Showing 112 items

matching suppliers-chemical and equipment

-

J. Ward Museum Complex

J. Ward Museum ComplexEquipment - 'Electroshock Therapy' Machine, Konvulsator 2077, Post 1930's

Electroconvulsive therapy (ECT) was invented in Italy in the late 1930s. ECT is a medical treatment most commonly used in patients with severe major depression or bipolar disorder that has not responded to other treatments. Psychiatrists had already discovered that inducing seizures could relieve symptoms of mental illness. Before ECT, this was done with the use of chemicals, usually one called Metrazol. More can be read here: http://theconversation.com/electroconvulsive-therapy-a-history-of-controversy-but-also-of-help-70938 This machine was used both at Aradale Mental Hospital and J Ward. The object is significant because it is a well preserved instrument that illustrates the medical apparatus used at both Ararat Mental Hospital and J Ward for the treatment of mental illness.A metal instrument. The front contains three knobs, two switches, and power button. Two fully intact electrical cords - One leads to the paddles used on the patient: One used to attach to the electric source [power point]. Paddles are made of hard plastic and stainless steel metal. The back has a compartment where the paddles can be stored. The top has a carry handle.Manufacturer: Siemens Power supply: 220V 85AC, 50Hzmentalhealth, psychiatrichealth, depression, #bipolardisorder -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers,Shaving cream, J.B.Williams Co, mid 20thC

Shaving cream is a cream applied to the face, or wherever else hair grows, to facilitate shaving. The use of cream achieves three effects: lubricates the cutting process; swells keratin; and de-sensitizes skin. Shaving creams commonly consist of an emulsion of oils, soaps or surfactants, and water. James Baker Williams was born in 1818 in Lebanon, Connecticut USA and, in 1834, began employment with F. and H.C. Woodbridge, a general store located in Manchester. Williams was offered half-interest in the store in 1838, after which its name was changed to Keeny and Williams. Two years later, Williams sold his interest in the store, but retained his share in the drug department. He began experimenting with various soaps to determine which were best for shaving, and eventually developed Williams' Genuine Yankee Soap, the first manufactured soap for use in shaving mugs. In 1847, Williams moved his enterprise to a rented gristmill on William Street in Glastonbury, Connecticut, and his brother, William S. Williams, joined the firm around 1848, when the firm's name was changed to the James B. Williams and Company. William's shaving soaps were sold throughout the United States and Canada and James Williams supervised many aspects of the company until shortly before his death in 1907 at the age of eighty-eight. The Williams family continued to manage the company until it was sold in 1957. By the early 1900s, the company was known throughout the world. In addition to its line of shaving creams, the firm produced talcum powder, toilet soaps, and other toilet preparations. The original 1847 factory is still standing in Glastonbury and, in 1979, was converted into a condominium complex. I In 1983 it was placed on the National Register of Historic Places. 1927 - 1990 Salmond and Spraggon (Australia) Limited , Sydney , New South Wales, was registered as a company on 10 June 1927 following the liquidation of Salmond and Spraggon (Australia) Limited known as the Old Company. The company distributed household cleaning and mineral, metal and chemical wholesaling, pharmaceutical wholesaling throughout Australia on behalf of manufacturers. In 1990 the company was taken over by Alberto Culver, a manufacturer of hair and skin products. A clear glass jar with a screw lid containing 'Williams Shaving Cream' Front Label : J.B WILLIAMS / LUXURY / SHAVING CREAM Back Label : The contents of this jar are guaranteed to be / The J.B.WILLIAMS Luxury Shaving Cream Jar has been changed to meet the Wartime conditions but / the cream is of the same high quality / made in Australia for / J.B. WILLIAMS COMPANY / Glastonbury, Conn. U.S.A. / Vendors / SALMOND & SPRAGGON (AUST.) PTY.LTD. / All Statesshaving equipment, razors, safety razors, cutthroat razors, soap, world war 11 1939-1945, moorabbin, bentleigh, cheltenham, early settlers, shaving cream, williams j.b. company ltd, connecticut usa, glastonbury connecticut usa, salmond & spraggon pty ltd, sydney, new south wales, toiletries, shaving soap, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyConsole Telephone 10 shutter, circa early 1900s

This manual telephone exchange console is an important piece of equipment which provided the most efficient method of long distance communications in the 1950's to the 1980's. Communications were critical, not only for the regional Hospital, but also for large construction sites i.e. the Kiewa Hydro Scheme, especially if they are in dense rugged mountainous regions. The degree of Occupation Health and Welfare on industrial sites were at a bare minimum compared to the work scene after the 1980's.This telephone exchange console is highly significant to both the Kiewa Valley and Mount Beauty region because it was so important in the communications field relating to operational safety and work related controls. The success of any large undertaken relies heavily upon good communications. In the hospital this method of communications is still used i.e. patient to ward station. This flag system link a patient's room to the controlling nursing station. Identification of the patient needing help is crucial for swift action from the available medical staff. Similarly in large construction sites such as the Kiewa Hydro Scheme, successful instant communications was also essential. This switchboard required a 50 volt supply to successfully operate and was in use when both telecommunications and postal were under the one Federal Government carrier i.e. The Post Master General. A benefit with a line communication system (such as the one that fed this console was that interference from atmospheric conditions did not impede the connection.This console telephone switchboard (manual) unit has a shutter operation (precursor to the light indicator) to identify the caller to the telephone switchboard operator. This switchboard has a ten point indication shutter system allowing the operator to clearly identify where the caller is located. The console has a 44 connection point holes with their configurations in a triangular shape. The shutters are held closed by a small lever at the top which is opened by a small electrical charge from the incoming call. The operator uses a wind up handle to power a magneto connector(handle on the console's right side). The telephone hand set is located on the left side of the console. sec vic kiewa hydro scheme, alternate energy supplies, alpine population growth and communications -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTypewriter - Remington

The first typewriters were placed on the market in 1874.It includes both upper and lower case letters via a 'shift' key and has a QUERTY layout.Used by typists working in the office for the State Electricity Commission of Victoria during the construction of the Kiewa Hydro Electric Scheme.Large heavy typewriter. Rusty condition 1926 ? Metal frame with black paint"Remington" on the front above the keyys "Chartre? Business Service" suppliertypewriter, remington, office equipment -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBag Camera, circa 1920s

This item was manufactured in a period where the cheapest containers for portable equipment was canvas. The market place for cheap cameras was still restricted to European, England and its colonies. It was well before the post World War II explosion of the Asian manufacturing juggernaut.This item shows one of the most popular avenues of not only bringing new "modern" age equipment into the Kiewa Valley but also providing the local market with actual overseas inexpensive merchandise. It was a time when the new European fashion and "new age" equipment took years to permeate into regional Australia. The world, through Australia eyes, was still a very large planet and supply of "modern" lifestyle equipment emphasised the geographic isolation of Australia. Post World War II emigrants and an increasing flow of tourists to Australia provided the contact needed by rural settlements to open up not only their social contacts but lifestyle activities.Canvas, yellow, cream in color and with a weave pattern on the external side. It has stitched brown laminated fabric boarders containing all ends and corners. A flap opening top fastened on one side by a large press stud (15mm). A brown coloured leather carry strap (adjustable and 10mm wide) fasted at either of the longitudinal ends of the bag.camera, case photography, hobby, personal equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Caldwell’s Ink Factory, Late 19th to early 20th centuries

This design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a three-piece mould, a method often used in the late 19th and early 20th centuries, with the maker's name engraved into the mould section for the base. The glass blower would cut the bottle off the end of his blowpipe with a tool and join a mouth onto the top, rolling the lip. The bottle was then filled with ink and sealed with a cork. This method of manufacture was more time-consuming and costly to produce than those made in a simple two-piece mould and 'cracked' off the blowpipe. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. This particular bottle is unusual as it has four sloping indents at the corners of the shoulder, most likely for resting a pen with its nib upwards and the handle resting on a flat surface. Most of the bottles made during this era had horizontal pen rests that were indented into both of the long sides of the shoulder. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. This only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This hand-blown bottle is significant for being the only bottle in our collection with the unusual sloping pen rests on its shoulder. It is also significant for being made in a less common three-piece mould. The method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle is of state significance for being produced by an early Melbourne industry and exported overseas. This ink bottle is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottle; rectangular base, hand-blown clear glass bottle with its own cork. The bottle has side seams from the base to the mouth, an indented base and an applied lip. The corners of the shoulder sides have unusual diagonal grooves that slope down and outwards that may have been used as pen rests. Inside the bottle are remnants of dried blue-black ink. The glass has imperfections and some ripples on the surface. The bottle has an attached oval black label label with gold-brown printed text and border. The base has an embossed inscription. The bottles once contained Caldwell’s blend of blue black ink.Printed on label; “CALDWELL's BLUE BLACK INK” Embossed on the base "CALDWELLS"flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture, three part mould, cauldwells, cauldwell's -

Federation University Historical Collection

Federation University Historical CollectionInstrument - equipment, Mechanical Pinwheel Calculator, c1940, 1935-1945

Willgodt T. Odhner invented his very successful “pinwheel” four-function calculator mechanism in Russia in 1874, and his invention was cloned by numerous companies, resulting in dozens of similar models that remained in wide use for almost a century. Numbers are dialed into the sliding levers on the top part of the machine, and are added to the register visible in the carriage at the bottom when the large crank is turned. Shifting the carriage sideways allows multiplication through a sequence of addition operations; the two small cranks zero the registers. The design includes ingenious error-preventing interlocks between all the controls: should the operator fail to return a crank to its resting position, the other controls are frozen until this is corrected. A bell indicates calculations in the negative. Used in Ballarat Institute of Advanced Education (B.I.A.E) Physics department.Black, mechanical calculating machine. Metal. Hand-operated, with three hand-cranks. 10x10 rotor with 13 digit result. Ser. No. 29-286781.5 Black symotape on base front: "PHYSICS". Maker's identification on top surface. Supplier's label (metal, silver & blue) on back: "STOTT & HOARE Pty. Ltd. 171 William St. Melbourne C1 M1991". Stamped on rear panel: "MADE IN SWEDEN". Cast lettering on underside: "M-602 07".calculating machine, pinwheel, calculator, scientific instruments, stott & hoare pty ltd, physics, odhner, ballarat institute of advanced education -

Federation University Historical Collection

Federation University Historical CollectionInstrument - Scientific Equipment, Miner's Dial, c1893 - 1901

Used for surveying classes at the Ballarat School of Mines. Purchased/acquired during Queen Victoria's reign. The 1893 Ballarat School of Mines Calendar states that mine surveying instruments "always at the disposal of the students" including "one miner's dial".A surveying instrument consisting of theodolite with single crosshair(.1) mountable on a magnetic compass (.2), designed to sit inside a polished wood carry box. Serial Number 4470On suppliers label: "Instrument maker to the surveying and engineering departments of her Majesty's Government of South Australia"ballarat school of mines, surveying, scientific instruments, scientific objects, otto boettger, optician, miner's dial -

Federation University Historical Collection

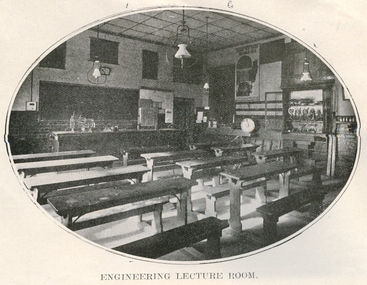

Federation University Historical CollectionBook, Ballarat School of Mines, Ballarat School of Mines Calendar, 1911, 1911

In 1911 R. Maddern was President of the Ballarat School of Mines. Contents of this booklet are: Asssociateship, Calendar, Certificate Courses, Departmental Regulations, Discipline, Discipline Board, Examination Results, Fees, Full Certificates Issued, General Regulations, Introduction, Junior Technical School, Officer Bearers, Professors and Lecturers, Subjects of Instruction - Department of Chemistry and Metallurgy, Geological Department, Engineering Department, Electrical Engineering Department, Department of Mathematics and Physics, Practical, Plane and Solid Geometry, Photography, Subscriptions and Donations 1910. Plan of Buildings and Grounds Engineers with qualifications from the Ballarat School of Mines were sought by mines throughout the world. Blue soft covered book of 64 pages titled the Ballarat School of Mines Calendar. The book includes images of the Engineering Room, the Maddern Roasting Furnace, Museum, Junior Chemical Laboratory, Plan of Buildings and Ground, Chemical Laboratory, Concentration Floor, Linkenbach Table, Engineering Laboratory, Experimental Steam Engine, Chemical Lecture Room, Physics Instruction Room, Newtonian Telescopy, Ballarat Observatory, Instructor's Laoratory, Wilfrey Table, Chlorination plant, Cyanide House and R. Maddern. ballarat school of mines, scientific equipment, engineering, classroom, desks, gas lighting, calendar, r. maddern, j. m. bickett, w. h. middleton, j. d. woolcott, w. nixon, daniel. walker, fred j. martell, professor a. mica smith, hubert r. murphy, charles a. deane, arthur garrard, professor t. s. hart, professor a. d. gilchrist, a. e. c. kerr, j. brittain, e. j. a. mcconnon, john m. sutherland, bertram whitington, h. j. hall, e. gutheil, charles campbell, t. williams, d. e. mullins, sir redmond barry, judge rogers, r. m. sergeant, thomas bath, andrew anderson, general regulations, discipline, discipline board, associateship and final certificates, mining engineering, metallurgy, geology, electrical engineering, certificate courses, junior technical school, fees, subjects of instruction, chemistry, geological department, engineering department, electrical engineering department, department of mathematics and physics, practical, plane and solid geometry, photography, full certificates issued, supplementary examination results - may 1910, supplementary examination results - april 1908, subscriptions and donations 1910 -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Scientific Instrument, Nobel Explosives Co. Ltd, Nobel's Explosives Co Galvanometer, Between 1877 and 1926

Nobel Industries Limited was founded in 1870 by Swedish chemist and industrialist Alfred Nobel for the production of the new explosive dynamite in the United Kingdom. Ardeer, on the coast at Ayrshire, was chosen for the company's first factory. Between 1877 amd 1926 it was known as Nobel’s Explosives Company Limited. The business later diversified into the production of blasting gelatine, gelignite, ballistite, guncotton, and cordite. At its peak, the factory employed nearly 13,000 men and women. In 1926, the firm merged with Brunner, Mond & Company, the United Alkali Company, and the British Dyestuffs Corporation, creating a new group, Imperial Chemical Industries, then one of Britain's largest firms. Nobel Industries continued as the ICI Nobel division of the company. Small black timber box with small screw holding back on, and leather handle on top. A pivoted needle remains vertical as box angle changes. Graded scale behing top end of needle. Two adjusting points at top.No 10070nobel, ballarat school of mines, scientific instruments, galvanometer -

Federation University Historical Collection

Federation University Historical CollectionDocument - Invoice, Invoice from Walter Cornell to the Ballarat School of Mines, 1898, 30/04/1898

During the 1890s the Ballarat School of Mines started teaching photography.Handwritten invoice on printed letterhead. The invoice was for chemicals and apparatus for the Ballarat School of Mines, including items for the Chemical Laboratory, Photography Laboratory, Electrical Laboratory and Cyanide.walter cornell, ballarat school of mines, laboratory, chemist, pharmacy, photography electricity, photographic equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle and Pen, Caldwell’s Ink Factory, Early 20th century

This shaped ink bottle made by Caldwell's is called a 'boat ink bottle'. It was shaped especially to hold a nib pen when the pen was not in use. The design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a two-piece mould, a method often used in the mid-to-late 19th century. The glass blower burst the bottle off the end of his blowpipe with a tool, leaving an uneven mouth and sharp edge on the bottle, which was usually filed. The bottle was then filled with ink and sealed with a cork. More expensive bottles would have a lip added, which was more time-consuming and costly to produce. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. The nis only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This pen and ink bottle set is of significance as the bottle has its original cork and retains remnants of ink, which was made from a recipe that at the time was over 100 years old, according to Caldwell.. The handmade, mould blown method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle and its contents are of state significance for being produced by an early Melbourne industry and exported overseas. The pen and ink set is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Victorian boat ink bottle; small rectangular clear glass ink bottle with horizontal grooves made in the glass for resting and holding the pen. The set includes one pen and nib with the bottle and cork. The bottle is made by Caldwell's and contains its Flo-Eesi Blue Black Ink brand."Caldwell's Flo-Eesi Blue Black Ink."flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, flo-eesi, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, two-part mould, sheer-lip bottle, burst-lip, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw, 1905-1913

This crosscut saw was originally part of the equipment on the barque Marjorie Craig, which brought New Zealand timber into Warrnambool from about 1908 to 1912 for the local merchants P J McGennan & Co. The toolbox was donated by a member of a local family connected with the La Bella rescue in 1905. The toolbox has carvings and markings that make it unique and connect it to the Marjorie Craig. The Craig Line of sailing ships was from Auckland, New Zealand, and traded in timber and some coal from New Zealand ports to Australia, including Sydney, Adelaide, Melbourne and Warrnambool. They returned with produce from Australia as ballast. In 1912 the Craig fleet included the Ihumata, Inga, Jessie Craig, Marjorie Craig, Louisa Craig and Joseph Craig. The steel barque Marjorie Craig, 500 ton, was built in 1891 as the 'Hirotha', in Ardrossan, Scotland for Norwegian owners. The ship was sold to Auckland’s Donald Ross and others in 1900, then in 1905 it was sold, registered by J.J. Craig in Auckland, New Zealand and renamed Marjorie Craig. Marjorie Craig’s commanders included Master R A Campbell in 1907, J MacFarlane in 1909 and Master R.G. Holmes in 1913. From February 1908, the Marjorie Craig was regularly seen in the Port of Warrnambool with loads of timber for merchants P J McGennan & Co. In February 1912 Marjorie Craig delivered white pine for P J McGennan & Co. In April of the same year, she brought 500,000 feet of timber for McGennan & Co and again in May 1912. On May 12 1912 Marjorie left the Port of Warrnambool with 500 tons of flour for New Zealand; it seems that this was her last time at Warrnambool. Prior to 1908, the vessel Speculant brought in timber from New Zealand for the McGennan firm. The Marjorie Craig had a strong reputation for being a ‘Fast Flyer’, breaking the sailing records for voyages between New Zealand and Australia. It was reported that she made passages with a speed equal to steamboats on several occasions. One of her records was from Warrnambool to Hokianga, NZ in eight-and-a-half days. The ship broke the record in October 1913 for the time from Adelaide to Auckland, sailing in 28 days, even with a damaged ship, and the owner presented Captain Holmes with a gold watch and chain. By the end of December 1913, the Craig Line’s last two surviving sailing ships, Marjorie Craig and Jessie Craig, had been purchased by Huddart, Parker & Co. Ltd. to work as coal hulks, one in Melbourne and one in Hobart.The saw is significant for being created for use in 1905 when the steel barque Marjorie Craig was purchased by J J Craig and given that name. The saw would be part of the sip's equipment and could have been used for the timber carried as cargo on the Marjorie Craig. The saw is significant for its association with the well-known Marjorie Craig, a frequent visitor to the Port of Warrnambool 1908 to 1912, a supplier of New Zealand timber for the local firm P J McGennan & Co, and one of the fastest inter-colonial sailing ships that broke numerous records for its speed including the fastest sailing from Warrnambool to Hokianga. Crosscut saw; blade attached to wooden handles by wingnut each end. The saw has 63 teeth. Also has a tag attached with an inscription. The saw was ship's equipment on the barque, Marjorie Craig.Handwritten on tab: "From sailing ship Marjorie Craig early 1900 Port of Warrnambool"flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shiopwreck coast, woodworking tool, crosscut saw, shipwright tool, saw, marine trade, carpenter, marjorie craig, j j craig, craig line, 1905-1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Carbide Lamp, Powell & Hanmer, 1920s

Francis Powell (1861-) and Francis Hanmer (1858-1925) founded Powell and Hanmer Ltd in the Summer of 1885 for the manufacturer of bike and carriage lamps. Their first advertisements began to appear in November of 1885. In 1890 they lodged a Patent for “velocipede” lamps to be used by lightweight wheeled vehicles propelled by a rider, such as a bike, tricycle and railroad handcar. In April of 1913, they were selling headlamps for cars and in 1914 built their second factory manufacturing dynamo lighting sets in Rocky Lane Birmingham, also for the production of dynamos for motor cars. Then in 1929 Powell and Hanmer Ltd, was acquired by the Lucas company which was at that time the main competitor for the manufacture of non-electrical equipment for cycles and motorcycles. When a director of Powell and Hanmer joined the board of Austin motor cars, Lucas feared that Austins might encourage Powell and Hanmer to start to produce electrical equipment for supply to the company and as a result this association might affect Lucas's business with other large vehicle manufacturers. As a result, Lucas made an offer to Powell & Hanmer and purchased the business for £500,000. Carbide lighting was used in rural and urban areas of Australia which were not served by electrification. Its use began shortly after 1900 in many countries and continued past the 1950s. Calcium carbide pellets were placed in a container outside the home, with water piped to the container and allowed to drip on the pellets releasing acetylene. This gas was piped to lighting fixtures inside the house, where it was burned, creating a very bright flame. Carbide lighting was inexpensive but was prone to gas leaks and explosions. Early models of the automobile, motorbike and bicycles used carbide lamps as headlamps. Acetylene gas, derived from carbide, enabled early automobiles to drive safely at night. Thick concave mirrors combined with magnifying lenses projected the acetylene flame light. These type of lights were used until reliable batteries and dynamos became available, and manufacturers switched to electric lights. Acetylene lamps were also used on riverboats for night navigation. The National Museum of Australia has a lamp made in about 1910 that was used onboard the PS Enterprise, an 1878 Australian paddle steamer, currently owned by the National Museum of Australia in Canberra. It is still operational, and one of the oldest working paddle steamers in the world, listed on the Australian Register of Historic Vehicles.Acetylene Carbide lamp, Model “Panther” distinct patterned side red and green lenses. These lamps were also known as acetylene gas lamps. They work off a chemical reaction between calcium carbide and water.Model 75flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, carbide lamp, motor vehicle, bike lamp, lighting, vehicle lighting, powell, hanmer, acetylene gas lamp, early lighting -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Electrical Instrument, Moore Reed "Universal" Acoustic Coupler: Type TC301, c1980

The Universal Acoustic Coupler was made and would have been used to connect a telephone to dial a computer remotely. The control panel is under the wooden flap. There is a power switch, full duplex switch, 500 Ma Fuse, CCITT Port. When not in use it can be folded up into a small timber carry case with handle.Wooden box with two sections that open. Top section hinged and folds back. inside are controls and cables for connecting to a computer. Instructions for use are on the lid. Front section has clips and folds down to a phone to placed in "speakers". English maker's plate and Melbourne supplier's plate with A.P.O. Permit No. C74/8/903 Serial No. 775326 moore reed, universal acoustic coupler, telephone, remote connection, computer connection -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Object, 'Crest' Home Hair Perm Kit in box, c1950

A permanent hairstyle, commonly called a perm or "permanent" is a hairstyle consisting of styles set into the hair lasting a number of months using thermal or chemical means. In the latter method, chemicals are applied to the hair, which is then wrapped around forms / rods to produce hairstyles with varying degrees of wave or curls. Usually this styling is performed by Hairdressers, in Beauty Salons, however, manufacturers appealing to the 'thriftiness' of the post world war 2 women produced products that could be used at home. It became very popular for women in the new estates to gather with their neighbours to give each other this new 'Home perm' with some success and failure. Gladys Reed used this type of Home perm while a resident of City of Moorabbin c 1950Typical Home Hair Perming equipment used to style their own hair by women in City of Moorabbin c1950A cardboard box containing solution, equipment and instruction booklet for home treatment of hair to produce permanent waves.hairdressers, hairdressing equipment, permanent wave, hair fashion, hair styling 1950, grooming, personal effects, early settlers, post world war 2 estates moorabbin, reed gladys. reed george, clark judy, bentleigh, moorabbin, highett, ormond. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - 'KIX' Insecticide Powder, DAVID CHEMICALS PTY LTD, for dogs, cats and all animals, 20thC

Kix was first manufactured by Clark King & Co.after World War II. The offices were located in 237 Queen Street Melbourne. Clark, King &Co Pty Ltd started business in the early 1920's and were known as the poultry food specialist. The head of the firm, Mr Clive Harrison Clark was know as a successful poultry farmer and exhibitor of prize birds, he was the secretary of the Brighton Poultry Society.KIX was used by citizens of MoorabbinA yellow heavy cardboard container with metal swivel top containing a white powder. Front: KIX - STRONGEST - INSEDTICIDE - keeps on killing - FLEAS - SILVERFISH - BUGS - LICE - MOTHS - ANTS - COCKROACHES - FOR DOGS, CATS AND ALL ANIMALS BACK: DIRECTIONS Fleas and Lice. Kix keeps on killing fleas and lice for weeks. An occasional dusting will FLEA-PROFF dogs and cats. Dust Kix on the hair of dogs commencing at the neck and ru it in with the fingers. If the dog appears irritated after treatment, it will be due to the efforts of fleas to escape and indicates both the effectiveness of Kix and the necessity of treatment. Sprinkle Kix on the head and neck of cats and rub well in. Use Kix on poultry also. In personal hygiene against fleas Kix may may dusted on underwear socks etc. Use Kix also for head lice and body lice. Silverfish, cockroaches, Bugs, Ants. Duct Kix where necessary and it will remain effective for months. These pest take some hours to die, but death is certain. Active Constituents: 5% Para Para Dichlorodiphenyltrichloroethane, 2.5% Isobornly Thiocyanoacetate. DAVID CHEMICALS PTY LTD. Clayton, Victoria Contents 1½ ozskix, insecticide, ddt, pets, moorabbin, poultry -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

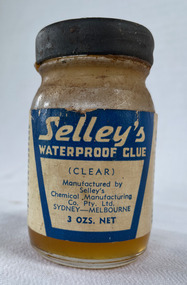

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Selley's Waterproof Glue, Selley's Chemical Manufacturing Co. Pty Ltd, 20thC

Selley's is an Australian company which produces household 'do it yourself' and cleaning products. Martin Selley, who fled Germany in 1939, prior to the start of WWII, established the Selleys Chemical Company - selling wood putty.Selley's is an Australian company which produces household 'do it yourself' and cleaning products that were used by residents of City of Moorabbin in 20thC3 oz Glass bottle with screw on metal lid, painted blue - with a blue and white labelFRONT: Selley's Waterproof glue - (Clear) Manufactured by Selley's Chemical Manufacturing Co. Pty Ltd - SYDNEY - MELBOURNE 3 ozs. Net. BACK: Instructions for use. Selley's Waterproof Glue is a unique material which can be used for almost any type of joint. When used for wood to wood it gives excellent results, comparing favourably with all other types of wood glues, but in addition has the advantage that it is applied cold, and further, when set, is completely water-proof. It does not require any catalyst or hardening agent to set, but dries by evaporation of the solvent, leaving a tough, hard film. The glue contains thinners. Do not use near a naked flame, but after it has dried it is no more inflammable than dry timber. If glue too stiff, add acetone. glue, selley's, waterproof glue, bottle -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - BRASSO, Reckitt and Colman Ltd, Metal Polish, 20thC

Reckitt & Sons' opened a branch in Sydney in1886. Brasso was developed by Reckitt & Sons in 1905. In 1938 Reckitt and Sons merged with J. and J. Colman to become Reckitt and Colman Ltd.Brasso was used by most Housewives for cleaning and polishing Kitchen Equipment in the City of Moorabbin during 20thC Metal container with blue sun burst effect, with a red circle with 'BRASSO' printed, in white and blue, inside. The instructions are printed on the back. FRONT: 'BRASSO' Back: Picture of the Royal Coat of Arms - By appointment to Her Majesty Queen ElizabethII. Suppliers of Metal Polish Reckitt & Colman Ltd. BRASSO Metal Polish for polishing Brass, Copper, Zinc, Steel, Pewter etc. SHAKE WELL Apply with a soft cloth. Polish off with a dry, soft cloth preferably before the polish has completely dried. DO NOT PLACE THIS TIN CLOSE TO THE FIRE Made in Australia by Reckitt & Colman (Australia) Ltd. No. 6 - Contents 6½ Fl oz when packed. brasso, metal polish -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902

This design of ink bottle or ink well was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf ink bottle. It was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century. Up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use. Ink wells, used with steel nib dip pens, were commonly used up until the mid-20th century. The pens only held a small amount of ink so users had to frequently dip the nib of the pen into an ink well for more ink. Hand writing with pen and ink left wet writing on the paper, so blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased, ready to use, or in the powdered form, which needed to be mixed with water. After the invention of fountain pens, which had a reservoir of ink, and then ballpoint pens, which also had ink that flowed freely, the dip pen was slowly replaced. However, artisans continue to use nib pens to create beautiful calligraphy. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This ink bottle is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The Ink bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This Ink bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history.Ink bottle or ink well; cylindrical shaped, salt-glazed, mid-brown ceramic bottle. It has a small round mouth, rounded lip that extend past the short neck, wide shoulders, straight sides, flat bottom. Handmade. Also called a Penny Ink Well.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, ink bottle, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, dwarf ink -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902