Showing 212 items matching "textile company"

-

National Wool Museum

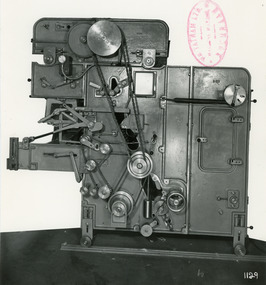

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

... was made by William Tatham Ltd, a textile engineering company..., The photographed machine was made by William Tatham Ltd, a textile ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

National Wool Museum

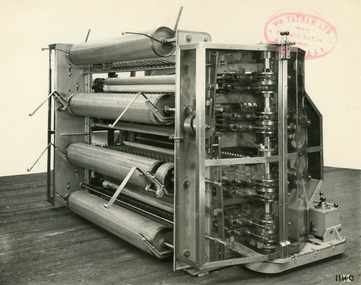

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

... , a textile engineering company based in Rochdale, UK. Established... by William Tatham Ltd, a textile engineering company based ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

National Wool Museum

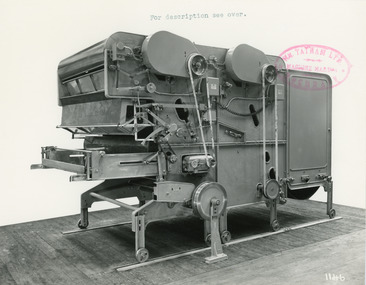

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

... by William Tatham Ltd, a textile engineering company based.... The photographed machine was made by William Tatham Ltd, a textile ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Packaging, W'bool Woollen Mill, between 1983 and 1994

The Warrnambool Woollen Mill was established in South Warrnambool in 1909 and was officially opened in 1910 with John Bennett as the first manager. In 1968 the mill was sold to the Dunlop company and in 1982 Dunlop sold the mill to Onkaparinga Woollen Company. In 1983 Onkaparinga was taken over by Macquarie Worsteds and traded in Warrnambool as Warrnambool Textiles. This arrangement ceased in 1994. In 2000 the mill closed after 90 years of operations.This is not a very significant item but it is interesting as it is connected to one of the major industries operating in Warrnambool for 90 years (1910-2000). It highlights also one aspect of the mill’s history- the years 1983-1994 when the mill operated as Warrnambool Textiles. This is a plastic shopping bag from the Warrnambool Woollen Mill shop. It has red printing on the front and back.‘Bargains Galore at the Woollen Mill Shop, Located at the Mill, Warrnambool Textiles, Harris Street, South Warrnambool, 3280, Phone: (055) 64 0044’warrnambool woollen mill -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Wooden box, Reckitts Round Blue

This box contained packets of Reckitts Blue and was probably displayed in a shop with the lid up showing the brand name and the items. Blue or laundry blue was a household product used up to about 1960 to improve the appearance of textiles during the washing process. It added a trace of blue dye which made white fabrics appear whiter and it was widely used. Reckitts was a firm established by Isaac Reckitt in Hull, England, in 1840. By 1888 it was a public company and in 1938 it merged with J.& J. Colman, a food manufacturer. Later it sold the Colman side of the business and today it trades as the Reckitt Benckiser Group. The firm established an Australian branch in the late 19th century.This box has been used to store the Charles Brittlebank birds’ eggs collection but it is of interest in its own right as a box that held Reckitts Blue packets. Most Australian households in the 19th and 20th centuries (up to about 1960) would have used blue bags or packets in the laundering process so they are part of our social history. Today a bleach is used as a replacement for a blue bag.This is a wooden box with a hinged lid (the hinges are hooks and eyes). The box once contained one gross of Reckitt’s Blue. The printing on the box is coloured but some of it is now faded. Inside the lid, pasted on, is the name of the manufacturer. The side of the box also has the name of the manufacturer pasted on but the printing has been discoloured at the edge by the application of maroon-coloured paint. On side of box: ‘Reckitt’s Round Blue, contains one gross of circular blocks’ Inside the lid: ‘Reckitt’s Round Blue’ social history, history of warrnambool, reckitt’ blue -

Warrnambool and District Historical Society Inc.

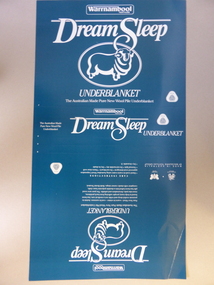

Warrnambool and District Historical Society Inc.Packaging, Blanket Box, 1990s

... Textiles Onkaparinga Woollen Company This is a cardboard sheet ...This item has been made to package a ‘Dream Sleep’ underblanket. This item was produced by the Warrnambool Textiles factory in the 1990s. In 1910 the Warrnambool Woollen Mill was established and it produced blankets, rugs etc with a staff of over 700 in the 1940s. In 1958 the Mill became the first in Australia to manufacture electric blankets. In 1968 the business was sold to Dunlop and in 1982 Dunlop sold the Mill to Onkaparinga Woollen Company. In 1983 Onkaparinga was taken over by Macquarie Worsteds and the Warrnambool Woollen Mill then traded as Warrnambool Textiles. In 2000 the Mill closed. This packaging is of some interest as a memento of the old Warrnambool Woollen Mill which operated in Warrnambool for 90 years and was a major industry in the town/city and a major employer of local residents. It is still remembered fondly by many local people today. This is a cardboard sheet for packaging an underblanket for Warrnambool Textiles. It has white printing on a dark blue background on one side and is white and unmarked on the other. It has an image of a sheep, three symbols for ‘Pure New Wool’, a symbol for ‘Naturally Flame Resistant’ and one for ‘Moth-Resist Treated’. The sheet is designed to be folded in four places to cover an underblanket. This is a cardboard sheet for packaging an underblanket for Warrnambool Textiles. It has white printing on a dark blue background on one side and is white and unmarked on the other. It has an image of a sheep, three symbols for ‘Pure New Wool’, a symbol for ‘Naturally Flame Resistant’ and one for ‘Moth-Resist Treated’. The sheet is designed to be folded in four places to cover an underblanket. warrnambool woollen mill, warrnambool textiles, onkaparinga woollen company -

Warrnambool and District Historical Society Inc.

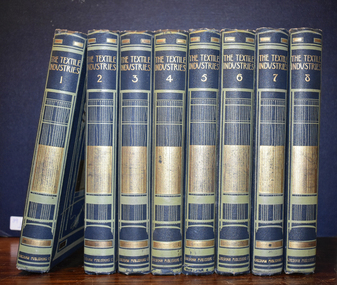

Warrnambool and District Historical Society Inc.Book, William S. Murphy, The Textile Industries ( eight volumes)

Technical information on the textile industryThese volumes have blue hard covers with pale green printing and stylised images of a loom and spindles in gold. The spines also feature a loom. The pages contain printed text, a colour photo, diagrams and black and white illustrations on inserted pages.non-fictionTechnical information on the textile industrywarrnambool woollen mill, textile industries -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile, Fletcher Jones, Mid 20th century

This piece of cloth came from the Fletcher Jones factory in Warrnambool. David Fletcher Jones (1895-1977) served in the First World War and in the 1920s set up as a travelling hawker selling drapery in the Western District of Victoria. In 1924 he leased three shops in Liebig Street, Warrnambool and in 1928 he moved to the Koroit/Liebig Streets intersection with his Man’s Shop. He manufactured men’s clothing on site. In 1931 he moved the business into a new two-storeyed building on the site. He opened a Fletcher Jones shop in Melbourne in 1946 and in 1948 a factory was established in Warrnambool. In 1951 the business of Fletcher Jones and Staff was established. The company expanded and became known Australia- wide, firstly for the production of men’s trousers and later both men’s and women’s clothing. By 2011 the Warrnambool factory was sold and the company was dissolved. This piece of material is of interest as an example of the cloth used in the Fletcher Jones factory in Warrnambool. The Fletcher Jones clothing company, known Australia-wide, was one of the important industries based in Warrnambool in the 20th and early 21st centuryThis is a bolt of check corded material in grey and blue tonings. It is stained in various places.fletcher jones clothing stores, warrnambool, history of warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile, Fletcher Jones, Men's Fletcher Jones Jeans, Early 21st century

This pair of jeans comes from the Fletcher Jones factory in Warrnambool. David Fletcher Jones (1895-1977) served in World War One and in the 1920s set up as a travelling hawker selling drapery in the Western District of Victoria. In 1924 he leased three shops in Liebig Street Warrnambool and in 1928 he moved the business to the corner of Koroit and Liebig Streets with his Man’s Shop. He manufactured men’s clothing on site. In 1931 a new set of buildings was erected on the site and Fletcher Jones moved into the new building. In 1946 a Fletcher Jones shop was opened in Melbourne and in 1948 a factory was opened in Warrnambool with a new company Fletcher Jones and Staff established in 1951. This company became known Australia-wide, firstly for the production of men’s trousers and later for both men’s and women’s clothing. By 2011 the factory was sold and the company dissolved. These jeans are retained as an example of the clothing made at the Warrnambool Fletcher Jones factory. The Fletcher Jones clothing company was one of the most important businesses in Warrnambool in the 20th century. This is a pair of blue cotton jeans pants with yellow stitching and a metal zip The garment has four pockets. The back pocket has the maker’s label and there are two labels attached to the inside. The front inside top section is lined with white material. ‘Fletcher Jones Australia’fletcher jones clothing company, history of warrnambool -

Warrnambool and District Historical Society Inc.

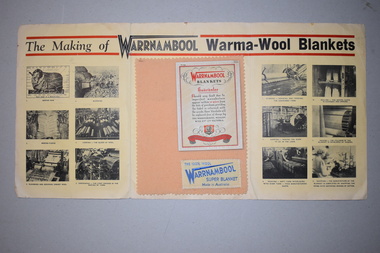

Warrnambool and District Historical Society Inc.Folder, Warrnambool Woollen Mill Co Ltd, Warrnambool Woollen Mill, 1950s

This folder contains photographs, advertisements and a sample of a piece of blanket from the Warrnambool Woollen Mill. This mill was officially opened in South Warrnambool in 1910 following the establishment of a local public company. The first manager was John Bennett from Yorkshire, England. The operations of the mill expanded with new buildings enabling the business to double in size by 1915. In the 1940s the factory was employing 700 people. In 1968 the factory was sold to Dunlop Australia but was sold again in 1982 to Onkaparinga Woollen Company. In 1983 Mcquarie Worsteds took over the factory with the business then known as Warrnambool Textiles. In 2000 the mill closed and most of the buildings were later demolished for a housing estate. This item is an attractive and informative memento of one of Warrnambool’s most important businesses of the past. The Warrnambool Woollen Mill operated for 90 years and employed many local people. The photographs are of particular interest.This is a rectangular-shaped sheet of buff-coloured lightweight cardboard. It has been folded twice to create six pages in a folder. Three pages contain black and white photographs of the woollen mill operations and two pages contain advertising material with black and white images. One page has a cream blanket piece of material attached to the page by two staples and this has the brand name stitched onto the right hand corner This piece of blanket also has a paper guarantee card attached by staples. The Warrnambool Woollen Mill Co. Ltd. South Warrnambool The 100% Wool Warrnambool Super Blanket Made in Australia warrnambool woollen mill, history of warrnambool -

Nhill Aviation Heritage Centre

Nhill Aviation Heritage CentreMemorabilia - Water bottle, 1942

... Textile were a Canadian company..... (Zephyr Loom Textile were a Canadian company. Metal container ...Metal container with cork stopper, coated with soft fabric material to create evaporative cooling when wetted, has an adjustable leather shoulder strap.ZL&Tt, 1942 broad arrow military insignia. (Zephyr Loom Textile were a Canadian company.water bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Standard measure, Mid to late 19th Century

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995. J & M Ewan History: J&M Ewan was a Melbourne firm that began by selling retail furniture and wholesale ironmongery. They had substantial warehouses situated at the intersection of 81-83 Elizabeth and Little Collins Streets, the business was established by James M Ewan in 1852. Shortly afterwards he went into partnership with William Kerr Thomson and Samuel Renwick. When Ewan died in 1868 his partners carried on and expanded the business under his name J & M Ewan. The business was expanded to provide a retail shop, counting-house and private offices. Wholesale warehouses adjoined these premises at 4, 6 and 10 Little Collins Street, West. This company provided and sold a large and varied amount of imported goods into the colony that consisted of agriculture equipment, building materials, mining items as well as steam engines, tools of all types and marble fireplaces. They also supplied the Bronze measuring containers in the Flagstaff Hill collection and the probability is that these containers were obtained by the local Melbourne authority that monitored weights and measures in the mid to late 19th century. The company grew to employ over 150 people in Melbourne and opened offices at 27 Lombard St London as well as in New Zealand and Fiji. The company also serviced the Mauritius islands and the pacific area with their steamship the Suva and a brig the Shannon, the company ceased trading in 1993. Robert Bate History: Robert Brettell Bate (1782-1847) was born in Stourbridge, England, one of four sons of Overs Bate, a mercer (a dealer in textile fabrics, especially silks, velvet's, and other fine materials)and banker. Bate moved to London, and in 1813 was noticed for his scientific instrument making ability through the authority of the “Clockmakers Company”. Sometime in the year 1813 it was discovered that one Robert Brettell Bate, regarded as a foreigner in London had opened a premises in the Poultry selling area of London. He was a Mathematical Instrument maker selling sundials and other various instruments of the clock making. In 1824, Bate, in preparation for his work on standards and weights, leased larger premises at 20 and 21 Poultry, London, at a rental of four hundred pounds per annum. It was there that Bate produced quality metrological instruments, which afforded him the recognition as one of one of the finest and principal English metrological instrument-makers of the nineteenth century. English standards at this time were generally in a muddle, with local standards varying from shire to shire. On 17 June 1824, an Act of Parliament was passed making a universal range of weights, measures, and lengths for the United Kingdom, and Bate was given the job of crafting many of the metrological artifacts. He was under instruction from the renown physicist Henry Kater F.R.S. (1777-1835) to make standards and to have them deposited in the principal cities throughout the United Kingdom and colonies. Bate experimented with tin-copper alloys to find the best combination for these items and by October 1824, he had provided Kater with prototypes to test troy and avoirdupois pounds, and samples with which to divide the troy into grams. Bate also cast the standard for the bushel, and by February 1825, had provided all the standards required of him by the Exchequer, Guildhalls of Edinburgh, and Dublin. In 1824, he also made a troy pound standard weight for the United States, which was certified for its accuracy by Kater and deposited with the US Mint in 1827. Kater, in his address to the Royal Society of London, acknowledged Bate's outstanding experimentation and craftsmanship in producing standards of weights, measures, and lengths. An example of a dry Bronze measuring container made specifically for J & M Ewan by possibly the most important makers of measurement artefacts that gives us today a snapshot of how imperial weights and measures were used and how a standard of measurement for merchants was developed in the Australian colonies based on the Imperial British measurement system. The container has social significance as an item retailed by J & M Ewan and used in Victoria by the authorities who were given legal responsibility to ensure that wholesalers and retailers of dry goods sold in Victoria were correct. The container was a legal standard measure so was also used to test merchants containers to ensure that their distribution of dry goods to a customer was correct.Maker Possibly Robert Brettell Blake or De Grave, Short & Co Ltd both of LondonContainer bronze round shape for measuring dry quantities has brass handles & is a 'half-bushel' measurement"IMPERIAL STANDARD HALF BUSHEL" engraved around the top of the container. VICTORIA engraved under "J & M Ewan & Co London and Melbourne" engraved around the bottom of the container.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, standard measure, bronze, peck measurement, j & m ewan, victorian standard dry measurement, bronze container, victorian standards, melbourne observatory, robert brettell bate -

Seaworks Maritime Museum

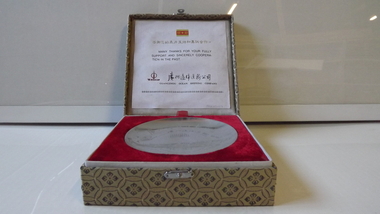

Seaworks Maritime MuseumGuangzhou Ocean Shipping company plate

Silver coloured plate with Guangzhou Ocean Shipping Company logo and a picture of ship depicted. Case is decorated with fine textile patern and has a simple metal lock. A square piece of paper is adhered to the interior of the lid and contains Asian and English writing noting ‘Many thanks for you fully support and sincerely cooperaticn in the past.’ The plate sits in a red velvet mount which can be lifted out. A second compartment below houses a wooden varnished stand also in a red velvet support.On paper documentation in box ‘MANY THANKS FOR YOUR FULLY SUPPORT AND SINCERELY COOPERATICN IN THE PAST.’ Plate engraved ‘1961 Asian characters 1991./COSCO/ GUANGZHOU OCEAN SHIPPING CO. PMA 0208/s in greylead on the lower right corner of the paper documentation. Back of plate: WMA67 white sricker PMA0208/1 ink and B72gifts -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, child's cream 'Viyella' coat, c1900

This small child’s cream, ‘Viyella’ coat is an example of the dressmaking skills of the women of the pioneer settlers families in Moorabbin Shire c1900. The material is very soft and easy to sew, wash and iron and was therefore very popular for all ages. Viyella material The original owner of the Mill, Wm. Hollins also ran the mill in Pleasley, U.K. on a rather unusually named road ‘Via Gellia’ now the A5012 near Matlock, about 20miles away. Via-Gellia later gave its name to the famous soft fabric ‘Viyella’ which Hollins & Co patented in 1893. Later Viyella was also to become the company name in 1961 after a merger. Viyella has faded into obscurity now, and in 2009 went into administration, finally being bought out by Austin Reed.A cream 'Viyella' small child's long sleeved coat, buttoned front and smocked frontclothing, moorabbin, ormond, bentleigh, dressmaking, market gardeners, early settlers, craftwork, textiles, viyella -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings "Holeproof', mid 20thC

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. A unused pair of lady's silk stockings in original box. 'Holeproof' 'Truly Yours' Candlelight, size 10Box Cover: Truly Yours / by / Holeproof Side Holeproof 'Candlelight' Size 10clothing, stockings, nylons, holeproof hosiery pty ltd, lingerie, melbourne, bentleigh, cheltenham moorabbin, brunswick milwaukee usa, wisconsin -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. An unused pair of lady's nylon stockings in original box. 'Holeproof' 'For you', 'Precious' size 91/2Box Cover : For You / HOLEPROOF/ SUPERFINE EXQUISITE SHEERS Side : Precious 9 1/2 Package : 60 GUAGE / SHEER NYLON / BY / HOLEPROOF / 9 1/2 Card : Especially / For You / fromclothing, stockings, nylons, holeproof pty ltd, milwaukee usa, hosiery, fashion, melbourne, bentleigh, cheltenham moorabbin, brunswick, lingerie -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific BrandsAn unused pair of lady's stockings, in original box, 'Holeproof', 'Beauty Fit', ' Nocturn' Size 81/2 - 9 Box Cover : HOLEPROOF / Beauty Fit / LADDERPROOF MESH SHEERS STRETCH Inside Wrapper ; HOLEPROOF / Beauty Fit / LADDERPROOF STRETCH NYLONS 8 1/2 - 9clothing, stockings, nylons, hosiery, melbourne, bentleigh, cheltenham moorabbin, brunswick, holeproof pty ltd, lingerie, fashion -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Work Apron, 1883-1899

The personal 'carry-all', a cloth apron like article was utilised by Thomas Hamilton Osborne in his work with the Warrnambool Steamship Navigation Company. He was Company manager in 1883 until its dissolution in 1899. Osborne wrote many articles on early Warrnambool, particularly maritime material under the name of " Sliding Gunter". When he died he was buried at sea off the breakwater.His sister Mrs Annabella Kell is thought to have made this article.This is a significant item as T.H.Osborne was a key figure in 19th Century Warrnambool history, particularly in maritime affairs. Six sided, scalloped edges, four pockets, two metal hooks, purple woven fabric with yellow and gold embroidery, lifebuoy outline with W.S.N.Co and THO initials embroidered and two flags. Machine sewing of pockets and tab to base apron.W.S.N.Co THO initials on top of each other Two metal hookswork apron, warrnambool steamship navigation company, wsnc, thomas hamilton tracey osborne, annabella kell, sliding gunter -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Fire screen, Tapestry, Post 1967

David Fletcher Jones (1895-1977) was a travelling hawker who opened a business in Liebig Street, Warrnambool in 1924. In 1931 he opened The Man's Shop at the corner of Liebig Street and Koroit Street. He sold suits and overcoats tailored in the work rooms upstairs. In 1948 his factory known as Pleasant Hill was opened in Flaxman Street in Warrnambool, the site of an old quarry. In 1951 the company Fletcher Jones and Staff was formed with the staff owning 51% of the shares, By the 1970s Fletcher Jones and Staff had become one of the largest clothing companies in Australia with 55 shops and 3000 employees. In 1992 the Warrnambool City Council bought the factory and gardens with the site now a tourist attraction. Although the name is retained today for trading purposes the original Fletcher Jones company has been dissolved. The screen is a representation of the Fletcher Jones factory post 1967. It a wool tapestry by Martin Prider who was a painter and caretaker what the Fletcher Jones factory. He lived in one of the Fletcher Jones cottages on site. (Robin Boyd Age Small Homes Scheme, today Heritage listed.)This is an interesting memento of the Fletcher Jones company and the factory. It was done by a local resident and features the famous Fletcher Jones gardensTapestry fire screen in a rectangular light timber frame depicting the Fletcher Jones Factory Gardens. The screen has two timber feet, non relective glass and appears to be a wool tapestry. The image of the gardens is after 1967 as the silver ball is included and that was erected in 1967. Nilfletcher jones company and warrnambool factory, pleasant hill warrnambool, martin prider, fletcher jones, tapestry of fletcher jones factory -

Orbost & District Historical Society

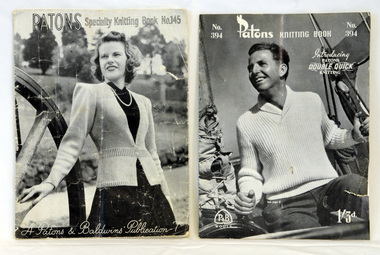

Orbost & District Historical Societypattern books, Patons Specialty Knitting Book, 1940-1950

These knitting pattern leaflets were published by Patons and Baldwins and contain knitting patterns for women's and men's garments. Patons & Baldwin began as two separate companies: J & J Baldwin and Partners, founded in the late 1770s by James Baldwin of Halifax, West Yorkshire, England, and John Paton Son and Co., founded in 1814 by John Paton of Alloa, Scotland. Both men had formed their businesses using the spinning mule developed by Samuel Crompton. They mainly produced yarns for commercial knitting machines. Patons established itself in Australia with its first mill built in Tasmania in 1923. For decades, Patons was the leading hand knitting yarn brand but due to the market conditions in the mid 1980's, Patons felt the decline and eventually amalgamated with Alliance Textiles, New Zealand in 1996. Patons Australia was acquired by Australian Country Spinners in 2000. Knitting has always had a great appeal to women, as it needs few tools. Companies which manufactured yarn often produced instruction guides and patterns. These pattern books are typical of the knitting pattern books commonly used in the mid 20th century. The patterns contained are for garments commonly worn at that time.Two knitting pattern books. Both are black / white and contain knitting patterns. 821.1 cost 7d, is titled "Patons Specialty Knitting Book No. 145" and has on the front cover a lady standing near a buggy wheel. 821.2 cost 1/3, is titled " Patons Knitting Book No. 394 (introducing Patons Double Quick Knitting)" and has has on the front cover a photograph of a man on a boat.knitting-patterns needlecraft patons-baldwin -

Orbost & District Historical Society

Orbost & District Historical Societybook, first half 20th century

In the early 20th century, smocking appears in women’s magazines and sewing manuals on garments, domestic textiles and children’s wear. The 1930s and 1940s were the heyday of patterns and innovative stitch development. Embroidery has always had a great appeal to women, as it needs few tools. Historically the skills were taught within the family or in primary schools. Articles to make or embroider had been available in kits since the 1850s. Fancy work, the opposite of plain sewing, enjoyed great popularity in the 19th and 20th centuries. Companies which manufactured threads often produced instruction guides and patterns. This instruction book has been well-used. A small 30pp book with no cover. It contains instructions for embroidery stitches, including smocking.book-embroidery smocking handcraft needlework -

Orbost & District Historical Society

Orbost & District Historical Societypattern book, Patons Knitting Book, mid 20th century

This knitting pattern leaflet was published by Patons and Baldwins and contains knitting patterns for women's garments. Patons & Baldwin began as two separate companies: J & J Baldwin and Partners, founded in the late 1770s by James Baldwin of Halifax, West Yorkshire, England, and John Paton Son and Co., founded in 1814 by John Paton of Alloa, Scotland. Both men had formed their businesses using the spinning mule developed by Samuel Crompton. They mainly produced yarns for commercial knitting machines. Patons established itself in Australia with its first mill built in Tasmania in 1923. For decades, Patons was the leading hand knitting yarn brand but due to the market conditions in the mid 1980's, Patons felt the decline and eventually amalgamated with Alliance Textiles, New Zealand in 1996. Patons Australia was acquired by Australian Country Spinners in 2000.Knitting has always had a great appeal to women, as it needs few tools. Companies which manufactured yarn often produced instruction guides and patterns. This pattern book is typical of the knitting pattern books commonly used in the mid 20th century. The patterns contained are for garments worn at that time.A seven page stapled booklet of knitting patterns. It is titled Patons Knitting Book No. 444, Ladies' and Girls' Gloves and Hats. It has a price 1/3.On the front cover are photos of the garments for which the patterns are provided.knitting handicrafts patons-and-baldwins -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, late 19th or early 20th century

This Eclipse model, treadle operated sewing machine was made by the Oldham Sewing Machine Company in Greater Manchester U.K.. It was used by sailmakers for sewing sails with box shape top and slim neck. Sewing machine, foot treadle, for sewing sails with box shape top and slim neck. Brand is Eclipse. Cast iron base is bolted to square wooden table-top with drawer under table. Drawer has 3 partitions and wood fitting with 5 drilled holes for needle storage, lock has diamond shaped, decorative metal surrounds; half of inside drawer is painted black. Decorative metal stand, painted green, with 2 foot pedals; 1 foot pedal drives the wheel wheel. Padals both have "ECLIPSE" cast into the iron.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, textile machines, sailmaker's machine, maritime sewing machine -

Federation University Historical Collection

Federation University Historical CollectionLetter, F.E. Ferguson, Correspondence between Robert Reid & Co. Limited and Ballarat School of Mines, 20/05/1958 and 29/05/1958

Robert Reid & Co. Ltd was a textile, clothing and footwear retailer between 1919-1966. The company was bought be Joseph Pickles and Son in 1936. The Ballarat School of Mines began in 1870, and gradually developed to become an education institution. F. E Ferguson was the registrar at the time. The letter concerns the acquirement of the fabric Actil "Fasco" No. 49, which was out of stock and instead a sample of No. 57 was sent. This was not suitable for intended purpose. Two letters between Robert Reid & Co. Limited and Ballarat School of Mines. Both have pen annotations and signatures. The Robert Reid & Co. letter enclosed a piece of fabric, Actil "Fasco" No. 57Secretary marks include "Not suitable" Signatures from Registrar F. E Ferguson at Ballarat School of Mines and J. Pickles and Son of Robert Reid & Co.robert reid, robert reid & co. limited, ballarat school of mines, ballarat, j. pickles, j. pickles and son, f. e. ferguson, registrar, fabric, actil "fasco" no. 49 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Company seal embosser, Unknown

The former Albion (West) Woollen and Worsted Mills is a functional structure which has been built in stages, possibly dating from the 1880s, with the earliest sections near to the Barwon River.The Worsted mill operated for about 50 years and at its peak employed around 500 people. In 1973 the mill merged with the British John Foster and Sons Company under some controversial stock and shareholding issues. The mill continued for a short period before closing at a time when much of the Australian textile industry was finding it difficult to compete with overseas operations. In the 30 plus years after the closure, the site was used for several ventures, including the Mill Vintage Markets and a vehicle trim manufacturing operation. In 2011 the site was purchased by Little Creatures of Western Australia to become their main brewery for the eastern states of Australia. Now owned by the Lion Group, Little Creatures started their 60 million dollar transformation of the old mill in 2012. Finally, in 2013 these former walls of industry were soon rattling away to the sounds of a different type of industry, as the first bottles of beer made their way out of the Geelong Little Creatures Brewery. The remaining building of the former Albion Woollen and Worsted Mills has historical significance as one of Geelong's major woollen mills. The venture has operated on the same site for more than a century. The Albion Woollen Mill was one of the four key sites along with Victoria, Barwon and Union Mills that was established in the late 1860s to mid-1870s. These mills were in constant operation on the west side of the Barwon Bridge over the last century and led to Geelong's fame as milling and scouring locality. The Albion Mill was probably the most successful survivor of the early private company operations. It was regarded as a model mill in the late 1880s and was, from all accounts, well-planned and organised with machinery on a par with the great mills of England. It produced high-quality tweeds. Together with the (now demolished) Union Mill it was regarded as the borough's principal industry over the 1870-1900 period and was one of Australia's most significant producers of tweed by 1900. These two mills were more successful, competitive and long-lived than the Barwon and Victoria Mills. The remaining building form is an important reminder of the private ventures of both the Albion and Union Mills and represents a key site of spinning, carding and finishing as well as scouring and dying that occurred in the lower section near to the river. The loss of the adjacent former Union Mill is unfortunate because the complex, together with the former Collins Union Mill office building, was an important reminder of the success of these industries and the reputation they earned for the Geelong region as a centre for quality textile products. Company seal embosser hand operated matte black & brass colour Western District Worsted Mills emblem on frontflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand operated embossing document press, 1910

The woollen mill was a vital part of Warrnambool for all but 22 years of the town’s history since it's the establishment in 1847 when the first land sales were held and white settlement began. In 1869 the Warrnambool Meat Preserving Company began operations on the mill site, in 1875, shareholders of the then defunct Warrnambool Meat Preserving Company happily sold the land and buildings on the Merri river to Warrnambool Woollen Mill Company Ltd for £5,000. The site was sold again in 1876 to grazer Robert Hood of Sherwood, who was chairman of directors of the failed company, which couldn’t raise sufficient capital to keep the works operating. The entrepreneurial Hood then used the existing plant to turn his own wool into tweed cloth. But just as the mill was starting to show a profit, a fire destroyed the building and plant on the night of 25 March 1882. So again, the mill was operational for six short years. Insurers only paid a fraction over 10% of the damage, Hood couldn't raise sufficient capital to rebuild on his own, and so the site lay unused until 1910. In 1908 Marcus Saltau and Peter John McGennan convinced the Warrnambool Chamber of Commerce to invest in a secondary industry with local capital. A public meeting in September 1908 agreed to raise £40,000, electing Saltau chairman of directors, a post he held for 34 years. A year later, using mostly local money, the Warrnambool Woollen Mill Company dispatched its first manager, John E. Bennett, to buy a plant and recruit 20 experienced staff from the Yorkshire woollen industry in December 1909. Another year more, the new mill was officially opened on 14 November 1910 by Marcus Saltau as company chairman and town mayor. Eighteen months on, in May 1912, the mill paid its first half-yearly dividend of 2 ½%. It was now working two shifts, with a year's orders to fill. In 1914 the mill ordered its own generator, providing the town with electricity and effectively doubling its plant size by October 1915, six months after Gallipoli. Thereafter, government orders for cloth and military supplies assured the mill’s success right through the First World War and on until 1923. A plant upgrade in 1922 for machinery to make worsted fabric drained profits, which, with a fall in demand, led to a loss in 1925. Profits were restored by the 1930s, despite the Depression, mostly due to tight management and robust marketing. Production boomed again during the Second World War, but soon foreign competition bit into profits, forcing the company to consolidate operations. The ‘50s and ‘60s were golden years for the mill. Security and growth gave the company confidence to trial Australia’s first electric blanket in 1958 and to install Swiss Sulzer looms in 1965. Over time, the building facades took on the modern look that the mill presented until it closed. The Dunlop company bought the mill in 1968, fending off a challenge from Onkaparinga in South Australia, and continued to expand by adding Wendouree Woollen Mill in the same year and Dream-spun Textiles a decade later, in 1979. Soon after that purchase, however, the mill began its slippery slide into decline. Dunlop sold to its former rival bidder Onkaparinga Woollen Co. Ltd in 1982, which in turn was taken over by Macquarie Worsted's only a year later, in 1983. Operations remained stable for a decade until 1994 when the Macquarie Group signaled that its newly rationalised operations left no room for the Warrnambool investment. The final operator of the mill was The Smith Family charity group, which ran the site by agreement with the Warrnambool City Council and a state government grant in that same year, 1994. The mill became more of a fabric recycler than a manufacturer. The site was sold to private operators in February 2003 and rezoned four months later to allow for the mixed housing development. The embossing press is significant for its association with the Warrnambool Woollen Mills 1910-1968, a major employer in the Warrnambool district. The press is also significant as an example of commercial office equipment used in the 19th and 20th century.Press, metal, for Company seal of Warrnambool Woollen Mill, stamping their brand as Western District Worsted Mills Pty Ltd. Metal is black with red and gold floral markings. Inscription of stamp reads "WESTERN DISTRICT WORSTED MILLS PROPRIETRY LIMITED" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, warrnambool woollen mills, western district worsted mills proprietry limited, worsted fabric, printing press, logo printing press, stamp printing press, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Standard measure, Mid to late 19th Century

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995. J & M Ewan History: J&M Ewan was a Melbourne firm that began by selling retail furniture and wholesale ironmongery. They had substantial warehouses situated at the intersection of 81-83 Elizabeth and Little Collins Streets, the business was established by James M Ewan in 1852. Shortly afterwards he went into partnership with William Kerr Thomson and Samuel Renwick. When Ewan died in 1868 his partners carried on and expanded the business under his name J & M Ewan. The business was expanded to provide a retail shop, counting-house and private offices. Wholesale warehouses adjoined these premises at 4, 6 and 10 Little Collins Street, West. This company provided and sold a large and varied amount of imported goods into the colony that consisted of agriculture equipment, building materials, mining items as well as steam engines, tools of all types and marble fireplaces. They also supplied the Bronze measuring containers in the Flagstaff Hill collection and the probability is that these containers were obtained by the local Melbourne authority that monitored weights and measures in the mid to late 19th century. The company grew to employ over 150 people in Melbourne and opened offices at 27 Lombard St London as well as in New Zealand and Fiji. The company also serviced the Mauritius islands and the pacific area with their steamship the Suva and a brig the Shannon. Robert Bate History: Robert Brettell Bate (1782-1847) was born in Stourbridge, England, one of four sons of Overs Bate, a mercer (a dealer in textile fabrics, especially silks, velvet's, and other fine materials)and banker. Bate moved to London, and in 1813 was noticed for his scientific instrument making ability through the authority of the “Clockmakers Company”. Sometime in the year 1813 it was discovered that one Robert Brettell Bate, regarded as a foreigner in London had opened a premises in the Poultry selling area of London. He was a Mathematical Instrument maker selling sundials and other various instruments of the clock making. In 1824, Bate, in preparation for his work on standards and weights, leased larger premises at 20 and 21 Poultry, London, at a rental of four hundred pounds per annum. It was there that Bate produced quality metrological instruments, which afforded him the recognition as one of one of the finest and principal English metrological instrument-makers of the nineteenth century. English standards at this time were generally in a muddle, with local standards varying from shire to shire. On 17 June 1824, an Act of Parliament was passed making a universal range of weights, measures, and lengths for the United Kingdom, and Bate was given the job of crafting many of the metrological artifacts. He was under instruction from the renown physicist Henry Kater F.R.S. (1777-1835) to make standards and to have them deposited in the principal cities throughout the United Kingdom and colonies. Bate experimented with tin-copper alloys to find the best combination for these items and by October 1824, he had provided Kater with prototypes to test troy and avoirdupois pounds, and samples with which to divide the troy into grams. Bate also cast the standard for the bushel, and by February 1825, had provided all the standards required of him by the Exchequer, Guildhalls of Edinburgh, and Dublin. In 1824, he also made a troy pound standard weight for the United States, which was certified for its accuracy by Kater and deposited with the US Mint in 1827. Kater, in his address to the Royal Society of London, acknowledged Bate's outstanding experimentation and craftsmanship in producing standards of weights, measures, and lengths. An example of a dry Bronze measuring container made specifically for J & M Ewan by possibly the most important makers of measurement artifacts that gives us today a snapshot of how imperial weights and measures were used and how a standard of measurement for merchants was developed in the Australian colonies based on the Imperial British measurement system. The container has social significance as an item retailed by J & M Ewan and used in Victoria by the authorities who were given legal responsibility to ensure that wholesalers and retailers of dry goods sold in Victoria were correct. The container was a legal standard measure so was also used to test merchants containers to ensure that their distribution of dry goods to a customer was correct. Bronze round container with brass two handles used as a legal standard for measuring dry quantities & is a 'peck' measurement. "IMPERIAL STANDARD PECK" engraved around top of container with " VICTORIA" engraved under.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, standard measure, bronze, peck measurement, j & m ewan, victorian standard dry measurement, bronze container, victorian standards, melbourne observatory, robert bettell bate -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Standard measure, Mid to Late 19th Century

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995. J & M Ewan History: J&M Ewan was a Melbourne firm that began by selling retail furniture and wholesale ironmongery. They had substantial warehouses situated at the intersection of 81-83 Elizabeth and Little Collins Streets, the business was established by James M Ewan in 1852. Shortly afterwards he went into partnership with William Kerr Thomson and Samuel Renwick. When Ewan died in 1868 his partners carried on and expanded the business under his name J & M Ewan. The business was expanded to provide a retail shop, counting-house and private offices. Wholesale warehouses adjoined these premises at 4, 6 and 10 Little Collins Street, West. This company provided and sold a large and varied amount of imported goods into the colony that consisted of agriculture equipment, building materials, mining items as well as steam engines, tools of all types and marble fireplaces. They also supplied the Bronze measuring containers in the Flagstaff Hill collection and the probability is that these containers were obtained by the local Melbourne authority that monitored weights and measures in the mid to late 19th century. The company grew to employ over 150 people in Melbourne and opened offices at 27 Lombard St London as well as in New Zealand and Fiji. The company also serviced the Mauritius islands and the pacific area with their steamship the Suva and a brig the Shannon. Robert Bate History: Robert Brettell Bate (1782-1847) was born in Stourbridge, England, one of four sons of Overs Bate, a mercer (a dealer in textile fabrics, especially silks, velvet's, and other fine materials)and banker. Bate moved to London, and in 1813 was noticed for his scientific instrument making ability through the authority of the “Clockmakers Company”. Sometime in the year 1813 it was discovered that one Robert Brettell Bate, regarded as a foreigner in London had opened a premises in the Poultry selling area of London. He was a Mathematical Instrument maker selling sundials and other various instruments of the clock making. In 1824, Bate, in preparation for his work on standards and weights, leased larger premises at 20 and 21 Poultry, London, at a rental of four hundred pounds per annum. It was there that Bate produced quality metrological instruments, which afforded him the recognition as one of one of the finest and principal English metrological instrument-makers of the nineteenth century. English standards at this time were generally in a muddle, with local standards varying from shire to shire. On 17 June 1824, an Act of Parliament was passed making a universal range of weights, measures, and lengths for the United Kingdom, and Bate was given the job of crafting many of the metrological artifacts. He was under instruction from the renown physicist Henry Kater F.R.S. (1777-1835) to make standards and to have them deposited in the principal cities throughout the United Kingdom and colonies. Bate experimented with tin-copper alloys to find the best combination for these items and by October 1824, he had provided Kater with prototypes to test troy and avoirdupois pounds, and samples with which to divide the troy into grams. Bate also cast the standard for the bushel, and by February 1825, had provided all the standards required of him by the Exchequer, Guildhalls of Edinburgh, and Dublin. In 1824, he also made a troy pound standard weight for the United States, which was certified for its accuracy by Kater and deposited with the US Mint in 1827. Kater, in his address to the Royal Society of London, acknowledged Bate's outstanding experimentation and craftsmanship in producing standards of weights, measures, and lengths. An example of a dry Bronze measuring container made specifically for J & M Ewan by possibly the most important makers of measurement artefacts that gives us today a snapshot of how imperial weights and measures were used and how a standard of measurement for merchants was developed in the Australian colonies based on the Imperial British measurement system. The container has social significance as an item retailed by J & M Ewan and used in Victoria by the authorities who were given legal responsibility to ensure that wholesalers and retailers of dry goods sold in Victoria were correct. The container was a legal standard measure so was also used to test merchants containers to ensure that their distribution of dry goods to a customer was correct.Maker Possibly Robert Brettell Blake or De Grave, Short & Co Ltd both of LondonContainer brass round for measuring quantities- Has brass handles & is a 'Bushel' measurement. 'Imperial Standard Bushel Victoria' engraved around container. Container bronze round shape for measuring dry quantities has brass handles & is a 'Bushel' measurement"IMPERIAL STANDARD BUSHEL" engraved around the top of the container. VICTORIA engraved under "J & M Ewan & Co London and Melbourne" engraved around the bottom of the container.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, standard measure, bushel, bushel measurement, j & m ewan, dry measurement, victorian measurement standard, bronze container, melbourne observatory, robert brettell bate -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Luggage Trolley, Harry Crowther Slingsby, 1930 - 1950

In 1893 Harry Crowther Slingsby founded the company the family firm was at first wholesale bottlers and had established themselves in Bradford, England, later they had a branch in London. Harry Crowther Slingsby began to look into the invention of labor-saving devices for the company. He had recognised that working practices in the local factories relied heavily on manual hauling and gravity for the movement of raw materials and products from floor to floor. However, this did not solve the problem of moving items horizontally around large buildings. Slingsby then set about creating robust trucks and trolleys to move heavy loads with relative ease. Different designs were created for different purposes sack trolleys for moving large sacks of flour, sugar and dried fruit around grocery stores; high wheeled flat carts towed by one or two people; trucks fitted with wicker baskets carried fibers around textile mills and railway platform trolley to move luggage. The company is still in existence today manufacturing many different types of products.An item from the early to mid 20th century connected with railway memorabilia and a company that had humble beginnings to become today a leading UK manufacture. Railway platform luggage trolley large metal frame & wood top with 4 black metal cast iron wheels & metal structure at front with holes to put rope/harness through. Front 2 wheels swivel. Trolley painted red. Wheels are marked Bradford & Londonflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village