Showing 221 items

matching blacksmith tools

-

Orbost & District Historical Society

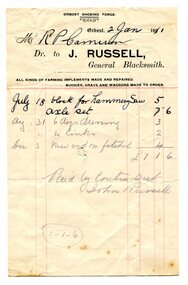

Orbost & District Historical Societyaccount, 1911

John Russell Senior was a blacksmith, wheelwright, farmer and later chairman of the Orbost Butter Factory, makers of Sunny South Butter (today part of Murray Goulburn Co Ltd). His blacksmith business was in Nicholson Street, Orbost. Robert Pullar Cameron was a Shire Councillor for many years. He married Penuel Hossack and had a family of James, Flora, Penuel and Alex.This item is an example of the book-keeping of an early 20th century Orbost business and is a useful research tool.A white paper account with red lines and black print. Details are hand-written in blue ink. It is from J. Russell to R. P. Cameron.account-book-keeping russell-john blacksmith cameron-r.p. -

Orbost & District Historical Society

Orbost & District Historical Societybooks, The Curlip No.1, 1991

This book/magazine was produced by students at Orbost Secondary College.This publication is a useful research tool for the history of Orbost. Two copies of an orange covered stapled book with 48 pp, titled The Curlip No. 1. On the front cover is a black stylised sketch of a paddle wheel. Text is black. - Contents The Diary of an ANZAC by Jackie Herbert Farming in the Jarrahmond Area by Kim Stirzaker Orbost blacksmiths by Craig Terrell.curlip-orbost-secondary-college history-orbost jarrahmond orbost-blacksmiths -

Orbost & District Historical Society

Orbost & District Historical Societysledge hammer, first half 20th century

... or blacksmiths. hammer sledge-hammer tool Underneath hammer - 10 A large ...A sledge hammer is generally wielded with both hands and is used for driving wedges and posts and for other heavy work. It can be used to remove concrete slabs, to drive heavy steel bolts into concrete, to hammer large stakes as well as for demolition.This item was a common tool used by farmers or blacksmiths.A large flat hammer with a wooden handle.Underneath hammer - 10hammer sledge-hammer tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Leg Vice, Mid 19th Century

... " and is one of the most important tools in the blacksmith's shop.... A vintage tool used in a Blacksmiths shop during the early 19th ...The blacksmith leg vise is also called the "solid box vise" and is one of the most important tools in the blacksmith's shop. It firmly holds hot iron while it is hammered, chiseled, or twisted. These are the only vises that are designed to take this kind of use day in and day out. A small 30-pound blacksmith's vise can survive pounding that would wreck a much heavier cast iron bench model. Three things make a blacksmith's vice special. One is that they are forgings, not cast iron or ductile iron. The second is the leg that provides support to the floor or from a sunken post. The last is the hinge, while not a perfect way to construct a vice the pin joint is durable and can take a considerable beating. If sheared it is easy to replace. These things all combine into a tool that can take decades of heavy use and abuse. Most in use is one to two hundred years old.Some of these vises were made by specialists such as Atwood of Stourbridge England, Steel City and Columbian in the U.S. and others were made in anvil manufacturing plants such as "Mousehole Forge" and "Peter Wright" in England and "Fisher-Norris" and others in North America. The design of these vises right down to the last chamfer seems to have been perfected in the 1600s and remained more or less the same until the 20th century. The bodies are forged wrought iron or mild steel and they have hard steel surfaces welded into the jaws. The jaws have little or very shallow serrations which are generally worn off.Around the turn of the 20th Century during the hey-day of the blacksmith shop in North America, these tools were considered so standard a commodity that they were sold without reference to the manufacturer. Very few were even marked with the maker's name. Size is best defined by weight as there is some variation in jaw size from manufacturer to manufacturer. They were sold by the pound and are still best judged by the pound.A vintage tool used in a Blacksmiths shop during the early 19th century to the beginning of the 20th century. Regarded as a significant into social history of the time.Leg Vice attached with screws to bench via a block of wood. Has large metal pole which practically reaches the floor. Also has a metal device to either tighten or slacken vice.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Compass, late 19th to early 20th century

This large compass is well made. It is now pitted and scratched, indication much use. Compasses were used to measure and mark out the head of the barrel by coopers. Very large compasses were used by block, spar and pump makers to help shave off angles left by axes and other tools on mast sides. Also they were used by blacksmiths in their work draftsmen, carpenters, engineers and navigators.This compass is an example of a drawing instrument that could have been used in the 19th and early 20th century by coopers and blacksmiths as well as navigators and ship smiths.Compass; large metal compass, 90-degree angle, two pointed arms hinged at the top. Inscription on the top of one arm.Stamped into the metal " J J E " ( or J J F )flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, compass, drawing instrument, measuring instrument, scientific instrument, draftsman, technical drawing, navigation, engineering, blacksmith, cooper, plumber -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnvil

... -village anvil blacksmiths tinsmith tools trades Warrnambool Ports ...This anvil was once the property of Warrnambool Ports and Harbours. It is associated with the shipping trade and wold have been used by a blacksmith or tinsmith for forging and shaping metal. According to Pliny, the anvil is supposed to be invented by Cinyra of Cyprus, but it was probably much older. There has been very little change in the basic design of the anvil since Greek and Roman times. This anvil is significant for its association with the local government body of Warrnambool Ports and Harbours, which is of local historic significance. It is also significant for its association with blacksmiths and tinsmiths, which are rare trades today.Anvil, small, for use by blacksmiths and tinsmiths.It was once the property of the Warrnambool Ports and Harbours.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, anvil, blacksmiths, tinsmith, tools, trades, warrnambool ports and harbours -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

... of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s ...This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVice, 1800s

... ) terang wheelwright tool blacksmith trade blacksmithing equipment ...A wheelwright’s spoke vice was used to hold the wheel hub firmly while the spokes were hammered into the wheel hub, then the spokes would be joined to the wooden wheel felloe before finally the metal flat tyre, or later the rubber tyre, would be attached to the felloe. A wheelwright’s spoke vice would have been very necessary for blacksmiths circa 1800s-1920s as it would have been used in the manufacture and repair of carts, wagons, coaches and other horse-drawn vehicles. This wheelwright’s spoke vice was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The wheelwright’s spoke vice is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Vice; wheelwright’s wheel spoke vice. Manufactured in 1800s. This was once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, machinery, wagon wheel, steel rim wheels, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, wheel hub, wheel spoke, wheel felloe, wheel tyre, wheel tire -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Lead shot mould, Early 20th century

This lead shot mould would have been used by those people wanting ammunition for shotguns. The moulds were probably originally used in a blacksmith’s forge. Although it has no known local provenance, this lead shot mould is of interest as an example of an early tool. This is a metal tool with handles in the shape of calipers with a rounded ball of metal at one end. The ball is split in the middle to allow molten material to be inserted for casting into lead shot. The object is heavily rusted.‘16’history of warrnambool, vintage tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wrench, Late 19th Century

... blacksmith workshop tool dropforged handmade wrench adjustable wrench ...Johann Elias Bleckmann (1784-1856) founded a steel goods shop in Ronsdorf near Dusseldorf Germany. After completing a business education in his father's business, his son Johann Heinrich August Bleckmann (1826-1891) gained further experience through travel in North and South America. When his father died, he took over the steel goods store and moved it to Solingen. He bought a hammer mill in Mürzzuschlag Styria (Austria) in 1862 and converted it into a modern crucible casting steel smelter. His "Phoenix Steel", which he produced himself, achieved worldwide renown. He then went on to establish a file and tool factory and later founded a steel and plate rolling mill. Apart from cutlery blades, the company's self-produced steel was also processed into tools, scythes, rifle parts, etc. His sons Eugen and Walter continued after his death in 1891 at the Phoenix steelworks. However, by the end of the First World War, the two brothers fell into economic difficulties as a result of eliminating a large part of their foreign trade. In 1921, the company was converted into a public limited company and merged three years later with the company Schoeller & Stahlwerke. Made by Bleckmanns a significant Austrian manufacture of cutlery and tools in a recognized area of Germany famous for the production of steel items. The item is giving a snapshot of early colonial and European trades persons tools and gives an interesting insight into the development and progression of European tool and steel development and innervation prior to the First World War.Drop hand forged steel wrench with unusual locking mechanism to size jaw opening made by J E Bleckmann, Solingen Germany.Machine stamped on handle of wrench LOTUS L R GEBRAUCHS under has MUNSTER, J E BLECKMANN, SOLINGEN Germany. [ Translated: LR Gebrauchs= use,usage, or custom application] [Lotos] Translated: Lotus ie flower] [Solingen =town in Rhine valley]manufactures, tools, engineering, blacksmith, workshop tool, dropforged, handmade, wrench, adjustable wrench, phoenix steel, j e bleckmann, solingen, murzzuschlag, steel mill, cutlery, steel foundery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

... blacksmith tool... flagstaff hill maritime village great ocean road blacksmith tool ...This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith's Tongs, n.d

... , forged Tool Blacksmith's Tongs ...Port of Portland Collection -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Anvil, Bradford and Kendall, n.d

... Metal blacksmiths anvil. An anvil is used by blacksmiths... pieces. The anvil is a common tool of the blacksmiths (‘smithies ...Port of Portland Collection Bradken, originally Bradford and Kendall, began as a steel foundry in Sydney in 1920 and produced BK anvils at its factories in Alexandria and Mascot NSW. Leslie Bradford (General Manager) and Jim Kendall (Chief Mechanical Engineer), two BHP steelworks employees, got lucky at the races one day in 1920 and pledged their £15,000 winnings to start a steel foundry business. The horse they backed, ‘Jack Findlay’ completed a remarkable sequence of five wins during 1919 and 1920. With each win Leslie Bradford, Jim Kendall and a group of friends rolled-over their bets. By January 24, 1920 they had won a small fortune. On April 28 1920, the group used their winnings to establish the Alloy Steel Syndicate and build a steel foundry in Alexandria, Sydney to take advantage of what they saw as an untapped potential for industrial growth. Bradford Kendall Ltd was incorporated on 20th March 1922.Metal blacksmiths anvil. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Blacksmith anvil, 5CWT, iron BK Sydney Australia.Front: 'BK SYDNEY AUST. 5CWT' Back: -port of portland, anvil, blacksmith, industry, bk anvil, bradken, brandford and kendall -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Chicory Devil, 1870's approximate

Chicory Devil made by Dinny Justice who was a Blacksmith on Phillip Island.Hand forged Iron Tool for chicory harvesting by hand. 1050mm long with a blade 370mm x 50mm sharpened at the end. Footrest protruding 90mm - 100mm each side of the shaft at the top of the blade. Handle loop at top of shaft 130mm x 77mm.local history, rural industry, horticulture, chicory devil -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith Tongs, n.d

... . Tool Blacksmith Tongs ...Port of Portland CollectionBlacksmith's tongs - hand forged, steel.port of portland -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith Tongs, n.d

... . Tool Blacksmith Tongs ...Port of Portland CollectionBlacksmith's tongs, hand forged, steel.port of portland -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith's Tongs, n.d

... Tool Blacksmith's Tongs ...Port of Portland CollectionBlacksmith's tongs, forged steelport of portland archives -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith Tongs, n.d

... tongs - hand forged Tool Blacksmith Tongs ...PORT OF PORTLAND COLLECTIONBlacksmith's tongs - hand forgedport of portland, trade, industry, blacksmith -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith's Tongs, n.d

... Collection Blacksmith's tongs - forged, steel Tool Blacksmith's Tongs ...Port of Portland CollectionBlacksmith's tongs - forged, steel -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith Tongs, n.d

... Blacksmith's tongs, hand forged Tool Blacksmith Tongs ...PORT OF PORTLAND COLLECTIONBlacksmith's tongs, hand forgedport of portland, blacksmith, tongs, trade, industry, metalwork -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith's Tongs, n.d

... tongs, hand forged, steel Tool Blacksmith's Tongs ...PORT OF PORTLAND COLLECTIONBlacksmith's tongs, hand forged, steelport of portland, blacksmith, trade, industry -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith's Tongs, n.d

... COLLECTION Port of Portland blacksmith tongs tool industry trade ...PORT OF PORTLAND COLLECTIONBlacksmith's tongs, forged steelport of portland, blacksmith, tongs, tool, industry, trade -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel spiral bit Auger, c1900

... , Cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths ...Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes A steel spiral bit Auger* pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, drills, augers, gimlets -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

... , Moorabbin, Bentleigh, Cheltenham, brighton, tools, craftsman ...A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Brace and Bit hand drill, 20thC

... , Cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths ...Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes. Chucks were patented as vigorously as the braces themselves The braces themselves also evolved for particular trades, from furniture makers to surgeons. The operator holds the ‘head’ in one hand, positions the drill in the wood , applies pressure and rotates the ‘centre piece’ to cause the drill to pierce the wood. A steel revolving hand tool for boring and screw-driving with wood handles * pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, wooden hammer with steel head, c1900

... , cheltenham, tools, craftsman, carpenters, blacksmiths, builders ...A hammer is a tool with a heavy head and a handle, often made of shock-absorbent wood or fiberglass that is used to strike an object. The most common uses for hammers are to drive nails, fit parts, forge metal, and break apart objects. Hammers vary in shape, size, and structure, depending on their uses. Hammers are basic tools in many trades. A hammer is composed of a head most often made of steel and a handle also called a helve or haft. Most hammers are hand tools. A traditional hand-held hammer consists of a separate head and a handle, fastened together by means of a special wedge made for the purpose, or by glue, or both. This two-piece design is often used, to combine a dense metallic striking head with a non-metallic mechanical-shock-absorbing handle -to reduce user fatigue from repeated strikes. If wood is used for the handle, it is often hickory or ash, which are tough and long-lasting materials that can dissipate shock waves from the hammer head. A well used hammer with wooden handle and steel headpioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, tools, craftsman, carpenters, blacksmiths, builders, woodwork, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel leather punch, c1900

... . Blacksmiths made the tools leatherwork craftwork moorabbin bentleigh ...This steel leather punch would be used by early settlers in Moorabbin Shire c1900when making and repairing, farm and household leather goods.Early settlers in Moorabbin Shire had to be self sufficient and made and repaired their farm and household equipment. Blacksmiths made the toolsA solid steel leather punchleatherwork, craftwork, moorabbin, bentleigh, cheltenham, early settlers -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith Tongs, n.d

... , steel Blacksmith's tongs - hand forged, steel Tool Blacksmith ...Port of Portland CollectionBlacksmith's tongs - hand forged, steelBack: Blacksmith's tongs - hand forged, steelport of portland -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTuyere Pipe, circa mid to late 1900's

... blacksmith tool.... blacksmith tool tue bellows fashioning metal forge manufacturing ...This tuyere (word from French origin) was used by professional blacksmiths and or cattlemen before and during the Kiewa Hydro Electricity Scheme was being constructed. The need to use a furnace or forge in the shaping of metal rods, horse shoes and pipes is both a rural necessity and a construction, on site requirement. The "inventiveness" of cattlemen and construction workers to produce metal objects not available "off the shelf" is one of the inherent traits not only of rural self sufficiency but in the "pioneer" days of rural isolation one of survival.This tuyere is of great significance to the Kiewa Valley and its regions because it highlights one of the greatest strengths of the rural (especially isolated) life and its folk living there, and that is the great human factor of adaptability and survival techniques in sometimes harsh and demanding environmental circumstances. The inventiveness and the attitude, "she'll be right mate", demonstrates life on the land where specialised blacksmith activities can be found in non "professionals" because of the fact that "someone" has to do the job. This is one of the differences between country "rural" life and that found in cities and larger towns.This iron cone shaped tuyere has a small hole (diamenter 25mm) starting within an ever enlarging cone (amplification of the air pressure going through) delivering varying hot or extremely hot air into a furnace or hearth which intensifies the heat to allow the "shaping" of metal objects. The larger "flared" cone extension allows for the directed air to be spread and not concentrated.blacksmith tool, tue, bellows, fashioning metal, forge manufacturing process -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBlacksmith Tool - Vice

... Blacksmith Tool - Vice ... in the Kiewa Valley. blacksmith's tool vice blacksmith's vice Formerly ...Formerly KV113. The blacksmith's vice firmly holds hot iron while it is hammered, chiseled or twisted. It is the only vice that is designed to take this kind of use day in and day out.Used by blacksmiths in the Kiewa Valley.Formerly KV 113. Large 4 inch and heavy steel blacksmith's vice missing the handle bit that turns around making the jaws go in and out. Ref. Page 74 Tools for all Trades Catalogue.blacksmith's tool, vice, blacksmith's vice