworth, 6th ed. 1930.Sturgeonwool - history wool growing wool processing, wool - history, wool growing, wool processing -

National Wool Museum

National Wool MuseumBook, Australasian Sheep and Wool

... treatise from paddock to loom; from shearing shed to textile... to textile factory" - Alfred Hawkesworth, 6th ed. 1930. Wool ..."Australasian Sheep and Wool: a practical and theoretical treatise from paddock to loom; from shearing shed to textile factory" - Alfred Hawkesworth, 6th ed. 1930.wool - history wool growing wool processing, wool - history, wool growing, wool processing -

National Wool Museum

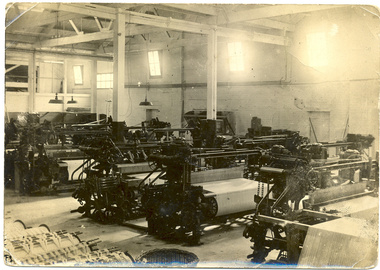

National Wool MuseumPhotograph - Textile Machinery, Fred Murgatroyd, c.1920s

... Black and white photograph showing interior view of factory... and white photograph showing interior view of factory with textile ...Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Black and white photograph showing interior view of factory with textile machinery.Back: [printed] F Murgatroyd Back: [handwritten] Tweedsidetextile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

Whitehorse Historical Society Inc.

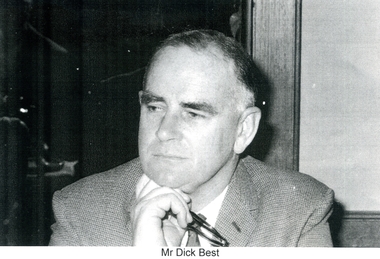

Whitehorse Historical Society Inc.Photograph, Dick Best

... a textile factory in Australia. Land was purchased in Blackburn... up a textile factory in Australia. Land was purchased ...Richard Best was an Australian Textile industry agent and Businessman. While travelling in Belgium he contacted the de Stoop family, textile manufacturers, whose business had been closed down by German occupation after the 2nd World War. They took up Dick Best's offer to relocate and join with him to set up a textile factory in Australia. Land was purchased in Blackburn North and when the de Stoop and Best Aust P/L traded, Dick best was in charge of marketing their products.2 Black and white photograph of the head and shoulders of Richard Best. He has a pair of glasses in his right hand(on smaller photocopy) Mr Dick Bestbest, richard, weaving mills, de stoop and best aust, p/l -

Warrnambool and District Historical Society Inc.

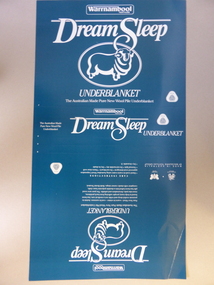

Warrnambool and District Historical Society Inc.Packaging, Blanket Box, 1990s

... ’ underblanket. This item was produced by the Warrnambool Textiles.... This item was produced by the Warrnambool Textiles factory ...This item has been made to package a ‘Dream Sleep’ underblanket. This item was produced by the Warrnambool Textiles factory in the 1990s. In 1910 the Warrnambool Woollen Mill was established and it produced blankets, rugs etc with a staff of over 700 in the 1940s. In 1958 the Mill became the first in Australia to manufacture electric blankets. In 1968 the business was sold to Dunlop and in 1982 Dunlop sold the Mill to Onkaparinga Woollen Company. In 1983 Onkaparinga was taken over by Macquarie Worsteds and the Warrnambool Woollen Mill then traded as Warrnambool Textiles. In 2000 the Mill closed. This packaging is of some interest as a memento of the old Warrnambool Woollen Mill which operated in Warrnambool for 90 years and was a major industry in the town/city and a major employer of local residents. It is still remembered fondly by many local people today. This is a cardboard sheet for packaging an underblanket for Warrnambool Textiles. It has white printing on a dark blue background on one side and is white and unmarked on the other. It has an image of a sheep, three symbols for ‘Pure New Wool’, a symbol for ‘Naturally Flame Resistant’ and one for ‘Moth-Resist Treated’. The sheet is designed to be folded in four places to cover an underblanket. This is a cardboard sheet for packaging an underblanket for Warrnambool Textiles. It has white printing on a dark blue background on one side and is white and unmarked on the other. It has an image of a sheep, three symbols for ‘Pure New Wool’, a symbol for ‘Naturally Flame Resistant’ and one for ‘Moth-Resist Treated’. The sheet is designed to be folded in four places to cover an underblanket. warrnambool woollen mill, warrnambool textiles, onkaparinga woollen company -

National Wool Museum

National Wool MuseumTrunk

... Hirst. Godfrey Hirst set up a successful woollen textile factory... Hirst. Godfrey Hirst set up a successful woollen textile factory ...Trunk belonged to Godfrey Hirst and was used in his travels between Australian and England. Godfrey Hirst's first trip to Australia was in 1885 and his last trip was in 1916. In this time Hirst was known to travel between Australia and England regularly on the lookout for the latest updates from England that he could bring to his factory in Geelong. The trunk was donated by Susan Wiffen (née Betts), the great granddaughter of Godfrey Hirst. Godfrey Hirst set up a successful woollen textile factory in Geelong in 1888. The factory stayed in operation until 1966. The company still bearing his name has since been purchased by various investment companies but continues to be the largest carpet manufacturer in Australia. Predominately black trunk with two wooden bands around the sides of the trunk and five across the top (lid). The lid is slightly curved and contains white printed lettering GODFREY HIRST. The trunk also contains small wheel underneath locked for pushing the trunk sideways only. The trunk contains two leather handles on either side. Internally, the trunk contains three levels of storage with baskets stackable on top of one another. The baskets are finished in a white and brown striped fabric which has red taped edging for additional strength. The top layer of baskets also has brown leather latches in order to keep the basket lids shut. The layered levels of storage are synonymous of Saratoga style trunk.Printed. Letters: Godfrey Hirstgodfrey hirst -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Clothing - Suit, Shirt and Bowtie, 1973

... at Yarra Falls (a Textile Factory making fabrics for school... chemist at Yarra Falls (a Textile Factory making fabrics ...In 1973 when Brian Schultz was working as a dye chemist at Yarra Falls (a Textile Factory making fabrics for school uniforms, suits etc.) in Abbotsford, he was invited by his friend to be his best man. He chose the colour green, dyed the fabric himself, and took the fabric to a tailor in Smith Street, Collingwood to have the suits made up for the December wedding. The green shirt which Brian wore with the green suit at the wedding in 1973 came in handy when he wore it 37 years later at his son's 30th birthday Halloween dress up party, when he dressed up as The Hulk. He cut up the sleeves of the shirt and painted himself green. For the December wedding, the groom wore a white suit, lemon shirt and emerald green velvet bow tie.Green two piece suit with shirt and bow tie. 1. Single breasted jacket with two pearl buttons centre and smaller buttons on sleeves. White stitching around collar edge and down the front on pockets. 2. Trousers with wide belt carrier, zip fly, cuffs wide with 6cm turnback. 3. Shirt is a polyester fine knit, pale green with dark green buttons and collar stitched with dark green edge-stitching. 4. Dark green velvet and ready-tied bow tie..MENS SLACKS BY TRAVELLERS APPAREL - For the man who goes placescostume, male -

National Wool Museum

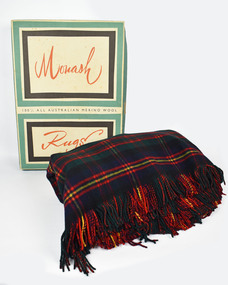

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

... fine yarn from medium quality wool at a textile factory... fine yarn from medium quality wool at a textile factory ...The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Photograph - Don Jenkins - Woollen Mill

Don Jenkins was the Managing Director of the Warrnambool Woollen Mill from 1971 to 1989. He was first employed at the Woollen Mill in 1935. The Warrnambool Woollen Mill in South Warrnambool was established in 1910 with the first manager, J.E. Bennett. By 1915 there were 160 employees and in 1969 there were 380 employees. In 1980 acrylic blankets and fabrics were made on the site and in 1982 there was a name change to Warrnambool Textiles. In 1995 the Smith Family took over the factory, following its ownership by several other Australian firms. It closed in 2000. This is an important photograph as the Warrnambool Woollen Mill was a prominent business in Warrnambool for 90 years. Don Jenkins was the Managing Director for 19 years and this is a good photograph of him and is very useful for display and research purposes. This is a colour photograph of Don Jenkins in a wooden and gilt edged frame with a linen insert. On back of photograph handwritten in biro – ‘Don Jenkins, Managing Director, 1970-1988?’ (Note that Mr Jenkins was the Managing Director from 1971 to 1989)warrnambool, woollen mill, don jenkins, manager warrnambool woollen mill -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile, Fletcher Jones, late 20th century

These are samples of the material used at the Fletcher Jones Factory in Warrnambool to make garments for men (suits, trousers, shorts) and women (suits, slacks, skirts, shorts). Fletcher Jones Clothing Factory was a key industry in Warrnambool from 1948 to its closure in 2005. The business was founded by David Fletcher Jones (1897-1977), a clothing manufacturer and retailer who worked as a hawker in the Western District following service with the A.I.F. in World War One. In 1924 Fletcher Jones opened three shops in Liebig Street selling men’s wear, hosiery and linen and operating a small tailoring business. He moved his shop to another location in Liebig Street and began to concentrate on men’s trousers production. In 1946 he opened a shop in Collins Street in Melbourne and eventually had stores and factories all over Australia. In Warrnambool he opened his factory at Pleasant Hill in Flaxman Street in 1948 and became a major Warrnambool employer, with over 1000 employees at one time. He transformed his business into a co-operative, with the name, ‘Fletcher Jones and Staff’ registered in 1947. The business diversified into other ranges of clothing for men and women but failed to compete with cheaper overseas clothing imports and the factory and shops were closed in the early 21st century. These pieces of material are of some interest as examples of the materials used in one of the most important businesses in Warrnambool and one that was of national significance for many decades. The Fletcher Jones label was well-known throughout Australia and Fletcher Jones himself was a prominent person in Warrnambool’s history, not only for his business interests but also for his philanthropy, his advocacy of business co-operatives and his support for many Warrnambool institutions. The Fletcher Jones Factory Gardens are still today a feature of Warrnambool and a tourist attraction. These two packets contain samples of materials used at the Fletcher Jones factory in Warrnambool. One packet (VC000690.1) contains four pieces of woollen material, one grey striped, one grey weave, one navy and one green, red and white tartan. The other packet (VC000690.2) contains two pieces of woollen grey and navy material and five small woollen samples of dark grey, light grey, navy, beige and blue and grey check material. warrnambool, industry -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile, Fletcher Jones, Men's Fletcher Jones Jeans, Early 21st century

This pair of jeans comes from the Fletcher Jones factory in Warrnambool. David Fletcher Jones (1895-1977) served in World War One and in the 1920s set up as a travelling hawker selling drapery in the Western District of Victoria. In 1924 he leased three shops in Liebig Street Warrnambool and in 1928 he moved the business to the corner of Koroit and Liebig Streets with his Man’s Shop. He manufactured men’s clothing on site. In 1931 a new set of buildings was erected on the site and Fletcher Jones moved into the new building. In 1946 a Fletcher Jones shop was opened in Melbourne and in 1948 a factory was opened in Warrnambool with a new company Fletcher Jones and Staff established in 1951. This company became known Australia-wide, firstly for the production of men’s trousers and later for both men’s and women’s clothing. By 2011 the factory was sold and the company dissolved. These jeans are retained as an example of the clothing made at the Warrnambool Fletcher Jones factory. The Fletcher Jones clothing company was one of the most important businesses in Warrnambool in the 20th century. This is a pair of blue cotton jeans pants with yellow stitching and a metal zip The garment has four pockets. The back pocket has the maker’s label and there are two labels attached to the inside. The front inside top section is lined with white material. ‘Fletcher Jones Australia’fletcher jones clothing company, history of warrnambool -

Warrnambool and District Historical Society Inc.

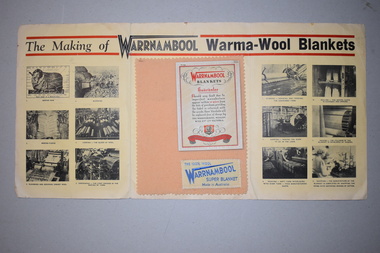

Warrnambool and District Historical Society Inc.Folder, Warrnambool Woollen Mill Co Ltd, Warrnambool Woollen Mill, 1950s

This folder contains photographs, advertisements and a sample of a piece of blanket from the Warrnambool Woollen Mill. This mill was officially opened in South Warrnambool in 1910 following the establishment of a local public company. The first manager was John Bennett from Yorkshire, England. The operations of the mill expanded with new buildings enabling the business to double in size by 1915. In the 1940s the factory was employing 700 people. In 1968 the factory was sold to Dunlop Australia but was sold again in 1982 to Onkaparinga Woollen Company. In 1983 Mcquarie Worsteds took over the factory with the business then known as Warrnambool Textiles. In 2000 the mill closed and most of the buildings were later demolished for a housing estate. This item is an attractive and informative memento of one of Warrnambool’s most important businesses of the past. The Warrnambool Woollen Mill operated for 90 years and employed many local people. The photographs are of particular interest.This is a rectangular-shaped sheet of buff-coloured lightweight cardboard. It has been folded twice to create six pages in a folder. Three pages contain black and white photographs of the woollen mill operations and two pages contain advertising material with black and white images. One page has a cream blanket piece of material attached to the page by two staples and this has the brand name stitched onto the right hand corner This piece of blanket also has a paper guarantee card attached by staples. The Warrnambool Woollen Mill Co. Ltd. South Warrnambool The 100% Wool Warrnambool Super Blanket Made in Australia warrnambool woollen mill, history of warrnambool -

Glen Eira Historical Society

Glen Eira Historical SocietyDocument - Classic Retirement Village, Brighton

... Stanley Mills Wool Industry Weaving Mills Textile Factories ...Four documents about the history of this site pre Classic Retirement Village: 1/A copy of a description of the sale process of the Gascor site, cnr Nepean Highway and Thomas Street, to Becton Corporation in 1997 And 1998. Printed on 31/07/2010 from the Victorian Auditor General’s Department website with aerial photograph 2/A copy of page one of the Gleneira Planning Scheme dated 19/01/2006 which mentions the Gascor site. 3/Research note by Andrew Frederick dated August 2010 listing occupiers of the site in the 1960 and the 1970 Sands and Mc Dougall Directories. 4/Research note by Claire Barton dated May 2010 containing Ian Swan’s recollections of working at Daylesford Worsted Woollen, occupier of the site, in the 1960s.thomas street, brewer road, bentleigh, gascor, becton corporation pty ltd, virginia park, gas and fuel, hughesdale dairy, east boundary road, moorabin, east bentleigh, hooblerstone, clairmont avenue, glen eira, daylesford centenary woollen and worsted mills pty ltd., nepean highway, f and j industries australia plastic and rubber division., swan ian, korman stanley, mills, wool industry, weaving mills, textile factories, textile manufacturing, manufacturing industry -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Fire screen, Tapestry, Post 1967

David Fletcher Jones (1895-1977) was a travelling hawker who opened a business in Liebig Street, Warrnambool in 1924. In 1931 he opened The Man's Shop at the corner of Liebig Street and Koroit Street. He sold suits and overcoats tailored in the work rooms upstairs. In 1948 his factory known as Pleasant Hill was opened in Flaxman Street in Warrnambool, the site of an old quarry. In 1951 the company Fletcher Jones and Staff was formed with the staff owning 51% of the shares, By the 1970s Fletcher Jones and Staff had become one of the largest clothing companies in Australia with 55 shops and 3000 employees. In 1992 the Warrnambool City Council bought the factory and gardens with the site now a tourist attraction. Although the name is retained today for trading purposes the original Fletcher Jones company has been dissolved. The screen is a representation of the Fletcher Jones factory post 1967. It a wool tapestry by Martin Prider who was a painter and caretaker what the Fletcher Jones factory. He lived in one of the Fletcher Jones cottages on site. (Robin Boyd Age Small Homes Scheme, today Heritage listed.)This is an interesting memento of the Fletcher Jones company and the factory. It was done by a local resident and features the famous Fletcher Jones gardensTapestry fire screen in a rectangular light timber frame depicting the Fletcher Jones Factory Gardens. The screen has two timber feet, non relective glass and appears to be a wool tapestry. The image of the gardens is after 1967 as the silver ball is included and that was erected in 1967. Nilfletcher jones company and warrnambool factory, pleasant hill warrnambool, martin prider, fletcher jones, tapestry of fletcher jones factory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Petticoat, late 19th century to early 20th century

This petticoat was one of several items donated from the estate of Susan Henry OAM nee Vedmore (1944 - 2021). It is in very good condition and appears to be from the Edwardian era - early 20th century. A petticoat is a lady's undergarment - worn under a skirt or dress. They provided warmth, modesty and shape to the dress. In the middle of the 19th century, petticoats were worn over hoops, bustles or in layers. Petticoats varied according to the style of the outside skirt or dress. Plain petticoats tended to be worn with everyday wear whilst better dresses (party dresses or silk gowns) were worn with petticoats that often had more trim and embellishments. Edwardian petticoats had less volume than Victorian era petticoats and they had a "dust ruffle" or lining under a lace flounce. The "dust ruffle" protected the lace flounce and gave the petticoat more flare at the bottom, greater freedom when walking as well as saving the flounce (which was often made of finer material) from everyday wear and tear. Tucks are another feature of Edwardian petticoats - when the lace at the bottom became worn, it could be cut off and the tucks released. This extended the life of the petticoat. This petticoat features an intricate trim of broderie anglaise. Although broderie anglaise was a lace that could be made by hand, it was very time consuming to make. St Gallen was a city in Switzerland that had become known for producing quality textiles. At the beginning of the 19th century, the first embroidery machines were developed in St Gallen. Factories used embroidery machines but people also had them in their homes. They were able to produce broderie anglaise for export. By the early 20th century, machine made lace, fabric, ribbons etc. were being sold in drapers shops all over England and Wales to women who were making clothes and furnishings for their families. It is highly likely that the lady who made this petticoat brought the lengths of broderie anglaise already made to embellish and personalise her petticoat. Susan's family (Harold and Gladys Vedmore) immigrated to Australia from Wales in 1955 and settled in Warrnambool. Susan was well known in the Warrnambool community for her work supporting children and families across the district - particular those with disabilities, or those who were homeless, unemployed or isolated. Susan was the founding trustee of the "Vedmore Foundation" - a Warrnambool philanthropic trust set up in 2010 to support a range of charitable and not-for-profit causes by providing grant assistance. In 2021, she was awarded a Medal of the Order of Australia for services to the community.This item is an example of the needlework skills of women in the late 19th century - creating pintucks and adding lace to personalise and embellish a practical item of clothing. It is also significant as an example of a practical solution to the difficulties that women of this era faced with regard to the washing of clothes and household linens.A white lawn petticoat with a 22.5 cm opening that fastens with 2 small buttons and a drawstring tie. It is decorated with two wide pintucks followed by two gathered frills (or flounces) - one decorated with three rows of narrow pintucks and a single row of broderie anglaise and the bottom frilled hem finished with 3 rows of broderie anglaise in a flower design. The two bottom frills are lined with plain white cotton fabric.flagstaff hill maritime museum and village, great ocean road, petticoat, lady's petticoat, undergarment, lady's undergarment, lingerie, edwardian petticoat, broderie anglaise, lace, machine made lace, hand sewn, machine sewn, draper's shop, susan henry oam, vedmore foundation