Showing 165 items matching "oil lamp"

-

Melbourne Tram Museum

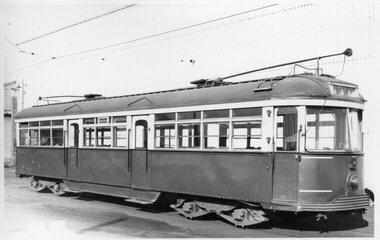

Melbourne Tram MuseumPhotograph - Black and White - VR Tram 37 - Elwood Depot, Victorian Railways (VR)

... scheme, the oil lamp that was provided on VR trams on the St..., the oil lamp that was provided on VR trams on the St Kilda ...Photograph of tram 37 shows the Victorian Railways colour scheme, the oil lamp that was provided on VR trams on the St Kilda to Brighton, Electric Street Railway. Has 3 Robur Tea roof advertisements. The tram is shunting at the depot or waiting to run to St Kilda Railway Station, possibly after the closure of section south of the depot. Original Victorian Railways Photograph. Yields information about the location, the streetscape and the trams in use at the time. Black and white photograph of Victorian Railways tram 37 outside Elwood Depot in St Kilda St, possibly in the early 1950s. Original Victorian Railways Photograph.tramways, trams, vr trams, elwood tram depot, st kilda st, tram 37, victorian railways -

Bendigo Military Museum

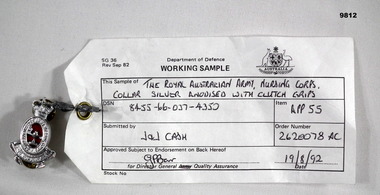

Bendigo Military MuseumManual - SAMPLE BADGE, SILVER COLOUR, c. 1992

... (pointed end). Lit oil lamp in centre of oval with red textile... (pointed end). Lit oil lamp in centre of oval with red textile ...Badge is an example of sample used to ensure standard of manufacture among local contractors. See item 9806.Silver coloured badge with two (2) pins, one (1) at top and bottom; gold coloured clasp on each. Crown on top of oval (pointed end). Lit oil lamp in centre of oval with red textile (possibly velvet) behind. Banner at base with motto. Gold coloured plate on back. Tag secured to badge with wire and lead seal.In oval around lamp - "ROYAL AUSTRALIAN ARMY NURSING CORPS." In banner - "PRO HUMANITATE [for humanity (or kindness)]" Tag (handwritten sections) - "THE ROYAL AUSTRALIAN ARMY, NURSING CORPS/COLLAR SILVER ANODISED WITH CLUTCH GRIPS" "8455-66-037-4350/APP 55" "J+J CASH/2620078 AC" " G P Barr [signature]/ 19/8/92"insignia, badge -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchPlaque - TOC H Memorial Plaque bronze WW2, TOC H Warrnambool

... Eastern oil Lamp with cross, on top of plaque. 1939-1945... Eastern oil Lamp with cross, on top of plaque. 1939-1945. Text ...List of deceased local TOC H men who passed during World War 2. Historical. ResearchBronze PlaqueEastern oil Lamp with cross, on top of plaque. 1939-1945. Text below reads 'WITH PROUD THANKSGIVINGG WE REMEMBER THE GOOD FELLOWSHIP OF LOCAL "TOC H" MEN WHO JOINED THE RANKS OF THE ELDER BRETHREN DURING THE WAR.' 4 Wall mounting holes, 1 in each corner.ww2 memorial -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLamp, Late 19th Century

... Isaac Sherwoods Ltd were manufacturers of oil lamps... of oil lamps and burners in Birmingham, in 1904 they were trading ...Isaac Sherwoods Ltd were manufacturers of oil lamps and burners in Birmingham, in 1904 they were trading as Isaac Sherwood & Son Ltd. but by 1920 they had taken over Linley & Co. of 73-75 Great Lister Street, makers of `American' pattern lamps to become Sherwood-Linley at Nechells Park Works, Eliot Street. The company were a leading manufacturer of oil and candle lamps exporting their goods all over the world. The subject lamp is operated with a candle, which is inserted on the underside, it is sprung and as the candle burns the spring keeps the candle pushed upwards keeping the flame burning until the candle is extinct. Sherwoods invented and patented this innovation for candle lamps.The subject item is incomplete however it has some significance as it was designed to be used in a sea going vessel, as a result is quite rare also the item is made by a well known manufacturer.Spring loaded candle Lamp, brass, with gimbal wall attachment for use on a ship, shade and mount missing. Candle-stop has the words "Sherwoods Limited, trademark sound".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, candle lamp, gimbal spring, sherwoods limited -

Orbost & District Historical Society

Orbost & District Historical SocietyLamp - kerosene, first half of 20th century

... and that style of collar was used on most of them. (ref Oil Lamp Antiques)... and that style of collar was used on most of them. (ref Oil Lamp Antiques ...This lamp pattern was originally made in USA between 1880 and 1900. The pattern is called Feathered Cartouche and generally had a painted motif on each of the panels on the front. This lamp is probably a copy of the American lamp and made in Australia sometime in the first half of the 20th century. The lamp has an English style collar rather than an American one and the pattern is not as crisp as the American ones. There were several lamp patterns made here that were copies of American patterns and that style of collar was used on most of them. (ref Oil Lamp Antiques)This item is an important example of the early technology of artificial light. It has historical significance in demonstrating lighting devices used before the widespread use of electricity.Ornate clear glass kerosene lamp. Glass chimney is missing. Base is square and patterned with raised oval shapes, as is the stem. Both base and stem are hollow. At the top, the kerosene holder is squarish with round corners.. The wick holder is of brass and has a small wick adjustor.lamp, kerosene lamp, lighting - domestic -

Kiewa Valley Historical Society

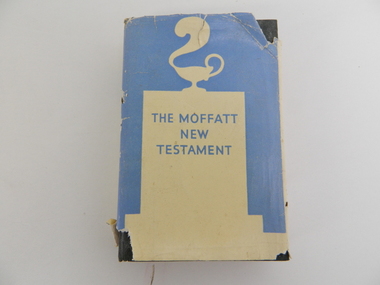

Kiewa Valley Historical SocietyBible, Bible Moffat, 1935

... highlighting a smoking "Aladdin's" Arabic oil lamp on a cenotaph... "Aladdin's" Arabic oil lamp on a cenotaph. The hard cover has ...This Christian Bible by Professor James Moffatt from the United Free Church College in Glasglow Scotland was at a time when translated Christian bibles(Greek to English) were being review as to the accuracy of their translated words. This period was in the early 1900's specifically during and between the two major World Wars of 1914-18 and 1939-45 and also covering the Great Depression(1939). All these periods were ones of death, destruction and "loss of faith". Bibles which provided greater clarity of better times ahead flourished. This book offered its readers hope for the future (in terrible times). The regions that it covered were those who belonged to the Christian Faith. The significance of this bible to the Kiewa Valley is that it provides an insight of those Christians living in a semi remote rural region at the period in Australian history where forces outside of this area were placing hardships which were "foreign" to them, as a family and as a community. The major Christian religions within the Kiewa Valley were either of the Catholic or English Protestant teachings. These groups still remain the dominant ones well into the 2nd Millennium. Spiritual relief to overcome harsh rural setbacks is not just specific to the Australian rural sector but is also global. With the influx of migrant workers from the war torn European nations (after WWII) a broader coverage of Christian and other faiths developed. A "positive" saying, when crops failed and bush fires and river floods sprang up, rallied the faithful "with God's help" This hard covered bible consists of six pages of preamble including title, publishing details, printer and author's preface. The book has 388 pages of black print. Relevant reference lines are notated by numbers on the left side of the page. On the front dust cover is a cream silhouette against a light blue backdrop highlighting a smoking "Aladdin's" Arabic oil lamp on a cenotaph. The hard cover has a embossed emblem of a lantern with a plume of smoke rising from the spout. This is all encapsulated by a circle. The spine also has this emblem. On the dust jacket, front "THE MOFFATT NEW TESTAMENT", and the back cover has blue writing on a cream background. On the spine, at the top "JAMES MOFFATT" below this a white on blue silhouette of "Alalddin's lamp" below this is (in blue letters against a light blue background " THE NEW TESTAMENT A NEW TRANSLATION" On inside cover a signature "Clare Roper". The hard cover has marked in red print "THE NEW TESTAMENT ANEW TRANSLATION MOFFAT" christian bible, prayer, new testament, religion, faith. -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Black and White - Victorian Railways Tram at Preston Workshops 1959

... the blackout blinds, route number boxes, removal of the red oil lamps... blinds, route number boxes, removal of the red oil lamps above ...Photograph of one of the three Victorian Railways "Luxury" cars that were sold to the MMTB following the closure of the final section of the St Kilda - Brighton tramway on 28-2-1959. The tramcar has been placed on No. 15 trucks to enable movement around the workshops. Two of the trams, No. 52 and 53 were modified with longer running boards, full driver's bulkheads to replace the blackout blinds, route number boxes, removal of the red oil lamps above the headlight, conversion to from Broad gauge (5'3") to standard gauge, changes to destination boxes, seating and many other changes. Reference Destination City, Edition 5, page 103.Yields information about the former VR "Luxury" trams sold to the MMTB in 1959.Black and white photograph of one of the three Victorian Railways Trams sold to the MMTB at Preston Workshops.tramways, mmtb, trams, victorian railways, st kilda brighton electric tramway, preston workshops, vr class -

Returned Nurses RSL Sub-branch

Returned Nurses RSL Sub-branchBadge - Collar Badge, Royal Australian Army Nursing Corps (RAANC), unknown

... Corps'. In the centre of the oval is a Nightingale oil lamp...'. In the centre of the oval is a Nightingale oil lamp on a dull cherry ...The Royal Australian Army Nursing Corps (RAANC) provides health care and medical assistance to Australian Army personnel in military health facilities. The Royal Australian Army Nursing Corps embraces the values of compassion and service to others, reflecting the care and dedication provided to the wounded and sick. The Australian Army employs registered general nurses as nursing officers in Army hospitals and medical centres. These officers form the Royal Australian Army Nursing Corps. The collar badge would have been worn on the collar of official uniform. This badge is in good condition and provides context and interests in nurse uniform. However, it is hard to guarantee that this is an original badge or a replica. Photograph of Royal Australian Army Nursing Corps collar badge. Oval shaped badge surmounted by St Edward's crown. Around the edge of the oval is embossed 'Royal Australian Army Nursing Corps'. In the centre of the oval is a Nightingale oil lamp on a dull cherry coloured felt background. Across the bottom is a scroll embossed with the Latin motto 'Pro Humanitate', translating to 'for humanity'. The metallic nature of the badge leaves it cool to the touch, with rounded edges and a round collar attachment peg, unlike the sharp attachment pegs like typical badges and pins. 'Royal Australian Army Nursing Corps'/ 'Pro Humanitate'[Latin translating to English as 'for humanity']. raanc, uniform, badge, royal australian army nursing corps -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Marine Lamp, Kempthorne Pty Ltd, 1941

... including oil lamps for marine use as well as for the domestic... fixtures and fittings including oil lamps for marine use as well ...Kempthorne Lighting Pty. was established as Coffey Lanterns in East Malvern, Melbourne Victoria in 1931 by brothers Selwyn and Owen Coffey. They manufactured lighting fixtures and fittings including oil lamps for marine use as well as for the domestic market. In early 1936 two other brothers, Erle and Terence had joined the company which was renamed Kempthorne Lantern Works Pty., Ltd. In 1946 Kempthorne joined with a small design team who had developed a domestic fan to form the subsidiary, Mistral fans. The company previously known as Kempthorne Holding Ltd was listed on the stock exchange in 1968. In 1977-1979 Kempthorne Mistral Ltd. Was a holding company comprising of Kempthorne Lighting Pty., Ltd. & Mistral Fans Pty., Ltd. An early Australian made marine lamp by a significant manufacturer that is still in business today making electrical equipment. The item is an important artefact that was made by an early Australian business that started in the 1930s. Over the years this company has demonstrated many innovations to the manufacturer of electrical items. Marine copper Lamp, round with brass makers lozenge and rounded hollow lugs set on either side of the lamp. Heavy metal handle with brass locking pin. Lid with catch on top. Made by Kempthorne Pty Ltd Melb. 1941flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, copper ship lamp, ship lamp, kempthorne pty ltd -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Brass Lamp, n.d

... Brass whale oil 3 burner lamp, not polished, original... Cliff Street Portland great-ocean-road Brass whale oil 3 burner ...Brass whale oil 3 burner lamp, not polished, original patina. 3 brass tools hanging from brass chains attached to the lamp. -

Gippsland Vehicle Collection

Gippsland Vehicle CollectionTail-lamp, (exact); Post 28th August 1917 patent

... Oil burning Tail-lamp for a (1917/23) model Ford T Model... TAIL-LIGHT 1912 - 1919 T MODEL FORD" Oil burning Tail-lamp ...Oil burning Tail-lamp for a (1917/23) model Ford T Model Motor Car in unused condition. Mounted on a varnished wooden block mount.Faintly engraved on top "Ford" Faintly engraved on bottom "PAT MAY 26 -14 PAT JUN 23 - 14 PAT NOV 23 - 15 PAT DEC 21 - 15 PAT NOV 7 - 16 PAT AUG 28 - 17" On front of Timber Mounting "Donated by Jim Dowton Sale FORD - Model T 1917 - 1923 Tailamp - part 6568x" On back of timber mounting "ON LOAN J.DOWTON SALE TAIL-LIGHT 1912 - 1919 T MODEL FORD"1920, 1918, 1919, 1917, 1923, ford, tail light, tail lamp, henry ford, t model, ford car, kerosene lamp, 1921, 1922, 6568x, part number 6568x, dowton -

Federation University Historical Collection

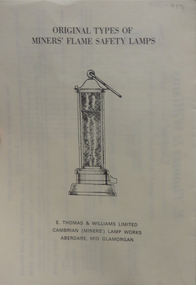

Federation University Historical CollectionMining Lamp, E. Thomas and Williams Ltd, Welsh Mining Lamp

... the safest metal to use underground. The lamp burns lamp oil... the safest metal to use underground. The lamp burns lamp oil ...This lamp is typical of lamps used in Welsh Coal Mines. It was purchased from the supplier around mid 1995. The Welsh Miners’ Lamps were ingeniously designed over 180 years ago to alert coal miners to danger. It ensures the burning of a protected flame in the presence of explosive gas, by regulating the necessary supply of atmospheric air, and by allowing the products of combustion to pass through without igniting the gaseous atmosphere. If the atmosphere is so heavily charged that noxious gas enters the lamp, its presence will be indicated by a change in the length and color of the flame, and (unless there are exceptional circumstances), the miner has sufficient warning to secure his safety. (http://www.welshminerslamps.com/info_lamp_personaluse.shtml, accessed 06/05/2015) E. Thomas & Williams, Ltd. mining lamps have been in continuous production since 1860. Cambrian Lamps are approved for use in coal mines where methan gas and oxygem deficinecy are hazards.Solid Brass traditional miners Flame Safety Lamp with Copper Chimney. The base of this lamp is tooled from solid brass because brass does not spark when it hits rock and is therefore the safest metal to use underground. The lamp burns lamp oil (kerosene). R. Thomas and Williams Ltd Makers Aberdare Wales Cambrian No 152897mining lamp, miner's lamp, thomas and williams, wales, welsh, welsh miners lamp, mining, cambrian lampworks, miners flame safety lamps -

![Photo of Queen Elizabeth II Silver jubilee dish laid upon the dish's matching red felt box. The cool-to-touch silver dish has engravings upon its face including the royal mark of Queen Elizabeth the Second, 'EIIR' under surmounted by St Edward's crown, '1952' on the left of the dish, 'Royal Australian Army Nursing Cross' is embossed within an oval central press, surmounted by St Edwards crown, in the centre of the oval is a Nightingale oil lamp, across the bottom of the central oval is a scroll embossed with the motto 'Pro Humanitate' Latin for 'For Humanity'. Underneath the central embossment and aligned with the royal Elizabeth sigil is an engraving of the dates '1902 - 1977' [seemingly this date was engraved after the making of the dish, it is unknown how long after the presenting of the dish the engraving was added.] Underneath those dates are engravings/marks of silver, nickel and makers quality marks. Upon flipping the dish over, on the slight foot of the dish is an embossing of 'Nickel Silver' and an engraving of the silver quality number '49'. The red felt box lid is also pictured, white satin with soft cushioning to protect the dish when closed. This photograph is taken upon a black background, with a scale card and object number included.](/media/collectors/64a5077bc83bd7b7b94f4211/items/67d1436203274031f6b50116/item-media/67d1462403274031f6b51496/item-fit-380x285.jpg) Returned Nurses RSL Sub-branch

Returned Nurses RSL Sub-branchCeremonial object - Queen Elizabeth II Silver Jubilee Dish, Goldsmith's Company Assay Office, c. 1977

... Corps'/[surrounding Nightingale oil lamp, surmounted by St... oil lamp, surmounted by St Edward's Crown.], 'Pro Humnitate ...The Queen Elizabeth II Silver Jubilee Medal was awarded to citizens in the Commonwealth (Canada, United Kingdom, Australia and New Zealand) for their healthcare/nursing services. This ceremonial dish appears to serve the same or similar purpose to the medal, it is unknown whether the dish was awarded, or whether it was purchased and customised to reflect the respect of service that the medal from the same year served. This dish is peculiar, which in turn increases the significance of the object. Though similar to the Queen Elizabeth II Silver Jubilee Medal in social purpose, it is less historically significant. However, due to the nature of the collection at large, this object is of medium to high significance. Additionally, it may be a crucial object in reflecting thoughts, feelings and social organisation of Australian nurses. Nickel silver dish with several engravings and embossing, small dish foot, shallow dish, including Royal Australian Army Nursing Corps logo upon the centre of dish. 'EIIR' (Royal Elizabeth the Second sigil.)/[surmounted by St Edward's Crown]/'1952'/'Royal Australian Army Nursing Corps'/[surrounding Nightingale oil lamp, surmounted by St Edward's Crown.], 'Pro Humnitate'/[scroll embossing.]/'1902-1977'/'D-M S'[Makers mark]/Lion passant mark [indicates a fineness of 925/1000 sterling silver]/British silver hallmark [Leopard face that indicates the London Assay Office]/'C'[Denotes the date of silver pressing, capital C indicates 1977.]/Portrait of Queen Elizabeth the Second [Duty mark reflecting a tax on precious metals collected between 1784 and 1890 and that the tax had been paid.] On the base of dish: 'Nickel Silver' [material]. / '49'. silver jubilee, queen elizabeth ii, queen elizabeth 2, queen elizabeth the second, royal australian army nursing corps -

Puffing Billy Railway

Puffing Billy RailwayBlackstone Oil Engine, 6 November 1908

... 8HP Blackstone Lamps Start Oil Engine engine number 71076...-valley-and-the-dandenong-ranges 8HP Blackstone Lamps Start Oil ...8HP Blackstone Lamps Start Oil Engine engine number 71076 Engine Details Maximum operating RPM of 240. Fitted with a 3'9" Flywheel Tested on the 6th of November 1908. Shipped to Cluter buck South Australia for installation on concrete base. Recovered and restored during the 80's in South Australia Purchased privately in 2013 in Tailem Bend South Australia and transported to Victoria. Currently on loan to the Puffing Billy Museum at Menzies Creek as an operating exhibit. Blackstone & Co. was a farm implement maker at Stamford, Lincolnshire, United Kingdom. In 1896 they built lamp start oil engines. The Lamp or hot-bulb engine (also hotbulb or heavy-oil engine) is a type of internal combustion engine. It is an engine in which fuel is ignited by being brought into contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine. Most hot-bulb engines were produced as one-cylinder, low-speed two-stroke crankcase scavenged units Historic - Industrial - single cylinder, horizontal, 4 stroke, hot-bulb ignition oil engine Blackstone 8HP Oil Engine made from steel, wrought iron and brassOval Plate with Black Stones and Clutter Buck Brass Plaque engine number 71076blackstone, oil engine, clutter buck, black stone, puffing billy, hit and miss, engine, blackstone & co -

Bendigo Military Museum

Bendigo Military MuseumUniform - DRESS & CAPE, RAANC, Commonwealth Government Clothing Factory, 1976 - 1971

... " . Centre of oval Nightingale oil lamp. Across bottom scroll... NURSING CORPS" . Centre of oval Nightingale oil lamp. Across ...1. Dress - white colour polyester cotton fabric ward dress. Collar, long sleeves with attached collar and plastic buttons. Front opening with concealed button closure. Buttons - white plastic with metal shank and split pin. Shoulder straps with attached red colour fabric epaulettes, with button hole. Button - silver colour plastic with metal shank and clasp. Epaulette badge, silver metal letters RAANC, two silver metal letters RAANC, two silver and red colour metal rank insignia - Lieutenant. Manufacturers label - white colour cotton, front lining. 2. Cape - red colour wool fabric cape style elbow length. Shoulder epaulettes with silver colour plastic embossed buttons, Queens Crown, Map of Australia with shank. Three silver and red colour metal rank insignia - Captain - per epaulette. Bar badge - plastic and metal - silver colour, oval shaped surmounted by Queen's crown, oval embossed with "ROYAL ASUTRALIAN NURSING CORPS" . Centre of oval Nightingale oil lamp. Across bottom scroll embossed with motto "PRO HUMANITATE".Manufacturer's information - black print. 1. A.G.C.F./ VICTORIA/ 1976/ ^/ SIZE OS/ 8410.66.038.1474/ ARMY NO/ NAME" 2. Back of cape "C.G.C.F./ VICTORIA/ 1971/ ^/ SIZE - OS/ 8410.66.013.0771/ ARMY NO/ NAME" Front lining "S4S/ M.603493/DKT./ 35768/ F/NO/ 1842/ SIZE/ OS/ CAPE NURSES. WINT. SCARLET/ ARMY/ 125 29". uniform, royal australian army nursing corps -

Bendigo Military Museum

Bendigo Military MuseumUniform - DRESS COAT, WAIST COAT, RAANC, Commonwealth Government Clothing Factory, c.1971

... of oval is Nightingale oil lamp. Across bottom scroll embossed...". Centre of oval is Nightingale oil lamp. Across bottom scroll ...1. Dress Coat - formal jacket style ending at waist. Collar with shawl lapels, shoulder epaulettes and one button fastening front. Red colour wool fabric with red polyester satin fabric lining. Three silver and red colour metal rank insignia - Captain - on each shoulder epaulette. Two silver colour plastic buttons with nursing emblem and shank. Two silver colour plastic lapel badges - oval shaped surmounted by Queen's Crown, oval embossed with 'ROYAL AUSTRALIAN ARMY NURSING CORPS". Centre of oval is Nightingale oil lamp. Across bottom scroll embossed with "PRO HUMANITATE". 2. Waist Coat - vest with two front concealed pockets, red colour wool fabric front, back and lining red colour polyester satin fabric. Front - four silver colour plastic embossed buttons - Queen's Crown, Map of Australia, with shank and metal safety pins. 3. Belt - red and grey colour woven belt fabric with silver colour metal clasp buckle and waist length adjuster. Buckle - circular centre embossed with "ROYAL AUSTRALIAN ARMY NURSING CORPS", SURROUNDING AN EMBOSSED OVAL BADGE - DESCRIPTION AS PER LAPEL BADGES.. Attached to belt end - white fabric manufacturers label.Manufacturers white fabric label - black ink print. "Hobson/ & sons (Lindon) Ltd ........Large".uniform, royal australian army nursing corps -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCompass, c. 1930s

... . The compass fluid was typically lamp oil, or a mixture of alcohol... wooden box. The compass fluid was typically lamp oil ...The nautical compass is used for determining directions, using a free moving magnetised needle, indicating north and south. This is a medium sized compass and was suitable for mounting in a fixed brass binnacle or a portable wooden box. The compass fluid was typically lamp oil, or a mixture of alcohol and water. This compass, based on its pattern, was probably manufactured around the 1930s. The compass’s maker, Bergen Nautik, was a 20th Century compass manufacturer, making compasses from the 1900s but no longer in business.The factory was located in Hordaland County, Bergen, on the west coast of Norway. This compass is not a very significant marine item as it was made in the 20th century. Examples of the same compass that have been salvaged can be purchased today mounted either in a wooden box or a brass pedestal.Compass; marine or ship's compass, brass, gimbal mounting, in blue metal casing. Manufacturer’s inscription is on the face. Made by Bergen Nautik of Bergen in Norway. Circa 1930s."BERGEN . NAUTIK", "BERGEN", "NORWAY" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, compass, nautical compass, marine compass, maritime compass, technical instrument, navigation instrument, bergen nautik, 20th-century marine compass, gimbal compass, ship's compass, bergan nautik, norway, 1930s marine compass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lamp Light, late 19th - early-20th century

... the first oil lamp was used in the city. In 1849 a gas lamp... oil lamp was used in the city. In 1849 a gas lamp ...This gas lamp light and stand came from the original manufacturer in Melbourne. Gas street lights such as this one were used in Melbourne from the mid-19th century. The lights enabled safer after-dark travel for pedestrians and vehicles and were a deterrent to crime. A lamp lighter was employed to keep the lamps lit, sometimes with little success due to weather conditions and the pranks of youths. WARRNAMBOOL Gasworks In Warrnambool prior to 1874 there were about twenty rare, individually lit street lights in Warrnambool, each with its own supply of kerosene. These lamps were in the central business area of Timor, Koroit and Liebig Streets. The Warrnambool Gas Company Ltd. was registered as an incorporated company in 1873. It was a private, locally owned business. It was located at 209-215 Merri Street, Warrnambool, on the land, which is just west of the later-built railway station. The first managers of the Gas Company lived in a substantial stone house on site, but later the managers lived in a residence in Henna Street between Merri and Timor Streets. The original home, which still stands, became a residence for the Railway Station Master from about 1890. In August 1874 the construction of the gasworks was complete and at the end of that month gas was supplied to all of the existing lamps in Warrnambool for the first time. The Warrnambool Gas Company wound up in 1880-1881 and was purchased by the Warrnambool Borough Council with money raised by a loan – the Borough’s first ‘loan transaction’. The Council established a piped network to supply gas to other street connections. The gasworks were privatised and upgraded in 1952. In 1972 the town supply was converted to liquid petroleum gas and by the early 1980s the gasworks were closed down. In 1986 Warrnambool was supplied with natural gas from a site near Port Campbell. The Warrnambool gasworks supplied all street and shop lighting and most domestic lighting until 1923 when electricity was available for lighting. Bromfield Street in Warrnambool was named after the director of the gasworks, James Astley Bromfield (1823-1903). He arrived in Warrnambool from Worcestershire, England, in 1852 and was very active in the local council and community. Cockman Street was named after the first secretary of the gasworks in 1874, Walter Cockman (c.1821-1892). He was a Mayor and businessman. The second Manager, Luther Rodgers, worked for the gas company for about twenty years and both Rodger Place and Rodgers Road in Warrnambool have been named after him. LAMP LIGHTS IN MELBOURNE In the 1820s Melbourne's innkeepers were legally required to have a lamp light outside their premises from sunset to sunrise. This was the first instance of street lamps being used in Melbourne. In 1847 the first oil lamp was used in the city. In 1849 a gas lamp was installed on the Swanston Street Bridge and much of the city had oil lamps installed by then. In August 1857 the installation of street gas lamps began in Melbourne. They were welcomed for the much brighter illumination they gave. By 1860 there were 414 lamp pillars. The phrase was quoted often - "A light was as good as a policeman". The first gas burners used for street lighting were called 'fishtail' gas burners. These were replaced in the early 1900s by gas mantles. The City of Melbourne Gas Coke Company was formed in 1850 but due to the Gold Rush the manufacture and distribution of the gas supply was delayed until January 1856. By the 1890s the gas supplying the lights was supplied by three companies in Melbourne. In 1879 a football match was played at the MCG under electric lighting and gradually electric arc lights were installed inside and outside buildings in the city. Lamp lights such as the one in Flagstaff Hill’s collection were no longer needed. (References: John Lindsay re Lamp Light history 2019-01-29, Former Warrnambool Gas Company Limited, Victorian Heritage Database Report, Heritage Number 149746 https://vhd.heritagecouncil.vic.gov.au/places/149746/download-report ) The lamp light is representative of the lamps used in Melbourne from the mid-nineteenth century to light the streets at night and make Melbourne a safer city. The lamp is also representative of the gas street lighting in Warrnambool from the mid-1870s-1920s.Lamp light or gas light. Street light, one of the last gas street lights removed from Melbourne. (Reconditioned by Friends of Flagstaff Hill, 2013)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lamp light, gas light, gas lamp, street lamp, street light, gas street light, melbourne street lighting, warrnambool street lighting, melbourne gas street light, warrnambool gas company, warrnambool gasworks, james bromfield, walter cockman, luther rodgers, city of melbourne gas coke company -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Blowtorch 'Sievert', 20thC

... ", a wick oil lamp with a mouth-blown tube alongside the flame... and silversmiths. They began literally as a "blown lamp", a wick oil lamp ...A blowtorch or blowlamp is a fuel-burning tool used for applying flame and heat to various applications, usually metalworking. Early blowlamps used liquid fuel, carried in a refillable reservoir attached to the lamp. Modern blowtorches are mostly gas-fuelled. The blowlamp is of ancient origin and was used as a tool by gold and silversmiths. They began literally as a "blown lamp", a wick oil lamp with a mouth-blown tube alongside the flame. This type of lamp, with spirit fuel, continued to be in use for such small tasks into the late 20th century. In 1882, a new vaporizing technique was developed by Carl Richard Nyberg in Sweden, and the year after, the production of the Nyberg blow lamp started. It was quickly copied or licensed by many other manufacturers. Carl Richard Nyberg (May 28, 1858, – 1939) was the founder of Max Sievert’s Lödlampfabrik, then one of the largest industries in Sundbyberg, Sweden. After school he started working for a jeweller and later he moved to Stockholm and worked with various metalworks. 1882 and set up a workshop at Luntmakargatan in Stockholm making blowtorches. However the business didn't work well because it took too long to both manufacture and sell them. In 1886 he met Max Sievert (1849 - 1913) at a country fair and Sievert became interested in Nyberg's blowtorch and started selling it. In 1922 the company was sold to Max Sievert who continued to own it until 1964 when it was bought by Esso. The blowtorch is commonly used where a diffuse high temperature naked flame heat is required but not so hot as to cause combustion or welding: soldering, brazing, softening paint for removal, melting roof tar, or pre-heating large castings before welding such as for repairing. It is also common for use in weed control by controlled burn methods, melting snow and ice from pavements and driveways in cold climate areas, road repair crews may use a blowtorch to heat asphalt or bitumen for repairing cracks in preventive maintenance. It is also used in cooking; one common use is for the creation of the layer of hard caramelised sugar in a crème brûlée. A brass blowtorch, 'Sievert' with a wooden handleSIEVERTtools, blow torches, blow lamps, welding, brazing, jewellery, cookery, soldering, nyberg carl, sievert max, stockholm, sweden, spirit fuel, kerosene, gas fuel, moorabbin, bentleigh, cheltenham, market gardeners, pioneers, early settlers, plumbing, carpenters, -

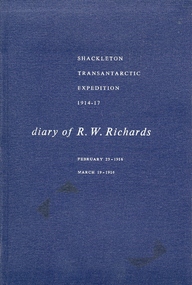

Federation University Historical Collection

Federation University Historical CollectionBook, Diary of R.W. Richards, c1960

... oil from the lamps on the paper. Heather was told that Dick... oil from the lamps on the paper. Heather was told that Dick ...Dick Richards was a member of the Shackleton Trans Antarctic Expedition Ross Sea Shore Party. He later became Principal of the Ballarat School of Mines. The text for this book was typed by Ballarat School of Mines librarian Heather Durant, who remembered that at times it was difficult to read the writing due to whale blubber oil from the lamps on the paper. Heather was told that Dick Richards only started keeping the diary when ther became a chance the Ross Sea Shore Party may not survive. Heather remembered Dick Richards affectionately - he always carried a pipe and called her 'girlie'.Blue hard covered book of 14 pages. It is the verbatim copy of the diary kept by Dick Richards from 23 February 1916 to 19 March 1918, during the Shackleton trans-antarctic Expedition 1914-17.Bookplate inside cover - "Ex Libris School of Mines and industries. Presented by Mr R.W. Richards"ballarat school of mines, dick richards, r.w. richards, antarctica, shackleton, heather durant, diary, bookplate, ballarat school of mines bookplate, scott's hut, richard w. richards -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Lamp, Bradley & Hubbard, Early 20th century

... by the Standard Oil Company. The lamp’s huge appetite for fuel meant... kerosene lamps one can find in the USA and Canada is the Rayo ...One of the most common centre draft kerosene lamps one can find in the USA and Canada is the Rayo. Large and sturdy, simple to use, but also notorious for being a fuel hog. This lamp was made by Bradley and Hubbard Metalworks in Chicago also Bradley and Hubbard made the “Perfection” brand lamps that look like the Rayo and are pretty much the same lamp with all parts interchangeable. The Rayo was given away to customers for free as a promotional item by the Standard Oil Company. The lamp’s huge appetite for fuel meant a hefty increase in sales of kerosene for the company and increased profits. The Rayo is a classic centre draft lamp that uses a widely available tubular wick that measures 62mm flat. It employs a simple and reliable mechanism for securing wicks in the burner along with a brass tube with many small teeth at its end. The tube is attached to the toothed rack that’s moved up and down by the adjuster knob. This type of lamp was used in most households and on rural properties before the introduction of electricity and is an early example of a promotional. The lamp was given away to customers of Kerosene oil as a means of increasing the Standard Oil Company sales of Kerosene during the late19th to early 20th century.Kerosene Lamp, side lifting arm to light.Inscribed "Rayo" and "Made in the USA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kerosene lamp, lighting, hurricane lamp, storm lamp, rayo ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Lamp, Bradley & Hubbard, Early 20th century

... by the Standard Oil Company. The lamp’s huge appetite for fuel meant... kerosene lamps one can find in the USA and Canada is the Rayo ...One of the most common centre draft kerosene lamps one can find in the USA and Canada is the Rayo. Large and sturdy, simple to use, but also notorious for being a fuel hog. This lamp was made by Bradley and Hubbard Metalworks in Chicago also Bradley and Hubbard made the “Perfection” brand lamps that look like the Rayo and are pretty much the same lamp with all parts interchangeable. The Rayo was given away to customers for free as a promotional item by the Standard Oil Company. The lamp’s huge appetite for fuel meant a hefty increase in sales of kerosene for the company and increased profits. The Rayo is a classic centre draft lamp that uses a widely available tubular wick that measures 62mm flat. It employs a simple and reliable mechanism for securing wicks in the burner along with a brass tube with many small teeth at its end. The tube is attached to the toothed rack that’s moved up and down by the adjuster knob. This type of lamp was used in most households and on rural properties before the introduction of electricity and is an early example of a promotional. The lamp was given away to customers of Kerosene oil as a means of increasing the Standard Oil Company sales of Kerosene during the late19th to early 20th century.Kerosene Lamp, side lifting arm to light.Inscribed "Rayo" and "Made in the USA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kerosene lamp, lighting, hurricane lamp, storm lamp, rayo ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Kerosene Lamp Burner, Bradley and Hubbard Manufacturing Company, Late 19th to early 20th century

... for the demise of whale oil as lamp fuel. Soon after Colonel Edwin Drake... and early 1860s paved the way for the demise of whale oil as lamp ...Bradley and Hubbard established their company in 1852 in Meriden, Connecticut when Nathaniel and William Bradley, Orson and Chitten Hatch, and Walter Hubbard, formed Bradley, Hatch & Company. This incarnation of the company only manufactured clocks. The Hatch brothers sold their interest in the company in 1854 and it was renamed, Bradley & Hubbard. Clocks remained the firm's primary product into the 1860s. In addition to their line of clocks, Bradley & Hubbard also produced a wide range of household items including match safes, call bells, andirons, urns, bookends, frames, desk accessories and vases. Technological advances in drilling and refining crude oil in the late 1850s and early 1860s paved the way for the demise of whale oil as lamp fuel. Soon after Colonel Edwin Drake struck oil in Titusville, Pennsylvania on August 27, 1859, Nathaniel Bradley saw an opportunity to capitalize on the future of this new fuel. Nathaniel decided to produce an extensive line of kerosene burning lamps this proved to be a wise business decision. Kerosene was soon to become a widely used, safe and relatively inexpensive lamp fuel. Between April 7, 1868, and December 23, 1913, the company was listed as the assignee for at least 89 lighting patents. Many of these patents were for lamp and chandelier designs and various improvements in lamp burners. In 1875 the company reorganized to form the Bradley and Hubbard Manufacturing Company. Walter Hubbard served as President and Nathaniel Bradley as Treasurer. The firm enjoyed rapid growth throughout the 1880s. By 1888, the company employed over one thousand workers and had showrooms in major cities including New York, Philadelphia, Boston and Chicago. One of the most prolific of the B&H products was the Rayo lamp it produced under contract for Standard Oil. In keeping with the changing times, Bradley & Hubbard produced a variety of electric lamps as well. Walter Hubbard passed away in 1911 and Nathaniel Bradley in 1915. The company continued through the 1930s and was purchased by the Charles Parker Company, also of Meriden, Connecticut, in 1940. The Parker Company was quite diversified in its product line, also producing an extensive line of lamps and high-end chandeliers. Parker operated its acquisition as the "Bradley & Hubbard Division." Parker ceased production of the Rayo lamp in the early 1950s. In 1973, the Bradley and Hubbard buildings were demolished, effectively ending that chapter in American lighting manufacture.Early innovation in kerosene lamp burner design by Bradley and Hubbard lamp manufacturers who at the turn of the 20th century were the biggest lamp producers in the world. The item is significant due to its historic connection with a major innovator of lamp design.Lamp Burner, metal container with turning screw for wick and mesh walls. Is made in 2 parts. Raised embossing on wick adjustment screw " PAT APPLIED FOR" on top of burner "B & H Patented.July.1.90.Nov.20.94"flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bradley & hubbard manufacturing company, kerosene lamp burner, early lighting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Murweh Carriage, c.1874

... . The carriage could have been illuminated by oil or carbide lamps placed.... The carriage could have been illuminated by oil or carbide lamps placed ...This private late-nineteenth-century four-wheeled carriage has been built to transport a family or group of passengers with a coachman in the front seat. It can be pulled by one horse, or by two horses if the T-pole is attached. The button fittings along each side of the carriage indicate that a folding roof or hood was once attached. The frame across the front of the carriagewas likely to have been a ‘dashboard’ with a leather or wood covering to prevent water, mud and other particles from splashing onto the passengers. The rear step between the two side-facing bench seats is adjustable to allow for ladies’ long skirts. These rear seats appear to be removable, in which case the carriage could be converted to a wagon to transport goods and equipment. The carriage could have been illuminated by oil or carbide lamps placed into the lamp holders on the sides. The carriage was kept under cover for many years in an open-front sandstone building that also included living quarters and an area that may have been stable. It was at ‘Murweh’ a Warrnambool property at 203 Liebig Street. The home is now Heritage and National Trust Listed and described as a ‘gentleman’s residence’. It was built by James Wotton Shevill in the 1860s. Shevill was a councillor from 1875 to 1878, serving in 1878 as Mayor of the Borough of Warrnambool. Jeremiah Wade lived at Murweh there from 1879-1880. By 1915 F.B. Whitehead and his family were living there, and by 1930 the address was used by Mr T.J. Rome and his family. Thomas James Rome was still using that address in September 1973 after his 100th birthday. It is believed that one of the property’s owners had been an Obstetrician in Warrnambool. The current owner re-told the story that children used to hide in the back section of the carriage and smoke, hidden from the sight of onlookers. He had heard the story from a previous owner.The well-appointed horse-drawn four-wheeled carriage is likely to have first belonged to a local councillor and past Mayor of the town of Warrnambool, J.W. Shervill, whose 1860s city property was the carriage location for many years. The carriage is a rare local example of a town-based lifestyle befitting a prosperous personality of the late 19th century. It adds to the story of Warrnambool's development as a town influenced by the port, wealth gained from shipping and the home place of prominent local people such as the Councillor and later Mayor. The side-facing rear seating is unusual for a passenger carriage. It has the feature of removable rear bench seats, allowing for the dual purpose of a carriage or wagon.Carriage; the Victorian-era horse-drawn four-wheeled open carriage has a coachman’s bench seat across the front and two side-facing bench seats in the rear. There are steps at the front on each side and a centre adjustable step and the back. It has a hinged shaft, two lamp holders and a separate T-pole. The bench seats have padded backrests upholstered in green leather and each has padded armrests at the ends. A rectangular metal frame, likely to have been a dashboard, is mounted across the front of the carriage. It has two inner vertical bars. The carriage's body is painted dark green with crimson highlights on some of the panelling. Decorative oval panels with hand-painted motifs are mounted along the sides. The side panels of the carriage have metal fastener buttons attached. The iron-rimmed wheels have sixteen wooden spokes and copper cuffs on the outside of the hubs, and the rear wheels are higher than the front wheels. Wooden brake blocks are mounted onto the back wheels and are active by a metal lever at the front right side of the carriage. The undercarriage is fitted with leaf springs on each side, mounted from front to back axles. Included are: (1) The separate T-pole that allows two horses to be harnessed to the carriage (2) Leather horse winkers with metal hardware and oval brass plate on the side of each winkerMotif painted on an oval panel [a musical lyre within a blue floral wreath flanked by scrolls] flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, murweh, buggy, cart, carriage, wagon, horse-drawn vehicle, victorian buggy, four-wheeled carriage, coachman’s seat, bench seat, side-facing benches, upholstered seats, victorian decals, heritage vehicle decoration, antique hand painting, hand painted decals, motifs, iron-rimmed wheels, wooden brake blocks, leaf springs, t-pole shaft, rear step, equine carriage, 19th century vehicle, victorian transport, transport, gentleman’s vehicle, james wotton shevill, councillor, mayor, jeremiah wade, f.b. whitehead, thomas james rome, warrnambool obstruction, warrnambool genealogy, warrnambool pioneers, victorian carriage, one horse carriage, two horse carriage, horse drawn carriage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... used, distilled in liquid form, as an oil to fuel lamps... form, as an oil to fuel lamps. The main American whaling port ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... used, distilled in liquid form, as an oil to fuel lamps... form, as an oil to fuel lamps. The main American whaling port ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... used, distilled in liquid form, as an oil to fuel lamps... form, as an oil to fuel lamps. The main American whaling port ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined