Showing 620 items

matching planning day

-

Federation University Historical Collection

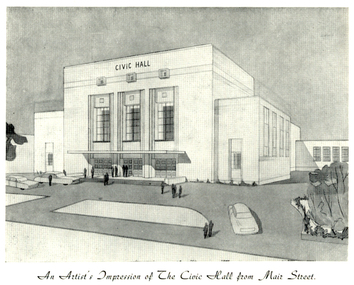

Federation University Historical CollectionProgramme, The Opening of Civic Hall, 1956, 1956

The City of Ballarat unanimously resolved to erect a Civic Hall in Mair Street in 1951. The architects, Gordon Murphy, of Melbourne, and H.L. and L.J. Coburn, of Ballarat, were commissioned in 1952. The Council constructed the foundations and footings for the building under the supervision of the former City engineer, Mr L.H. Finch, in 1953. These footings are of massed concrete. The design for the building took advantage of the cross fall of the land, providing for the Small Hall to be entered from the Doveton Street frontage through a foyer under the Main Stage, the structure is steel with brick panels, with accommodation for 1,592 persons in the Main Hall and 440 persons in the Lower Hall. The front facade faces Mair Street, set back from the building line to provide for the entrance drive-ways and kerbed gardens. Tenders were invited on a firm price basis. A young Ballarat master Builter, Walter Benbow Trahar was the successful tenderer, the contract price being 139,841 pounds. the work was commenced in 1953 and has proceeded in spite of material and labour difficulties until its completion. The following statistics are of interest:- * The foundations contained 200 cubic yards of concrete. * The constructional steel work weighs approximately 270 tons. * The reinforcing steel 47 tons. * Reinforced concrete in the structure, 1,100 cubic yards. * The approximate number of bricks in the building, 580,000. * The flooring is of selected kiln-dried hard wood and totals 40,000 lineal feet. * The dimensions of the Main Auditorium, 100ft by 86 ft, including the side promenades each 82ft by 13ft. *The Main stage, of reinforced concret with parquette finish measures 62 ft by 40ft. *The floor area of the Lower Hall is 74 ft by 38 ft, and has a stage dimensions of 40ft by 20 ft. * Each hall has independent heating and ventillating systems. Where possible the material in the building was furnished from local business houses. The public address installation, which provided for additional microphones, is on the main Stage. There is inter-communication throughout the building connecting the front office, with the bioscope box, the stages in both the large and lower halls, and the Hallkeeper's residence. Local craftsmen have completed the painting, plaster work, and the electrical installation; local produced materials being used in the construction of the buildings with the exception of the timber for the Main Floor, the roofing and the structural steel. The City of Ballarat Councillors in 1956 were Councillors N. T. Callow, F.J. Cutts, K.C. Webb, W.E. Roff, O.W. Curnow, F.T. Woodward, Allan C. Pittard, A.W. Nicholson, J.A. Chisholm, G.L. Scott, F.W. Oliver, A.D. Mason. The Town clerk was H.R. Maddern and the City Engineer was G. Murrowood. A City of Ballarat Council meeting of 25 September 2013 voted to demolish the Ballarat Civic Hall. The Council heard from nearly 50 members of the public during a marathon six-hour meeting. Councilors John Birt, Des Hudson, Amy Johnson, Josh Morris, Peter Innes, John Philips supported the motion to demolish Civic Hall. Councillors Samantha McIntosh, Vicki Coltman and Belinda Coates voted against the motion.Six page souvenir Program of citizens' entertainment on the occasion of the Opening of Ballarat Civic Hall on in August 1956. The front cover features the City of Ballarat Coat of Arms. The programme starts with a message from the Mayor, Cr Neil T. Carrow. It includes the Concert Programme directed by James H. Davey, an asrtist's impression of the Civic Hall from Mair Street, and information relative to the New Civic Hall. The programme features images of the City of Ballarat Coat of Arms, Cr N.T. Callow, , James H, Davey, and an artist's impression of the Ballarat Civic Hall. Mayor Neil Callow's Message: "To-day, our citizens witness the fulfilment of the most extensive Municipal undertaking in the City's period of recent prosperity and development. Their Hall now fills a requirement of which they have been deprived since the Coliseum building was destroyed by fire over 20 years ago. The building has been designed as an all purpose structure and I am hopeful the citizens will use it and enjoy it to its fullest extent. Your Council and its Architects have planned as broadly as possible for the benefit of all to-day and for years to come. We are proud of the work executed by a Ballaarat Master Builder whose work is a monument to the City's craftsmen. I feel I should also remind this assembly that the women of Ballaarat, back in 1951, provided funds which have been applied in the purchase of a Grand Piano and two Upright Pianos which are now installed in this building. The sincere hope of myself and your Councillors is that this Hall and its amenities will prove of immense value to the development of the cultural and artistic tastes of this community and that it will be freely used for these and many other purposes. From now on this magnificent building and its furnishings and equipment will be available to all. I strongly exhort you to use and protect it. My hope is that the citizens will, for many years to come, enjoy the amenities which it has to offer. ballarat civic hall, civic hall, architecture, finch, art deco, city of ballarat, coat of arms, city of ballarat coat of arms, callow, shugg, lemke, oates, gullan, tuuri, john, robertson, sorrell, antonio, gordon murphy, walter benbow trahar, trahar, coburn, h.l. coburn, l.j. coburn, n.t. callow -

Federation University Historical Collection

Federation University Historical CollectionBooklet - Report, Sturt Street Gardens, Ballarat, Victoria, Conservation and Landscape Management Plan, July 2007, 07/2007

The Sturt Street Gardens had its origins in the 1851 survey of Ballarat West by W.S. Urquhart. A generous reserve was allocated for the main streets of Ballarat, of which Sturt Street was the first. In the 1860s Sturt Street was planted with blue gums, with dual carriageway and central median Strip. Bandstands were soon erected.70 page report on the Ballarat Sturt Street gardens. The report includes an historical overview, Physical Analysis, Statement of Cultural Significance, and Consideration and Landscape Policies.queen alexandra bandstand, titanic memorial bandstand, sturt street, sturt street gardens, blue gum, statues, eight hour day memorial, boer war memorial, peter lalor statue, bluestone, bluestone guttering, william dunstan vc, time capsule, conservation management plan, landscape management plan -

Federation University Historical Collection

Federation University Historical CollectionBooklet, D. Wixted, Garden at School of Mines and Industries Ballarat: Conservation Analysis, 1988, 07/1988

The Ballarat School of Mines Botanical Garden was established in 1879, and was used by students of botany and materia medica. In February 1881 George Porter Day was appointed gardener at a rate of 17 pounds and ten shillings per annum. Yellow covered stapled report of 20 pages. Includes information about the establishment of the Ballarat School of Mines, plans of ground and buildings (1880, 1881, 1903 and 1988), Botany subjects, history of the garden, the garden in 1988.Some words have been highlighted in orange.ballarat school of mines botanical gardens, ballarat school of mines, george day, george porter day, james oddie, baron von mueller, von mueller, ferdinand von mueller, joseph flude, materia medica, botany, system garden, ferdinand krause, field club and science society, pharmacy, alfred mica smith -

Flagstaff Hill Maritime Museum and Village

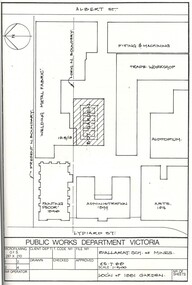

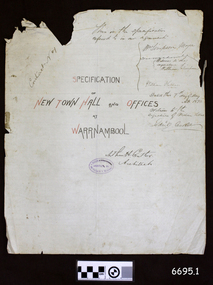

Flagstaff Hill Maritime Museum and VillageLegal record - Plans and Contract, Arthur H. Cutler, Architect, Warrnambool Town Hall, 1890-1892

This is a set of documents including three sheets of blueprint plans for the New Town Hall and Offices for Warrnambool, created in 1890 by the Architect Mr Arthur H. Cutler of Melbourne. The Contract was signed by the Town Mayor for Warrnambool, Mr William Simpson on May 7th 1890. Also, a Council copy of the Contract dated 26 June 1890, with the signatures and diagram where the two official stamps would be placed. The Foundation Stone was laid the following year by the next Mayor, John Hyland on February 24th 1891. The contractor for the building was granted to W. Kellas (William) of Warrnambool. The Town Hall and Offices were built on the corner of Liebig and Timor Streets in Warrnambool. On March 20th 1983 the new Performing Arts Centre was opened y the Mayor, Councillor R w Andreson, on the same site. The new building incorporates the 1890 Town Hall building. The plans, contracts, documents and various references to people on the documents are significant to the history of the City of Warrnambool and its community. The Warrnambool Town Hall building is also significant for the many community events held there over the decades after it was built. Appreciation for the significance of the almost century-old Town Hall building is demonstrated by its inclusion in the new Performing Arts Centre.Set of five documents that includes Plans for the Warrnambool Town Hall, the Contract cover page and a letter from the Architect to the Council. The Contract cover page and the Letter are hand written on cream-coloured paper with a waxy finish, with watermarks. 1) Contract Cover Page, 5th May 1890, Specification of the New Town Hall and Offices at Warrnambool. 2) Letter, 29th January 1892, from Architect Arthur H. Cutler to Mayor and Councilors, Town of Warrnambool 3) Blueprint Sheet 4, Longitudinal Section, and profiles of Liebig Street and Timor Street, Warrnambool Town Hall, 4) Blueprint Sheet 3, First Floor & Balcony Plan, and Roof Plan 5) Blueprint Sheet 2, Ground Floor Plan, Warrnambool Town Hall 6) Contract, 26 June 1890, marked (Draft Copy Tow Hall Contract), Between Mayor, Councillors and Rate Payers, and William Kellas, ContractorWatermarks on handwritten pages [horizontal lines], "36" "BUSBRIDGE'S / LOFT DRIED" Contract cover page, Oval stamp "CUTLER - 281 COLLINS ST. E. MELBOURNE - ARCHITECT " (other crossed out text) Handwritten script "This is the specifications referred to in our agreement" "Dated this 7th day of May A.D. 1890" Signed "W. Simpson Mayor" "Arthur H. Cutler Architect", [two Witnesses' signatures and others] Letter from Arthur Cutler, handwritten, has his address "472 Chancery Lane, Melbourne" CONTRACT of 26 June 1890: "The Mayor, Councillors and Rate Payers of Warrnambool" "William Kellas of Warrnambool" "Signed William Simpson, Maoyorr" "R F Kennedy, Councillor" "Wm Kellas" with diagrams where the round Common Seal and square Stamp would be applied.warrnambool, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime village, shipwreck coast, great ocean roaad, warrnamboo town hall, warrnambool council offices, mayor william simpson, arthur h cutler, architect, civic centre, town hall, performing arts centre, mayor john hyland, william kellas, mayor r w anderson, r f kennedy, contract -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour, Phil Bryce, Removal of a fibre-glass chimney extension from a chimney from the former Ballarat Brewery, 2015, 13/11/2015

The chimney extension on what was the former Carlton and United Breweries boiler house at Ballarat installed in 1972 and it is constructed of a special formulation of fibreglass reinforced plastics designed to operate at elevated temperature (ie boiler flue gas). It is thought to be one of 26 or 28 fibreglass boiler chimneys designed and installed in Victoria in the 1970s, and is thought to be one of the last to be removed. In its day the fibreglass chimney extension was at the cutting edge of fibreglass technology and is therefore well worth retaining. Removal of the chimney extension to the brick chimney outside the brewery building was deemed necessary to prolong the life of the chimney, and also because the fibreglass extension had reached end of life and posing a possible threat. According an Engineering assessment, fibreglass structures have a life expectancy of between 20 years (when fatigue loaded) and up to 100 years (static loaded). We don’t know when it was added to the chimney but believe it was most likely in the early 1970s. Given that it is subject to wind load and often observed to be moving in the wind it is likely that it will be at the end of its life. The chimney will be made good and we have the necessary planning approvals in place to undertake the works. The chimney extension was removed on 13 November 2015 in accordance with a planning permit obtained by the University. The extension is believed to have been added in the 1970s and was predominantly made from fibre glass. The structure was removed for safety reasons and to preserve the integrity of the historic brick chimney which supported it. Coloured digital photographs associated with the removal of a fibreglass extension to a chimney which was part of the Former Ballarat Brewery/Carlton and United Breweries complex. Images also include the last day the chimney was in situ.chimney, fibreglass, former ballarat brewery, former carlton and united breweries, ballarat school of mines, brewery complex -

Federation University Historical Collection

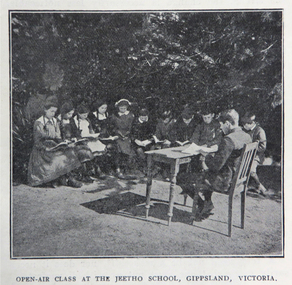

Federation University Historical CollectionBook, Victoria Education Gazette and Teachers' Aid, 1911-1919, 1910-1919

Black hard covered book with red spine, holding Victorian Education Gazettes for one calendar year. .1) 1910 .2) 1912 .3) 1911 .4) 1914 .5) 1918 Images: Open Air Classroom Black Rock; Open Air Classroom, Jeetho, Gippsland; Open Air Nurses bedroom, Mildura; Gym at Canterbury School ; Babies and Nurses at Melbourne Foundling Hospital; Camp at Portland; Alexander Peacock Opens a Melbourne School; Unveiling Major Mitchell Memorial at Mt Arapiles; Agricultural Plot; School Interior; Swimming Drill; Graham Dux Prize Board; Bathing Place; Classroom with blackboard and pictures; Major Mitchell's Map; Melbourne, Derbyshire; Market Place Melbourne; The Blackwood; World War One Send-off at The Athenaeum; Scarsdale Old Boy's logo; Sloyd articles for the Field Hospital; World War One; Gifts for Transport to the Wharf; soldiers; ANZAC Day; ANZAC Day Medalion .5) 1915: Education Department's War Relief Fund, William Park obituary, Closer Settlement Act 1912, Agriculture, needlework, Swimming and Life Saving, explorers, Gregory Blaxland, Matthew Flinders, Composition, Geography, potatoes, onions, gardens, Needlework for Infants, Iona and Staffa, Trained Primary Teacher's Course, Electricity, Electrical Technology, hygiene, Arbour Day, Horticulture, Wattle Day, Bird Day, Technical Schools, Landing at Gaba Tepe, Evils of Alcohol, Old Boys of Scarsdale, Belgium, Teachers' College Images: The British at War, The Sonnet, History and Patriotism, Male Swimming Teachers Summer School at Geelong, Women Swimming Teachers at Port Fairy, Buln Buln State School, Burwood East State School, needlework plans, methods of Rescue and Resucitation. plan of the journey of Gregory Blaxland, Macquarie House, teachers killed (William Ross Hoggart, Stanley Robert Close, William Roy Hodgson, Campbell McDiarmid Peter, William Henry Dawkins, William Hugh Hamilton, Frederick McRae Neal, Vernon Brookes, Frank J. Olle, Alfred J. Collins, Ernest R. Fairlie, William J. McLaren, A.E. Smith, Thomas Patton, Francis W. Kemp, Frederick G. Hall, Rupert O. Hepburn, Woolston J. Govan), Frederick Harold Tubb VC, Botanic Gardens Red Gum, Shelter Pavillions, Head of Wheat, Australian Commonwealth Flag, Iona Cathedral, Drawing exercises, ANZAC Madallion, School Rolls of Honor .6) 1916 - Nature Study, war relief, school gardening, horticulture, singing class, geography of the war, School Rolls of Honour, Ponsonby Carew-Smyth, Astronomy, ANZAC Day, Empire Day, Arbor Day, "Some Suul of Goodness in Things Evil" by Frank Tate, War Relief Gardeners' League, ANZAC Day medallion, Solar System, Abolition of German Schools in Victoria, ANZAC Avenues, avenues of honour, Geography of the War: The West, War relief and handwork, Victorian State Schools Horticultural Society, Patrick Maloney obituary, formalin lamps, Victoria League of Victoria, Wonwondah East Roll of Honor Images - Teachers killed (John Clarke, A.C.H. Jackson, Alexander Robertson, Noel Gambetta, Ralp E. Leyland, Laurance J. Woodruff, Walter E. Cass, Percy D. Moncur, Thomas M. Carmichael, Edward G. Brain, Reginald N.F. Woods, George E. James, William Colvin, David Dobson, Stanley L. Robinson, Charles Allen, G.E. James, H.F. Curnow, Franl L. Cousins, James R. Thompson, Henry H. Campbell, George E. Read, Ernest D. Morshead, Wilfred S. Merlin, Henry R. Wright, George B. Webb, Noel Nicholas, David H. Thomas, Charles A. Levens, Thomas R. Fenner, John M. Daniell, P.J. Larkin, Ralph Smith, Philip Ormsby), school rolls of honour, Swimming Instructors at Queenscliff, The Southern Sky, Map of the North Sea and its Littorals, Easter School of Horticulture at Oakleigh, Map of the Eastern Front, Map of Mesopotamia, Map of the War Area in the Egyptian Campaign, leeches for the Melbourne Hospital .7) 1917 - Swimming and Life-Saving, Childre's FLower Day, Education Department's War Relief Fund, State War Council, Horticulture, Bird Day, Swimming, Growing Chicory at Cowes Images - Teachers killed during World War One (G.M. Nicholas, William C.W. Spencer, J.W.C. Profitt, Ivon C. Bromilow, John Colwell, Robert W. Campbell, Arthur P. Bourchier, Francid G. Houston, Claude N. Harrison, Edgar Williams, Leslie A. Stevens, Charles E. W. Chester, Stanley R. Green, Walter Baker, Arthur G. Scott, Harry L. Swinburne, Horace W. Brown, Arnold Bretherton, Edward W. Jenkins Aubrey Liddelow, Ewen A. Cameron, Edmund R. Lyall, John H. Martin, Harry Bell, Frank L. Nicholls, Melville R. Hughes, Edwin W. Hauser, Walter S. Filmer, Walter G. Barlow, Henry A. Donaldson, Edward H. Jones, Walter W. Raw, Alfred W. Dean, Wiliam Lea, Frederick G. Drury, J.T. Richards, Norman G. Pelton, Lance-Corporal Doran, Kenneth F. McKenzie, William F. Robertson, Wiliam Jarrott, Norman Graham, George G. Paul, Victor Green, Arthur William Rennie, Alfred J. Glendinning, Robert B. Liston, Eward P. Toll, George Jones, Errol E. Rodda, Christian P. Christensen, Charles F. Sydes, H.G. Clements, Norman C. Fricker, J.M. Romeo. Eric N. Lear, Thomas J. Bartley, Norval Birrell, Frederick H. Tubb. J.T. Hamilton Aram, Arthur Wilcock, William M. Conroy, Alex. H. Miller, Patrick J. Cunningham, Charles S. Mitchell, John R. Maddern, James Roadknight, Harry Arundel, Jack C. McKellar, duncan M. McKellar, George S. Manfield, Edgar C. Holmes, George A. Young, Raymond A. Gardiner, William B. Bell, William Opie, George R. Scott, Richard V.B. Vine, Herbery S. Marshall, Hugh St Omer Dentry, George B. Fullerton, Harry Oulton, Iva F. Morieson), School Honor Books, Drawing, Presentation of 30,000 pounds to the British Red Cross at Melbourne Town Hall .8) 1918 .9) 1919 - Photographs of World War One soldiers from the Education Department, Margaret Montgomery Memorial, 1918 Act relating to State School Teachers, State Scolarships, Victorian State Schools' Horticultural Society, Pneumonic Influenza, Spanish Flu, epedemic, swimming and life savinfJunior cadet training, vacancies in Fiji, School Committees, Arbor Day, Arbour Day, Henry Harding of Yinnar, Planting Trees and Shrubs, Juvenile Crime, The use of 'Get', Soldier-Teachers from Overseas in Congress London, Australia's Effort in the War, Military, Working Bees, Tree Planting, fence building, Welcoming Home a Returned Soldier, Avenue of Honour planting, Discipline, Unveiling an Honor Board, School gymnasium, school tennis court, E. E. Crogger grave at Aldershot, The School Honor Book. War Relief Fund, Commonwealth War Record, Caulfield Military Hosptial, ANZAC Day Pilgrimage, Jimmie Panikin, Donald Fraser, Arthur Mee, Card Sun Dial, Balboa Day in Honolulu, William Hamilton, Alfred Jackson, The Backward Child, Flies, Language Teaching and Learning, Spelling, The Education of the Adolescent, victorian education gazette, education gazette and teachers' aid, sloyd, william a. cavanagh, james i froebel, school, education, world war one, memorials, alfred williams, exploration and settlement, cadets, australian naval college, bernard o;dowd, birds, swimming, drawingempire league, eucalypts, paper in history, forestry, arbor day, identification of trees, forestrey museums, fiji, gravel hill school band, horticulture, hygiene, gould league of bird lovers, life saving, la perouse, bandin, j. holland, w. hamilton, charles sturt, principles of archimedes, james holland, william hamilton, scarsdale old boys' reunion, foundling home melbourne, montessori education, open air schools, james hughes, marie corelli, flinders sydney harbour, major mitchell's map, tooth brushing, r.h.s. bailey -

Federation University Historical Collection

Federation University Historical CollectionDocument - Report, University of Ballarat Canadian Wetlands Project Report, 2000, 04/2000

1992 - Property purchased fronting Geelong Road, Mount Helen 1994 - Additional adjoining property purchased 1995 - Wetlands included in the Corporate Plan for the area 1997 - Launch of Wetlands Development by Minister Maclennan 1998 - Preliminary planning and plant identification underway - Contract signed for funding 1999 - Stage 1; Planning finalised, earthworks undertaken and weed infestation assaulted - "Work for the Dole" project undertaken - Deluge of rain on Boxing Day provides the centrepiece f the project, the just-completed dam, with a body of water to overflowing level. - Waterbirds move in and the germination of native wetland plant species begins 2000 - Stage 2 plans developed, including additional walkways, bird hides and interpretation. Three page report on the University of Ballarat Canadian Wetlands Project. Direct funding for the project was provided by the University of Ballarat; The Department of Employment, Workplace Relations and Small Business and the Corangamite Catchment Authority.ballarat technology park, canadian wetlands, ian howe, mount helen, mount helen campus -

Federation University Historical Collection

Federation University Historical CollectionBook, Victoria Education Gazette and Teachers' Aid, 1900-1910, 1900-1910

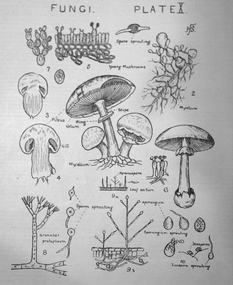

The Federation University Historical Collection holds a full range of Victoria Education Gazette and Teachers' Aid from 1900-1968.Ten black hard covered volumes with red tape spine, covering 1900 to 1910. The gazettes include Education Department appointments, transfers, resignations and retirements, notices, queries, notices of books, examination papers, original articles, lesson plans, suggestions for lessons, drawing, obituaries, notes on nature study, mathematics, music, sloyd woodwork, English grammar, Victorian State School Swimming Clubs, Geography, penmanship, science, History, Latin, Geography; The School Garden - Shean's Creek .1) Arbour Day (pg 135) Images: Melbourne Teachers' College 1888 Building (p.8); Union Jack (p. 80); Gasometer (p. 132) .2) Plant Life lesson plans, The Antarctic in 1910, Model Nature Lesson - what plants live on , Superannuation Fund, Saluting the Flag, A.N.A. School Children's Competitions, school garden awards, Teacher Training College, Nature Study - A page from a Teacher's Diary, A Mushroom, Mrs Bush's Kindergarten Christmas Images: Dookie Agricultural College, George R. Button, training college students attending the university, Sloyd teachers, Staff at the Summer School, Outside Wilson Hall, Watt's River Weir, Fungi .3) Images: Walhalla State School; Francis W. Parker (p. 18); Freearm Drawing- Sale State School (p.71) .5) Images: Map of Australia (p.33); Formalin lamps for disinfecting rooms (p. 80); Melbourne Teachers Training College (p. 167) .6) Werribee Gorge Supplement (p. 3, 4, 11, 12, 13) .7) First Exhibition of Women's Work (p. 7, 73-76) .8) Images: Franco-British Exhibition; Memorial to William H. Nichols (p. 191) .9) Temperance Teaching; Birds native to Australia (p.4) Images: Royal Agricultural Show State Schools Exhibit (p. 5-18); Leonard's Hill School; Visit of the American Fleet .10) Funeral of Edward VII Images: Portsea Quarantine Station (p. 33-35)w.o. ryan, f. thomas, a.a. tipping, t.n. considine, w.c. fordyce, e.e. bull, h.w. byrne, j.t. flynn, r.t. smith, a.w. steane, james bagge, theo fink, frank tate, siede, nature, garden, education, school, teacher, teaching, arbor day, arbour day -

Federation University Historical Collection

Federation University Historical CollectionPlan, Sulieman Pasha Co Plan Transverse Section

The Sulieman Pasha is possibly named after the most important Sultan of the Ottoman Empire, Suleiman One, or Suleiman the Magnificent, when the Ottoman Empire was at its peak. Or potentially a number of Ottoman governors, statesmen and military commanders with the same name after, however the spelling is slightly different to the mine name. No Turkish connection was found relating to the formation of the company, and remains unconfirmed. The mine operated from two shafts; No. 1 near the corner of Humffray and Mair streets, and also near where the Welcome Nugget (2217 ounces) was found years earlier; and the controversial No. 2 shaft several blocks south bordering the northern side of the main highway through Ballarat. The company produced 62 666 ounces of gold, the twelfth highest quartz reef gold production for any mine on the Ballarat goldfield. Some crushing figure examples are January-June 1881: 3674 tonnes 1085 ounces; January-June 1885: 2949 tonnes 1281 ounces; July-December 1885: 4459 tonnes 1119 ounces; January-June 1887: 1869 tonnes 730 ounces; July-December 1892: 1450 tonnes 771 ounces; July-December 1896: 4365 tonnes 1372 ounces. Like many mines in the area, gold grades were low. John Watson was noted as mine manager in the 1880s, and John Williams 1890s. The company was re-organised twice increasing the number of shares from 4000 to 24 000, and increasing the capital available. The Sulieman Pasha Company was formed in 1878. David Fitzpatrick was given the honour of turning the first sod of both the No.1 and later No. 2 shafts. The first dividend was given to shareholders in July 1881. The company obtained a prospecting vote (government grant) to start, and was very proud to be the first Victorian gold mining company to pay the funds back to the government. The event was marked by a lavish banquet laid out for ministers and government officials by the company. Leases were purchased to the south in 1885 to the Llanberris Mine boundary, after poor results began accumulating from the small No. 1 shaft. To take advantage of this new land the company planned to sink a second shaft. Initially this was to take place on government land, but the uproar from nearby residents caused the company to purchase land along the Main Road (now Western Highway), and the old Yarrowee Hotel which had occupied the site since the alluvial digger days of the 1850's was demolished. The area had since those days become heavily occupied with a number of shops, houses, a post office, church and two schools in the immediate area. The thought of an underground mine next door drew considerable opposition. The company (before the days of public relations departments) wrote 'most people would have thought that progress as vital as mining would be supported by tradesmen whose business rely on the mining industry. It seems when it comes to mining they are bereft of their senses, and considering the low ebb of mining in Ballarat East, the action of our opponents are unaccountable. (Sarcastically) There are certain engineering difficulties in moving the quartz reefs to a new location, but if we could to appease our opponents we would'. The company also wanted to take over 4 acres of the St Paul's school oval for machinery, but accused the St Paul's Church of wanting extortionate amounts of money upfront, and on a yearly basis for the privilege. It stated the church could not be opposed to mining when several years earlier it had formed its own company to mine the land, only for shareholders to lose their money. In 1886, the company approached the Minister for Mines, and attended heated public meetings on the matter. The local residents, shop owners, and church submitted a 60 person petition to the local council and government authorities. They stated the shaft contravened the mining statutes, which stating no mining could take place within 150 yards of a public building or church. A speech by a resident stated 'mining always comes with glorious pictures of the great benefits which would accrue all parties concerned if their request is granted, but if property is destroyed or depreciated in value, no-one then comes forward and compensates them'. The No. 2 shaft was approved including taking over part of the school oval. In 1888, workers at the company's No. 2 shaft went on strike to try and bring their wages in line with other mines in the district (the No. 1 shaft was operated by tributers). William Madden (26) was killed from a fall of earth underground the same year, while a year later his father John Madden (70) was similarly killed in the Madame Berry Mine elsewhere in the district. In 1897 as the amount of gold being found fell away, it came to light part of the deal to purchase the Yarrowee Hotel site was a 5% royalty on gold found. Shareholders could not understand why they were paying a royalty to the former owners of the property. The mine closed in 1898 due to a lack of gold. In 1902 a boy (age unknown) called Charles Lee was killed from a fractured skull while working to dismantle the Sulieman Pasha plant. The fuss over the No. 2 shaft had a sequel. On the company winding up, the land was purchased by J.S. Trethowan who built a house next to the shaft. In 1907, the shaft caved-in creating a sinkhole immediately at the back of the house. A Mr Chamberlain heard a deep rumbling sound at 5am, and looked out the window to see his fowl house and thirteen chickens disappear down an expanding hole. He then went back to bed, and called the police later in the day. The shaft was 1050 feet deep, and the hole at the surface that developed was 20 feet by 17 feet across, and 20 feet depth. In 1930 it is reported a syndicate had been formed to clean out the old shaft, and re-open the mine. It is assumed this was the No. 1 shaft but no more was found. (https://www.mindat.org/loc-304239.html, accessed 07/08/2019) A transverse section plan of the Sulieman Pasha Mine.sulieman pasha company, plan, mining, united black hill mine, victoria united mine, victoria street, britannia united mine, last chance mine, llanberris mine, ottoman empire, john watson, john williams, david fitzpatrick -

Federation University Historical Collection

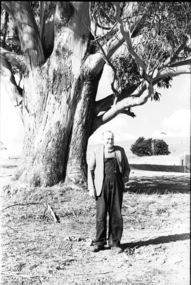

Federation University Historical CollectionPhotograph - black and white, Mr Downing by the Federation University Tree of Knowledge, 1970

Federation University Mount Helen Campus was open to students in 1970. In that year Mr Dowling as photographed beside a big Tasmanian bluegum which was used a the centre Mount Helen Campus concept plan, and later became known as the Tree of Knowledge. Mr Dowling watered the tree after it was planted by his mother, Elizabeth Downing, on Arbour Day 1896. Mrs Downing raised her large family on the site of the Mount Helen Campus, which included an orchard and milking cows. The Tree of Knowledge is actually two trees, the trunks have fused together over time, and there is further evidence of fusion. The Downing farmhouse was situated in the vicinity of the present Administration and Caro Conference Centre buildings and the tree was planted beside the "dunny". It was carefully watered by the nine Downing children from a brick-lined well situated under what is now the Albert Coates Building. As the tree grew to maturity, it was used to hang a meat safe after slaughtering a sheep for the family table. Some years ago, when the foundations were being dug for the E-Building, an old rusted percussion pistol was found. One of Mrs Downing's sons, at that time well into his nineties, remembered getting into trouble for playing with it without permission, and losing it. The land was purchased in 1966 as part of a 241-acre site for Ballarat's new tertiary institution. When the architects and planners inspected the site, they decided "The Big Tree" must remain as a central landmark in preparing the layout of the campus amenities. In 1982, the spread of the tree was 36 metres, girth 7 metres, and height 36 metres. By 2003 the spread was 39.5 metres (N-S) and 35.5 metres (E-W), girth 7.75 metres, and height 42.5 metres. A man in overalls and jacket stands beside the Federation University Tree of Knowledge. Stage one buildings on the Mount Helen Campus are evident in the background.elizabeth downing, downing, tree of knowledge, big tree, mount helen campus, mount helen -

Flagstaff Hill Maritime Museum and Village

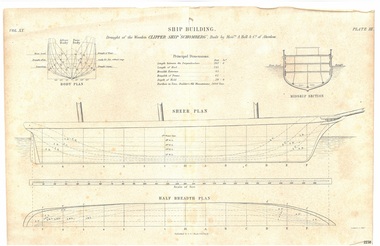

Flagstaff Hill Maritime Museum and VillageDrawing - Vessel Line Drawing, Ship Building Clipper Ship Schomberg, 1855-1876

This draft plan, a line etching, is of the wooden clipper ship "Schomberg" . It can be assumed from the heading "Ship Building." and the phrase "Built by Messrs. A Hall & Co. of Aberdeen" that the drawing is an example of plans for building a ship, and that the Schomberg ship has chosen to demonstrate this. The plan may have possibly been in a book, as it is made from two well-joined pieces of paper. The original plans would have been drawn up, discussed, reviewed and drawn in more detail before the building of the ship in Aberdeen, Scotland, in 1855. Information on the draft Is as follows: “Principal dimensions: Length between the perpendiculars: 262 feet 6 inches Length of keel 245 feet Breadth extreme: 45 feet Breadth of frame: 42 feet Depth of hold: 29 feet 9 inches Burthen in tons, Builders Old Measurement: 2600 Tons” The publisher firm A & C Black, was founded by Adam and Charles Black in Edinburgh in 1807. Over the years the company has published editions of Encyclopedia Britannica and Whose Who, and reference books, guides and technical books. The printer G Aikman (1788-1865) or his son G Aikman (1830-1905), were both named George. George senior was an early-19th century Scottish printer and publisher. After his death his son became the sole proprietor of the firm until he sold it in 1876. The draft plan uses the vessel Schomberg as its example ship building plan for demonstration purposes. It is significant for its association with the Victorian Heritage Registered shipwreck, the Schomberg. It is an example of a shipo building plan. The Schomberg collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. The Schomberg collection is archaeologically significant as the remains of an international passenger ship. The shipwreck collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day. The Schomberg collection meets the following criteria for assessment: Criterion A: Importance to the course, or pattern, of Victoria’s cultural history. Criterion B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history. Criterion C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history.Plan; line engraving; draft of the wooden clipper ship 'Schomberg', built in 1855. The drawing on cream paper is made from two well- joined pages. The drawing gives the principal dimensions and labels for the Body Plan, Middle Section, Sheer Plan and Half Breadth Plan. Inscriptions are on the drawing and its rough cardboard storage folder. Publisher: A & C Black. Edinburgh. Printer: G. Aikman sc. EdinborughOn drawing: "SHIP BUILDING" "Draught of the Wooden CLIPPER SHIP SCHOMBERG", Buiilt by Messrs A Halt & Co. of Aberdeen" "Vol XX" "Plate III" "Principal Dimensions""BODY PLAN" "MIDDLE SECTION" "SHEER PLAN" "HALF BREDTH PLAN" "Published by A & C Black, Edinburgh" "G Aikman sc. Edinr" On storage folder: "Receipt Number 381A: "Line engraving draught of wooden ship "Schomberg" "warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, schomberg, schomberg plan, vessel schomberg, ship building, g. aikman ship plan draftsman, a.& c. black publisher aberdoon, a. hall & co. maker aberdeen, peterborough, clipper ship, captain forbes, black ball line, ship's plan, ship's drawing, line drawing, vessel plan, draft plan, line engraving, vol xx plate iii, a & c black, ship building example drawing, g aikman, 19th century -

Flagstaff Hill Maritime Museum and Village

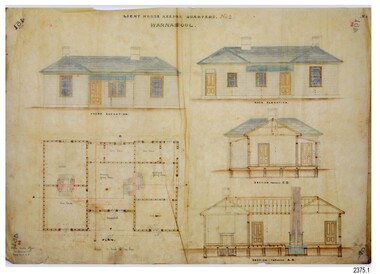

Flagstaff Hill Maritime Museum and VillageDocument - Plans, Lighthouse Keeper's Quarters Warrnambool, 1858-1909

... to this day. The plans are also significant as an example of a product ...The set of seven 1858 plans shows proposed plans for the original Lighthouse Complex that was built on Middle Island in 1858-1859. The whole complex was then transferred to Flagstaff Hill in 1871. The plan, dated 1909, is for proposed additions and repairs to the Quarters at Flagstaff Hill. The plan 'Alterations and Additions' shows alternate plans for changes to the quarters at the Flagstaff Hill location. This plan has no date. The Complex comprised the Lighthouse, the Lighthouse Keepers’ Quarters, the Store (now called the Chart Room) and a Privy, which was not included in these plans. The Keeper’s bluestone Quarters was a cottage divided into two compartments, one for each keeper and his family. The bluestone Store was divided into three; a store, a workshop an oil store (or office). The Privy comprised of a small building also divided into two separate, back-to-back toilets, one for each Keeper and his family. The Flagstaff Hill Keeper's Quarters have had extensions and additions at various times, and these have also been removed at various other times. THE PLANS - *Dec. 1858 (12/58) ‘Lighthouse Keepers Quarters No.2 Warrnambool’ (2375.01)* Public Works Office Melbourne – Front and Back elevations, sections, and floor plan. The drawing shows timber walls. [The floor plan is the closest plan to the current building, however, the walls are timber in this plan.] *Nov. 1858 – No.3 ‘Lighthouse Keepers Quarters Warrnambool’ (2375.02)* Office of Public Works, Melbourne – Back and End elevations and section through. The drawing shows stone walls. One side; Senior Keeper’s bedroom, living room and kitchen with storeroom. Another side; is the Assistant’s bedroom, living room and storeroom. *Nov. 1858 - No.4 ‘Lighthouse Stores Warrnambool’ (2375.03)* Office of Public Works – Front, Side and end elevations, centre section. The drawing shows stone walls. *Nov. 1858 – No.4, ‘Lighthouse Stores No. 2 Warrnambool’ (2375.04)* Office of Public Works – Front, side and end elevations, centre section. The drawing shows timber walls. *Nov. 1858 – ‘Details Lighthouse Keepers Quarters No. 2 Warrnambool’ (2375.05)* Public Works Office Melbourne. The plan shows the foundations, joists and eaves. The drawing shows timber walls. (Nov. 1858 – ‘No.4 ‘Lighthouse No. 2 – Warrnambool’ (2375.06)* Public Works Melbourne (Part of the paper is missing). This plan shows an octagonal tower, internal stairs, a balcony landing, and a weather vane on top. *November 1858 – No. 1, ‘Lighthouse – Warrnambool’ (2375.07)* Office of Public Works Melbourne. This plan shows a round tower, including the stairs, windows on the tower and the weather vane on the top. *4/3/9 [1909] – ‘Additions and Repairs, Lighthouse Quarters, Warrnambool, General Plan’ (2375.8)* Department of Public Works Melbourne’s official stamp is signed by Croft. It shows the floor plans of the Store, Upper Lighthouse and the Quarters. The Store building has three sections; a Store, Work-Shop and Office, with an internal wall between them and separate entries. The Quarters are divided into two dwellings. The Senior Keeper’s side on the left has fireplaces in two of the three bedrooms and there is a pantry and wash house. The Assistant’s side has no fireplaces in the bedrooms and there’s no pantry or washhouse. These plans include proposed changes to the buildings. The Senior Keeper’s Quarters would have a partition on bedroom 2, a bath with plumbing and drainage, a wall moved and a built-in side porch. The Store would also have a built-in porch. The undated plan 'Additions and Alterations' (2375.9) shows alternative arrangements for water tanks, plumbing and such. WARRNAMBOOL'S LADY BAY LIGHTHOUSES- In the 1800s ships sailing from England to Australia began to use Bass Strait as a faster route to Melbourne. Small navigation errors led to many tragic shipwrecks. From 1848 lighthouses were operating along Victoria’s southern coast as a guide for sailors. Coastal towns such as Warrnambool grew and the exchange of trade and passengers were of great benefit. However, the uncertain weather changes, relatively shallow waters and treacherous, hidden rocky reefs were not suitable for a Harbour and in the 1840s and 1850s there were many shipwrecks in the area, with some even stranded in its Lady Bay harbour. A jetty was built in 1850 and a flagstaff to guide seafarers was placed up high on what became known now as Flagstaff Hill. In November 1857 the Victorian Government recommended that Warrnambool Harbour had beacons and two lighthouses to guide vessels into and out of the Harbour safely. The white light of the Middle Island lighthouse was to be used for the first time on September 1, 1859. The red light of the Beach Lighthouse, a wooden obelisk structure, was first operated on March 25, 1860, but in 1868 this light was ‘discontinued’ due to it being too low. Melbourne’s Department of Public Works decided to relocate the Middle Island Lighthouse Complex - Lighthouse, Keeper’s Quarters, Privy, Store Room and even water tanks - to Flagstaff Hill. The lower obelisk was shortened, and a protruding gallery, railing, and external ladder were added, as well as the light from the Beach Lighthouse. A green guiding light was erected on the end of the jetty. The transfer of the Complex began in March 1871. Each shaped stone of the lighthouse was carefully numbered, removed then reassembled on Flagstaff Hill. In 1872 the well was sunk behind the Lighthouse Keeper’s Cottage. The Keepers and families had left Middle Island in April and moved to Flagstaff Hill in October 1871. Vessels entering Lady Bay align the Upper and Lower Lighthouse towers during the day and the lights at night. The Upper Lighthouse is a round tower, the Lower Light is square. The Lighthouses were categorised as harbour lights rather than coastal lights, so they remain under the control of the Victorian Government’s Ports and Harbours section. The lights were originally powered by oil, then acetylene gas, later by electricity, and then converted to solar power in 1988. In 1993 the solar panel was replaced by a battery charger. A decision was made in 1936 to replace the lighthouses’ lights with unattended lights that no longer required Keepers and Assistants. At least 29 Keepers had attended to the lighthouse from its opening in 1859 to when the last official Lightkeepers left In April 1916. The Warrnambool Harbour Board rented out the Quarters from 1916 to 1936. The Board closed down but the rentals continued with other unknown landlords. In the 1970s the Flagstaff Hill Planning Board was set up under the chairmanship of John Lindsay. The Board was to make recommendations to the Warrnambool City Council regarding the use of the buildings and the rest of the Crown Land on the site. The Flagstaff Hill Maritime Village opened in 1975 and began renovating the Cottage in stages, during which time evidence of a 1920s fire was found in the eastern section of the cottage. Additions of a porch on the west and a washroom on the east were made in the 1980s. The western part of the building is now a Shipwreck Museum and the east has returned to a late 19th-century Lighthouse Keeper’s cottage and includes the screen made by Assistant Lighthouse Keeper Thomas Hope during one of his two periods of service there. THE LIGHTHOUSE KEEPERS Lighthouse Keepers were responsible for keeping their Lighthouse’s lights shining at night. They kept a lookout for passing vessels and changes in weather. They were expected to clean, polish and maintain the equipment and buildings. They kept regular and detailed records of who was on watch, and the time the light was lit, trimmed and extinguished. They kept a journal about other events that occurred. They keep regular, accurate Meteorological Logs. It was expected that they were competent in Morse code signalling. They would be called to help in times of disasters and shipwrecks, and to give official statements about these events. Many Lighthouse Keepers also volunteered as members of the lifeboat crew. The Lady Bay lighthouses were officially classified as small, so the Keepers had the official titles of Senior Assistant Lighthouse Keeper and Assistant Lighthouse Keeper. They were employed by the Public Service and paid rent to live in the Lighthouse Quarters. They were compulsorily retired at the age of 60, with most receiving a superannuation payment. Despite their time-consuming duties, there was time to follow hobbies and crafts such as growing vegetables, playing musical instruments, making models of buildings including lighthouses, and crafting furniture pieces. An example of a keeper’s skills is the carved fire screen made by /assistant Keeper Thomas Hope in the early 20th century and displayed in the Lighthouse Keeper’s cottage at Flagstaff Hill. The last occupants of the Middle Island Complex were Senior Keeper Robert Deverell, his Assistant Keeper, Andrew Farncombe, and their families. They all became the first occupants at the Lady Bay Lighthouse Keepers’ Quarters on Merri Street. The Warrnambool Lighthouse Complex plans are the origin of what is now the Lady Bay Lighthouse Complex. They are a record of the people, process and departments involved in bringing the complex into fruition. The plans are significant to the Complex, which is now listed on the Victorian Heritage Register, H1520, for being of historical, scientific (technological) and architectural significance to the State of Victoria. The Complex is significant as an example of early colonial development. The plan are significant for their connection with the important navigational function of the Lighthouses, a function still being performed to this day. The plans are also significant as an example of a product from the Public Works Department in Victoria in the mid-to-late 19th century. The structures built to these plans still stand strong. Plans for the Lighthouse Complex in Warrnambool, including Lighthouses, Keeper's Quarters and Stores. Seven of the plans are on thin fragile paper, one is on thicker, stronger paper. The drawings have been made in pens coloured red and black. They originate from Public Works in Melbourne. Seven were drawn in 1858, one in 1904, the other is not dated.Dec. 1858 - Lighthouse Keepers Quarters No.2 Warrnambool. Public Works Office Melbourne. Nov. 1858 - No.3 ‘Lighthouse Keepers Quarters Warrnambool. Public Works Office Melbourne. Nov. 1858 - No.4 ‘Lighthouse Stores Warrnambool. Office of Public Works. Nov. 1858 - No.4, ‘Lighthouse Stores No. 2 Warrnambool. Office of Public Works. Nov. 1858 - Details Lighthouse Keepers Quarters No. 2 Warrnambool. Public Works Office Melbourne. Nov. 1858 - No.4 ‘Lighthouse No. 2 – Warrnambool. Public Works Melbourne. Nov. 1858 - No. 1, Lighthouse - Warrnambool. Office of Public Works Melbourne. 4/3/9 [1909] - Additions and Repairs, Lighthouse Quarters, Warrnambool, General Plan. Department of Public Works Melbourne. SIGNED "Croft" "15A" on reverse [no date] - Lighthouse Quarters Warrnambool, Additions and Alterations. "9A" on reverseflagstaff hill, warrnambool, lighthouse keeper's cottage, lighthouse residence, lighthouse, plans, public works, melbourne, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, chart room, quarters, privy, middle island, beach lighthouse, obelisk, lighthouse keeper, assistant keeper, lighthouse complex, lady bay, lady bay complex, keepers, upper lighthouse, lower lighthouse, ports and harbours, cottage, harbour board, flagstaff hill planning board, meteorological record, robert deverell, andrew farncombe, warrnambool port, warrnambool harbour, residence, alterations, repairs, department of works -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Loch Torridon, Early 20th century

The Loch Torridon was built in response to the need for a large cargo-carrying ship in the 1870s becoming famous for being one of the most per4fect four-masted barques ever built. She was built for the Loch Line in 1880 by Messrs. Barclay, Curle, and Co. Her measurements were 287 feet in length and 42 feet in beam, and 24 feet depth of hold. She was well sparred and her sail plan was so perfectly balanced that she was a very handy ship, easy on her helm, which was not a common virtue amongst large four-masted ships of her day. Her sails were interchangeable on all three masts, which was common in the last days of sail for both economical and practical purposes. The Loch Torridon was considered one of the most graceful and elegant ships ever launched from the Glasgow shipyards. The first master was Captain Pinder, the first cargo was bound for Melbourne Australia, after which she went on to Calcutta with a cargo of horses. On August the 22nd 1882 with a cargo of Jute onboard loaded in Calcutta the Loch Torridon ran into a storm. Sailing in heavy seas the captain, the second mate also the man at the wheel, and a boy was washed overboard with the first mate just escaping the same fate. Captain Pinder and the crew members could not be rescued and were never seen again with the first mate having to bring the ship home. The next Captain was Robert Pattman who was regarded as a fine navigator and seaman who sailed the Loch Torridon for the next twenty-six years and nine months. He had made 25 voyages around the world during this time without any serious mishap. In 1909 Captain Pattman resigned his command of the ship to switch to a steam vessel but unfortunately was injured on his first voyage and had to be landed at Falmouth, he dies of his injuries shortly afterwards. The Loch Torridon kept on sailing until 1915 after having been sold to a Russian company two years earlier. Near the end of January 1915, the ship sprang a leak of the west coast of Ireland and was abandoned sinking shortly afterwards. For further information regards possible maker of the model see Provenance sec this document: The item is of significance as an item made possibly by a man who served on the original ship making the item of historical significance given that the original craft was a well-known and respected trade vessel making voyages between England and Australia as well as the near East. Ship model Loch Torridon 4 masted, hull is black, grey and white. Ship in full sail with 4 lifeboats on deck. Ship sits on textured base. Has plain blue background. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin