Showing 93 items

matching power tools

-

Federation University Historical Collection

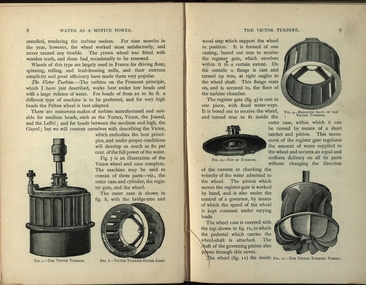

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Flagstaff Hill Maritime Museum and Village

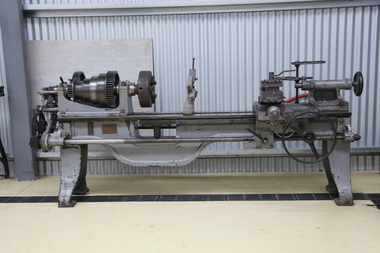

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Plane, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will named his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard's estate when he died in 1856. From John's will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool-making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield.A vintage tool made by a well-known company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items.Jack Plane metal body with rose wood filler.Mosley & Sons London No 2flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john moseley & son, jack plane, woodworking tool, carpenders tools, cabinet makers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Saw, Mid to late 20th century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone. The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, as the maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture around the mid to late 20th century.Wood hand saw with wooden handle attached to saw by 4 rivets. No blade markings Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, handsaw, wood saw, carpenders tools, cabinet makers tools, wood cutting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Federation University Historical Collection

Federation University Historical CollectionElectrical Instrument, Stanley Router, Estimated 1940s

Used at Ballarat School of Mines Building Studies, Yuille Street, Ballarat. This probably in the 1960s. It was sourced from David Flintoff. Steel cased electric motor, two wooden handles, power cord and spannerUpper Plate: STANLEY ELECTRIC TOOLS; Type H39; Model B; Serial No. CT 4887 Lower Plate: STANLEY H-13-B; US Pat. - 2562143stanley router, electric router, ballarat school of mines, building studies, david flintoff -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw, Mid 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw blade with wooden with open handle blade attached with wingnut lever at side to adjust long narrow blade Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - WAGES, PRICES & STAMP HEADS

Handwritten notes detailing the wages per week S'hurst year 1868, from boys to the General Manager. Also prices for tools, rope, chain, powder, candles, oil, tallow, quicksilver, leather, cleaning and packing materials, and iron and steel. Also mentioned is the weight of the stampers, their cost, the height they fall, the number of strokes per minute, the number of holes in the gratings, the horse-power to drive each stamper, the quantity of water used per stamp-head in crushing and the quantity of mercury used in the ripples per stamper and the quantity lost per stamp head per week.document, gold, mining reports, mining reports, wages prices & stamp heads, goldfields & mineral districts of victoria, r brough smyth 1869, sandhurst goldfield 1868 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BROADCASTING STATION 3CV, MARYBOROUGH, 2 March, 1956

Broadcasting Station 3CV, Maryborough. A souvenir of the opening of the New Studios and Offices of Central Victoria Broadcasters Pty Ltd. March 2nd, 1956. Established 1956, offices in Burke Street, opening coincides with the stations 21st birthday, March 2 for the former celebration, October 26 for the latter. Coverage included Bendigo, Ballarat, Daylesford, Castlemaine and Maryborough. 3CV plays active part in assisting charities and hospitals at Maryborough, Daylesford, Maldon and Dunolly. Active Women's Radio Club with branches in country centres adds strength to station's charitable efforts. Opening 3CV's new premises will widen the scope of the station's charitable efforts, and stronger link with Australian Commercial Broadcasting stations. Writer Harold V Nunn writes history of district of Mayborough. Manager Ken J Parker, Central Victoria Broadcasters Pty. Ltd. The Souvenir brochure also covers topics such as: deep lead mining. WWI. Houses being pulled down. New settlements of Mildura. Secondary Industries. Bowenvale, Alma, Majorca, Craigie, Amherst, Adelaide Lead, Havelock, Bet Bet, Bently. Primary production and a railway staff of approximately 150. Maryborough a little town without a future. Coal fields at Wonthaggi. 1917 a public meeting was convened in an effort to stem the tide of adversity. Mayor George Frost, M.L.A., decision to form a Progress Association, a policy of secondary industry was decided upon and committees were appointed, James L Drew much credit is due. Maryborough's move for rejuvenation was revolutionary, because apart from Ballarat, Bendigo and Geelong, it was regarded as so much presumption that industry could be expected to function with success in a country town. Governments were unsympathetic. Maryborough & district people showed determination to succeed and their faith in their town. Employment and economic security provided by the industries outweighed the debt. Maryborough's general position is that it is no longer dependent upon one particular phase of activity. The first of the industries to be formed in 1918 was the Butter Factory. The nearer dairy companies did not take kindly to the prospect of another opposition company taking supplies from their districts, and in the first few years of establishment completion made the going hard for the management. But adopting a conservative policy and placing all profits to reserve I the first six years of operation headway was gradually made. Thus it was a red letter day for the company in 1925 when the first dividend of 5 percent was paid.1955 dividend of 10 per cent. Operating it's own trucks the dairy serviced local dairymen up to 40 miles. Maryborough Knitting mills est. 1923, having transferred from Clunes. Out bid Ballarat and Bendigo to the industry. The mill has what is probably the largest circular underwear plant in the Commonwealth, which is conservatively valued at 198,913 pounds. It produces between four and five million garments each year, worth over one million pounds. The company has established subsidiary mills at Dunolly, Talbot and Avoca. The company also assisted in the establishment of the Interknit Hosiery Co. Ltd., Clunes. The Maryborough Flour Mills is the second oldest of Mayborough's industries. It was built by Mr Cadwallader over 70 years ago. It was later sold to Mr. A Land and then to Jas. Minifie & Co. It had a somewhat 'in-and -out' existence until purchased in 1923 by Messrs. Willersdorf and Forbes, of Eddington. In 1939 the firm began to build silos for the storage of bulk wheat and the present storage capacity is 100,000 bushels. 1944 power was changed from steam to electricity. The mill has an out put of 20 sacks an hour. 1938 a chaff mill was built, and now is regarded as one of the best in Victoria. Its output in one year of approximately 6,800 tons is a State record for a single cutter. During this 30 year period Patience and Nicholson Limited has grown with Maryborough and is now one of the major key industries of Australia. The P&N brand covers precision tools - taps, dies and twist drills - indispensable to the country's economy, and quality is acknowledged equally by an air craft factory in Canada, a dockyard in Thailand, a railway workshop in New Zealand, no less than by our own Australian industries. Maryborough can be proud of the part played by P&N in war when, geared to the needs of the times, it poured countless millions of tools into defence factories and to the armed forces of the Allies, and now in peace when it is providing, hydro-electric undertakings and the manufacture of cars and tractors. From 1858, W Phelan & Sons Pty Ltd has made phenomenal and spectacular growth, becoming incorporated as a private company in 1929. It is without doubt the greatest private development in the history of Maryborough. 1940 joinery manufacture was commenced. The company entered the Ready Built Housing field in `950 - and in 1951 established a factory at Cairns, Northern Queensland to overcome the manufacturing difficulties being experienced due to the shortage of plywood in Victoria. Present activities include: Ready Built Housing Factory, on-site building, a modern joinery, timber yard, drying kilns, etc., and plumbing & electrical & engineering services, a door and panel factory at Cairns, retail hardware store, Melbourne Sales Depot. Hedges & Bell Pty Ltd were est 1945, with a staff of 40 employees are the largest printing firm outside the metropolitan area. The branch of Premier Wireworks is a contribution made by the decentralisation policy of the State.event, official, celebration, broadcasting station 3cv, maryborough. a souvenir of the opening of the new studios and offices of central victoria broadcasters pty ltd. march 2nd, 1956. established 1956, offices in burke street, 21st birthday. coverage bendigo, ballarat, daylesford, castlemaine maryborough. assisting charities and hospitals maldon and dunolly. women's radio club opening 3cv's new premises australian commercial broadcasting stations. writer harold v nunn writes history of district of mayborough. manager ken j parker, central victoria broadcasters pty. ltd. souvenir brochure: deep lead mining. wwi. houses pulled down. new settlements. primary production railway staff. coal fields wonthaggi. 1917 a public meeting was convened in an effort to stem the tide of adversity. mayor george frost, m.l.a., form a progress association, policy of secondary industry, james l drew rejuvenation was revolutionary, employment and economic security. the first of the industries to be formed in 1918 was the butter factory. thus it was a red letter day for the company in 1925 when the first dividend of 5 percent was paid.1955 dividend of 10 per cent. operating it's own trucks serviced local dairymen. maryborough knitting mills est. 1923 largest circular underwear plant in the commonwealth. established subsidiary mills at dunolly, talbot, avoca. interknit hosiery co. ltd., clunes. the maryborough flour mills it was built by mr cadwallader. mr. a land jas. minifie & co. messrs. willersdorf and forbes, build silos for wheat storage capacity is 100, 000 bushels. 1944 power was changed from steam to electricity. 20 sacks an hour. 1938 a chaff mill was built, best in victoria. patience and nicholson limited the p&n precision tools - taps, dies and twist drills. war, geared to the needs of the times, countless millions of tools into defence factories the armed forces of the allies, hydro-electric undertakings and the manufacture of cars and tractors. from 1858, w phelan & sons pty ltd, incorporated 1929. 1940 joinery manufacture. ready built housing field in 1950 - 1951 established a factory at cairns, northern queensland to overcome the manufacturing difficulties being experienced due to the shortage of plywood in victoria. present activities: ready built housing factory, on-site building, a modern joinery, timber yard, drying kilns, etc., and plumbing & electrical & engineering services, a door and panel factory at cairns, retail hardware store, melbourne sales depot. hedges & bell pty ltd were est. 1945, with a staff of 40 employees are the largest printing firm outside the metropolitan area. the branch of premier wireworks is a contribution made by the decentralisation policy of the state. -

Puffing Billy Railway

Puffing Billy RailwayLathe - Gap Bed, early 1900s

Possibly ex Victorian Railways Newport workshops Supplied by Bevan & Edwards Machinery Merchants, Melbourne Sebastian Lathes Described by its makers as the Utility School, Garage and Repair-shop Lathe, the machine immediately below, a Sebastian 15" (circa 1910 - 1926) was the Company's cheapest offering and, in its basic form, lacked a compound slide rest, the tailstock did not set over for taper turning and the bed lacked a gap. However, a friction-type countershaft unit was included in the price as well as a tool post, faceplate, drive plate, changewheels for screwcutting and a small tool kit. As with modern cars (especially BMW) everything worthwhile was on the options' list and by spending more it was possible to specify all those small but important extras. Although in its lowest-cost form this model was reduced to the fundamentals required for a useable, screwcutting centre (engine) lathe it was still reasonably specified and would certainly have fulfilled many requirements when installed in a school or training workshop. The true swing was 15.25", it was properly backgeared and screwcutting was through a conventional tumble-reverse mechanism that allowed both left and right-hand powered movement to the carriage by altering the position of just one lever. As standard it accepted 40" between centres, but any capacity could be ordered, in foot intervals, up to a maximum of 88" - when it is hoped that a central bed support might have been included …… The spindle, which ran in white-metal bearings, had a useful 15/8" hole and a No. 3 Morse taper centre. Some models appear to have had the leadscrew clasp-nut lever on the right-hand side of the apron, while on others it was positioned to the left.. Early Sebastian 13-inch lathe Typical of the Centre or "Engine" lathe made by many manufacturers from the late 1800s until the late 1930s, the basic flat-belt drive Sebastian, with separate countershaft, was eventually relegated to the economy end of the Company's range by the introduction of geared headstocks and self-contained motor-drive systems.Historic - Industrial Machinery - Gap Bed Lathe - Possibly ex Victorian Railways Newport workshops - Purchased and supplied from Bevan & Edwards Gap Bed Lathe - Grey with raw steel parts and a timber cupboard with gears and tools. Bevan & Edwards PTY,LTD Machinery Merchants Melbourne (possible government tag) 365bevan & edwards pty,ltd machinery merchants melbourne, puffing billy -

Chelsea & District Historical Society Inc

Chelsea & District Historical Society IncTool - Fuse Wire, lindsay electrics, Lindsay White Electrics, Electrical Contractor, 7 Ruvina Street , PO Box 8, Mordialloc, 3195 PH: 90 2409, C 1940's

donated by lindsay electrics from aspendale item shows how electricians had to repair power boards within the home one had to take out the old fuse which was installed on power board, fuse was made of ceramic, and then rewire object significant is that this is now a unique sample of how our home were wired for home and industryfuse wire on paper mountlindsay white electrics electrical contractor in industrial or domestic installations if this wont fix your trouble phone us for expert sevice 8 amp light fuse 15 mp power fuseelectrical/electrics, contractor, domestic/industrial -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Mortising Tool, Axe

... and power equipment Timber tools Mortising Tool Axe Mortising Tool ...A mortising tool is a specialist axe designed for hewing sills and cutting notches in timber. It has a long, narrow head, making it easier to work on large logs. The shape enables the user to cut a long way down into the notch, where otherwise a chisel would be used. Example of a common bush woodworking tool used before the advent of chainsaws and power equipmentMortising Tooltimber tools -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Mortising Tool, Axe

... and power equipment Timber tools Prades Co Solid Steel Mortising ...A mortising tool is a specialist axe designed for hewing sills and cutting notches in timber. It has a long, narrow head, making it easier to work on large logs. The shape enables the user to cut a long way down into the notch, where otherwise a chisel would be used.Example of a common bush woodworking tool used before the advent of chainsaws and power equipmentMortising Tool, AxePrades Co Solid Steeltimber tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Pamphlet, Stanley-Titan Pty Ltd, 1960s?

Hand tool catalogue.Hand tool catalogue: wood chisels, auger bits, eyed augers, machine bits, masonry drills, linoleum or leather knives, handsaws, plane irons, woos screw pilot bits and flat power bits.Hand tool catalogue.stanley-titan pty ltd, woodworking tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Fuse wire, c1950

Fuse wire loops on cardboard card which has John March & Con P/L Electricians, marked.Fuse wire card - Controlled vehicles, City and suburbs/ Immediate breakdown service, Electricians, Est 1906. John March & Co P/L, 43-45 Hancock St. Sth Melb. Light, ring 697422, Power, Prompt Personalised Attention. Installations & alterations, Australia's Oldest Electrical Contractors.electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sledge Hammer, c1940

... blacksmithing 1791 12 lbs Brales Co Made by a power hammer. Solid Steel ...Made by a power hammer. Solid Steel.1791 12 lbs Brales Corural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Stanley Works Pty. Ltd, 1972

In 1970,Stanley Works took over toolmakers, Turner Manufacturing Company, who were situated in Whitehorse Road, Nunawading. Stanley Works Pty Ltd, shut their doors in 1993Coloured photograph of the head office at Stanley Works Pty. Ltd, Nunawading Circa 1972. Yellow Stanley sign on the roof. Cars parked in front of building. Power pole an left.stanley works pty. ltd, tools, manufacturing industry, turner manufacturing company -

Ballarat Tramway Museum

Ballarat Tramway MuseumMagazine, K. V. Newmann and MMTB Public Relations Officer, "MMTB News", 1965

Eight issues of "MMTB News" - The Magazine of the Melbourne and Metropolitan Tramways Board. Two copies of each issue. Second copy added 31/8/2004. All issues printed with an off-white gloss paper cover with the rest of the magazine white glass paper. 2719.1 - Vol. 2, No. 1 - 16 pages, January 1965, with a photo of the Board meeting in the Board room of the MMTB, notes or articles on traffic congestion, a short history of public street transport in Melbourne, TMSV tour of 7/2/1965 with PCC 980, and" Some Views on Public Transport". 2719.2 - Vol. 2, No. 2 - 16 pages, February 1965, with a photo of Dusseldorf 3 section tramcar on the front cover, notes on the costs of concessions, press visit to the Carlton Power control supervisory centre, "Melbourne - 1985", Mark VI buses, tool safety, "Staggered Working Hours", hydro-foil on Sydney Harbour, "Traffic Congestion". 2719.3 - Vol. 2, No. 3 - 12 pages, March - April 1965, with a photo of W7 1012 and bus 751 on the front cover, notes or articles on "New Trams for Melbourne", retirement of D.H. Eakin, "Traffic Congestion", "Tramway buses at the Gippsland Fires", The Australian Good Neighbour movement. 2719.4 - Vol. 2, No. 4 - 16 pages, May - June 1965, with a photo of L 101 at West Maribyrnong terminus during an Association of Railway Enthusiasts tour (photo Robert Wilson), notes or articles; "A Motorist Speaks Up for Trams", "Tramways Hospital a Major Benefit", parking in the central city, tramway ambulance, "Radio Control is Human Nerve Centre", staff shortages, retirement of Mr. Stan Bowen, the ARE Tram Tour, and Port Melbourne Tramways Social Angling Club. 2719.5 - Vol. 2, No. 5 - 16 pages, July 1965, with a photo of the Doncaster Bus depot on the front cover, articles or notes; Freeways, Public Transport, Decimal conversion, Doncaster Bus depot, Melbourne in twenty years, Engineering Department - Bus branch, visit of Mr Ken Hall and Frank Kirby overseas to study new trams. 2719.6 - Vol. 2, No. 6 - 20 pages, August September 1965 with a photo of W6 921 being lowered at Preston Depot, with notes or articles; an abridged version of an address by R. J. Risson to the Constitutional Club in Melbourne, lost items on trams, Bus Engineering, and social or sporting club news. 2719.7 - Vol. 2, No. 7 - 16 pages, October - November 1965 with a photo of PCC 980 on the front cover, notes or articles on; free travel for USA City shoppers, safety, Stores Department printing section, Ballarat's Tramways Diamond Jubilee - TMSV tour to Ballarat on 15/8/1965 including two photos, PCC 980, Christmas functions, retirement of Arthur Wisdom and Bill Wallis. (Reference photos Reg. Item - 1877). See btm2819i9 for image of the article re the TMSV Tour to Ballarat. 2719.8 - Vol. 2, No. 8 - 16 pages, December 1965 with a photo of cable car set No. 1 on the front cover with notes or articles; Children's art show, "Quest for New Tram", "The Development of Melbourne's Trams" and sporting or social club news. Has a Christmas message from Chairman, Mr. Risson with photograph.Each issue has stamped on the front cover or inside "The Australian Railway Historical Society (S.A. Branch).trams, tramways, mmtb, carlton control, buses, pcc 980, ballarat, new trams, are, tmsv -

Ararat Gallery TAMA

Ararat Gallery TAMAMixed media, Inga Hunter, Nrat-tuan Net Leader's Robe, 1986-1989

“A silver-grey robe, denoting a powerful official. The Netleader, or Netmaster, as he is sometimes called is head of one of the many craft guilds on Nrat-Tuan. Fishers Guilds are not only vital economic groups for Nrat-Tuan, but also for the whole Imperium, since the water planet is the major source of foodstuffs for Irusaqu, who cannot produce enough crops on what Is a relatively barren, planet. The various fishing crafts are most responsible occupations, entailing great care for the environment and the food chains. Fishing is carried out by means of either mirrors or nets, both being about equally popular. Mirror-faceted fabrics have always been used by Nrati-Tuan fishermen to dazzle and bemuse the creatures they are trying to catch, (the mirror may also have some predictive power). Research indicates that this odd technique is surprisingly effective. And the harvests are unfailingly good. Contact with the humans of Irusag, when the Imperium was first founded, brought the technique of netting to Nrat-Tuan. The Netleader heads the Netter Guild, which does not limit itself to the merely traditional fishing net, but works with a complex and sophisticated membrane technology, which has, in recent years, revolutionised the whole netting industry. The Master controls the experimental membrane laboratories, which deal with the extraction of metals from sea water, as well as with tools for the fishing industry.” -Inga Hunter -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - Hawthorn Tram Depot during construction, 1915

One of a series of photographs, taken by Edgar James Dower in the second decade of the twentieth century. Born and raised in Olinda, his family later moved to Surrey Hills. He worked as an adult as a clerk in the city office of the Metropolitan Gas Company, and in his role as a 'collector', he was able to photograph scenes including the construction of tramlines and associated buildings in Kew, Hawthorn, Camberwell and Surrey Hills. Later he established a real estate agency with his brother - the E.J. Dower Real Estate Agency, Dandenong Office.The image is an historically significant record of the development of transport infrastructure which was used to connect Victorians in the first two decades of the twentieth century. This development resulted from increases in population and the consequent extension of Melbourne's suburbs. The photographs, both individually and collectively, richly detail the labour of workers and the tools and machinery used to create and extend Melbourne's tram network in the years preceding and during World War 1.Two faded original horizontal photographs, mounted on vertical card showing external and internal features of the Hawthorn Tram Depot during its construction phase. The top photo shows a panoramic view of the exterior while the second photo shows workers posed within the building.Recto: "The tramways building in course of creation. C/r of Power St & Wallen Road, Hawthorn. Showing one of the original horse drawn trams which ran from Hawthorn Bridge to Auburn Road".. theme --- travelling by tram, theme -- connecting victorians by transport and communications, tramways -- hawthorn -

Kew Historical Society Inc

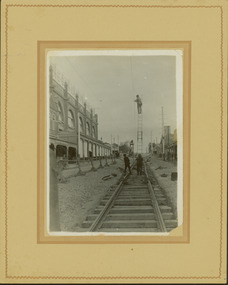

Kew Historical Society IncPhotograph - Construction of the electric tram line in Glenferrie Road, Glenferrie, E.J. Dower, 1914

One of a series of photographs, taken by Edgar James Dower in the second decade of the twentieth century. Born and raised in Olinda, his family later moved to Surrey Hills. He worked as an adult as a clerk in the city office of the Metropolitan Gas Company, and in his role as a 'collector', he was able to photograph scenes including the construction of tramlines and associated buildings in Kew, Hawthorn, Camberwell and Surrey Hills. Later he established a real estate agency with his brother - the E.J. Dower Real Estate Agency, Dandenong Office.The image is an historically significant record of the development of transport infrastructure which was used to connect Victorians in the first two decades of the twentieth century. This development resulted from increases in population and the consequent extension of Melbourne's suburbs. The photographs, both individually and collectively, richly detail the labour of workers and the tools and machinery used to create and extend Melbourne's public transport network in the years preceding and during World War 1.Digital copy of an original mounted photograph showing a worker standing on a ladder in Glenferrie Road, Hawthorn, working on the overhead electric cables that would be used to power trams on the New Kew tramline.Other railway workers are working on platforms or viewing the man on the ladder. The ladder appears to be only supported by one other worker. "The Don Store" at left is immediately behind the old railway level crossing which can be seen in the distance to the south.Annotated verso: "Preparing for electric trams in Glenferrie Road, near Glenferrie Station, showing railway gates / Taken by E.J. Dower 1914"theme --- travelling by tram, theme -- connecting victorians by transport and communications, glenferrie road -- hawthorn (vic.), railways -- hawthorn -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncCatalogue

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.Catalogue barnes motor + foot powered mach -

Clunes Museum

Clunes MuseumTool - PULLEY

This wooden pulley was used in mineshafts. The pulley is a wheel with a grooved rim inside a wooden frame for carrying a rope, turning in the frame and serving to change the direction of, or transmit power, as in pulling at one end of the line to raise a weight or object at the other end.USED IN UNDERGROWN MINING ON THE GOLD FIELDSWooden Pulley with ropes attached. Pulley has rope bound round outside to form a metal lined loop to attach to hook above and one lead reinforced loop to attach load to be lowered. The grooved wheel in centre of pulley houses the rope or to attach the load for transport.underground mining, mining tool, wooden pulley -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPlan, Power Tool Practical, 1980-1990

... Power Tool Practical... of construction work. Power Tool Practical Plan ...Tracing paper and paper copies of plan of where to put bolts and nails in a piece of construction work.tools, construction -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillTool - Pattern, ring gear

Used to make cast for the metal ring gear for the water wheel which powered the Mill.Slightly arched wooden pattern with wooden ridges along the edge. Three square metal plates with a hole in the centre, bolted on with four bolts. Ten pentagin pieces of wood attached to the face. -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hand drill mounted on wooden stand, Early to mid 20th Century

... of power tools. The construction of the basic wooden frame also ...This style of geared drill was commonly referred to as an egg-beater drill and was first patented in 1838. During the late 19th century these drills became more common due to the development of mass production. Users also began to mount the drill onto a frame. This allowed greater control over the drill and removed the need to be holding it in both hands. This gave the operater greater control over the item to be drilled. The drill could be easily removed when required. This item is an example of a domestic woodworking tool commonly used before the widespread use of power tools. The construction of the basic wooden frame also demonstrates the ingenuity of early pioneers and tradesmen in adapting tools to suit their own needs.A metal hand drill which has been mounted on to an improvised wooden stand. hand tools, mass production, egg beater drills -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPower Launcher

Used for planned burning operationsIncendiary Launcher in boxOtwaysforests commission victoria (fcv), planned burning, bushfire, hand tools