Showing 289 items

matching trimmings

-

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncPhotograph, Dillon Building and Globe Hotel, High St Charlton c.1987

Dillon Building built 1889. The third building operated as a cafe in the 1960s - 1980s. Heather's Choice Gift Shop sold out in early 1990s. The Old Globe Hotel established 1874, rebuilt c. 1903 and again in 1940 for licensee J. Credlin. Was the Soil Conservation Authority office , then flats and offices.Colour photograph of the café section of the Dillon Building and the Globe Hotel. LH side of the photo is the cafe section of the two storet, red brick Dillon building. Signage in LH café window reads CHARLTON BYO RESTAURANT and on the RH window MEALS, TAKE AWAYS, SNACKS, COFFEE, DRINKS. Sheer curtains in the cafe windows. The signage on the RH building reads SOIL CONSERVATION AUTHORITY. There are two men in a cherry picker in front of the Soil Conservation building trimming the tree. There are three witches hats on the road and a man in an orange hi-vis vest watching, A woman is walking past on the footpath.dillon, globe hotel, the old globe hotel, credlin, soil conservation authority -

Ballarat Tramway Museum

Ballarat Tramway MuseumUniform - Cap, Commonwealth Government Clothing Factories Melbourne, mid 1960's

Demonstrates uniform cap manufacture for a SEC Inspector, shows the "braid" worn by inspectors and has a strong association with Theo Dunstan.SEC Inspectors/Conductors cap - black cloth exterior, grey cotton interior lining, brown leather internal hat band, black cotton hat band with gold trimmings, on exterior with a plastic band at the front half of the cap terminating in two small SEC gold coloured metal buttons on either side, black plastic peak. Fitted with and "Inspector" cap badge - brass, has been polished with Brasso remains on interior of letters. Received from donor as three individual items - reassembled. Assumed made by the Commonwealth Government Clothing Factories Melbourne, as identical style to that of a crew cap.tramways, trams, ballarat, uniforms, cap, inspectors -

Bendigo Military Museum

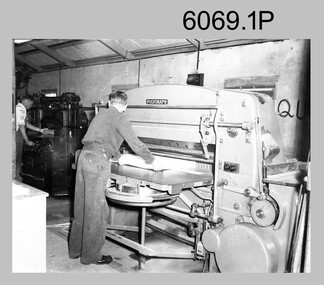

Bendigo Military MuseumPhotograph - Printer Technicians trimming printed map stock at the Army Survey Regiment, c1960s to c1980s

These six photographs of Printer Technicians using a heavy-duty guillotine to trim bulk printed map stock were probably taken circa 1960s to 1980s in Lithographic Squadron at the Army Survey Regiment, Fortuna, Bendigo. Personnel are not identified on Photos .3P and .4P, however names are annotated on photos .1P, .2P, .4P and .5P. Cartographers normally provided trim marks to specified map dimensions as guidance to the printer. The trimming stage, like all the other printing processes required high levels of accuracy. These guillotines were extremely powerful to cut through bulk quantities of printed maps, as evident in photos .1P .3P, .4P and .6P.This is a set of photographs of Printer Technicians using a heavy-duty guillotine to trim bulk printed map stock c1960s to 1980s. The photographs were printed on photographic paper and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 300 dpi. .1) - Photo, black & white, c1960s, L to R: ‘Wanger’ Payne, unidentified, Lithographic Squadron .2) - Photo, black & white, c1980s, CPL Ken Cavanagh, Lithographic Squadron .3) - Photo, black & white, c1970s, unidentified, Lithographic Squadron .4) - Photo, colour, c1970s, Peter Saunders, Lithographic Squadron .5) - Photo, black & white, c1980s, L to R: unidentified, WO1 Noel ‘Nesty’ Coulthard, Lithographic Squadron .6) - Photo, black & white, c1980s, unidentified, Lithographic Squadron.1P, .2P, .4P and .5P. personnel annotation on back. * unidentified on .1P due to poor writing. .3P and .6P – no annotationroyal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, litho, printing -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (Digital), Geoff Paine, St Margaret's Church, Eltham: Stories of the Nillumbik Shire with Geoff Paine, June 2020

One of a series of videos "Stories from the Nillumbik Shire with Geoff Paine" Geoff Sandy, Parish Historian and Archivist gives a history of the church which was opened 12 December 1861. It is constructed of polychrome bricks (lots of different colours). References a long relationship of over 159 years between the church committee and the Eltham Hotel across the road for refeshments for church events. The land was donated by Henry Dendy, the founder of Brighton where he lived for five years before going bankrupt and moving to Eltham where he bought a steam powered flour mill on the banks of the Diamond Creek at the end of Pitt Street. The church is heritage protected as well as the 1870 parsonage, Dendy House. It was always meant to be a much bigger church and extended along the north wall. This was finally achieved in 2014. Shows views inside of the original section and the extension. Also discusses the original tall windows on the south with gold trimming and other windows with gold trimming. Some original windows have been replaced by stained glass. Discussion about the Patron Saint of the Church, Margaret of Scotland. The original window made for £1 by Yuri and Fergusson in Melbourne and possibly one of the first made in the Colony of Victoria was relocated to the north wall during the 2014 extension. The crucifix was made by Matcham Skipper. Also features the Honour Roll. The walls of the extension are mudbrick, timber from a variety of sources and very much in keeping of the character of Eltham. The bell and bell tower are original. At the end of the First World War the bell was rung so vigorously that the bell broke.MP4 Digital file 00:05:48; 672MBvideo recording, church bell, dendy house, eltham, eltham hotel, flour mill, geoff sandy, henry dendy, honour roll, matcham skipper, mudbrick construction, pitt street, st margaret's anglican church, stained glass -

Supreme Court of Victoria Library

Supreme Court of Victoria LibraryPortrait, Justice Sir Thomas a'Beckett

The Argus reports that “In 1916 the members of the bar took the opportunity afforded by his [a’Beckett’s] 80th birthday, and the completion of 30 years on the bench to present to the judges of the Supreme Court, with his permission a portrait of himself, to be placed in line with portraits of other judges in the Supreme Court library. The portrait which depicts Sir Thomas a’Beckett in his robes, was an excellent piece of work of Mr Max Meldrum. The unveiling was made the occasion of a little demonstration at which some congratulatory speeches were made." Sir Thomas a'Beckett arrive in Melbourne as a teenager with his parents in 1851. His uncle was the former Chief Justice, his father a well known solicitor. At the Bar Sir Thomas mainly worked in the Equity jurisdiction, which he took as a specialisation with him to the bench. This is an early work of Meldrum, he won the Archibald prize for portraiture in 1939 and 1940.The portrait is of interest for whom it portrays and as the early work of a well known artist.A full length portrait in oils of Justice Sir Thomas a'Beckett. Sir Thomas is seated, his feet placed on a plush red foot stool. He is dressed in his red judicial robes with white fur trimming and black trousers and a full bottomed wing. Justice a’Beckett has a white beard and moustache, he was 80 years of age when this portrait was painted. In his hand he holds a rolled document. At his elbow, there are books upon a table. He sits in a fine carved wood and leather chair, in the background a gold frame is just visible. A line in the canvas indicates that the size of the painting was expanded. The frame is gold with a gum leaf motif.Max Meldrum 1916a beckett, max meldrum, judge -

Wycheproof & District Historical Society Inc.

Wycheproof & District Historical Society Inc.Photograph, St Andrew's Presbyterian Church Complex

The first Presbyterian gathering was held in Wycheproof in 1876, this led to the organization of a congregation and the building of a church. The first church was in Charles Street on the north side of the Mount. It served the congregation for twenty years. The new church in Mount Street opened 06-09-1896 and after 115 years the doors closed for worship in 2011.A building of spiritual and social significance to the Presbyterian congregation and wider community of Wycheproof and District for 115 years.Small format sepia print taken between 1912-1937of the Wycheproof Presbyterian Church Complex. Designed on early English lines, the church dated 1896 was built of red-brick with buttresses and decorated cream-brick trimmings. The arched windows are glazed in diamond shaped leadlight. The high pitched roof is of galvanized corrugated iron. The Sunday School Hall 1912, of timber construction with feature trim of arched windows and doors and a galvanized corrugated iron roof. The Manse 1909, of timber construction with galvanized corrugated iron roof and fret-work on the space above the verandah. Iron lace decorates the wooden verandah posts. Fencing: Post and Rail. Kodak print /501presbyterian, church, sunday school, manse, building, 1896, post and rail fence, red-brick, timber -

Ballarat Tramway Museum

Ballarat Tramway MuseumUniform - Uniform Jacket, David Lack Pty Ltd, early 1960's?

SECV Uniform Jacket - dark green cloth, lined with black cloth on inside and striped white cloth inside sleeves. Fitted with 4 silver large SECV uniform buttons on front, shoulder epaulets each fitted with small SECV uniform buttons, leather trimming on large pockets and ends of arms. Jacket fitted with four pockets - two side, one small top left and one large inside right. On top of inside of coat, "David Lack Pty Ltd. Melbourne" label, that can be used as a hanging point. On the inside right pocket, white label, with red and black printing, giving name of manufacturer and space for Name and Number. Typed for "T. Dunstan." and "926".ballarat, inspectors, uniforms -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBed Jacket

The bed jacket, a woman's garment, is a waist-length robe worn to cover the chest, shoulders and arms while sitting up in bed. Its short length and cape-like cut allowed it to be put on (or removed) while in bed. Often made of sheer or lacy fabrics and displaying very feminine trimmings and details, it was often used more for seduction, rather than warmth or modesty. It was popularized in 1930s Hollywood films featuring glamorous settings and glamorous stars lounging languorously in their silken bedrooms. Ostrich feather tips, swan’s down, pleated tulle and shirred lace were just a few examples of the extravagant materials that could be used in creating these confections. These garments are currently very popular with people who have been hospitalized or recommended bed rest. (Source: http://www.wikipedia.com) Pale lemon coloured ladies silk bed jacket with silk lace edging. Figured silk bow tie at front neck.home, lace, female, ladies, silk, bed, jacket, bow, made -

Kew Historical Society Inc

Kew Historical Society IncHeadwear - Pale Green Silk & Gauze Floral Hat, Harbig, 1950s

The firm of Harbig was a Melbourne millinery company owned by Mr and Mrs Richard Ernest Harbig. In 1949, an article in the West Australian newspaper reported their return from the United States. It records that: 'FEATHERS SYDNEY, Sept. 14: Mr. and Mr. Richard Harbig, Melbourne milliners who reached Sydney by air tonight from America, gave these details of hat trends for next winter. Shapes: Head-hugging cloches to suit short hair, cut away at the back to clear high collars, and built up and out at the front to give height. Materals: Felts, velours, velvets, and a new long-haired fur fabric called flamond. Colours: Muted pastels, few jewel shades, and no vivid colours. Trimmings: Little veiling, "but feathers and feathers and feathers".'The Kew Historical Society’s fashion and design collection is comprised of costumes, hats, shoes and personal accessories. Many of these items were purchased or handmade in Victoria; some locally in Kew. The extensive hat collection comprises items dating from the 1860s to the 1970s. While most of the hats in the collection were created by milliners for women, there are a number of early and important men’s hats in the collection. The headwear collection is particularly significant in that it includes the work of notable Australian and international milliners.Pale green woman’s hat created by Harbig of Melbourne with a large border of flowers and leaves in shades of green. The crown of the hat is swathed with pale green silk gauze.Label: Harbig. Melbourne, New York, Parismilliners -- harbig, women's clothing -- hats, floral hats -

Kew Historical Society Inc

Kew Historical Society IncHeadwear - Ivory Silk Floral Hat, Harbig, 1950s

The firm of Harbig was a Melbourne millinery company owned by Mr and Mrs Richard Ernest Harbig. In 1949, an article in the West Australian newspaper reported their return from the United States. It records that: 'FEATHERS SYDNEY, Sept. 14: Mr. and Mr. Richard Harbig, Melbourne milliners who reached Sydney by air tonight from America, gave these details of hat trends for next winter. Shapes: Head-hugging cloches to suit short hair, cut away at the back to clear high collars, and built up and out at the front to give height. Materals: Felts, velours, velvets, and a new long-haired fur fabric called flamond. Colours: Muted pastels, few jewel shades, and no vivid colours. Trimmings: Little veiling, "but feathers and feathers and feathers".'The Kew Historical Society’s fashion and design collection is comprised of costumes, hats, shoes and personal accessories. Many of these items were purchased or handmade in Victoria; some locally in Kew. The extensive hat collection comprises items dating from the 1860s to the 1970s. While most of the hats in the collection were created by milliners for women, there are a number of early and important men’s hats in the collection. The headwear collection is particularly significant in that it includes the work of notable Australian and international milliners.Rounded hat covered with ivory coloured silk, simulated flowers attached to a stiffened net. Label: Harbigmilliners -- melbourne (vic.) -- harbig, women's clothing -- hats, headwear -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhoto - Family dressed in the fashion of the early 1900s

During the early 1900s little girls' dresses were fashioned on the style worn by older women. Girls dresses were knee length with trimmings of lace and ribbon. Collars were often removable for ease of washing. Leather lace-up boots and woollen stocking or socks were usually worn with these dresses. A pinafore or apron would be worn over the dresses to help keep them clean. Girls' hair was kept long, with curls and tied with ribbons.Boys' clothing was fashioned on sailor suits, blouses/shirts with a collar and trousers or knickerbockers. Woollen jackets, shirts and ties were suitable attire for older boys. Children's fashion of this time was dictated by long lasting durability, local manufacture, earthy colours and ease of mobility. Because of the long distance to haberdashery stores, the majority of children's garments would have been hand made by a local seamstress, mother or relation.Black and white photo of a family with 5 children in the foreground with trees in the background.children's clothing -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Transport, Bicycle 'Bastide' 1909, c1909

1891 Paris - Bordeaux Cycle Race started in the Place du Pont Bastide in Bordeaux. So the name Bastide was already known to cycle enthusiasts even before the cycle manufacturer made its first iconic bicycle.The Bastide frame was built from top quality English Reynolds tubing with lugs and fittings provided by BSA. (Birmingham Small Arms Company ). Bastide, was based at Boulevard de Clichy, Paris and turned these fittings into a totally superb racer. Leon (Jack) Meredith,UK Olympic Cycling Champion, of the Constrictor Tyre Company, was responsible for importing the first Bastides and displaying them at the 1913 Olympia Cycle show where they were the sensation of the show. The Bastide, though almost as expensive as top range cycles, was fitted with a single brake and gear and no trimmings and was lighter, slimmer and faster Weight 15lb. ( 6.8Kg) Bastide stopped making frames in 1936. Bastide was the bike that changed the style for road bikes in England for ever more after the First World War 1914-18 and this bicycle was used by Mr L Forde in Moorabbin Shire c1910A Racing Bicycle c1909 'BASTIDE"Frame Bastide Frame Stem ; Perfect / BUILT BY / CANADA CYCLES / & MOTOR Gear wheel ; BSAparis-bordeaux cycling road race, bicycles, bastide bicycles paris, birmingham small arms company uk , meredith leon jack , olympic cycling, road races, cycling clubs, cheltenham, moorabbin, victoria, geelong, werribee, whitehead clarice, whitehead eric, world war 1914-1918, early settlers, moorabbin shire, bentleigh, -

Kew Historical Society Inc

Kew Historical Society IncClothing - Grey silk wedding dress, 1842

This wedding gown was worn by Mary Ann Lawrence at 8.00am on 5 January 1842 at St John's Church, Launceston, when she married Francis Henty. The couple were to catch the tide on their way to Portland two hours later. Francis Henty was the youngest son of Thomas Henty, who with his family, their retainers and property moved to the Australian colonies between 1829 and 1832. In 1834, Francis’ older brother, Edward, sailed from Launceston in Van Diemen’s Land to what was to become Portland in the western part of Port Phillip District [Victoria]. Francis, together with the first flock of Merino sheep [in Victoria], followed some months later. The first and second generations of the Henty family established vast pastoral properties in the Western part of the Port Phillip District. Francis Henty managed ‘Merino Downs’ near Casterton, while also living in his retirement at ‘Field Place' in Kew. The Henty Collection of nineteenth and twentieth century clothing, including outerwear and underwear, was collected, stored and exhibited over time by female family members descended from Francis and Mary Ann Henty. During the twentieth century, items from the collection were modelled in two fashion parades by various descendants [1937, 1959]. The items in the collection are historically and aesthetically significant, with provenance provided by oral and written tradition within or held by the family. A number of the items in the collection are very rare survivors, and provide researchers with the evidence needed to reconstruct the lives of notable women in the Port Phillip District [later Victoria] during the nineteenth and early twentieth century.Mary Ann Lawrence's grey silk wedding gown has a v-line waist and a partly smocked bodice. It is lined with muslin throughout. It has hand-tatted cotton lace and handmade piping around the neck and bodice and pleated short sleeves. There was originally trimming on the skirt which was removed at a later date. Orange blossom made of chamois and tiny coiled springs originally decorated the neckline. The outfit was complemented by a bonnet to which a Limerick lace veil was attached. Measurements (mm): Girth - Neck 914, Chest 812.8, Waist 660.4, Cuff 330.2, Hem circumference 3200.4. Vertical - Front neck to hem 1270, Front waist to hem 1016, Back neck to hem 1320.8, Back waist to hem 1041.4, Sleeve length 114.3. Horizontal - Neck to sleeve head 50.8, Chest back 406.4, Underarm to underarm 406.4.mary ann lawrence, francis henty, wedding dresses, fashion -- 1840s, women's clothing -

![Ivory silk and lace wedding dress [bodice]](/media/collectors/550653872162f11fb04854aa/items/644fb461495d06a04226c26a/item-media/644fb5fd495d06a04226db5d/item-fit-380x285.jpg) Kew Historical Society Inc

Kew Historical Society IncClothing - Ivory silk crepe and lace bodice, 1912

This bodice was part of the wedding outfit worn by Grace Burland at her marriage to John Henty Hindson in 1912. Her husband's grandfather, Francis Henty, was the youngest son of Thomas Henty, who with his family, their retainers and property moved to the Australian colonies between 1829 and 1832. In 1834, Francis’ older brother, Edward, sailed from Launceston in Van Diemen’s Land to what was to become Portland in the western part of Port Phillip District [Victoria]. Francis, together with the first flock of Merino sheep [in Victoria], followed some months later. The first and second generations of the Henty family established vast pastoral properties in the Western part of the Port Phillip District. Francis Henty managed ‘Merino Downs’ near Casterton, while also living in his retirement at ‘Field Place' in Kew.The Henty Collection of nineteenth and twentieth century clothing, including outerwear and underwear, was collected, stored and exhibited over time by female family members descended from Francis and Mary Ann Henty. During the twentieth century, items from the collection were modelled in two fashion parades by various descendants [1937, 1959]. The items in the collection are historically and aesthetically significant, with provenance provided by oral and written tradition within or held by the family. A number of the items in the collection are very rare survivors, and provide researchers with the evidence needed to reconstruct the lives of notable women in the Port Phillip District [later Victoria] during the nineteenth and early twentieth century.Silk crepe wedding bodice decorated with Mechlin lace, pearls and jet, which was worn by Grace Burland at her marriage to John Henty Hindson in 1912. A report in Punch [12 September 1912] described her outfit as “... white crepe de chene finished with Mechlin lace and pearl trimming; also pearl crescent brooch (gift of the bridegroom' s mother).” Mechlin lace or Point de Malines is an old bobbin lace, one of the best-known Flemish laces, originally produced in Mechelen, Belgium. Used for women's clothing, it was popular until the first decade of the twentieth century. The high silk net neckline is finished with pearls. These are repeated on the loose fitted diagonal ornamentation on the front and back which is finished with pearl and jet beading. Similar ornamentation finishes the elbow length sleeves. [The wedding skirt is not part of the donation]. wedding dresses, women's clothing, fashion -- 1910s, bodices, grace burland -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s - set of 3, Chris Phillips, 28/12/1967 12:00:00 AM

Photo of two trams crossing each other at Carlton St loop, out of sequence running, normally crossed at Gardens loop Typical of the operation and the street scene at the time. The background trees were later removed.Bogie tram 36 and single trucker (20) crossing at Carlton St. Loop, early 1970's. View looking down track, towards south. No. 36 with Mt Pleasant destination, and No. 20 with Gardens via Sturt St. West on western track. Trees full with leaves. Note V crossing of frog, one made up by SEC? No. 20 has Twin Lakes sign under headlight. Image not square onto photo paper. 358.1 - duplicate copy from William F Scott, smaller print. 358.2 - as above - but mid size print.358.1 - On rear in ink "SEC Ballarat Tramways. Cars on Carlton Street loop, just outside the southern entrance to the Botanical Gardens" and in pencil "Christopher D Phillips, 113 Windermere Street Ballarat (053) 31 6075" and "12/1967" 358.2 - "44)" in top left hand corner, William F Scott address label in bottom right hand corner, trimming marks top and bottom. Label centrally, "photo page 40, Reduce to 5 1/2" and 3 1/4" " and along bottom :Ballarat Tramways (SEC) Christopher D Phillips "28.12.1967"trams, tramways, ballarat, carlton st., wendouree parade , tram 36, 20 -

Bendigo Historical Society Inc.

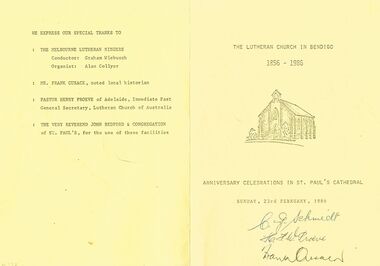

Bendigo Historical Society Inc.Document - THE LUTHERAN CHURCH IN BENDIGO, 1986

The Lutheran Church in Bendigo 1856 - 1986. 43 (Corner of Galvin Street and Barry Street, Bendigo. Red Brick with white trimmings.) Anniversary Celebrations in St. Paul's Cathedral, Sunday, 23rd February, 1986. Introduction: Clem Schmidt, Lutheran Pastor at Bendigo. Henry Prove: The Lutheran Church of Australia - Its development in the first five decades. Frank Cusack: The German contribution to early Bendigo. We express out special thanks to: The Melbourne Lutheran Singers, Conductor: Graham Wiebusch, Organist: Alan Collyer : Mr Frank Cusack, noted local historian : Pastor Henry Proeve of Adelaide, Immediate Past General Secretary, Lutheran Church of Australia : The Very Reverend John Bedford & Congregation of St. Paul's, for the use of these facilities. Markings: signatures of C J Schmidt, H J W Proeve, Frank Cusack. First 2 in blue pen 3rd in black pen.church, celebration, anniversary celebrations, the lutheran church 1856 - 1986. 43 galvin and barry street, . red white trimmings.) anniversary celebrations st. paul's cathedral, 23rd feb, 1986. clem schmidt, lutheran pastor. henry prove: the lutheran church of australia development decades. frank cusack: the german contribution: melbourne lutheran singers, conductor: graham wiebusch, organist: alan collyer : immediate past general secretary, lutheran church of australia : the very reverend john bedford & congregation of st. paul's, markings signatures c j schmidt, h j w proeve, frank cusack -

Robin Boyd Foundation

Robin Boyd FoundationFunctional object - Appliance

Mandie Boyd, Robin and Patricia's eldest daughter, has very vivid memories of this meat mincer, her favorite gadget. "Every Sunday until I was about 12 (mid-1950s), there would be roast lamb with all the trimmings, good homemade mint sauce, roast potato and pumpkin, parsnip, tomato and onion pie with breadcrumb topping, fresh green peas and gravy. Monday night was Shepherd’s Pie, and I looked forward to it. The cold meat was cut up and fed through the mincing machine fastened to the table at Riversdale Rd. I don't remember it ever coming out at Walsh Street. Maybe Patricia was over cold roast lamb at that stage. I loved turning the handle and watching the meat squidge out, could hardly call it mince, some onion and lastly a slice of bread to push the bits through. Then the mincer all came apart, was washed and put away until next Monday. The meat and onion tossed with leftover gravy, mash on top, loads of butter, etched with a fork tine and baked in the oven. Served with tomato sauce, very good." A beige coloured, heavy meat mincer. Detachable (discs 2) and outer cover for mincing. Long handle with wood end. Small black rubber stoppers underneath.cookware, gadget, walsh st appliances, walsh st kitchenware, robin boyd, ohm2022, ohm2022_11 -

Bendigo Military Museum

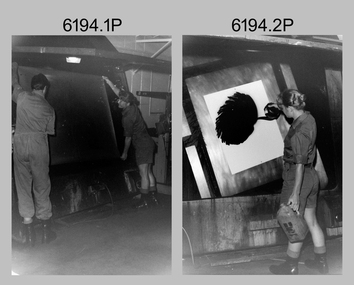

Bendigo Military MuseumPhotograph - Lithographic Technicians and Equipment at the Army Survey Regiment, Fortuna Villa Bendigo, c1990s

These 10 photographs were most likely taken in the 1990s in Lithographic Squadron at the Army Survey Regiment, Fortuna, Bendigo. In photos .1P to .2P the technicians are applying a UV-sensitive pigmented dye emulating one of the print colours to a white opaque polyester sheet mounted on a rotating table in a whirler. The coated sheet was dried before placement in a vacuum light frame beneath a stud registered map negative. They were then exposed to a carbon arc lamp. For more photos and details on the process, see item 6059.5P. In photos .3P to .5P the technician is preparing a orthophotomap film positive. Photo .6P is the rear view of the tri-linear film punch. In photos .7P and .8P the technician is operating a heavy-duty guillotine to trim bulk printed map stock. Cartographers normally provided trim marks to specified map dimensions as guidance to the printer. The trimming stage, like all the other printing processes required high levels of accuracy. These guillotines were extremely powerful to cut through bulk quantities of printed maps. For more photos and details on this process, see item 6069.6P. In photo .9P the technician is operating a daylight film contacting frame. In photo .10P LT Ian Stoddart is taking a well-earned break.This is a set of 10 photographs of lithographic technicians undertaking tasks at the Army Survey Regiment, Bendigo c1990s. Photos .1P to .7P and .9P to .11P are on 35mm negative film and scanned at 96 dpi. Photo .8P is printed on photographic paper and scanned at 300 dpi. They are part of the Army Survey Regiment’s Collection. .1) and .2) - Photo, black & white, c1990s, unidentified printer technician and SPR Janet Murray using the map proof whirler. .3) to .5) - Colour, c1990s, Mick ‘Buddha’ Ellis preparing an orthophotomap film positive. .6) - Photo, Colour, c1990s, rear view of tri-linear film punch. .7) & .8) - Photo, Colour, c1990s, unidentified technician operating a heavy-duty guillotine. .9) - Photo, Colour, c1990s, printer technician SPR Shona Hastie operating a daylight film contacting frame. .10) - Photo, Colour, c1990s, LT Ian Stoddart taking a well-earned break. .1P to .10P– no annotationroyal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, litho -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageUniform - Tunic or Doublet, David Lack Pty. Ltd, ca 1940s

The design of the uniform with its silver, diamond shaped buttons with the Scottish thistle symbol on them, indicate that the uniform was made for a Scottish Pipe Band member. There may be a connection with the local Warrnambool and District Pipes and Drums Inc, which began as the Warrnambool Pip Band in 1906, formed with the purpose of popularising Scottish music. Those with uniforms wore the Gordon tartan. In 1946 the uniforms were changed, with the Cameron or Errcht tartan chosen for the uniform. The Band now wears the Anderson tartan. The maker, David Lack Pty Ltd, advertised as a uniform specialist. In 1941 the business was located at 35-37 Little Latrobe Street, Melbourne. In the same year the firm won a contract with the Commonwealth Government Department of Supply, providing blue trousers for the Department of Air. In 1946 a branch of the firm operated in Myrtleford, Victoria. The Elizabeth Street, Melbourne, branch provided new uniforms in 1948 for the Leeton District Band. In the 1950s and 1960s David Lack manufactured blazers for the Olympic Teams as well as for bowls teams and schools. The Broken Hills Cameron Pipe Band' was gifted with uniforms that were also made by David Lack. It was a "... a Cameron of Lochlel red kilt and plaid, with black doublets and cross belts, and silver trimmings.” [Barrier Miner, Broken Hiss, 15-03-1954].The pipe band uniform jacket's design is associated with traditional Scottish pipe bands that originated in the United Kingdom and continue to this day in Australia and even locally in Warrnambool since 1908. The maker, David Lack Pty Ltd, is renowned as the maker of good quality uniforms who has supplied many government contracts for clothing and uniforms since the early 1940s. Uniform tunic; red jacket; Scottish Pipe Band Doublet with silver braid and silver diamond-shaped button closure and decoration. The buttons have the Scottish thistle symbol on them. There are seven buttons on the tunic front, three on each skirt flap, three on each contrasting black cuff and one on each black epaulette. The tunic has a two-inch stand-up collar. The whole item is fully lined with black nylon/silk blend fabric, the shoulders are padded, and there are pockets under the front skirts. There is an inscription on the maker's sewn-in label. Made by David Lack Pty Ltd, a uniform specialist in Melbourne.Label "David Lack Pty Ltd, uniform specialist Melbourne. "flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, uniform, tunic, dublet, jacket, scottish pipe band, pipe band, david lack pty ltd, david lack melbourne, uniform specialists, david lack, diamond buttons, silver buttons, scottish thistle buttons, scottish piper's buttons, thistle, scottland symbol, pipe band uniform, bag pipes -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - EDINBURGH TANNERY: SHEEPWASH CREEK, 1890 approx

In 1878, J H Abbott bought the Edinburgh tannery from Mr Lambert and Mr Sibley in 1878 and set about expanding and modernising it. Soon it consisted of the necessary sheds surrounded by cottages built for the workers. The tannery buidings and processes consisted of :- 1. Hide shed that held 400-500 salted hides 2. Salt pots where the salted hides were soaked to remove all salt 3. Lime water pits where the hides were soaked to remove hair and all adherent flesh. 4.Beam shed where hides were hung so they could be scraped clean with double handled knives 5. Water baths that soaked the hides to remove the lime 6. Tan yard where there were 10 pits containing tanning liquid made from ground wattle bark. The entire process could take up to 9 months depending on the type of leather required. A forward thinking initiative of this tannery was the lack of waste. The left over flesh was boiled down to make tallow, trimmings from the hides was used to make glue, hair was washed and used by saddlers and upholsterers and the lime was mixed with tanning liquid to produce fertilizer. The tannery was producing about 240 sides of leather a week, with about two thirds of this being sent to England where it was in great demand because of its quality. In December 1894 the plant was destroyed by a fire believed to have started in the engine room. The plant was quickly rebuilt at an estimated cost of ten thousand pounds. The plant at 145 Tannery Lane operated until 1906.Sepia photograph: 13 workmen, shed at rear. Brick, timber, corrugated iron buildings in back ground. Interesting industrial site of the time. Photo of workmen taken in front of open sheds. Brick chimney and pile on L.H.S. Suggests Edinburgh Tannery, Sheepwash. J.H Abbott & Co. On back on small piece of paper 1127 Bgo. New registration No. rather indistinct. James Lerk 26.11.1999, ' Edinburgh Tannery - Sheepwash?' Ken Arnold Book 'Bendigo A History in Bottles & Stoneware 1852-1930 p10. This photograph labelled 'Workers at Sheepwash Tannery,' C. 1880-1890 with section about J.H. Abbott & Co. See book 'Bendigo A History in Bottles & Stoneware 1852-1930 by Ken Arnold, p.10RHSV 1127, Bgoorganization, business, edinburgh tannery, sheepwash creek. -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white photographs, Grafting and Cutting Display

Photographs of various sizes pasted on cardboard for display purposes. Some annotated. (1)Rose with 4 pieces cut off it. (2)"Citrus rootstock in nursery ready for budding." (3) "Feb. Left. Healthy budstick of current season's growth. Right. Prepared budstick, foliage and undeveloped buds removed, short section of leaf-stick reatined." (4) Same as (3). (5)"Harvest scions while dormant and store in moist, well-drained soil." (6) "Whip-tongue graft after one season of growth." (7) "Graft after one season of growth." (8) "Mastic applied to keep air and moisture from the cut surfaces." (9) "Graft tied to prevent movement." (10) "Young camellia-struck cutting." (11) Cutting beside pot. (12) "Feb. Same pot camellia struck." (13) Clump of dug-up perennials. (14) Divided piece. (15) Trimmed. (16) "April. Seedling Polyanthus." (17) Cuttings. (18) Clump of rooted cuttings. (19) Trimming rooted cutting. (20) Clump of Begonia. (21) Dividing Begonia. (22) Begonia leaf cut into pieces. (23) Rooted cuttings from leaf. (24) Putting leaf pieces in pot. (25) Pot of rooted cuttings. (26) Lupin seedlings emerging. (27) Lupin seedlings. (28) Clump of roots? From A. W. Jessep.roses, nursery, budstick, grafting, growth, camellia, polyanthus, cutting, trimming, begonia, dividing, a. w. jessep, citrus rootstock, scions, whip-tongue graft, perennials, lupin seedlings -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Colour Photograph/s, Carolyn Dean, Mar. 1999

Set of 23 photographs taken by Carolyn Dean between 6/3/1999 and 16/4/1999 of the Begonia Festival operations and moving the ex SEC bike shed to Bungaree. On Kodak paper. 1094.1 - Group of tramway staff at Gardens Loop - used in May 1999 Fares Please! .2 - tram 40 at loop .3 - sign boards used in 1999 Begonia festival .4 - Welding joint 2-3 road - Warren Doubleday and Gary Wood .5 - ditto with Alastair Reither .6 - Fixing fence at Bungaree - John Phillips .7 - ditto .8 - ditto .9 - site for the hut to go at Bungaree .10 - ditto .11 - treated pine posts for stumps .12 - checking the layout - John Phillips .13 - cutting fire wood .14 - trimming trees .15 - Dismantling the roof on the shed at Ballarat East - John Phillips and Simon Jenkins .16 - roof off .17 - ditto .18 - the moving team - used in May 1999 Fares Please - see caption for people .19 - Lifting the shed out of position .20 - ditto .21 - ditto .22 - surveying the foundations - Peter Winspur, John Phillips and Alastair Reither .23 - ditto .1 > .3 - 6/3/1999: .4 & .5 - 7/3/1999: .6 > .13 - 20/3/1999: .14 - 21/3/1999: .15> .23 - 16/4/1999 See also Reg. No. 1095 and 1101 for next stage of the move. On rear of each photo in blue ink is date in the upper edge and on lower edge "Photo by Carolyn Dean"btm, sec bike shed, begonia festival, track repairs, tram 40 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate