Showing 1264 items

matching manufacturing industries

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBadge Red Cross, circa 1968

... towns and cities. The manufacturing industries including textile ...When this winter appeal badge was produced the Australian economy was in recession (financial down turn) and the ability of some of the unemployed sectors of the community required but could not purchase warm clothes. The Australian recessions of 1945 and 1961 left their mark on the economy and accounted for a long and slow recovery in the 1960's and 1970's. The Red Cross was one of a few benevolent agencies/organisations that provided those more affluent in society to donate money to these types of appeals for financial donations. the money collected was used in obtaining warm close for those in need.In the Kiewa Valley the lingering recessional consequences (high interest rates, slowdown in Australian manufacturing) had an effect upon those whose produce was consumed by large towns and cities. The manufacturing industries including textile and clothing industries were feeling the start of the invasion of cheaper imports. Unemployment was beginning to be an ongoing major political and social issue. The need for support for the financial strapped city and country towns was on the increase and this Red Cross Badge (Winter Appeal) was one of several appeals to help those financially disenfranchised families to overcome the severe clothing shortages in both country and city environments.This badge has an enamel front with red and blue lettering and the circumference is marked to represent a 'life ring, life buoy, life belt' which has all of the red lettering with in its boundary. The fastening mechanism is a "stick" pin made from mild steel (fashioned as a semi circular spring contained within the back rim of the badge. The "stick" protrudes beyond the badge allowing it to be fastened onto clothing.At the top of the badge and in red print "RED CROSS" and at the bottom "WINTER APPEAL" with a"1/-" (one shilling coin - modern equivalent to 10 cents). In the middle of the badge is printed a red cross and above that "HELP"societies, red cross appeals, apparel badges, numismatics badges -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTransformer Lamp System, late 1950's

This transformer lamp system, which has a dial to transform 240 volts to a minimum of 32 volts was used by electrical technicians to inspect internal parts of the large generators (even in small confined spaces). The reason for the reduction of the 240 volts to the 32 volts was for the safety of the inspector. The SEC Victoria Hydro Scheme's electrical generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro schemes was achieved from the mid 1900's to the 1960's. At this the point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This transformer lamp is very significant to the Kiewa Valley as it was introduced as a very small part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both industrial and larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley. This is also a specific electronic item which was manufactured in Melbourne and not sourced from Europe or Asia. This demonstrates the fast evolution of Australian technology to a high standard compatible to that of the rest of the world.This heavy hand held electrical transformer (transforms 240 volts to 32 Volts) an has one leather handle on the top with three small (gauze filtered) air holes. It also has two 2 pin directional cable distribution (clipsal) in/out points 10amps / 240 volts. There is one glassed in volts/ac meter and one variable switch (180 to 150 voltage in settings of 10 volt increments.There are two vents (one on each of the smaller sides). There is also one three pin electrical lead coming out from the top.On one side is a manufacturer's plaque with "ELECTRONIC A & R EQUIPMENT MELBOURNE" and underneath "TYPE 1719, PRI V. 180 250" underneath "V.A. 1250" underneath "CYC 50" underneath "SEC V. 115" underneath "SEC A. 10 . 8". The label on topside "CAUTION SET SWITCH TO 250 v BEFORE CONNECTING TO MAINS THEN, WITH EQUIPMENT OPERATING, SET METER TO RED LINE.kiewa hydro electricity scheme, victorian state electricity commission, transformers -

Kiewa Valley Historical Society

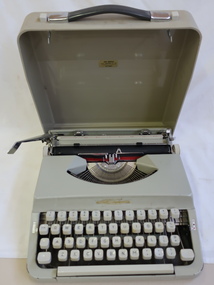

Kiewa Valley Historical SocietyTypewriter - Portable

... by CFM Industries. CFM (Curvie Furniture Manufacturing... These typewriters were imported fully assembled from Japan by CFM Industries ...These typewriters were imported fully assembled from Japan by CFM Industries. CFM (Curvie Furniture Manufacturing). The Nakajima portable typewriters were imported in the 1970s. Typewriters replaced hand written writing. Their benefits were that the work was written faster and was legible. The portable typewriter enabled the typist to take her typewriter with her. Typewriters have now been replaced by computers with the advantage of editing the work before the final copy is made and with the ability to add eg. photos, create different settings etc. Used by a resident of the Kiewa Valley in the 1970s.Beige hard plastic case with dark grey handle with chrome fittings and white buttons either side of the handle. Metal typewriter 'querty' key board, white keys with black inscriptions. Includes typewriter ribbonLabel inside cover for servicing. "CFM Industries Pty Ltd address, phone number" Label on back of typewriter for CFM Industriesportable typewriter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySuitcase

... manufacturing industries in the Australian market. The rarity ...Typical early 1920's to late 1950's suitcases made in Australia using Australian and British manufactured clasps and locks. The majority of manufactured goods especially locks and other metal components were sourced from England. English manufacturers, who in that period, where still world leaders of most manufactured items.This period 1920- 1950 shows the historical shift of the balance between the more complex metal imported items, mainly manufactured in Britain and that of the relevant infant stage of the developing manufacturing industries in the Australian market. The rarity of this type of suitcase is of significancy This suitcase belonged and was used by the C.W.A. of Tawonga.Suitcase brown, possibly lacquered cardboard with leather chrome studded reinforced corners. Lid has two silver coloured(chrome) clasps each end with chrome lock in centre. "D" rings for missing handle secured to main frame by leather straps, these having metal chrome studs. Substitute handle made from string. Metal protective trim on lid and top edge of suitcase compartmentLock stamped "Made in England" and two end clasps stamped "Made in Australia"case, luggage, travel suitcase, country women's association -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTypewriter Mechanical Portable, 1950s

The Olivetti company was founded in Italy in 1908.This particular typewriter is a Olivetti Lettera 22, oblique front stroke and portable manufactured after 1950. The 1950s and 1960s was a time when British manufactured goods were still purchased by many Australian consumers. The later 1960s onwards, there was a shift, mainly in the cities, to European made goods. The invasion of Japanese manufactured goods was relatively slower, especially in rural areas. The demand for long lasted and dependable merchandise was in the rural area still the most important criteria. The ease of setting up this typewriter and its compact mobility was its major benefit to trades people and travelling professionals, e.g. rural doctors, other medical professionals, accountants, lawyers and educators. This item facilitated the growing numbers of professional nomads requiring a relatively light office stationery package e.g. travelling novelist, writer, businessman and academics. This typewriter needed no electrical or battery power to operate it. Outback Australia, where at this point in time, was still relatively isolated from a good available electrical power reticulation and battery power, and therefore could not be totally measured as a highly efficient office environment.Although this typewriter was purchased from a business in Penrith, Sydney, N.S.W., it is significant that it travelled easily to the Kiewa Valley, demonstrating the mobility of certain sections of the community. This typewriter was designed by an Italian industrial designer, Marcello Nizzoli, in line with the art deco style of the 1930s and the colour and flexibility of the vibrant 1950s. The underlying theme of manufacturing in the 1950s was to produce equipment that was more efficient than what was inherited from the earlier period of 20th century. Improvements were made to this Olivetti typewriter by Giuseppe Beccio by reducing the number of parts made from 3,000 to 2,000. This reduction of parts and therefore cost of production was the major principle of the Japanese manufacturing juggernauts of the post World War II era. Efficiency and low costs material was becoming prime factors in the success of rural industries from the 1960s. Competition from overseas producers was starting to affect rural industries and the removal of the large range of tariff protection, especially rural products, required not only a shift of farm management but a more efficient cost savings modus operandi. This Olivetti Lettera 22, oblique front stroke portable (weighs 4kg) mechanical typewriter has a coral coloured plastic casing. The keys are made of black hardened plastic with white lettering, numbers and symbols (imperial fractions, and pound). It has a QWERTY keyboard as opposed to the Italian QZERTY. It has a lever to move the ribbon between black, neutral (for mimeograph stencils)and red colours (a red key is provided for highlighting specific words,letters or symbols) . This machine is fitted with only a black ribbon. It has a black rubber paper rollers and chromed metal parts on the carriage way. It has four rubber feet underneath the main body. On the left side of the roller there is a lever to adjust the roller from fixed (when mobile) through 1,2 and 3 line space gradients. This model has a key for zero but not one for the number one (uppercase letter l is used) see KVHS 0459 for the carrying bag.On the cover over the ribbon wheels letter strikers has a plate marked "Lettera 22" and the back plate behind the paper roller and in front of the paper supports has a silver metal label marked "olivetti made in great britain".commercial, mobile office equipment, mechanical typewriter -

Warrnambool and District Historical Society Inc.

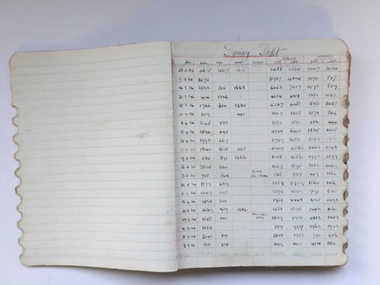

Warrnambool and District Historical Society Inc.Book, Ledger Woollen Mill - Departmental Weekly Reports, 1930s

This is an exercise book, probably purchased from a local stationers, which was used at the Warrnambool Woollen Mill in the 1930s to record weekly operations in each of the Mill’s departments. The Warrnambool Woollen Mill was established in 1910 in South Warrnambool by a local company, with the building erected on a site that formerly housed another woollen mill destroyed by fire in 1882. The Warrnambool Woollen Company operated successfully for many years with over 700 employees in the 1940s and a good national reputation for quality goods. It made blankets and other woollen goods and was the first company in Australia to manufacture electric blankets. In the 1960s the mill was sold to the Dunlop Company and for the next thirty years it was bought and sold several times, finally closing in 2000 after 90 years of operation. This exercise book is of some importance as it belonged to the Warrnambool Woollen Mill, a dominant and important industry in Warrnambool for most of the 20th century. Many present and past residents of Warrnambool and district were employed at the Mill. It is one of many items in our collection that outlines the mill’s day-to-day operations and contains information that may be useful to researchers. This is an exercise book which belonged to the Warrnambool Woollen Mill and appears to be two exercise books joined together as there is a black cover in the middle of the pages. The original black covers at the front and back are missing. The pages are lined in blue and most used pages have ruled red lines. The entries are in black ink and include the date and other information on the processes of the spinning, carding, scouring etc. The page edges on the right have been serrated in an oval shape to make tabs for the various departments in the Mill – Engineers, Scouring. Dyeing, Warehouse etc. and the book contains weekly entries regarding Mill operations from 1930 to 1936.Edge of book: ‘Records’warrnambool woollen mill, history of warrnambool -

Warrnambool and District Historical Society Inc.

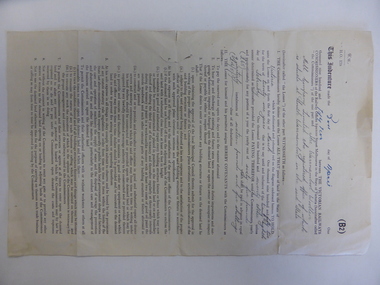

Warrnambool and District Historical Society Inc.Document, Lease of Land by Victorian Railways to Warrnambool Woollen Mill Co Ltd, 1952

The Warrnambool Woollen Mill was established in 1910 in South Warrnambool by a local company, with the building erected on a site that formerly housed another woollen mill destroyed by fire in 1882. The Warrnambool Woollen Company operated successfully for many years with over 700 employees in the 1940s and a good national reputation for quality goods. It made blankets and other woollen goods and was the first company in Australia to manufacture electric blankets. In the 1960s the mill was sold to the Dunlop Company and for the next thirty years it was bought and sold several times, finally closing in 2000 after 90 years of operation. The woollen Mill was built on a site which was in easy access to the railway line which operated along the original tramway line from the town to the jetty. It is possible that this land would have been used for parking during the period of 1950's to 1970's which was a successful period of manufacturing and trade for the Woollen Mill. A link between an important infrastructure and one of Warrnambool's most important industries.Four page folded document cream in colour . Printed form with diagram of the land in question coloured in pink . Seals of both Victorian railways and Warrnambool Woollen mill are stamped beside signatories on page 3. Dated 30th April 1952. Signed R Naylor for the Warrnambool Woollen Mill and two unreadable signatures for Victorian Railways.warrnambool, warrnambool woollen mill, warrnambool railways, lease victorian railways and warrnambool woollen mill -

Warrnambool and District Historical Society Inc.

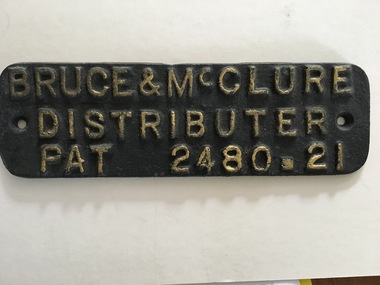

Warrnambool and District Historical Society Inc.Brass Plate, Bruce & McClure Distributer, C early 20th century

Bruce & McClure were manufacturers of windmills and agricultural machinery including motor engines , pumps, tanks,and appliances for supplying and conserving water.Also included was brass,iron and steel foundry works. They won 11 first prizes at the Grand national Show of 1907 and in 1914 designed and manufactured a new water boring machine which could also be used for oil and gold exploration They operated from Lava Street well into the 1940's as well as from the geelong area. This plaque is possibly from one of their machines.A tangible link to one of Warrnambool's manufacturing businesses which was innovative and an essential part of the beginnings of machine use in farms and industry in the district. Cast iron plaque with moulded text which is coloured in gold. rectangular with rounded corners. Back is painted grey.Bruce & McClure Distributer Pat 2480.21warrnambool, bruce & mcclure, bruce & mcclure machinery -

Orbost & District Historical Society

Orbost & District Historical Societybottle, C 1970's -1990's

Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips & Stone continued to manufacture soft drinks at Orbost until the early 1970s when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of the carpark at the rear of the Orbost Newsagency. (John Phillips) This bottle is an example of a product manufactured/distributed by a local industry no longer existing.A narrow-shouldered, clear glass bottle with white and red lettering. The neck is threaded (cap is missing). It is labelled "P & S 850ml; Phillips and stone; refreshing drinks. BAIRNSDALE AND ORBOST. Manufactured by Phillips & Stone Bairnsdale & Orbost E2361. Preservative added. Artificially coloured and flavoured."glass-bottle container phillips-and-stone -

Ringwood and District Historical Society

Ringwood and District Historical SocietyBook, Leigh Blackburn et al, Stokes - A Proud Heritage, 140 Years In Australian Manufacturing Industry - Leigh Blackburn and Gregor C. Eccleston, 2021

... , 140 Years In Australian Manufacturing Industry - Leigh ...Hardcover book based on a history of the Stokes company up to the mid-1990s.Dedication (by Leigh Blackburn) - To my son Peter James Blackburn 1945-1991 who shared with me my association with the Stokes company. -

Orbost & District Historical Society

Orbost & District Historical Societybottle, C 1970's

... manufacture by a local industry no longer existing. beverages Phillips ...Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. Phillips & stone operated a cordial factory in Orbost. This bottle is an example of a product manufacture by a local industry no longer existing.A tall clear glass cordial bottle with a red printed label on the front of the bottle, It has a metal lid.On glass -"manuf. by Phillips & Stone, Bairnsdale & Orbost 52361 preservative added, artificially coloured & flavoured 850ml" On lid - "Lemonade"beverages phillips-stone bottle -

Orbost & District Historical Society

Orbost & District Historical Societysoda syphon, first half 20th century

... manufacture by a local industry no longer existing Phillips&Stone ...Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. Phillips & Stone operated in Orbost and Bairnsdale. This bottle is an example of a product manufacture by a local industry no longer existingA clear glass soda syphon bottle with a red pump on the top."Soda Water Phillips & Stone Bairnsdale P S ORBOST (trademark) 30 Fl OZ"phillips&stone syphon bottle -

Orbost & District Historical Society

Orbost & District Historical Societysoda syphon bottle, first half 20th century

... of a product manufacture by a local industry no longer existing. syphon ...Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass soda syphon bottle. It has a red syphon pump.D.DROSSOU, ORBOST Soda Watersyphon-bottle drosseau -

Cheese World Museum

Cheese World MuseumPhotograph, Unknown photographer, The first mechanical milking machine public demonstration in Allansford district, 1905

... industry food manufacture machinery lkg cudgee briarwood milking ...The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This photograph is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No. Photograph tells the story of a special celebration marking the occssion of the demonstration of the first mechanical milking machine on the Ernst Uebergang property Briarwood at Cudgee Victoria. Ernst Uebergang is inside the shed. Reported in Warrnambool Standard 5 June 1905.Photo on badly damaged brown mount board. Image depicts LKG milking machine demonstration. Dignitories, farmers and children present. Two men are inside the shed with two cows. Written on back of photo 'LKG Milking Machine Lawrence Kennedy 1902/ Mr Ernst Uebergang inside shed.'uebergang, dairy industry, rural industry, food manufacture, machinery, lkg, cudgee, briarwood, milking machine, children, cows, dignitories, farmers, bucket -

Cheese World Museum

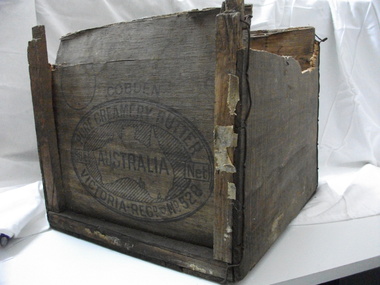

Cheese World MuseumBox, butter

... of these exist. butter dairying dairy manufacturing industry butter boxes ...This butter box belonged to Jack Gore of Warrnambool who used it in his garage to store car parts. It is connected to Warrnambool Cheese and Butter Factory Company Limited through the box manufacturer, Peter John McGennan, who was one of the instigators of the factory. Cobden and Warrnambool factories were the first two co-operative factories to produce butter in Victoria, both commencing in 1888. Warrnambool Cheese and Butter Factory Company Ltd is the only remaining independent butter factory still using its original name. It is an example of the manner in which butter was packed for export from the late 19th century until well into the 20th century. Its innovative design is light but strong, using plywood for the box body and struts 'stitched' to the body with wire. The ply was originally pine imported from New Zealand which did not taint the butter. Following the exclusion of the timber from NZ, plantations of local pine were planted and used. McGennan's box factory supplied butter boxes to the majority of butter factories in Victoria, producing up to half a million boxes per year by 1917.This Cobden butter box is historically significant relating to the butter industry and a rare item. Not many of these exist. Wooden butter box with broken ends and a hole in the bottom.Constructed using thin ply ends, sides and base with square wooden struts tied with wire to strengthen the box. The trade mark on the end of the box is an oval with text around a map of Australia with the word AUSTRALIA printing across the map.COBDEN/PURE CREAMERY BUTTER/56lb Net/VICTORIA/REGD No.528butter, dairying, dairy manufacturing industry, butter boxes, cobden -

Cheese World Museum

Cheese World MuseumTrophy, 2001

Awards for cheese quality have been part of the dairy industry since the 19th century and are designed to maintain and continue improving the quality and flavour of cheeses manufactured in Australia.Wooden trophy in form of cut-out shape of Victoria mounted on a plinth by two gold-coloured rods. Details of the award printed in black on the shaped area and a small plaque noting details of winner attached to the plinth.Rhodia DIAA Dairy Product Awards 2001/Rhodia Australia Award/Highest Scoring Cheddar Cheese - Mild in Class 7 Base plate - Presented to/Warrnambool/Cheese & Butter Factory Ltdallansford, dairy industry, cheese, warrnambool cheese and butter factory ltd, wcb, rhodia, dairy industry association of australia, trophies -

Cheese World Museum

Cheese World MuseumDVD, A Look at our History -Vol.2, 2005

Series of interviews with former employees of Kraft (Allansford) and directors of Warrnambool Cheese and Butter Factory discussing their time and experiences as employees and directors of the factories. Warrnambool Cheese and Butter Company Ltd was established in 1888 and in 1935 developed a relationship with Kraft Foods Australia whereby Kraft leased premises from WCB. The two companies shared the milk collected to make their core products of cheese (Kraft) and butter and milk for domestic use (WCB). This arrangement continued until 1997.Gold DVD in plastic case, B&W cover with colour WCB logo.A Look at our History: Ron Campbell, Steve Heazlewood, Jim Mahony, DJ (Barney) Loganallansford, heazlewood, steve, campbell, ron, mahony, jim, logan, dj (barney), wcb, warrnambool cheese and butter factory company ltd, kraft foods ltd, dairy industry, dairy processors, factories, local history, cairns, peter, cheese manufacture -

Cheese World Museum

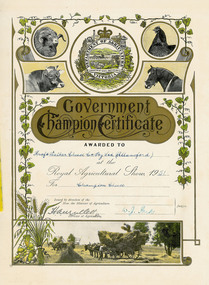

Cheese World MuseumCertificate, Government Champion Certificate, 1951

Kraft-Walker Cheese Company commenced in Allansford in 1935 leasing the factory premises from Warrnambool Cheese and Butter Factory Company. Dairy companies entered competitions organised by the Dairy Industry Association and associated organisations and local agricultural societies to encourage improvement in products. Some of these awards are considered prestigious and highly regarded within the industry. The certificates were passed to Cheese World Museum by the factory management.This certificate was held by the factory management until transfer to Cheese World Museum. The certificate provides an insight into the dairy industry during the 1950s.Cream card certificate from Royal Agricultural Show has a plain line border on left, bottom and right side with inner border of green vine plant on left, top and right side. A sheaf of oats and a scene of haymaking complete the border design. The top of the certificate has the Department of Agriculture Victoria logo flanked by circular images of a sheep and cow on the left and a hen and horse on the right. The centre of the certificate has a gold shape overprinted with black.Government Champion Certificate/ Awarded to Kraft Walker Cheese Co Pty Ltd (Allansford) at the Royal Agricultural Show 1951/ for Champion Cheese/ Issued by direction of/Hon. the Minister for Agriculture/H A Mullett/ Director of Agriculture/ W J Park/ Judgesallansford, kraft walker cheese company, cheese manufacture, dairy awards, product awards, warrnambool cheese and butter factory company, kraft walker pty ltd, royal agricultural show, department of agriculture victoria, cheeses, cheese manufac, warrnambool cheese and butter -

Cheese World Museum

Cheese World MuseumPhotograph, Kraft Walker Cheese Pty Ltd Garvoc Branch factory, c1940

... and was eventually demolished. Garvoc Allansford Dairy industry food ...The Kraft Walker Cheese Co Pty Ltd entered into an agreement with Warrnambool Cheese and Butter Factory Company in 1935 whereby the Kraft company leased premises from WCB. This arrangement remained in place until the 1990s. WCB took over the Garvoc factory in the 1920s. It became outdated and was eventually demolished.Black and white photograph showing timbered building with iron roof and turned wooden finial on the gable end. There are three timber ventilation ducts on the roof. The gable end has sign Kraft Walker Cheese Co Pty Ltd Garvoc Branch. A concrete block addition is at the front. A tray truck with milk cans is in between the main factory building and the outbuilding.garvoc, allansford, dairy industry, food manufacture, kraft walker cheese company, factories, cheese, kraft foods ltd, transport, milk cans -

Cheese World Museum

Cheese World MuseumTable, Cheddar cheese table

Believed to have come from Tooram where it was used for cheese making. Tooram commenced cheese manufacture in the mid 19th century in a purpose-built bluestone factory beside the homestead. It was initially set up by Pierce and a long article in the Warrnambool Standard describes the factory and its processes. Cheese production continued through changes of ownership until the 1930s when the Uebergangs ceased making cheese on site. The table was auctioned at Panmure and purchased by 'Flapper' Clarke of Panmure who donated it to the museum in 2012.Rectangular wooden table with trough top, two rounded handles at either end and four legs with stays at either end; has been lime washed on the outside.rural industry, agriculture, food technology, dairying, food processing, allansford, tooram, panmure, cheese making, clarke -

Cheese World Museum

Cheese World MuseumCheese press, Perfect Cheese company

... Company Avery cheese manufacturing dairy industry J & T YOUNG AYR ...Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This cheese press is significant as it represents the machinery used by an early cheese production company.Stainless cheese press machine with three steel supports and two threaded rods will spring tension wheels to screw down to pressurise the hoops containing cheese.J & T YOUNG AYR UKallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

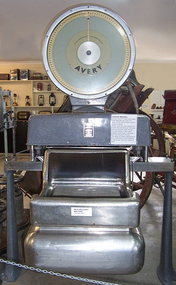

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

... company avery cheese manufacturing dairy industry Made in England ...Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

Cheese World MuseumBook, laboratory notes

Kraft Walker commenced cheese processing at Allansford in 1935 under a lease arrangement with Warrnambool Cheese and Butter Factory. This arrangement remained in place until Kraft officially ceased bulk cheese production at Allansford in February 1993. Kraft was responsible for farm collection of milk which was then shared between the two companies -Kraft for bulk cheese manufacture and Warrnambool Cheese and Butter Factory for whole milk, milk powder and butter manufacture. Laboratory technicians tested milk and cheese during the receival and manufacturing processes to ensure a high quality product. Derek Shaw, whose notebook this is, was the first person in charge of the Kraft Allansford laboratory. He kept notes of testing undertaken and recorded results of anything considered unusual. This notebook is one in a series of 33. Les O'Callaghan commenced work in the laboratory as Derek Shaw's assistant and technician in charge following Derek's retirement. He too kept notebooks of test results.Kraft laboratory technician/bio-chemist Les O'Callaghan was responsible for the introduction of a number of quality control measures which are still in use in the dairy industry today. Les was mentored by Derek Shaw. This note book provides an insight into the dairy processing industry at this period.Black exercise book with lined pages; white sticker on front cover showing dates usedLH/ 17/11/1938 / 2/5/1939allansford, dairy industry, dairy processors, cheese making, kraft foods ltd, warrnambool cheese and butter factory company -

Cheese World Museum

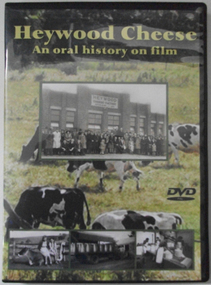

Cheese World MuseumDVD, Heywood Cheese; an oral history on film

For many years the Heywood Cheese Factory was an important part of life for Heywood and district farming and a vital place of employment for up to 40 men and 10 women. The factory opened in 1939 as a subsidiary of the Portland Butter Factory before becoming a world renowned cheese making enterprise. It was felt important to document its history from the surviving factory workers, including dairy suppliers and milk truck drivers. We hear their stories of the long hours and hard work without penalty rates, travelling unsealed roads and mixed with their humour of the bygone days is an important acknowledgement of that era. [blurb on back cover]This oral history provides significant material relating to the dairy industry in south west Victoria during the mid 20th century. The interviews give first-hand recollections of the interviewees involvement in the industry from a point of view of factory workers, milk pick-up drivers and farmers.Full colour DVD cover has photograph of Heywood Cheese factory and photographs of girls with calves, milk cans on a truck and workers in the cheese room, superimposed on a photograph of dairy cows grazing in a paddock. The DVD has the photograph of the cows grazing in the paddock.Heywood Cheese/An oral history on film (front) For many years Heywood Cheese Factory was ... [see historical information] Edited by Garry Kerr for the Heywood Pioneer Wagon Shed/ Museum History Group who wish to gratefully acknowledge the/ support of the Victorian Government and Public Records Office/ Victoria for making this project possible. Duration: 70 minutesallansford, heywood, cheese factories, cheese manufacturing, dairying, cheese -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Treadle Scroll Saw, Hobbies Ltd, Manufactured by Hobbies in England from 1928- 1965

Since 1895, Hobbies Ltd have been supplying model makers and enthusiasts throughout the world with a wide range of quality model kits, accessories, tools, components and handbooks. The Hobbies Company began life in Dereham, Norfolk in 1881 with a London Office opened later (1922) at 65 New Oxford Street, WC1. In 1895 Hobbies began supplying model makers with their products and in 1897 were incorporated into a Public company. In 1922 at a British Industries Fair the company had a stand advertising their products as "The All-British Firm with a World reputation". Fretwork Outfits. Fretwork Machines. Carpentry Outfits. Strip work Outfits. Also manufactures of Fretwork Tools and Benches, Wood, Circular Saws, Lathes, Picture Framing Outfits, Tools, etc. In 1947 the company had expanded and was still making tools and materials for the amateur craftsman in wood. They had acquired a reputation as manufacturers of quality Fretwork Outfits, Tools, Treadle Machines, Model Maker's Tool Kits. The company also publishers of ‘Hobbies Weekly magazine’ and also sold plans for fretwork, model making and wooden toys. In 1961 they were still manufacturers and retailers of craft tools and materials, timber merchants, light engineers and Government contractors with around 500 employees. A vintage tool made for hobbyists and distributed throughout the world by a British company that is still in existence today. The item is significant as it catalogues the manufactures history at a specific time in the company's development.Foot operated treadle Fret saw called "GEM" subject item is a short saw , the stand in the background is the base for a Delta Q3 model scroll saw. Gem inscription cast into the cast iron frameworkflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, saw, treadle saw, fret saw, pedal saw, the gem, tool, hobbies ltd, treadle, foot operated -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clock, late 1900s early 20th Century

In 1850 the Ansonia Clock Company was formed as a subsidiary of the Ansonia Brass Company by Phelps and two Bristol Connecticut clock makers, Theodore Terry and Franklin C. Andrews. Terry & Andrews were the largest clock manufacturers in Bristol at the time with more than 50 employees using 58 tons of brass in the production of about 25,000 clocks in 1849. Phelps decided to get into the clock making business to expand the market for his brass, while Terry and Andrews got access to better quality brass at better prices. They had then sold 50% of their business to Phelps and moved the business to Ansonia, Connecticut. In 1877 the clock company purchased a factory in New York and moved most of its production thereafter being spun off from the brass company. Henry J. Davies of Brooklyn, himself a clock maker, inventor and case designer, joined the newly reconstituted company as one of its founders. As President, he is thought to have been largely responsible for the figurine clocks, swing clocks and other unusual and desirable novelties for which the Ansonia firm became known. By 1879, a second factory was opened in Brooklyn, New York and by June 1880 employed 360 workers, while the Connecticut factory continued producing clocks as well with a workforce of 100 men and 25 women. Hence, clocks marked "Connecticut" were generally produced before 1879, while those marked "New York" were all produced after 1880 After the New York factory burnt down in 1880 the company rebuilt the factory on the same site, and reopened the expanded factory in 1881, with a capacity to exceed that of the Connecticut factory which by 1883 had closed. By 1886, the company had sales offices in New York, Chicago and London, with more than 225 different clock models being manufactured. In 1899, Phelps' grandson William Earle Dodge Stokes commissioned architect Duboy to build the "greatest and grandest hotel in Manhattan, New York” which became the city's first air-conditioned building. In 1929 the majority of the timekeeping machinery and tooling was sold to the Soviet government's US trading company Amtorg, just before the stock market crash. The parts, machinery and key skilled workers were shipped out of the USA to form the basis, along with the remains of a watch company purchased a year later, of the clock and watch industry in Moscow such as Poljot and Sekonda. In 1969, the rights to the use of the name, trademarks, and goodwill were transferred to Ansonia Clock Co., Inc., Lynnwood, Washington. The item marks the beginning of mass produced clocks in the United States, cheaply priced and available to all. The company had many innervation's during it’s life regards clock and later wrist watch making that led the way for other companies in many different countries to emulate.Clock, pendulum mantle model. Carved scallop "Ginger bread house" cottage clock. Oak case, white enamel face, floral etched glass door. Clock has an hour bell chime. Glass front opens to allow rewinding. Made by Ansonia Clock Co, New York. Marked "Manufactured by Ansonia Clock Co. New York, USA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, mantle clock, clock, pendulum clock, time keeper, horology, ansonia, ansonia clock co, america -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry