Showing 69 items matching "worker safety"

-

Puffing Billy Railway

Puffing Billy RailwayClothing - Shoes

... worker safety... worker safety linesmen VR & arrow symbol Leather soled slip ...These leather soled shoes were used by railway workers undertaking work on overhead electrical cables and HV boxes. Known as "slippers" they were provided just inside explosives vans and worn to stop metal protectors on shoes scraping across metal floor and possibly causing a spark and a explosion. info from Syd Coles : on Explosives Slippers Beaufort station used to get a explosive wagon with drums of gelignite regularly slipper type shoes were in a little box built into the inside wall of the wagon....A Special powdervan key was sent from H/OFFICE as a VALUE which each person handling it had to sign for it.....It would arrive on the early down Passenger Train ex Melbourne...then the "P" wagon was unloaded....Prior to the wagon leaving a Railway Internal telegram was sent to the SM @Beaufort giving the wagon number...consignee (owners of dynamite) contents and the KEY number which would be sent....When all unloaded the KEY sent back as a VALUE...a Internal telegram sent as to KEY number and train it was despatched on....fair bit of security.but couldn't afford to lose a KEY as they fitted all the LOCKS used on the EXPLOSIVE "P" wagons whatever Stations they went to.Historic - Victorian Railways - leather soled shoesLeather soled slip-on shoes, with single strap across bridge of foot and featuring stitchwork along edges.VR & arrow symbolpuffing billy, victorian railways, leather soled shoes, railway slippers, explosives, worker safety, linesmen -

Bendigo Military Museum

Bendigo Military MuseumBook - YEAR BOOK, The Brighton Print, R.S.S.I..L.A OFFICIAL YEAR BOOK 1936

... '. Under the RSL badge is the image of a happy construction worker...'. Under the RSL badge is the image of a happy construction worker ...A medium size paper book. It has a brown buckram spine cover. The front cover has the original style RSL badge in the centre, showing two characters. Left side of the RSL Badge in white is the phrase; "NSW Branch Incorporated", on the right side of the badge is "ANZAC MEMORIAL, Hyde Park, Sydney'. Under the RSL badge is the image of a happy construction worker with a safety helmet. Inside are approx 207 pages of print and illustrations. It also has advice on pension entitlements. It has first AIF history. Cost 1/-. rsl, book, ww1, veterans -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkHeadwear - Fire Fighters Helmet, MSA, c.1970s

... general worker protection and safety products. ... general worker protection and safety products. This helmet ...During the 1960s in Australia, helmets evolved from metal construction to that of polymer and other plastics. This helmet was donated by the Emerald Fire Brigade which was established on 14 March 1941 as the Emerald Bush Brigade. Originally its equipment was stored at Madigan's butcher's shop near the corner of Monbulk Road. The Brigade's first fire station was built around 1945. In 1966, this station was recorded as containing the fire truck and a Land rover pumper, three radio sets, 40 knapsacks, six lengths of hose, helmets, rake hoes and other hand tools. In 2010, the Brigade moved into a new purpose-built building in Monbulk Road. The manufacturer of this helmet, MSA, was founded in 1914 in the USA. MSA began as a mine safety company but since expanded into more general worker protection and safety products. This helmet is an historical artifact worn by members of a crucial volunteer fire fighting service operating in the Emerald district since 1941.Yellow, lightweight, hard plastic or polymer helmet with black leather detachable chin strap with Velcro fastening. inside the helmet is an adjustable head harnessInside helmet on a partly torn label: 'MSA / VGARD / Type 2 ...? / STANDARDS AUSTRALIA' Inside the brim black pen writing EMERALD SPARE 5 EMERALD at one end engraved: 'MSA'' and at the other end: '1801-1881 On the outside of the helmet there is a yellow reflector on each side and at the front and the back there is evidence of labels that have been removed.helmets, fire fighting, msa, emerald fire brigade, cfa -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkHeadwear - Fire Fighters Helmet, MSA, c.1970s

... safety company but since expanded into more general worker... safety company but since expanded into more general worker ...Helmets protect firefighters from heat, falling objects and cinders. During the 1960s in Australia, helmets evolved from metal construction to that of polymer and other plastics. The manufacturer of this helmet, MSA, was founded in 1914 in the USA. It began as a mine safety company but since expanded into more general worker protection and safety products. The Emerald Fire Brigade was established on 14 March 1941 as the Emerald Bush Brigade. Originally its equipment was stored at Madigan's butcher's shop near the corner of Monbulk Road. The Brigade's first fire station was built around 1945. In 1966, this station was recorded as containing the fire truck and a Land rover pumper, three radio sets, 40 knapsacks, six lengths of hose, helmets, rake hoes and other hand tools. In 2010, the Brigade moved into a new purpose-built building in Monbulk Road.This helmet is an historical artifact worn by members of a crucial volunteer fire fighting service operating in the Emerald district since 1941.Yellow, lightweight, hard plastic or polymer helmet with black leather detachable chin strap with velcro fastening.Inside helmet on a partly torn label: 'MSA / VGARD / Type 2 ...? / STANDARDS AUSTRALIA' Inside the brim at one end engraved: 'MSA'' and at the other end: '1801-1881 / LN70' On front of helmet a label with logo and red lettering: 'CFA' helmets, fire fighting, msa, emerald fire brigade, cfa -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Proposal, VIOSH: National Safety Council of America (NSCA) Congress and Expo, New Orleans, 1999

... Health and Safety and Workers Compensation discussed with VIOSH... Health and Safety and Workers Compensation discussed with VIOSH ...Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Chris Knight & Associates - Specialists in Occupational Health and Safety and Workers Compensation discussed with VIOSH the feasibility of them being involved in attending the National Safety Council of America Congress and Expo in New Orleans 1999. This would be in conjunction with other Australian groups. Together they would have a stand/exhibit promoting their what they did. Comments from VIOSH staff are shown on the first page of the letter.Eight A4 pages, typed. Pages 1 & 2 are letter. Pages 3 to 8 re NSCA Congress and Expo - Australian ConsortiumLetterhead of Chris Knight & Associates. Signature of Chris Knight. Comments written in biroviosh, victorian institute of occupational safety and health, steve cowley, chris knight, occupational health and safety, nsca, national safety council of america, congress and expo, new orleans, safety exhibit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotographs x 2 - Clover Dam, Circa 1940's

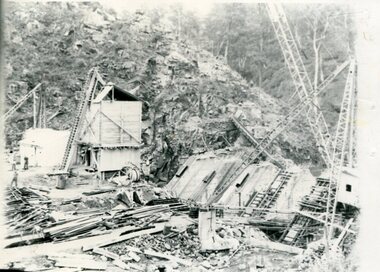

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level. Photographs also document early engineering and building techniques used in the construction of dams and power stations during the 1940’s and 1950’s. Note the lack of safety equipment and suitable work attire worn by construction workers on the sites 1. Black and white photograph of Clover Dam under construction. Has a .5cm white border around photo 2. Black and white photograph of Clover Dam under construction showing workmen at work. Has a .5cm white border around photo Written in pencil on back of both photographs - Clover Damclover dam, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotographs x 2 1. Lake Guy & Bogong Village 2. Bulldozer moving rocks

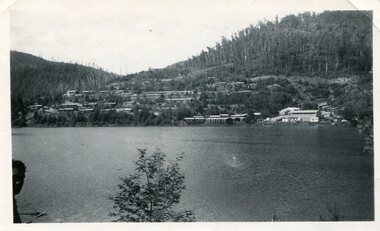

1. In 1940 Field Headquarters for the Kiewa Scheme were established at Bogong with office, workshop facilities and accommodation for workmen, staff and some families constructed. (There had been a 'tent camp' on this site in 1939 but was destroyed by bushfires) Construction of accommodation continued until 1947. A total of 40 houses plus a hostel for single staff, post office, police station, medical centre and primary school all with water and sewerage and electricity supply. The staff hostel was known as Kiewa House and is now occupied by the Education Department. Lake Guy was named after Mr. L.T. Guy who was the Resident Engineer in charge of construction work and associated activities on the Kiewa area. He held this position from 1939 to November 1946 when he was transferred to Head Office. 2. Example of the type of heavy machinery used in clearing and building of Lake Guy, Bogong Village and Clover Dam 1. The Bogong Township was developed firstly as an accommodation centre (base camp) for construction workers employed under the Kiewa Hydroelectric Scheme. At the completion of the scheme, in the 1960's, the village was opened to public/tourism use. Strict environmental control has not allowed for any extensive redevelopment in tourist accommodation and basically restricted it to the accommodation initially built for the construction workers. Lake Guy is one of the many water storage reservoirs used to supply the power stations their main power to run the huge turbines generating the final product, electricity 2. Pictorial record of the types of machinery used in the development of Bogong Village and the Hydro-electricity scheme including the Clover Dam. Note the lack of safety equipment worn by construction workers of the period. 2 black and white photographs taken at Bogong 1. Lake Guy with Bogong Village in the background 2. Workman in bulldozer clearing rocks, possibly for construction at Bogong1. Handwritten in blue ink on back of photo 'Lake Guy showing Bogong Village' 2. No markingslake guy, bogong village, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph – Photocopy of black and white photograph of Bogong Creek Race Line. 17/1/51, 17/01/1951

... or other safety equipment. Several workers can be seen working ...A start on the construction of Bogong Creek race line was made at the commencement of winter in 1948. Work proceeded in the following years when work on the High Plains was not practicable. In January, 1951 the special trimming machine, the special slip form and concrete mixing and placing equipment was put into service. A shortage of cement caused some delays as well as a sudden financial recession. The race line was completed and put into service in 1952.An historical record showing the machinery used during this time, the number of workers and supervisors involved and the mountainous terrain where they worked. It also demonstrates the OH&S of the period with workers mostly in street clothing with no hard hats or other safety equipment. Several workers can be seen working shirtless or in singlets.Photocopy of a black and white SECV photograph No: K 6209 labelled Bogong Creek Race Line ch. 1700. Depicting large group of workers and supervisors working at the site. Dated 17/1/52Printed underneath the photograph: STATE ELECTRICITY COMMISSION OF VICTORIA Date: 17/1/51 Time: 10.30am No: K 6209 Kiewa Hydro-Electric Works Bogong Creek Race Line ch. 1700 bogong creek raceline; secv; kiewa hydro electric scheme; -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyLeaflet - Kiewa, Welcome to Kiewa

The State Electricity Commission of Victoria constructed the Kiewa Hydro Electric Scheme from 1938 to 1961. The Scheme included three power stations, dams, tunnels and was becoming a popular tourist destination with Falls Creek Ski field within its boundaries.This leaflet was published by the SECV to ensure all visitors to the Kiewa Hydro Electric Scheme were made aware of safety measures with regard to their driving and to bush fires. These were necessary as the area was unique with driving on mountainous roads, changeable and extreme weather and the threat of bush fires. The gatehouse existed during construction, when the SECV was in charge, as a restriction to entry to the Scheme for SECV workers and those with permission to enter. The SECV controlled the area so in case of accident, the SECV was the body to contact not eg. the police.Small white and green leaflet made from one sheet of glossy paper and folded in half. Front cover has the title in the middle, the SECV emblem at the centre top and across the bottom is a message to read the inside pages which are safety messages for driving and bush fires. The back cover has a RACV road map of Kiewa and its 'works' including the Gatehouse which was the entrance to the scheme.The map also has an insert of the main roads & nearby cities. state electricity commission of victoria; kiewa hydro electric scheme; gatehouse; safety rules; kiewa -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySign - SECV, Safety - Grinding Wheels

The State Electricity Commission of Victoria produced and displayed safety signs for their employees during the construction of the Kiewa Hydro Electric Scheme.KHES was constructed from the late 1940s to early 1960s and included the construction of Mt Beauty and Bogong townships. Safety was a concern for the SECV towards its workers. Metal black print on white background with yellow 'emphasis' at the top - 'Safety'. "Instructions for the use of / Grinding Wheels". There is a circular hole in each corner with a black frame around the perimeter.state electricity commission of victoria, kiewa hydro electric scheme, safety sign, grinding wheels -

Kiewa Valley Historical Society

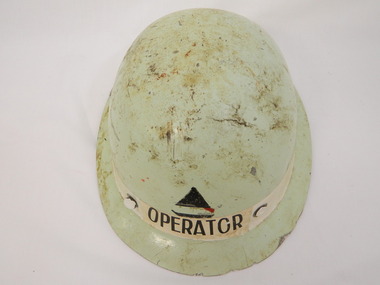

Kiewa Valley Historical SocietyHelmet Safety

Safety helmets were worn during construction work on the Kiewa Hydro Electric Scheme and during its operation. Each group of workers had a different coloured helmet to identify their role.A pale green fibre glass oval shaped helmet with a small rim and with hard white plastic 'netting' inside - shaped with 6 pieces coming towards the outside from an oval in the centre. These are attached with screws. Around the circumference of the head is a plastic adjustable piece covered by soft plastic in the front. This has a wide cord attached that fits under the chin.On the outside front: a triangle colored in black with "operator" underneath. Inside rim at front: "Made in England"helmet. safety. kiewa hydro electric scheme. operator. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPayroll Office Machine - S.E.C.V

This machine was used by the State Electricity Commission of Victoria on the Kiewa Hydro Electric Scheme by office workers who worked in the payroll office.The State Electricity Commission of Victoria used the latest technology available for office equipment on the Kiewa Hydro Electric Scheme. This machine was used in the payroll office.Black metal table with machine on top. Electric motor with belt drive to machine which is situated under the rear left side of the table. Safety metal mesh protects the leather belt and is at the rear of the table. The operator faces the machine which has a tray on the left and is divided longitudinally into two and holds new shiny metal plates on each side. There is a brown bakelite wheel on the left and two printing wheels inside a myriad of moving parts that enable the metal plates to be embossed with payroll information i.e. "Gang No. etc. / Names / Pay No. / Rate type. This has to be checked out each time / Date"ULQ 11 10"state electricity commission of victoria. kiewa hydro electric scheme. payroll office. office work. payroll machine. office equipment -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Safety Report, VIOSH: Safety Report conducted by University of Ballarat and the Association of Wall and Ceiling Industries, Victoria, 2007

Safety Development Fund Final Report, January 2007. This was conducted by the University of Ballarat and the Association of Wall and Ceiling Industries, Victoria. This was for the prevention of falls and manual handling injuries in the industries. Part of the Safety Development Fund Project was funded by Worksafe Victoria and supported by the Construction, Forestry, Mining and Energy Union and the Transport Workers Union. The authors of the Report are Steve Cowley and Susan Leggett of The University of Ballarat. The project presented an opportunity to increase the adoption of risk control measures that had potential to reduce musculo-skeletal injuries and falls among plasterers and those involved in handling and distribution of plaster and related products.Ninety-eight pages - includes diagrams and photographs in form digital.viosh, victorian institute of occupational safety and health, university of ballarat, steve cowley, susan leggett, association of wall and ceiling industries, awci victoria, cfmeu, construction forestry mining and energy union, transport workers union, risk control measures, safety development fund, twu -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 23, January 1985 to June 1985

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 15 January 1985 to 6 June 1985.Book with beige cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, new tafe board head - glen ludbrook, order of australia medal to agnes tweedle and william north, more funds for retraining for older workers, ballarat regional association for community education, tafe catering course for unemployed, forestry seminar centre opened, victorian school of forestry and land management creswick, industrial sewing machining course, short course to more satisfying life, government spending $6 million at smb, stephen bracks, roger lowrey, evan walker, minister for public works, $790000 smb work extension launched, $95000 for smb arts centre, community employment program grant, ballarat's job board launched, jim simmonds, ballarat employment and training board, bill gribble, andrea lees, begonia queen, firm donates car to traffic safety school, bulldozed out of existence, smb extensions, silvana faulkner equal opportunity officer, the age nikon school photographic contest 1985, smb offering dance as a subject, history of the school of mines and industries ballarat book, our aladdin's cave of rowing trophies -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 27, June 1986 to 30 August 1986

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 7 June 1986 to 30 August 1986.Book with yellow cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, fire hazard-memorial theatre, new women's skill program at smb, colin mccurry, funding delay hampers theatre repair, work skill newsletter, minister for the arts, race mathews, royal south street society, president peter barwood, secretary stan hooper, john snowden, smb school of performing arts, jared dickson student, smb fitness program older adults, lee-anne law, rehabilitation after accident, geoff browning hairdressing department, young workers show their skills, governor praises smb buildings, davis mccaughey, e j tippett, official opening, e j tippett learning resource centre, catering and hospitality, kay mcfarlane, david boyle, women's theatre, patrick kirby boilermaker, most skilful 10 chosen, andrew wardell apprentice of the year, bcae celebrations, ballarat college of advanced education, theatre funding restoration, dino procaccino, richard goss, tops at their trade, safety contribution, changing role of women, christine pearce welding, laurelle pearse welding, amanda burns drafting, michelle scott drafting, small business course at smb, jack barker to retire, sebastopol technical school 25 years, ballarat group apprenticeship schemme, electrical mechanics david thomson and ron irwin, panel beaters glenn virgo and geoffrey mason, motor mechanics alex bond and mark lewis, fund-raising by hairdressing students for new salon, annette evans and suzanne gandur, smb performing arts, mellissa bone photography prize, david stoddart cookery course at smb, nelson thomas and jamie holloway reiv scholarship winners, building work on schedule, literacy course for adults -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, matchbox 'Redhead' with matches, 20thC

On 15th December 1909, Bryant & May, Australia’s first match factory at Church Street, Richmond, Victoria. was opened by The Honourable Alfred Deakin, Prime Minister of Australia, and Mrs. Deakin. It was heralded by the first Commonwealth Government of newly-federated Australia because the government of the day was anxious to encourage secondary industry and pledged tariff protection of local manufacturers. The building was constructed in 1909 as the Empire Works to a design by prolific Melbourne architect William Pitt and was purchased soon after by British safety match manufacturer Bryant and May, who significantly expanded the building, adding another level and the landmark clock tower. Bryant and May were unique in that they operated as a model factory, providing workers with conditions and amenities that even today seem generous. These included a dining hall and sports facilities such as a tennis court and bowling green which were constructed in the 1920s. Bryant and May ceased Australian match manufacture in the early 1980s as a result of import competition. Their iconic Redheads matches are now imported from Sweden. The complex has since been converted for use as offices and showrooms but is extremely well preserved. It is listed on the Victorian Heritage Register. Bryant and May was a United Kingdom (UK) company created in the mid-nineteenth century specifically to make matches. Their original Bryant and May Factory was located in Bow, London. They later opened other match factories in the United Kingdom and Australia, such as the Bryant and May Factory, Melbourne; and owned match factories in other parts of the world. Bryant and May survived as an independent company for over seventy years, but went through a series of mergers with other match companies and later with consumer products companies. To protect its position Bryant and May merged with or took over its rivals. In 1971 the Northern Ireland factory, Maguire & Patterson closed down following a terrorist attack.. In the 1980s, factories in Gloucester and Glasgow closed too leaving Liverpool as the last match factory in the UK, until December 1994. . The registered trade name Bryant and May still exists and it is owned by Swedish Match, as are many of the other registered trade names of the other, formerly independent, companies within the Bryant and May group. Two French chemists, Henri Savene and Emile David Cahen, proved in 1898 that the addition of phosphorus sesquisulfide meant that the substance was not poisonous, that it could be used in a "strike-anywhere" match, and that the match heads were not explosive. British company Albright and Wilson, was the first company to produce phosphorus sesquisulfide ( Red Phosphorous) matches commercially. The company developed a safe means of making commercial quantities of phosphorus sesquisulfide in 1899 and started selling it to match manufacturers. Matches were first produced by Bryant & May in Australia in 1909. The Redhead name applies to the red striking heads of the matches which were introduced to Australia in 1946. The logo on the matchbox depicted the head and shoulder of a redheaded woman and has had four major updates since that time with a number of special issues depicting birds, animals and notable persons also produced.The Bryant & May Ltd factory in Church St Richmond is a listed building and has been converted to apartments following the closure of the Company 1980. Bryant & May's Ltd were influential in fighting against the dreadful disease known as Phossy jaw which was caused by white phosphorus used in the manufacture of the early matches. They were also the object of the 'Match Girls Strike' in London 1888, which won important improvements in working conditions and pay for the mostly female workforce working with the dangerous white phosphorus. The public were slow to purchase these safety matches because of the higher price .A box of safety matches with unused matches made by Bryant & May Pty Ltd , Richmond Victoria Australia. The tray containing the matches slides inside the open ended cover.. The striking patch is on both sides of the cover. Av. CONTENTS 50 MADE IN AUSTRALIA / Brymay / 1/3 / Safety Matches / Redheads / a colour picture of a Kookaburra / Laughing KOOKABURRAsafety matches, bryant & may pty ltd, phossy jaw disease, early settlers, moorabbin, bentleigh, cheltenham, lights, lamps, tobacco, white phosphorous, phosphorus sesquisulfide, swedish match pty ltd, pitt william, savens henri, cahen emile david , richmond victoria, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyHelmet Safety, circa mid to late 1960's

This helmet worn by SEC Victoria workers in the Kiewa Hydro Electricity Scheme is a mandatory safety requirement by all personnel employed by government and statutory agencies who worked on or around "dangerous" apparatus or underground location sites. This type of pressed fibre helmet was later superseded by moulded plastic helmets. The start of the project (late 1940's) was not greatly covered by later introduced health and safety regulations. This has been demonstrated by photos of workmen outside using heavy machinery and other apparatus, see KVHS 0396, KVHS 0405 and KVHS 0392. However in the tunnels and underground safety helmets were mandatory, see KVHS 0403.This safety helmet was used by workers during construction of the generators and tunnels of the Kiewa Hydro Scheme was issued once only to each worker during his employment covering the 1940's to 1960's period. The attitude to health and safety during this period, can be summed up by this "initiation" ritual. When the helmet had been instrumental in saving a bad accident to a worker, that worker would be "invested" into the "Turtle Club". Although a safety helmet was only issued once to a worker this changed when modern moulded plastic helmets and greater Health and Safety requirements were introduced. Helmets now are replaced bi-annually.This safety helmet is made from pressed fibres with eyelets for airflow to the head. On the base of the helmet (before the rim) are 15 metal eyelets and three quarters up are six other eyelets (3 on each side). A thick leather strap is fastened by two rivettes to the main helmet. This strap has a metal bar rivetted on to affix a "safety" lamp, for underground work (Tunneling). There are two additional metal prongs and a metal bar to secure the lamp on the rim of the front of the helmet.sec vic kiewa hydro scheme, alternate energy supplies, alpine population growth -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBelt Linesman Pole, circa mid to late 1900's

... mandatory for pole linesmen. The safety of fellow workers could... for pole linesmen. The safety of fellow workers could ...This linesman belt was used under the 1947 Electricity Regulations and before tighter Occupation and Health regulations (late 1990's early 2000's) were introduced that mechanical lifting platforms(wherever possible) replaced the belt up the pole method.The safety concern was that it required that tools needed by the linesman had to be placed in a large canvas bag and attached to the belt (extra weight) then the linesman had to climb the ladder. Ladders had to be at the correct angle and not able to "slip" from their initial footings. A full harness and a secondary fall belt is now mandatory for pole linesmen. The safety of fellow workers could be compromised if they were required to assist or recover the first linesman if needed. In 2006 an additional 269 registered lineworkers were employed. Please note that the terminology of linesman has become unisex. The linesman's belt enabled the linesman to place his feet against the pole adjust the belt (if needed) and lean back securely allowing both hands to be free to work with. This linesman belt is very significant to the Kiewa Valley due to the numerous poles and high voltage overhead power structures that needed maintenance for the extensive "mushroom" installation of electrical power polls(wood and metal). On high poles (steel) climbing pegs were welded on, however in the Alpine areas snow in winter caused an OH&S problem which were hard to overcome. The safety of a linesman when maintenance of electricity line on poles can be highlighted by the New Zealand linesman who survived an 11,000 volt shock when carrying out maintenance. For the record 11,000 volts is four times more powerful than execution by "the electric chair". The maintenance of the linesman's belt was his responsibility (keeping it clean and in "good" condition). Labour laws change this initial responsibility, from the linesman, to the employer. Climbing pegs were installed on higher poles that extended beyond the reach of ladders.This thick leather linesman belt is made from two lengths of heavy lengths of leather straps sewn together to make up 80% of the belt. The remaining 20% is "the belt tonge" which has eleven holes for three (solid steel tang) buckle connections.kiewa hydro electricity scheme, victorian state electricity commission, relays, generators, electrical pole maintenance -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySafety Helmet - SECV

Safety helmets were used by workers on the Kiewa Hydro Electric Scheme.While working at McKay Creek Power Station, Alec Menzies was hit on the head with a rock and fell about 10 metres. Luckily he survived, and after a stint in hospital he was admitted to what was known as the Turtle Club. Ref. Mal Menzies, his son.Cream coloured safety helmet with 3 ridges at the top from back to front. It is light in weight. Inside has an attached cloth band with 'netting' of 6 straps attached to band and an inner band. Underneath the shade, at the front, it is coloured green.Centre front - a sticker - "Member/ Turtle Club. Inside: embossed an oval shape with 'hard/soiled' in its middle and underneath also embossed E.D. Bullard Co. / S.F. U.S.A.safety helmet, mckay creek power station, alec menzies, turtle club -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySign - "S.E.C./Danger"

... appropriate signs for the safety of its workers and the public.... for the safety of its workers and the public. The Kiewa Hydro Electric ...Safety signs are important to warn people of dangers. The SEC constructed the Kiewa Hydro Electric Scheme and used appropriate signs for the safety of its workers and the public.The Kiewa Hydro Electric Scheme was constructed on the Bogong High Plains and included the town of Mt Beauty for accommodation etc. for its workers.White vertical print with red background on oval shaped tin sign. There is a hole at the top and bottom for attaching the sign with a nail.state electricity commission of victoria, safety sign -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph Junction Dam, Photo Junction Dam and Bogong Village in Background, circa 1950s

This item clearly shows the conditions covering both working conditions and housing in the construction of the Junction Dam in the 1940s. Working conditions were extreme and health and safety legislation was at its infancy. The residential buildings were intended to last only for the period of construction, however greater demand for longevity as a tourist haven prevailedThis photo of the construction of the Junction Dam, with The Bogong village as backdrop, details the harsh conditions faced by construction workers, building dams and villages to accommodate workers in the 1940s to the 1950s. Australia at this period in time, experienced a surge of population (influx of World War II refugees), which was the catalyst for developing and undergoing an enormous hydroelectricity program for the Alpine regions, both in Victoria and New South Wales. This program was initiated to supply electricity to the major southern Australian cities of Adelaide, Melbourne and Sydney. It was thought that these developments would reduce, if not eliminate, the requirement for coal driven power stations. However time has demonstrated that these power stations have not matched the demand required by the industries and the populations of the major urban and cities.Black and white photo of original photo with a flashlight reflection in the bottom centre. The photo is on Kodak XtraLife II paper. The paper is semi gloss.This photo is of the construction of the Junction Dam Wall with the Bogong Townshiip in the background.Back of photo is printed " Kodak XtraLite II paperdam construction, bogong village, alpine development, junction dam -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph KHS Rail, Kiewa Hydroelectric Scheme Railway, Circa1940s

... there was a lack of health and safety legislation covering workers ...This photograph shows part of the railway constructed and used for the removal of soil and rocks from the tunnels bored out of the mountains for the pipeline servicing the Hydro Electricity power stations in the Kiewa Hydroelectric Scheme. This photo details an era when there were 4,000 construction workers located in two main accommodation camps, Mount Beauty (the larger one) and Bogong village. These accommodation sites were constructed and maintained as a secured or gated residential area with access only available by a special pass authorised by the Kiewa Hydroelectric Scheme. All the power used by the rail system was from electric motors connected to batteries. Overhead power poles seen on either side of the embankment details that electricity from the Scheme was in use. This use was cleaner and more environmentally friendly than the coal still used by large locomotives from city to country railways. The worker shown is not however wearing protective head and hand coverings. This is also an era where there was a lack of health and safety legislation covering workers in dangerous working conditions.Scanned photo of original black and white photo on Kodak XtraLife II paper. Picture is of a section of railway track servicing the tunnels of the Hydroelectric scheme during the 1940s - 1950sOn back of photo "Kodak XtraLife II paper"railway in kiewa electric scheme, tunneling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Bosun's Chair, ca. 1922

This Bosun's char was part of the equipment on the vessel 'Reginald M. It is typical of items included on board a vessel in the late 19th and early 20th century. The nautical word 'bosun' is an abbreviation of the word 'boatswain' who is the person responsible for the repair and maintenance of the vessel. It could be used when rigging the sails and for rescue at sea, along with a thick rope anchored on shore or a rope between ships. It could also be used to move passengers to and from a ship as well as cargo on, to and from the vessel. A bosun's chair is a simple piece of equipment made from a short plank of wood and a sturdy piece of rope. It looks a little like a child's swing but usually has a pulley system that allows the user to adjust the length of the hanging piece of rope, and in so-doing adjusts the height above the floor or ground or sea. In modern times a harness would also be worn by the bosun’s chair user for safety reasons. Bosun's chairs are also used by window cleaners, construction workers and painters. The bosun’s chair is sometimes just a short plank, or even a canvas sling. The REGINALD M - The vessel “Reginald M” was a two-masted coastal ketch, owned and built by Mr. Jack (John) Murch of Birkenhead, Port of Adelaide, South Australia. Its construction took approximately 6 months and it was launched at Largs Bay in 1922. The vessel had many owners and adventures over the years until it was purchased by Flagstaff Hill Maritime Museum & Village in 1975 from the Melbourne Ferry Company at auction. It was then used as an active display until 2016. Visitors could go aboard, turn the ship's wheel, go below deck and get the feel of the captain's quarters, sailors' quarters and the storage space available. The Reginald M was a popular exhibit for young and old, until 2016.This bosun's chair is significant for its connection to the maritime history. It has been used for rigging, painting, maintenance and importantly for life saving and safety. The bonus's chair is also significant because of its connection to the history of the vessel REGINALD M, the coastal trading ketch from South Australia built in 1922 and in existence until 2016. Its flat bottom, single chine shape illustrates a very simple but robust method of construction, compared to other round bilged examples of trading vessels. The Reginald M is listed on the Australian Register of Historic Vessels (ARHV Number: HV000562.)Bosun's chair; seat is a rectangular plank of wood with a hole drilled in each corner and three reinforcing wood lengths attached below the plank. The ends of two looped thick ropes have been threaded through the holes in the plank, crossed over then spliced together. The loops of rope above the plank have been tied with light rope. A roughly made wire hook is attached at the base of one length of rope. Top surface reveals indents where the bottom wooden pieces are joined to the top and some of the metal fixtures can be seen along the edge. There are remnants of white paint on the top.flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, bosun's chair, bosuns chair, boatswains chair, rigging, maritime equipment, bosun's seat, life saving, marine technology, ship rigging -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Bosun's Chair, ca. mid-20th century

The bosun’s chair is a typical piece of equipment included on board a vessel in the late 19th and early 20th century. The nautical word 'bosun' is an abbreviation of the word 'boatswain' who is the person responsible for the repair and maintenance of the vessel. It could be used when rigging the sails and for rescue at sea, along with a thick rope anchored on shore or a rope between ships. It could also be used to move passengers to and from a ship as well as cargo on, to and from the vessel. A bosun's chair is a simple piece of equipment made from a short plank of wood and a sturdy piece of rope. It looks a little like a child's swing but usually has a pulley system that allows the user to adjust the length of the hanging piece of rope, and in so-doing adjusts the height above the floor or ground or sea. In modern times a harness would also be worn by the bosun’s chair user for safety reasons. Bosun's chairs are also used by window cleaners, construction workers and painters. The bosun’s chair is sometimes just a short plank, or even a canvas sling. The bosun's chair is significant for its association with maritime equipment carried on board a vessel in the late 19th and early 20th century for maintenance and safety purposes. It was occasionally used to save lives. The bosun's chair is also significant as an early version of equipment still used today. Since its invention there have been many safety features added in certain industries such as window cleaning and painting.Bosuns chair; flat smooth rectangular piece of wood, with rope passing through two holes at each end of plank and looped together above plank to form a suspended seat swing. Loops a are joined with knot work and ends are spliced together under the seat.flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, bosun's chair, bosuns chair, boatswains chair, rigging, maritime equipment, bosun's seat, life saving, marine technology, ship rigging -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Course Outline, VIOSH: Ministry of Employment and Training; Occupational Health and Safety Public Discussion Paper, March 1983

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. The booklet sets out in detail the proposals for the implementation of Government policy on occupational health and safety. The objective is to improve standards of health and safety in Victoria. The Government intends involving workers and employers directly in developing new standards and practices. Submissions to be forwarded to the Ministry of Employment and Training by 20 May 1983. Responses from Tom Norwood of Ballarat College of Advanced Education and Mark Hennessy from Lincoln Institute of Health Sciences indicate what is already being done in courses available at Ballarat, Lincoln and Deakin. Mark Hennessy comments that "a united approach might ensure rational decisions by government, beneficial to our mutually complimentary courses." . Booklet - outlining proposals. Nine A4 pages - typedEmblem of Ministry on cover. Signature of Jim Simmonds, Minister; Mark Hennessy, Lincoln Institute of Health Sciences; Tom Norwood, Ballarat College of Advanced Education. Letterhead Ballarat BCAE and Lincoln Instituteviosh, victorian institute of occupational safety and health, ministry of employment and training, public discussion paper, tom norwood, mark hennessy, jim simmonds, workers, employers, ballarat college of advanced education, lincoln institute of health sciences, deakin university -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeMatchbox and Matchbox Holder, Box : Bryant and May's, early 20th. century

The Bryant and May Factory is located in the suburb of Cremorne in Melbourne, Australia. It was constructed in 1909 as the Empire Works to a design by prolific Melbourne architect William Pitt. It was purchased soon after by British safety match manufacturer Bryant and May who significantly expanded the building adding an additional level and the landmark clock tower. Bryant and May were unique in that they operated as a model factory providing workers with conditions and amenities which even today seem generous. These included a dining hall and sports facilities such as a tennis court and bowling green which were constructed in the 1920s. Bryant and May ceased Australian match manufacture in the early 1980s as a result of import competition. Their iconic Redheads matches are now imported from Sweden. The complex has since been converted for use as offices and showrooms but is extremely well preserved. It is listed on the Victorian Heritage Register. Source: www.wikipedia.org Local social history of Bacchus MarshMetal matchbox holder for a matchbox-one side has a photo of a local cricket team, the other side has a caricature of a man's face when held one way up is smiling and when turned up the other way the face is looking unhappy. The cover is blue with yellow. The matchbox cover is made of a thin veneer wood. The makers inscription is in blue and red.Cover/spine: Strike The Border Inn Bacchus Marsh for a good spot Phone 16 Cyril Jones, Proprietor. Cover/side: This man always calls in at the Border Inn. This Man wishes he did Matchbox:Bryant & May's "Crown" Safety Matchesbox, souvenir, sport, item, cricket, match, team, cyril, jones, border, inn, cover, novelty -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Bosun's Chair, ca. mid-20th century

The bosun’s chair is a typical piece of equipment included on board a vessel in the late 19th and early 20th century. The nautical word 'bosun' is an abbreviation of the word 'boatswain' who is the person responsible for the repair and maintenance of the vessel. It could be used when rigging the sails and for rescue at sea, along with a thick rope anchored on shore or a rope between ships. It could also be used to move passengers to and from a ship as well as cargo on, to and from the vessel. A bosun's chair is a simple piece of equipment made from a short plank of wood and a sturdy piece of rope. It looks a little like a child's swing but usually has a pulley system that allows the user to adjust the length of the hanging piece of rope, and in so-doing adjusts the height above the floor or ground or sea. In modern times a harness would also be worn by the bosun’s chair user for safety reasons. Bosun's chairs are also used by window cleaners, construction workers and painters. The bosun’s chair is sometimes just a short plank, or even a canvas sling. The bosun's chair is significant for its association with maritime equipment carried on board a vessel in the late 19th and early 20th century for maintenance and safety purposes. It was occasionally used to save lives. The bosun's chair is also significant as an early version of equipment still used today. Since its invention there have been many safety features added in certain industries such as window cleaning and painting.Bosuns chair, rectangular slab of wood with two holes at both ends through which rope ends are threaded for support and the loops above the seat are tied with sailor's knotting to form a triangle. flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, bosun's chair, bosuns chair, boatswains chair, rigging, maritime equipment, bosun's seat, life saving, marine technology, ship rigging -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Navigation Lamp, W. T George and Co. Ltd, ca 1941

William Thomas George was born in Birmingham in 1884 and was a tin plate worker. He and his wife Ellene had a son Leslie Thomas George. The firm W T George & Co was formed sometime later. In 1939 his firm produced ship lamps. The Patent Number GB546575 on the lamp's plate was assigned to Leslie Thomas George in 1941 for improvements in, or relating to, ships' lanterns. From that time the patent number was affixed to their namufactured Meteorite lights. The ship navigation lamp is important as an example of the evolution of marine safety technology. Countries began passing laws and regulations in the 1830s that required ships to show navigation lights at night or in poor weather. From the late 1840s colours were standardised; red for portside of the vessel and green for starboard, a white masthead light, and a white light at anchor. By 1914 the International Convention for the Safety of Life at Sea was formed and continues, with decisions and notifications on improvements and changes.. Lamp; Portside ship's lamp is rounded in the front with two flat sides coming to a point at the rear. Glass has circular ridging. Metal handle with lid and clasp. The reflector has red colouring. Inscribed on fixed plates on the front, with maker's details and Patent number. This Meteorite lantern was made by W T George and Co Ltd, of Birmingham. "Port" "W T George and Co Ltd" "Sherlock Street Birmingham" "Meteorite 68990 Patented No 546575 and others pending"warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, portside ships lamp, portside, port lamp, ship's lamp, marine lamp, navigation lamp, w t george & co, coloured lens, red lens, ship fitting, marine technology, navigation light, signal lamp, leslie thomas george, gb546575, patent gb546575, meteorite, lantern, lamp, light -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, safety matches 'Redheads' 2015, c2015

This is a current example of the 'Redhead' logo used by Bryant & May Ltd Richmond,Victoria, Australia c 1946 - 1980 On 15th December 1909, Bryant & May, Australia’s first match factory at Church Street, Richmond, Victoria. was opened by The Honourable Alfred Deakin, Prime Minister of Australia, and Mrs. Deakin. It was heralded by the first Commonwealth Government of newly-federated Australia because the government of the day was anxious to encourage secondary industry and pledged tariff protection of local manufacturers. The building was constructed in 1909 as the Empire Works to a design by prolific Melbourne architect William Pitt and was purchased soon after by British safety match manufacturer Bryant and May, who significantly expanded the building, adding another level and the landmark clock tower. Bryant and May were unique in that they operated as a model factory, providing workers with conditions and amenities that even today seem generous. These included a dining hall and sports facilities such as a tennis court and bowling green which were constructed in the 1920s. Bryant and May ceased Australian match manufacture in the early 1980s as a result of import competition. Their iconic Redheads matches are now imported from Sweden. The complex has since been converted for use as offices and showrooms but is extremely well preserved. It is listed on the Victorian Heritage Register. Bryant and May was a United Kingdom (UK) company created in the mid-nineteenth century specifically to make matches. Their original Bryant and May Factory was located in Bow, London. They later opened other match factories in the United Kingdom and Australia, such as the Bryant and May Factory, Melbourne; and owned match factories in other parts of the world. Bryant and May survived as an independent company for over seventy years, but went through a series of mergers with other match companies and later with consumer products companies. To protect its position Bryant and May merged with or took over its rivals. In 1971 the Northern Ireland factory, Maguire & Patterson closed down following a terrorist attack.. In the 1980s, factories in Gloucester and Glasgow closed too leaving Liverpool as the last match factory in the UK, until December 1994. . The registered trade name Bryant and May still exists and it is owned by Swedish Match Industries as are many of the other registered trade names of the other, formerly independent, companies within the Bryant and May group. Two French chemists, Henri Savene and Emile David Cahen, proved in 1898 that the addition of phosphorus sesquisulfide meant that the substance was not poisonous, that it could be used in a "strike-anywhere" match, and that the match heads were not explosive. British company Albright and Wilson, was the first company to produce phosphorus sesquisulfide ( Red Phosphorous) matches commercially. The company developed a safe means of making commercial quantities of phosphorus sesquisulfide in 1899 and started selling it to match manufacturers. Matches were first produced by Bryant & May in Australia in 1909. The Redhead name applies to the red striking heads of the matches which were introduced to Australia in 1946. The logo on the matchbox depicted the head and shoulder of a redheaded woman and has had four major updates since that time with a number of special issues depicting animals, birds and notable persons also producedThe Bryant & May Ltd factory in Church St Richmond is a listed building and has been converted to apartments following the closure of the Company 1980. Bryant & May's Ltd were influential in fighting against the dreadful disease known as Phossy jaw which was caused by white phosphorus used in the manufacture of the early matches. They were also the object of the 'Match Girls Strike' in London 1888, which won important improvements in working conditions and pay for the mostly female workforce working with the dangerous white phosphorus. The public were slow to purchase these safety matches because of the higher price An empty box of 'Redheads' safety matches made in Sweden for ST-Group, Springvale, Victoria, Australia c2015. The tray for the matches slides inside the open ended cover. The striking patch is on both sides of the cover. The matches have been removed. Matches were first produced by Bryant & May in Australia in 1909. The Redhead name applies to the red striking heads of the matches which were introduced to Australia in 1946. The logo on the matchbox depicted the head and shoulder of a redheaded woman and has had four major updates since that time with a number of special issues depicting animals, birds and notable persons also produced. Bryant and May ceased Australian match manufacture in the early 1980s.Top of cover ; Redheads / 45 safety / matches . Logo ; head & shoulders of a female with red hair Base of coverMade in Sweden / Redheads (R) is proudly marketed / by ST- Group Australia. / 718 Princes Highway Springvale Vic. 3171 / .............../ Readheads is a registered trademark / of Swedish Match Industries AB. / Complies ith European / Match Standard EN 1783-1997-SAF/ WARNING; / KEEP OUT OF REACH / OF CHILDREN. STRIKE / GENTLY AWAY FROM BODY . / barcode.redheads safety matches, safety matches, bryant & may pty ltd, phossy jaw disease, early settlers, moorabbin, bentleigh, cheltenham, lights, lamps, tobacco, white phosphorous, phosphorus sesquisulfide, swedish match pty ltd, pitt william, savens henri, cahen emile david , richmond victoria, match girls strike 1888, -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO EXCAVATION

Worker in trench on a pipe laying machine. Orange safety netting attached to steel posts surrounds this large trench. 2 pieces of short tubing on ground next to safety fence.Kodakorganisation, industry, gas and fuel