Showing 751 items

matching machine made

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMedal - Commemorative, Edward William Cole, Coles Book Arcade, Federation of the World, 1885

The medal was issued by Cole's Book Arcade, with the proverb “Federation of the World, Be Good and Do Good”, circa 1885. This nickel-plated medal is one of a series of medals offering maxims and proverbs issued by E.W. Cole (Edward William Cole), owner of his Book Arcade. He called the medals 'little missionaries for the spread of educative knowledge' According to Sydney Endicott, an employee of Cole, customers were charged three pence for these medals (which he prefers to call tokens) which, when the Arcade was particularly busy, gave them admission to the second-hand books' gallery where the orchestra played. Each medal could be exchanged for thee pence worth of goods, but most were kept. The pierced ones were sometimes worn as pendants or on pocket watch chains. The medals served as perpetual advertisements of the Arcade (Victorian Historical Magazine, February 1962). George Dean suggests that the medals were also given in change at Christmas time, and could be used to operate amusement machines (presumably including the symphonion (clockwork instrument) and hens, although these only required one penny to operate). Cole had his first medal stuck in 1879 and his last one in 1903. The medals were variously gilded, silvered or bronzed, replicating the coinage and then circulating, or plated with nickel or white metal. The metal blanks were usually made of copper or brass, but some might have been bronze; aluminium was also sometimes used. In all, perhaps 300,000 medals were struck, in 97 different types or designs. Only 50 types are known to have circulated according to George Dean's 1988 book "A Handbook on E.W. Cole: His Book Arcade, Tokens and Medals'.The medal is significant for its association with Cole's Book Arcade in Melbourne, established in the 1870s. The unique shop not only had new books, but secondhand books, and many curious and interesting objects and musical treats. Cole's Book Arcade, at the time, was known as one of the wonders of 'marvellous Melbourne. it closed in 1929.Nickle plated bronze medal or token, round, featuring a tree fern and a thought provoking maxim. The medal was issued by E W Cole, Book Arcade, in Melbourne. Obverse: "BE GOOD AND" "DO GOOD" "HINDOO MAXIM" "PURE THOUGHTS" "PURE WORDS" "PURE DEEDS" "PARSES MAXIM" Reverse: "PURE / THOUGHTS / PURE WORDS / PURE DEEDS / PARSEE MAXIM" and below rainbow in tiny letters; "FEDERATION OF THE / WORLD MEDALS / ISSUED / BY E.W. COLE / BOOK ARCADE MELBOURNE"flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, medal, maxims, coles arcade melbourne, federation of the world, advertising token, edward william cole, book arcade, e w cole, cole's book arcade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Prior to 1878

This design of ink bottle was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf ink bottle. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use replacing the quill or dip pen. History of the Loch Ard: The Loch Ard got its name from "Loch Ard" a loch that lies to the west of Aberfoyle, and the east of Loch Lomond. It means "high lake" in Scottish Gaelic. The vessel belonged to the famous Loch Line which sailed many vessels from England to Australia. The Loch Ard was built in Glasgow by Barclay, Curle & Co. in 1873, the vessel was a three-masted square-rigged iron sailing ship that measured 79.87 meters in length, 11.58 m in width, and 7 m in depth with a gross tonnage of 1693 tons with a mainmast that measured a massive 45.7 m in height. Loch Ard made three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of 29-year-old Captain Gibbs, who was newly married. The ship was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen, and candles, as well as a heavier load of railway irons, cement, lead, and copper. There were other items included that were intended for display in the Melbourne International Exhibition of 1880. The voyage to Port Phillip was long but uneventful. Then at 3 am on June 1, 1878, Captain Gibbs was expecting to see land. But the Loch Ard was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4 am the fog lifted and a lookout aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head-on into the wind, the ship lost momentum, the sails fell limp and Loch Ard's bow swung back towards land. Gibbs then ordered the anchors to be released in an attempt to hold their position. The anchors sank some 50 fathoms - but did not hold. By this time the ship was among the breakers and the tall cliffs of Mutton Bird Island rose behind. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves subsequently broke over the ship and the top deck became loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of Loch Ard and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as Lochard Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael a passenger had raced onto the deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke the open case of brandy that had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a complete state of exhaustion, he told the men of the tragedy. Tom then returned to the gorge while the two men rode back to the station to get help. By the time they reached Loch Ard Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost families in the disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce, and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. Ten days after the Lochard tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of Lochard still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some items were washed up into Lochard Gorge. Cargo and artefact's have also been illegally salvaged over many years before protective legislation was introduced in March 1982. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton majolica peacock- one of only nine in the world. The peacock was destined for the Melbourne 1880 International Exhibition. It had been well packed, which gave it adequate protection during the violent storm. Today the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck it has now become Australia's most valuable shipwreck artifact and is one of very few 'objects' on the Victorian State Heritage Register.This ink well is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefact's from Loch Ard and its collection is significant for being one of the largest accumulation of artefact's from this notable Victorian shipwreck of which the subject items are a small part. The collection's objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history.Stoneware penny Ink bottle ironstone salt-glazed, stoneware cylindrical shape with small mouth and squat neck, broad shoulders brown colour, . with light coloured encrustation spots.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, penny ink well, writing equipment, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, ink bottle, dip pen, ink, hand writing, business, vintage, dwarf ink -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchFunctional object - Trench Art - Ashtray, 1938

Brass 25-pounder shell case cut off above the base and made into an ashtray with 3 indentations and set in the middle of the ashtray is a .50 calibre machine gun round.Outer edge underneath - 1938 LOT 379 25PR ECC 1 Inner edge - No II S45 CY5-40 SH&S 6/40brass shell case, .50 calibre round -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Adding Machine, n.d

Town of Portland collectionPlus Adding MachineFront: Town of Portland (tape back) Bell Punch Company Ltd/39 St. James's St/London/Plus/Guaranteed/Wholly made in Great Britian (embossed stamp, back) (Further details on plaque on base) PLUS (plaque, front) Made in England (engraved, base) -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionMachine - Embossing Press - Portland Star Pics Embossing Press, Excelsior, 1900

Portland Star Picture Theatre.Gold paint trim metal bottom, and brass.Front: Excelsior Underneath made in/United States of /America 28 Pa Cast into metal interior -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's long cream silk gloves, c1930

Ladies' evening gloves or opera gloves are a type of formal glove that reaches beyond the elbow. Ladies' gloves for formal and semi-formal wear come in three lengths for women: wrist, elbow, and opera or full-length (over the elbow, usually reaching to the biceps but sometimes to the full length of the arm). In the late 19thC and early 20thC Gloves were expected to be worn for both daytime and evening wear with most types of outfits. The most expensive full-length gloves are custom-made of kid leather. Many other types of leather, most usually soft varieties of cowhide, are used in making full-length gloves; patent leather and suede are especially popular as alternatives to kidskin. Satin materials were extremely popular, and there are mass-produced varieties as well. Carole Pedersen-Green was a founding member of CMHS. Her family were early settlers in Moorabbin ShireA pair of lady's long cream silk machine lace gloves with open fingers and thumb piece C 1930 They are the classic OPERA length, with the mousquetaire wrist openingclothing, gloves, formal wear, craftwork, lace making, dress etiquette, satin, silk, moorabbin, bentleigh, cheltenham, fashion, evening gloves., lace -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured objects, Cigarette papers ‘Zig Zag' x 2, 20thC

Rolling papers are small sheets, rolls, or leaves of paper which are sold for rolling cigarettes either by hand or with a rolling machine. When rolling a cigarette, one fills the rolling paper with tobacco. Rolling papers are most commonly made with wood pulp, hemp, flax, or rice straw as a base material. Zig-Zag papers, made in France, were the first interleaved brand (hence the name). Gold medal at 1900 Universal Exposition in Paris. 1860 Samuel Ramsden, a Yorkshire man, founded first paper mill in Victoria on the banks of the Yarra River, Fairfield, Melbourne. This was the Australian Paper and Pulp Company which for most of its history was called The Australian Paper Manufacturers Ltd. until it changed its name in 1986 to Amcor. In 1919 the company opened its mill on the corner of Upper Heidelberg Road and The Chandler Highway in Fairfield and remains there today. 2 packets of precut cigarette papers 'Zig Zag ' Paper Aust. Pty. Ltd. 60 leavesZIG ZAG PAPER AUST. PTY LTD 60 LEAVESciggarettes, cigarette papers, tobacco, moorabbin, cheltenham, early settlers, australian paper manufacturers, fairfield melbourne, zig zag cigarette papers ltd. amcor ltd, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

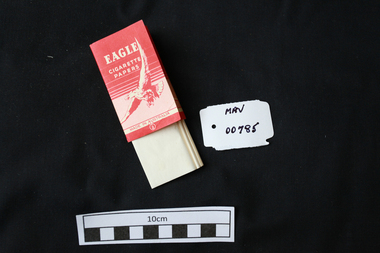

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured objects, Cigarette paper, ‘Eagle’, mid 20thC

Rolling papers are small sheets, rolls, or leaves of paper which are sold for rolling cigarettes either by hand or with a rolling machine. When rolling a cigarette, one fills the rolling paper with tobacco. Rolling papers are most commonly made with wood pulp, hemp, flax, or rice straw as a base material. 1860 Samuel Ramsden, a Yorkshire man, founded first paper mill in Victoria on the banks of the Yarra River, Fairfield, Melbourne. This was the Australian Paper and Pulp Company which for most of its history was called The Australian Paper Manufacturers Ltd. until it changed its name in 1986 to Amcor. In 1919 the company opened its mill on the corner of Upper Heidelberg Road and The Chandler Highway in Fairfield and remains there today. A packet of pre-cut cigarette papers 'Eagle ' brandEAGLE / CIGARETTE / PAPERS / MADE IN AUSTRALIA back 60 PAPERSciagarette papers, cigarettes, tobacco, melbourne, moorabin, paper mills, eagle cigarette papers ltd, australian paper manufacturers ltd, fairfield victoria, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, 'Vulcan' vitamizer, c1940

A machine fitted with sharp blades, for mashing, crushing or liquefying food ingredients. i.e vitamizing. The jug, made of glass, steel, aluminium or plastic, contains rotor blades that engage with a bit protruding from the base containing an electric motor. When activated by the switch on the base the sharp rotor blades chop, mix , mince, pulverize the ingredients in the jug . The degree of mince depends on the time the motor is running. The jug is easily removed from the base to pour the mixed ingredients where needed and the rotors are safely and easily cleaned by rinsing under water.c1940, an electric, 'Vulcan' Vitamizer, with the original cloth covered flex and bake-lite lever switch at front of the cream bake-lite base . The jug- shaped chrome blender has a red, thick, rubber lid. Front: : Vulcan / LM1 Base ; VULCAN / TYPE LM1 / Patent Pending Design / Volts 220 Amps 8vitamizer, food preparation, cooking, vulcan pty ltd australia, moorabbin, bentleigh, cheltenham, ormond, housekeeping -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, cigarette papers 'Boomerang', c1946

Cigarette or Rolling papers are small sheets, rolls, or leaves of pre-cut paper made from wood pulp, hemp, flax, or rice straw which are sold for rolling cigarettes either by hand or with a rolling machine. When rolling a cigarette, one fills the rolling paper with tobacco. PROV - The West Richmond heritage overlay - The smaller former Australian Automatic Cigarette Paper Company factory at no.103-05 Hoddle Street Richmond, also retains original Moderne detailing, which includes 'Boomerang' in Art Deco script set vertically within the piers at either end of the building. 'Boomerang' was the brand of the cigarette papers manufactured by the company until 1948. A packet of 'Boomerang' precut cigarette papers Top: 60 LEAVES / BOOMERANG/ RICE / STAINLESS CIGARETTE PAPER/ Back:: 1/3 / 60 LEAVES / BOOMERANG / RICE / AUTOMATIC GUMMED / MADE IN AUSTRALIA . Inside packet: AUSTRALIAN AUTOMATIC CIGARETTE / PAPER CO. PTY. LTD. / MELBOURNEmelbourne, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, cigarette papers, tobacco, boomerang papers, australian automatic cigarette paper co. pty.ltd. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, paper packet toothpicks 'Peacock', Peacock brand China, mid 20thC

A toothpick is a small stick of wood, plastic, bamboo, metal, bone or other substance used to remove detritus from the teeth, usually after a meal. A toothpick usually has one or two sharp ends to insert between teeth. They can come in both wood and plastic, and can also be used for picking up small appetizers (like cheese cubes or olives) or as a cocktail stick. Toothpicks are well known in all cultures. Before the toothbrush was invented, teeth were cleaned with hard and soft dental woods. The first toothpick-manufacturing machine was developed in 1869, by Marc Signorello. Another was patented in 1872, by Silas Noble and J. P. Cooley A small paper packet containing wooden toothpicksTRADE $ MARK / DOLLAR BRAND / STERILIZED / TOOTHPICKS / (chinese characters) / MADE OF BEST / WHITE BIRCH / QUALITY & PURITY / GUARANTEED / TRY ONCE USE / THEM FOREVER. wood, toothpicks, dental cleaning, dentists, timber, birch trees, signorello marc, noble silas, cooley j. p. , moorabbin bentleigh cheltenham, maret gardeners, early settlers, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMould Butter, unknown, post 1967

This butter mould/pat may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce. This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This well crafted circular wooden butter mould could also be used as a butter pat.The handle in the middle of the mould was not added after the crafting but has been fashioned from the initial block of wood when the bowl was crafted. The bowl structure has a rim around the edge.The top of the handle has an ink stamp "T. & W. Dav" on the top line and "Tawonga 3697" underneath.domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950s

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter Pat/Profiler has on its base two patterns. On each end it has horizontal grooves cut into the wood which produce distinct lines onto the surface of the butter. between these grooves there is a section of two double lines crossing in the middle and separated by eleven horizontal lines The base has an elongated rectangular shape. The upper body has been sanded into a smooth convex shaped form where a wooden circular hand grip has been fashioned.On the top of the hand grip is stamped in black print"T. & W. Davies" and under this"TAWONGA 3697"domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter, Circa 1950

This butter pat profiler may have been manufactured post 1967 (year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter pat is one of two,see KVHS 0071 (B). It has been crafted from wood. One side has grooves running from the handle to the square shaped bottom. These grooves would stop the wet butter from clinging to the pat. The top side of the pat has been bevelled on both sides and the bottom edge. The hand grip is flat and curved to allow for a comfortable hold.domestic food preparation, wooden butter pat, butter mould circular, dairy industry, butter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter pat is one of two,see KVHS 0071 (A). It has been crafted from wood. One side has grooves running from the handle to the square shaped bottom. These grooves would stop the wet butter from clinging to the pat. The top side of the pat has been bevelled on both sides and the bottom edge. The hand grip is flat and curved to allow for a comfortable hold.domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, early to late 1900's

This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State. In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (H Taylor) and where it originated from. These bottles were recyled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle. This heavy gauged glass ginger beer bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the filling production line. The method of pouring ginger beer into the bottle has been part of the "production line". This bottle has a one and a half pint capacity and is made from "light green" coloured glass(a protection against light penetration). This thick glass bottle, to contain ginger beer, required its thickness because of the extensive handling (man and machine) before final consumption. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck. Ginger beer was a "soft drink" of great demand. On the middle portion of this bottle is a large elongated circle within it and following the spherical line is "H. TAYLOR" ans a star separates this from "MELBOURNE" rounding out the bottom curviture. Within these words are the large initials "T H" . The "T" superimposed onto the "H". On the base and covering the whole bottom is the letter "T". At the opposite side to the manufacturers logo is "THIS BOTTLE CANNOT BE SOLD OR USED BY ANY OTHER PERSON & IS NOT COMPLETE WITHOUT STOPPER" glass bottle, non alcoholic drink, taylor ginger beer bottle, reuseable bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, mid 1960's

This meat mincer was born in a period where hand operated mincing and blending machines were only available for household mincing meats and blending ingredients up to the 1960's. Electrical kitchen based whitegoods were rare in areas where the connection to electricity was intermittent or not at all.This kitchen aid is a very significant item in the Kiewa Valley before suitable electrically operated mincers became available and constant reliable electrical connections were installed. The Kiewa Hydro Electricity Scheme provide the stable supply of electricity which made most of the hand operated mincing machines obsolete. However large mincers for bulk supplies were still required eg. kitchens for SEC workers during the 50's and 60's.This heavy industrial type meat mincer(cast iron) has a top "rounded feeder cup" with a mincer screw blade at the bottom. A winder handle rotates the screw like mechanism to mince and express solid pieces of meat at the other end. There is a clamp below the main structure which permits the fastening of the hand driven mincer to a table or solid ledge. The hand grip of the handle is made from wood and fashioned like a clothes peg.On the rounded feeder bowl "MAJOR" and on the winder handle "A POPE PRODUCT"hand operated meat mincers, meat grinders, kitchen utensils -

Kiewa Valley Historical Society

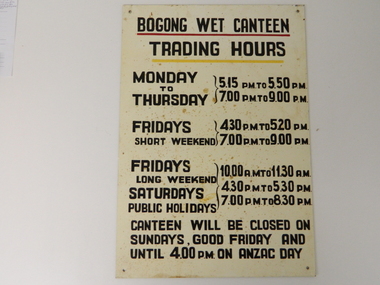

Kiewa Valley Historical SocietySign Canteen Painted, Circa 1950

This sign is a part of the "human" factor required for remote and difficult, large impact (both labour and other resources) projects. It is one of the "human" factors which was clearly used in the big 1930's to the 1970's "landscape redevelopment" schemes which started in the early 1900's and is highly regarded as lifting the Australian psyche of only primary producers to an industrial level, equal to any in the world.This "Wet Canteen" sign was installed at the entrance of the Bogong "workers" village "provision's hut" detailing the operational times for the SEC Victorian staff and construction workers, involved in the building of the Kiewa Hydro Electricity Scheme to obtain alcoholic beverages. This facility lasted for over the extensive period (1938 to 1961) of the "Schemes" building phase. This large project was the forerunner when industrial legislation provided for the welfare of workers living in the Bogong Village. The provision of facilities such as a "wet canteen" was of the utmost importance not only to ensure that the long running project was both successful, production wise, but also that its employees were not only physically but also mentally healthy. This sign details that all aspects required for a fit and productive labour force were in place, in this remote and demanding work environment. The majority of heavy equipment and machinery used was either made in England or Europe. A section of the specialised workforce came from local and European expertise in dam construction and water management in alpine terrain. The majority of labour came from migrants and some specialists recruited from England and Europe. At this point in time, the quality of the machines used came from England, Europe and the USA and could not be matched from anywhere else in the developed world. With a specialised workforce came the responsibility of providing all the "comforts of home" including alcoholic beverages. On site accommodation for the workforce is still a requirement for some mining areas but high market returns have produced fly in/out labour.This anodised metal sign has been "block" stenciled on. Black lettering and numbers with the main headings underlined with a red and a yellow line(emphasising the headings)In black stenciled type "BOGONG WET CANTEEN" underneath this "TRADING HOURS" Below this "MONDAY TO THURSDAY 5.15 PM TO 5.50 PM, 7.00 PM TO 9.00 PM" "FRIDAYS SHORT WEEKEND 4.30 PM TO 5.20 PM 7.00 PM TO 9.00 PM" Below this "FRIDAYS LONG WEEKEND 10.00AM TO 11.30 AM" Below this "SATURDAYS PUBLIC HOLIDAYS 4.30 PM TO 5.30 PM 7.00 PM TO 8.30 PM" bELOW THIS "CANTEEN WILL BE CLOSED ON SUNDAYS, GOOD FRIDAY AND UNTIL 4.00 PM ON ANZAC DAY"saucer, plate, secv, state electricity commission of victoria, canteen, bogong mess hall, recreational amenities, socialisation of sec vic kiewa hydro scheme labour force -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine - Singer

This sewing machine was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's grandmother used it in 1942. It still works (2013).Historical: Type of sewing machine used by S.E.C.V. wives living in Mt Beauty during the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and School fetes. eg. children's clothes and dolls' clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Singer sewing machine - brown wood lid & base. Handle on top of inside of lid as is the wooden bench that clips on to the side of the machine and also the steel knee lever that fits into the front of the machine. Black steel machine with silver fittings. Brown and white electric cord plugged in. "Singer" on front centre of lid. On machine - "Singer" above light. "The Singer manufacturing Co. / Manufactured in Great Britain" top of machine. "Singer" on front side of machine. Front - Gold plate - "The Singer Manfg. Co. / Trade Mark." Decoration on machine base and silver end.singer manufacturing co.. sewing. fetes. clothes. domestic. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine Attachment - Buttonhole

This sewing machine was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's grandmother used it in 1942 to make button holes.Historical: Type of machine used by S.E.C.V. wives living in Mt Beauty in the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and chook fetes e.g.. children's clothes and dolls clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Green & white box containing black & silver metal with 4 parts for attaching to Singer sewing machine for sewing button holes."Singer Buttonhole Attachment" on green 'cloud' top of box. "The Singer manufacturing Company" on green 'cloud' on side of box. "For Light Manufacturing and Home Use" on green 'cloud' on side of box. "Made in Great Britain" on white top half of end of box & teen 'cloud' below end of box is "Singer / Buttonhole Attachment / No. 86662 / For Singer Lock Stitch/ Family Sewing Machines.singer manufacturing co.. clothes. fetes. domestic. sewing. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine Accessories

This sewing machine and its accessories was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's mother used it and the accessories in 1942. Historical: Type of machine used by S.E.C.V. wives living in Mt Beauty in the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and School fetes. eg. children's clothes and dolls' clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Dark green box with red & white inscription on top. Inside are 7 metal (silver coloured) attachments for Singer Sewing Machine including one for sewing zips, ruffling foot, rolled hemming foot .singer manufacturing co.. clothes. fetes. domestic. sewing. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyAdding Machine - Addmaster

An adding machine is like a calculator enabling the user to do addition and subtraction and multiplication and division by repetition. Adding machines provided a printed receipt for each entry and calculators display information on a screen.Adding machines were used in the office and were replaced by calculators and comptometers.Used by a resident of the Kiewa Valley and possibly in the SECV office.Formerly UKV 242 or Contex UKV 253 - Electric (no cord). Beige and grey plastic covered adding machine with blue numbers and black function keys. Paper roll winder and dispenser at the top of the machine. Charcoal coloured plastic base with label and patent information. A blue handle for carrying. 2 small grooved wheels on the base.Left hand front: Addmaster label and logo Base: Label on base - "Addmaster Corp. Made in USA serial number 175614". Patent information labeladding machine, addmaster, mathematics -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFordigraph Machine

Invented in 1923 by Wilhelm Ritzerfeld. A Spirit duplicator' refers to the alcohols that were a major component of the solvents used in the machine.Limited number of copies one could make from an original along with the low cost and corresponding low quality of copying. Used to make multiple copies of a document eg. in office at a school for eg. a newsletterUsed at Bogong Primary SchoolFormerly UKV 048 Solid black, heavy, steel machine on 4 legs with flat tray at the front and roller at the back. The roller has a cover on the sides and front. From the top you can see the silver roller which is operated by a handle on the right side. There is a small lever and 2 knobs on the same side.In gold on the back "Fordigraph" and "The Nipper Fordigraph" with a blue circle made by 3 arcs with arrows. 2 labels on one side, screwed on. The labels have a silver background and black print. "Off" and "On"fordigraph machine, copying -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDress, Hand made, c.1900

... . Home made, with manual machine stitches and some hand sewing... in calico. Home made, with manual machine stitches and some hand ...This dress is hand made possibly by a mother for her daughters. It is hand and machine stitched. This style of dress would have been worn for special occasions, eg going to church or special outings.This item is very significant for the following reasons. Historic and social - it shows what little girls wore during the early 1900's of the Kiewa Valley. It also shows fashion of the times and how these styles of dresses were made. All of which is valuable for research on these topics. There are only two of these dresses in the collection of the KVSH, and therefore would be very rare. The condition is good enough to display, therefore it has good interpretive capacity.Brown Cotton Dress. Top and sleeves are lined in calico. Home made, with manual machine stitches and some hand sewing. The dress has a high round neck and long sleeves. There is a band around the waist to which a gathered skirt it attached with hand stitching. Two different shades of brown are used on this dress. Back opens with 8 hooks. Water stains on dresschild, homemade, dress, girl, kiewa-valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyApron, Hand Made, late 19th century to early 20th century

... is manual machine stitched Apron Hand Made ...This item is hand made possible by a mother for her daughters. It is hand and machine stitched. This style of aprons / pinafore is attached to the two brown dresses that are also in the collection. This item is very significant for the following reasons. Historic and social - it shows what little girls wore during the early 1900's of the Kiewa Valley. It also shows fashion of the times and how these styles of aprons were made. All which is valuable for research on these topics. There are only a few of these aprons in the collection of the KVSH, and therefore would be very rare. The condition is good enough to display, therefore it has good interpretive capacity.Girls apron or pinafore. White linen with crocheted lace around the edge which is continuous around the skirt, sleeve and neck. The shoulders flaps appears that they should be pinned to the dress beneath, and pinned together at the back of the waist. The apron is manual machine stitchedclothing, girls, children, pinafore, apron, kiewa-valley, alpine-shire -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyChurn Butter - Wooden

This type of butter churn was used around the early to mid 20 century by household and small farms of the Kiewa Valley who kept cows for Milk. The buy product of the milk was cream and butter. Once the cows had been milked, often by hand, women would place the milk in shallow dish, and next morning the cream would be separated from the milk. Or a cream separator machine would be used. The cream would then be churned by the paddles in the butter churner until it formed in butter clumps. Butter Pats would be used to take the butter out and press into triangle butter blocksThis butter churner is significant due to its historical value which explains how butter was made by hand before this process became mechanistically made. Many houses or small farms in the Kiewa Valley had these butter churns to make their own butter for their household or to sell. This has very good interpretation significance as it adds to the history of dairy industry in the Kiewa Valley. Wooden box with a metal handle for turning the blades /paddles /slats inside the box.These blades churn the cream when the handle is turned. There is also a wooden handle and a wooden lid.butter, dairy, milk, manual, domestic, item, food, preparation, dairying, technology -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyUndergarment Child, local seemstress or mother

local manufacture either a seemstress or a mother. Time Circa 1920s to 1940s. Distance from towns with haberdasheries would force local manufacture of garments by highly skilled women.Historical period Circa 1920s to 1940s was before easy access to branded manufactured clothes. Majority of basic clothing was hand made either family or skilled friends and neighbours This is Garment is cross referenced to KVHS 0249 and KVHS 0248 and details the growth of a young childGarment has sleeveless top attached to pantaloons at waist and open crotch and going down inner leg seam to 8cm from bottom. Bottom section of each leg adorned with crocheted lace and two pin tucks around bottom of the legs. Top back of garment has three "Mother of Pearl" buttons and narrow 8 mm wide shoulder cross reference to KVHS 0249 and KVHS 0240 straps. Machine stitched cream in colourvest, underwear, child's clothing -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDress

made locally circa 1910. Due to relative long distance to haberdashery stores majority of children's garments were hand made by a local talented seamstress or mother/relativeHistorical significant to the period circa 1900 to circa 1950 when fashion was dictated by long lasting durability, local manufacture, earthy colours and ease of mobility. Photos in the KVHS collection show girls from Tawonga Primary School in a dress that could be this dress which is dated 1910. Dress brown cotton with long sleeves. Dress top and sleeves lined. Back of dress is open with metal hooks for fastening. Hand stitched eyelets and decorative strip down centre front bodice and around hips. Gathered skirt is joined at hip. One pocket on left side 6cm from waist band.Decorative strip at bottom of dress with a pleated hand and machine stitched frill.no inscriptions or markings suggesting locally made.dress, clothing, girl's dress, home made -

Kiewa Valley Historical Society

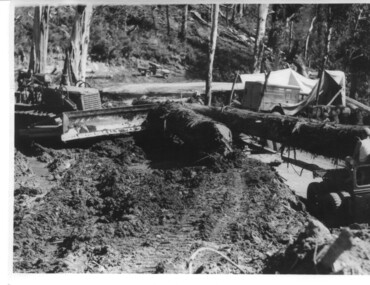

Kiewa Valley Historical SocietyPhotograph, logging at McKay Creek, Logging at McKay Creek, c1950's

... , a decision was made to place the machine hall of the power station... with landslides in this area, a decision was made to place the machine ...This photograph was probably taken at the site of McKay Creek Power Station. Excavation of this site did not commence until 1951 but road access(a narrow track) was provided in 1948 and widened in 1954. The logs would have been milled for timber at the State Electricity Commission's mill at Howman's Gap and thus provided a much needed source of timber for construction of camps and houses as there was a general of shortage of this commodity. Because of trouble with landslides in this area, a decision was made to place the machine hall of the power station underground instead of on the surface. Restricted financial resources and the repositioning of the power station retarded construction activities and it was not completed until early 1961.. An excellent pictorial record of the general working conditions, type of machinery and vehicles in use in the 1950/s.Black and white photograph showing logging equipment, fallen logs.Handwritten on the back of the photograph "Logging at McKay Creek)logging, mckay creek, timber, machinery