Showing 1464 items

matching industry and manufacture

-

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Container - Bottle, John Fletcher

The making of cordials and aerated waters was an important industry in Warrnambool from the time of the first settlement up to the 1980s. John Fletcher succeeded John Davis in Koroit Street in 1885 and manufactured aerated waters, soda, lithia, tonic waters, lemonade, ginger ale, hop beer, hop bitters, sarsparilla and cordials. He sold to Ralph Reeves in 1930 and the business continued until the 1908s under the name of Reeves. Warrnambool cordial bottles are of considerable significance as examples of an important local industry now gone. The Fletcher business was a well-known business in Warrnambool for 45 years.This is a small size plain glass bottle manufactured for liquids sold commercially.On side of bottle ‘John Fletcher Warrnambool’ ‘Trade Mark’ with incision of symbol showing a crown with a Maltese Cross and three fleurs-de-lys. Near the base of the bottle is the wording ‘This bottle is the property of John Fletcher Warrnambool & cannot be legally used by others’. On base: ‘M 942, M, A.G.M.’wa, warrnambool,fletcher bottle, fletchers cordials warrnambool, fletcher's aerated water, marble bottle, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Page Numbering Machine, EARLY 1900’S

Antique paging or page numbering machine, also referred to as a paginater. Machine prints six digit numbers consecutively. It was used in the printing industry to number consecutive pages of journals in the early 1900’s. Alex Cowan & Sons Ltd. of Melbourne, Sydney and Adelaide supplied printing equipment to other firms. The parent company, Alexander Cowan & Sons Ltd., manufactured fine paper in Valleyfield, Penicuik, Scotland from 1814-1937. This page numbering machine or paginater is an example of mechanical technology used in the printing industry in the early 1900's.Page numbering machine, also known as a paginater or paging machine. Printing machine with six digits for numbering pages consecutively. Steel frame, wooden treadle plate and bench. Inscription of maker's name on metal plate. Made by Alex Cowan & Sons Ltd.Inscribed on maker's plate, "Alex Cowan & Sons Ltd. / Printers Furnishers / Melbourne, Sydney, Adelaide". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, paging machine, treadle paging machine, printing machine, page numbering machine, paginater, alex cowan and sons ltd, australian printing industry -

Whitehorse Historical Society Inc.

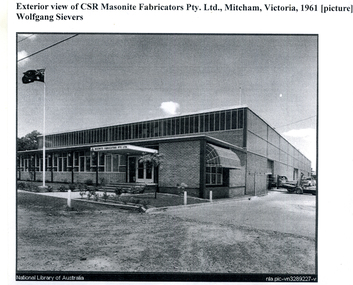

Whitehorse Historical Society Inc.Photograph, CSR Masonite Fabricators Pty Ltd, Mitcham, 1961

In the mid 1950's Masonite built a hard board plant at Eildon but the process could not be made to work satisfactorily on the eucalypt woods available. CSR took over the Masonite Corporation in 1959, closing down it Eildon plant and constructing plants at Bacchus Marsh and Mitcham which began producing in 1961. With the development of particledboard manufacture in the 1960's the fibreboard industry declined. Not known when the Mitcham site was closed down,Black and white photocopy of CSR Masonite Fabricators building in Mitcham. Flag flying at left.csr masonite fabricators pty ltd -

Bendigo Historical Society Inc.

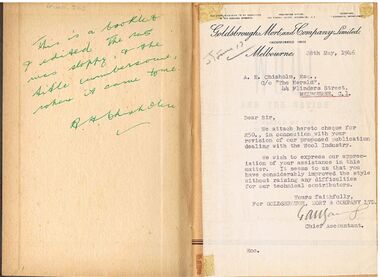

Bendigo Historical Society Inc.Book - ALEC H CHISHOLM COLLECTION: BOOK ''WOOL AND THE NATION''

Book. ALEC H CHISHOLM COLLECTION. 75 page brown cover hardback describing the wool industry in Australia from growing to the manufacturing process. Prepared by the staff of Goldsborough, Mort & Co. Ltd. A soft cover booklet enclosed in a hardcover. Set up and printed in 1946 by the Victorian Printing Works Pty. Ltd., Melbourne. Inside the front cover, handwritten in green biro ''This is a booklet I edited. The MS was sloppy and the title cumbersome, when it came to me. A. H. Chisholm.'' Pasted on the flyleaf is a typed letter from Goldsborough, Mort and Company to A. H. Chisholm thanking him for revising this publication and attaching a cheque for 50 pounds. Catalogue sticker ''2151 CHI'' on front cover.Goldsborough, Mort and Companybooks, collections, australiana, alec h chisholm collection, goldsborough, mort & company, wool industry -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCar Jack, Possibly 1960s

Mechanical mobile car jack made by the TREWELLAH company of Trentham for APAC Industries Ltd. Known as a "Service Jack" used for servicing cars and light vehicles. Mounted on 4 wheels, two being castors. Painted red. On a brass plate fixed to top of body "APAC / Service Jack No. 247 / Range 4 5/8" to 19 3/4" / Capacity 5000 lb / Caution: Do not overload / This jack is guaranteed to raised 5000 lb / Overloading renders this guarantee null and void / lubricate jack thoroughly before using / always keep jack clean and well oiled / Manufactured in Australia / APAC Industries Limited. / South Australia"tools, automotive, servicing -

Kiewa Valley Historical Society

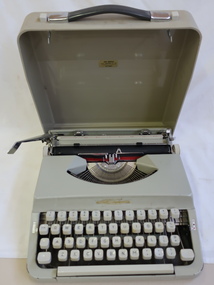

Kiewa Valley Historical SocietyTypewriter - Portable

These typewriters were imported fully assembled from Japan by CFM Industries. CFM (Curvie Furniture Manufacturing). The Nakajima portable typewriters were imported in the 1970s. Typewriters replaced hand written writing. Their benefits were that the work was written faster and was legible. The portable typewriter enabled the typist to take her typewriter with her. Typewriters have now been replaced by computers with the advantage of editing the work before the final copy is made and with the ability to add eg. photos, create different settings etc. Used by a resident of the Kiewa Valley in the 1970s.Beige hard plastic case with dark grey handle with chrome fittings and white buttons either side of the handle. Metal typewriter 'querty' key board, white keys with black inscriptions. Includes typewriter ribbonLabel inside cover for servicing. "CFM Industries Pty Ltd address, phone number" Label on back of typewriter for CFM Industriesportable typewriter -

Ballarat Tramway Museum

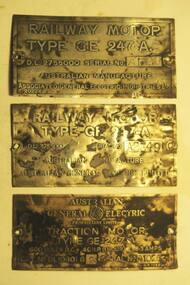

Ballarat Tramway MuseumSign - Manufacturers plate - GE 247 tram motors, Australian General Electric

Set of three manufacturer's serial plates from GE 247-A motors used in tramcars. Manufactured in Australia under licence from General Electric of the USA. Known as "railway motors" in the USA. Used extensively in Australian tramway systems. The company changed its name a number of times. 1 - Associated General Electric Industries - Serial Number A1307 2 - Australian General Electric Limited - A2349 3 - Australian General Electric Pty Ltd - A10253 - has the GE logo.Yields information about the Australian Company who made tramway motors in SydneySet of three metal (brass or steel) manufacturers plates for GE 247-A motorsge 247 motors, tramways, trams, motors, general electric, australian made -

Melbourne Tram Museum

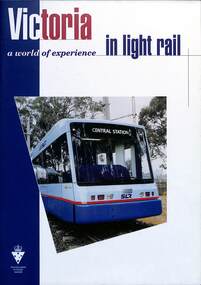

Melbourne Tram MuseumBooklet, Victorian Government, "Moving Victoria - a world of experience in Light Rail", c1998

Booklet - "Moving Victoria - A World of experience in Light Rail" - produced by the Victorian Government to advertise and market its expertise in Light Rail manufacturing and operation. Notes Melbourne trams, track infrastructure, Electrical systems and Asset Management. Includes images of Sydney Light Rail and Hong Kong vehicles. Has a forward by Mark Birrell, Minister for Industry Science and Technology (Minister from 1996 to 1999). Includes an extensive list of contacts, companies and their products. See item 7206 for a similar document c2003.Yields information about Victorian Light Rail manufacturing capacity.Booklet - 24 pages, centre stapled titled "Moving Victoria - a world of experience in Light Rail"victoria, tramcar manufacture, sydney, hong kong, melbourne, light rail, tramways, marketing -

Eltham District Historical Society Inc

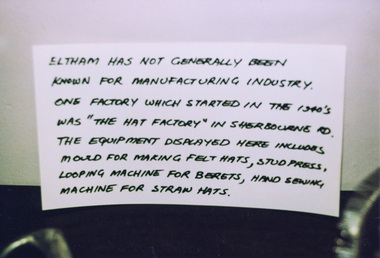

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

Colour photograph of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Wodonga & District Historical Society Inc

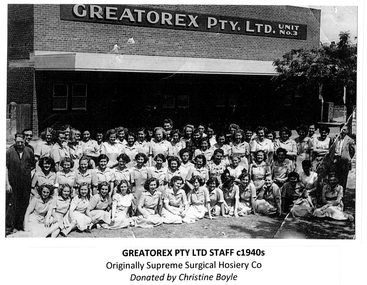

Wodonga & District Historical Society IncPhotograph - Greatorex/ Supreme Surgical Hosiery Co. Wodonga

The Greatorex company came to Wodonga in August 1945 under the Cain Government decentralisation policy. It initially had premises in Beechworth Road, around the corner from Tallangatta Road (now Thomas Mitchell Drive). Due to expansion they later relocated to the corner of Tallangatta Road and Anne Street Wodonga in 1952. Greatorex had its main manufacturing plant in Melbourne, Victoria. At their peak Greatorex Pty Ltd. which also operated as Supreme Surgical Hosiery Co., manufactured brassieres, swimsuits, elastic thread, surgical hosiery and employed 90 staff in Wodonga. The company which was operated by Thomas Greatorex with Mr M. P. Brain as Manager, also owned Fulflex Yarns Pty. Ltd. Fulflex produced elastic yarns to be used in the manufacture of garments at Supreme Surgical Hosiery. In 1960, due to the increasing cost of freight charges for moving raw materials and manufactured goods to and from Melbourne, the company was forced to close down. Plant and machinery valued at over £30,000 was moved to Melbourne. Some personnel were given the opportunity to also transfer to the parent company. In 2024, the company still operates as Greatorex Textile Industries P/L in Moorabbin, Victoria.These images are significant because they document an industry which operated in Wodonga in the 1940s and 1950s.A collection of black and white photos of workers at the Greatorex / Supreme Surgical Hosiery Co. in Wodonga.Names listed beneath one of the images.greatorex industries, wodonga industries -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1900

The Beechworth Foundry was vital to the industry of the town and surrounding district in the early years of the town’s development. Originally opened as the New Ford Street Foundry by A. Roger in 1858, J Duncan and M Straughair amalgamated and established the Beechworth Foundry in 1867. The business was extensive and operated out of many buildings, each with their own specialisation. All of the buildings pictured in this image are part of the larger Beechworth Foundry. In the late 1860s it employed 16 men. The foundry was fundamental to the running of the town and surrounding district, as it manufactured all manner of items, including tools and machinery for the mining and agricultural industries. The foundry business collapsed in 1896 after the death of it’s founder, John Duncan, the same year (Straughair had died in 1882). The foundry was reopened by W H Phillips in 1905 and taken over by H Delora in 1906 This image is significant as it shows some of the many buildings of the Beechworth Foundry, which was a fundamental business to the running of the town and surrounding district, and supplied many of the tools and machines required for the mining and agricultural industries, as well as other aspects of life between the 1850s and early 1900sSepia rectangular photograph printed on paper. It has rough, torn-looking edgesReverse 97.2321 / BMM A03115duncan, john duncan, j duncan, m straughair, straughair, foundry, beechworth foundry, industry, factory, newtown, new ford street foundry, a roger, roger, w h phillips, phillips, w phillips, h delora, delora, metalwork, farming and agriculture, tools, mining, workmen -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cream Can, Malleys Ltd, 1920-1950

This small cream can was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in various sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. This cream can was designed for domestic home use and was used to fetch cream from a dairy or retailer of dairy products between 1920 to 1950s. M Luscombe Diamond Creek on the nameplate suggests this is the farm dairy that supplied the cream the can would hold and that they were the owners of the can. This dairy no longer exists as the area is now a housing estate.Cream can, round metal container with fitted lid and carrying handle. Can has a short wide neck. Body has embossed letters and an attached metal nameplate that has been soldered. Made by Malleys. Embossed raised letters "MALLEYS". Text on nameplate ""M LUSCOMBE / DIAMOND CREEK " warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, domestic object, cream can, dairy container, diamond creek, m luscombe -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Book: TAFE Curricula, Syllabi and Accreditation Documents 1994-1998, TAFE Curricula, Syllabi and Accreditation Documents 1994-1998, 1994-1998

Contents: National Horticulture Curriculum Parts A and B 1997/98 National Horticulture Curriculum Level 4 1997/98 National Horticulture Curriculum Level 5 1997/98 National Horticulture Curriculum Level 6 1997/98 Pharmaceutical Manufacturing. Certificates 1,2,3 Core modules. !997/98 Pharmaceutical Manufacturing. Certificates 1,2,3 Special electives. !997/98 Associate Diploma of Applied Science (Food Technology) Syllabus Date not clear. [to Archives 1999] Certificate in Food Processing . Revised Core Modules. (Draft report) 1994 Certificate IV in Food Technology, Diploma of Food technology. 2 vols. Food industry Training accreditation board. National Certificate in food processing . Course advice. Core modules. Syllabus framework. Literacy, English language and numeracy. Nov 1993. Associate Diploma of Applied Science (Environmental Waste Management) and Advanced Certificate in Environmental waste management. Part 1 – Accreditation submission. 1988. Certificate III in Environmental Change Management. Submission for accreditation. 1995. Diploma in Natural Resource management. Primary Industries Training accreditation board. 1996. Advanced Building Studies. National curriculum module maintenance. 1997. Details of past courses and their accreditation.13 individual books in various bindings. Each details requirements for course accreditation in a variety of TAFE courses.tafe, technical and further education, environmental waste management, environmental change management, food technology, natural resource management, food processing, building studies, pharmaceutical manufacturing, horticulture, nmit, -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

Two Colour photographs of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - Seal Embossing Press

The Corona Paint Company Pty. Ltd. Bendigo was formed in November 1920 with £10,000 capital, in £1 shares. By July 1921, the Company had completed its factory and plant at Bendigo East, ready to begin the manufacture of paints. The Corona Paint works were opened on Saturday 28 January by the Prime Minister (Mr. Hughes) during a visit to Bendigo. Many new manufacturing industries were opened during this time after calls to address the decline of mining in the region. The factory of the CORONA PAINT COMPANY, BENDIGO, was advertised for sale in The Argus on 5 October 1923. It consisted of a “building on a railway siding, plant and machinery, including dry grinding plant, kalsomine mixer, paint mill, furnace, electric motor, etc., large stores of raw and finished material, kalsomine with range of 21 colours, oil paints, &c.”A cast iron embossing press. It's painted black with gold coulered floral decorations. The base is 18 centimetres long, nine centimetres wide and one and a half centimetres thick. A curved protrusion rises from the base that is eight centimetres by four centimetres which narrows to four centimetres by two and a half centimetres with a three-quarter centimetre wide slot. Inside the slot is a lever action with a ten centimetre by two and a half centimetre wooden handle. There is a removeable die on the end of the lever and an opposite removeable die the base. A small oval metal disc with paten no 3965 on is attached. The seal is The Corona Paint Company proprietary Limited seal embossing press, corona paint company -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionUniform - Department of Supply Cap, 1971

Established in 1950, the Department of Supply headquarters transferred to Canberra in January 1968 and was dissolved in 1974. It was superseded by the Department of Manufacturing Industry and Department of the Special Minister of State. The Department was a Commonwealth Public Service department, staffed by officials who were responsible to the Minister for Supply. The department's main function was to support Australia's Navy, Army and Air Force in defence production, research and development, purchasing, transport and storage. The Department was also the Commonwealth Disposals Authority. Finally, the Department was responsible for the Australian Antarctic program. Bendigo was the site of an Ordnance Factory and manufactured and reconditioned naval guns and mountings, turbine gears for large ships, general heavy engineering work, large fabricated structure and missile handling equipment. The factory was managed in 1970 by R.I.M Moss. The department may have had an office in the former Bendigo Post Office now the Bendigo Visitor Information Centre.Blue, felt or wool peaked service cap with woven band and plastic strap. Small brass buttons. The cap has a synthetic lining around the crown and on the roof of the cap. Marked on the inside with the maker's details.bendigo post office, city of greater bendigo uniform -

The Beechworth Burke Museum

The Beechworth Burke MuseumFunctional object - Ladies Coin Purse

Specific historical and contextual information pertaining to this object is unknown. There are no hallmarks or documentation to indicate provenance or historical significance. This coin purse appears to have a covering made of mother of pearl. Evidence of interest from over 20,000 years ago mark Aboriginal groups in Australia as some of the first people to value the power and beauty of pearlshell, while evidence of Australian pearlshell being taken across the sea to other countries dates back as early as the 1500s. The 1850s-60s saw the beginnings of the Australian pearling industry. Following the popularisation of plastic for items such as buttons the pearlshell market waned in the mid-twentieth century but was soon after began to re-forge in Australia with a new industry of cultured pearl farms. Most of Australian's pearling industry was initially located in Western Australia and off the Torres Strait Islands. The Australian War Memorial notes on their website that many tokens made from mother of pearl were sent home to loved ones throughout World Wars One and Two from the Middle East, England, the South West Pacific, Australia and elsewhere, but that unfortunately provenance such as the manufacture and sale of many of these items is not recorded.The social history objects held in the Burke Museum's collection help to tell the stories of Beechworth's past by showing the social, cultural, and economic aspects of the town's history.A small rectangular purse with silver edging and half clasp, covered in white and cream coloured shell (mother of pearl?)A01154burke museum, social history, accessories, mother of pearl, nacre, australian industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Company seal embosser, Unknown

The former Albion (West) Woollen and Worsted Mills is a functional structure which has been built in stages, possibly dating from the 1880s, with the earliest sections near to the Barwon River.The Worsted mill operated for about 50 years and at its peak employed around 500 people. In 1973 the mill merged with the British John Foster and Sons Company under some controversial stock and shareholding issues. The mill continued for a short period before closing at a time when much of the Australian textile industry was finding it difficult to compete with overseas operations. In the 30 plus years after the closure, the site was used for several ventures, including the Mill Vintage Markets and a vehicle trim manufacturing operation. In 2011 the site was purchased by Little Creatures of Western Australia to become their main brewery for the eastern states of Australia. Now owned by the Lion Group, Little Creatures started their 60 million dollar transformation of the old mill in 2012. Finally, in 2013 these former walls of industry were soon rattling away to the sounds of a different type of industry, as the first bottles of beer made their way out of the Geelong Little Creatures Brewery. The remaining building of the former Albion Woollen and Worsted Mills has historical significance as one of Geelong's major woollen mills. The venture has operated on the same site for more than a century. The Albion Woollen Mill was one of the four key sites along with Victoria, Barwon and Union Mills that was established in the late 1860s to mid-1870s. These mills were in constant operation on the west side of the Barwon Bridge over the last century and led to Geelong's fame as milling and scouring locality. The Albion Mill was probably the most successful survivor of the early private company operations. It was regarded as a model mill in the late 1880s and was, from all accounts, well-planned and organised with machinery on a par with the great mills of England. It produced high-quality tweeds. Together with the (now demolished) Union Mill it was regarded as the borough's principal industry over the 1870-1900 period and was one of Australia's most significant producers of tweed by 1900. These two mills were more successful, competitive and long-lived than the Barwon and Victoria Mills. The remaining building form is an important reminder of the private ventures of both the Albion and Union Mills and represents a key site of spinning, carding and finishing as well as scouring and dying that occurred in the lower section near to the river. The loss of the adjacent former Union Mill is unfortunate because the complex, together with the former Collins Union Mill office building, was an important reminder of the success of these industries and the reputation they earned for the Geelong region as a centre for quality textile products. Company seal embosser hand operated matte black & brass colour Western District Worsted Mills emblem on frontflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFunctional object - Pocket First Aid, Circa mid 1900s

This pocket First Aid kit is small and compact which became available to those venturing out in the outback and required an easily managed first aid kit. It was manufactured in the mid 1900s well before vinyl and or plastic pouches or bags where used. It was in an era where valuable items were stored in durable containers due to the harsh and rugged conditions of the Australian bush. Cheaper and less durable containers from Asian manufacturers had been kept out by the heavy Tariff imposed on their goods. This changed in the 1980's when the Tariff Board was dismantled by a then Labour Government. The Australian manufacturing industry was severely reduced by the Influx of cheaper goods. This item was made by an Australian company when the motto "true blue" was the catch cry for quality Australian made goods. This was in the period where the isolation of many rural communities required the basic first aid kits to be of a tougher quality than those offered in large cities and towns.This pocket first aid kit was very compact and would have been easy to carry without taking up too much space for bush walkers, camping scouts, drovers and independent miners and cattlemen. The Kiewa Valley and surrounding rural settlements did not have the medical backup that the larger cities and towns had up until the mid 1900s when the Hydro Electricity Schemes were built and the additional influx of workers made it feasible to have a hospital and better local health facilities. This influx of the construction workers associated with the Hydro Scheme. also brought European workers who where more inclined to go bush walking and climbing the Victorian alps than the average Australian rural worker. This item is a Sanax pocket first aid round tin, gold in colour with red and white print. It's contents are: one small tube of Sanax antiseptic cream, one small one inch x six yards of gauze bandages, rubber band type ligatures with a cast iron tightener., one small tweezers three safety pins, and one lancet.On the lid there are: are outlined white cross on a blue circular background. underneath is a whiite circle encased with a red line with the following printed "Sanax pocket first aid case" (in red print underneath this is a small curved blue background and in black print "No. 26"medicine, first aid tin, camping medical supplies, personal first aid, sanax -

National Alpine Museum of Australia

National Alpine Museum of AustraliaSki Jacket, 1970s

Reversible ski jacket made by Rosalie Kiessling, 1970s. Used by Rosalie's son and daughter-in-law, from the 1970s through to the 1990s. The Kiessling family skied at Mt Buller and are members of Omega Ski Lodge. German by birth Rosalie, grew up skiing and ice skating, studied fashion design in Munich and worked designing women’s ski wear and lingerie before migrating to Australia via New Zealand in 1939 with her husband. As skiing increased in popularity following the end of WWII, Rosalie’s business grew reaching its peak during the 1960s. Though it was never large; at most she employed three staff. Rosalie continued to design and manufacture fashionable but functional ski wear until the late 1970s, although increasing imports from large overseas manufactures and constant new innovations in fabric technology made it difficult for her to compete in a relatively small industry. Reversible ski jacket with side zip pockets and full zip front. One side of the jacket is black fabric, while the other is black checked with a yellow and red weave. Rosalie Kiessling sportswear Melbourne / All cottonskiing, ski clothing, fashion design -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document - Instruction manual, Details of component parts for Broadbent suspended steam driven Hydro Extractors, C 1926

Thomas Broadbent $ sons Ltd was established in 1864 in Huddersfield England. They are an engineering firm , specialists in heavy duty engineering products. By 1893 Broadbent had progressed to steam powered engines for the textile industry. Some of these machines operated for upwards of 50 years Today Broadbent is a leading world designer in the manufacture and maintenance of advanced centrifuges. This document is a manual for a suspended direct steam driven hydro extractor. It shows the various parts , maintenance instructions and erection and working instructions. While it is stamped as Albion Woollen mills which were situated at Geelong, it is likely to have connections to the Warrnambool Woollen Mills.This document is a good example of machinery manual. It is possibly linked to the Warrnambool Woollen Mill. The fact that the company which manufactured these items is still in existence today after 150 years is testament to the quality of the items produced.Cream coloured document with mainly black text with some red text for headings contained in the document. It is printed front and back and is folded in three sections.Stamp at top "Albion Woollen mills Pty Ltd" .4H x 4 in red pencil in top RHC. Printed on front page. Thomas Broadbent & Sons Ltd Central Iron Works Huddersfield. warrnambool, warrnambool woollen mill, broadbent direct steam driven hydo extractors,, broadbent centrifuge -

National Alpine Museum of Australia

National Alpine Museum of AustraliaSki Jacket, About 1967

This jacket and cap were designed by Rosalie 'Rosa' Kiessling about 1967. They formed part of the Fashion Group Inc's Walkabout Tour of the USA in 1967 which aimed to promote Australian fashion design in America. German by birth Rosalie, grew up skiing and ice skating, studied fashion design in Munich and worked designing women’s ski wear and lingerie before migrating to Australia via New Zealand in 1939 with her husband. As skiing increased in popularity following the end of WWII, Rosalie’s business grew reaching its peak during the 1960s. Though it was never large; at most she employed three staff. Her designs featured in the pages of Australian Vogue, Flair and the Women’s Weekly throughout the 1960s and received coverage from newspapers in Australia, New Zealand the United States. Rosalie was closely involved with the Swiss Club of Victoria, the Australian Wool Board and the Fur Traders Association, participating in numerous fashion shows and awards run by these groups. In the late 1960s she became involved with the Melbourne Branch of the Fashion Group Inc, a worldwide non-commercial association of women involved in the fashion industry. Rosalie continued to design and manufacture fashionable but functional ski wear until the late 1970s, although increasing imports from large overseas manufactures and constant new innovations in fabric technology made it difficult for her to compete in a relatively small industry. This ski jacket and cap illustrate Rosalie Kiessling's emphasis on practical glamour. She was the first Australian ski wear manufacturer to bring high fashion to ski wear design; which though common in the boutiques of St Mortiz, Chamonix and St Anton was new to Australia. The use of an Australian wildflower motif and of these pieces in the Fashion Group's Walkabout Tour also speak to her involvement in and promotion of the Australian fashion industry during the 1960s.Ski jacket and matching cap appliqued with Australian wildflowers.Noneskiing, ski clothing, fashion design, australian fashion, australian flora -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rowing Oar

The family-owned timber manufacturing business Pelco was started by Cecil Victor Woodfield in 1937. The joinery company Pelco began by making wooden ladders and was registered as the Palmerston Extension Ladder Company. C V Woodfield, who lived from 1884 -1959, arrived in Palmerston North from Canterbury NZ in the aftermath of the Great Depression to work in construction. The company got its first step up when Woodfield was asked by a commercial painter to make a ladder, and the founder set up shop in a garage on Ruahine St. According to the company website, Pelco made its name in New Zealand with its Oregon Extension Ladders, and up until its closure, manufactured non-conductive Lamilite Ladders for the electrical supply and service industry worldwide. The company was incorporated as a joinery business in 1946 and continued making high-end cabinetry for seven decades. Under director Geoff Woodfield, in the 1950s, the company embarked on the production of Fleetcraft plywood boats. Another water-related enterprise followed, with the manufacture of oars and paddles. Its branded Gull Superior Oars and Paddles business began exporting in 1972 to Australia and subsequently to the United States, UK and Japan. The company ceased trading in April 2018 and was placed into receivership.This pair of lightweight oars represents the maritime tradition of handmade oar making, which has evolved over the centuries. Their shape is still similar to early oars and continues to serve the same purpose, to steer and propel a boat. Pair of blonde varnished Tasman Fir oars with a flattened paddle at one end. Made by Gull of New Zealand, sold by James Edwards & Sons of Melbourne. Inscriptions on printed labels on the oars."GULL Superior Oars and Paddles, Pelco, Palmerston North NZ" "JAS. EDWARDS & SONS, Boat Builders, Oar and Skull Makers, & Importers, PRINCES BRIDGE MELBOURNE"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, oar, oars, gull oars and paddles, new zealand oars and paddles, jas edwards and sons melbourne, rowing equipment, new zealand oak, paddle, james edwards and sons melbourne, james edwards, tasman fir, gull superior oars, marine equipment, marine technology, ship fitting, boat fitting, rowing oar, boat oar -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rowing Oars

The family-owned timber manufacturing business Pelco was started by Cecil Victor Woodfield in 1937. The joinery company Pelco began by making wooden ladders and was registered as the Palmerston Extension Ladder Company. C V Woodfield, who lived from 1884 -1959, arrived in Palmerston North from Canterbury NZ in the aftermath of the Great Depression to work in construction. The company got its first step up when Woodfield was asked by a commercial painter to make a ladder, and the founder set up shop in a garage on Ruahine St. According to the company website, Pelco made its name in New Zealand with its Oregon Extension Ladders, and up until its closure, manufactured non-conductive Lamilite Ladders for the electrical supply and service industry worldwide. The company was incorporated as a joinery business in 1946, and continued making high-end cabinetry for seven decades. Under director Geoff Woodfield, in the 1950s, the company embarked on the production of Fleetcraft plywood boats. Another water-related enterprise followed, with the manufacture of oars and paddles Its branded Gull Superior Oars and Paddles business began exporting in 1972 to Australia and subsequently to the United States, UK and Japan. The company ceased trading in April 2018 and was placed into receivership.This pair of lightweight oars represents the maritime tradition of handmade oar making, which has evolved over the centuries. Their shape is still similar to early oars and continues to serve the same purpose, to steer and propel a boat. The oars are associated with a significant family business situated in Palmerston New Zealand that along with making ladders also graduated into making wooden boats and oars.Pair of blonde varnished Tasman Fir oars with a flattened paddle at one end. Made by Gull of New Zealand, sold by James Edwards & Sons of Melbourne. Inscriptions on printed labels on the oars.(1) "GULL Superior Oars and Paddles, Pelco, Palmerston North NZ" (2) "JAS. EDWARDS & SONS, Boat Builders, Oar and Skull Makers, & Importers, PRINCES BRIDGE MELBOURNE"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, oar, oars, gull oars and paddles, new zealand oars and paddles, jas edwards and sons melbourne, rowing equipment, new zealand oak, paddle, james edwards and sons melbourne, james edwards, tasman fir, gull superior oars, marine equipment, marine technology, ship fitting, boat fitting, rowing oar, boat oar -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BROADCASTING STATION 3CV, MARYBOROUGH, 2 March, 1956

Broadcasting Station 3CV, Maryborough. A souvenir of the opening of the New Studios and Offices of Central Victoria Broadcasters Pty Ltd. March 2nd, 1956. Established 1956, offices in Burke Street, opening coincides with the stations 21st birthday, March 2 for the former celebration, October 26 for the latter. Coverage included Bendigo, Ballarat, Daylesford, Castlemaine and Maryborough. 3CV plays active part in assisting charities and hospitals at Maryborough, Daylesford, Maldon and Dunolly. Active Women's Radio Club with branches in country centres adds strength to station's charitable efforts. Opening 3CV's new premises will widen the scope of the station's charitable efforts, and stronger link with Australian Commercial Broadcasting stations. Writer Harold V Nunn writes history of district of Mayborough. Manager Ken J Parker, Central Victoria Broadcasters Pty. Ltd. The Souvenir brochure also covers topics such as: deep lead mining. WWI. Houses being pulled down. New settlements of Mildura. Secondary Industries. Bowenvale, Alma, Majorca, Craigie, Amherst, Adelaide Lead, Havelock, Bet Bet, Bently. Primary production and a railway staff of approximately 150. Maryborough a little town without a future. Coal fields at Wonthaggi. 1917 a public meeting was convened in an effort to stem the tide of adversity. Mayor George Frost, M.L.A., decision to form a Progress Association, a policy of secondary industry was decided upon and committees were appointed, James L Drew much credit is due. Maryborough's move for rejuvenation was revolutionary, because apart from Ballarat, Bendigo and Geelong, it was regarded as so much presumption that industry could be expected to function with success in a country town. Governments were unsympathetic. Maryborough & district people showed determination to succeed and their faith in their town. Employment and economic security provided by the industries outweighed the debt. Maryborough's general position is that it is no longer dependent upon one particular phase of activity. The first of the industries to be formed in 1918 was the Butter Factory. The nearer dairy companies did not take kindly to the prospect of another opposition company taking supplies from their districts, and in the first few years of establishment completion made the going hard for the management. But adopting a conservative policy and placing all profits to reserve I the first six years of operation headway was gradually made. Thus it was a red letter day for the company in 1925 when the first dividend of 5 percent was paid.1955 dividend of 10 per cent. Operating it's own trucks the dairy serviced local dairymen up to 40 miles. Maryborough Knitting mills est. 1923, having transferred from Clunes. Out bid Ballarat and Bendigo to the industry. The mill has what is probably the largest circular underwear plant in the Commonwealth, which is conservatively valued at 198,913 pounds. It produces between four and five million garments each year, worth over one million pounds. The company has established subsidiary mills at Dunolly, Talbot and Avoca. The company also assisted in the establishment of the Interknit Hosiery Co. Ltd., Clunes. The Maryborough Flour Mills is the second oldest of Mayborough's industries. It was built by Mr Cadwallader over 70 years ago. It was later sold to Mr. A Land and then to Jas. Minifie & Co. It had a somewhat 'in-and -out' existence until purchased in 1923 by Messrs. Willersdorf and Forbes, of Eddington. In 1939 the firm began to build silos for the storage of bulk wheat and the present storage capacity is 100,000 bushels. 1944 power was changed from steam to electricity. The mill has an out put of 20 sacks an hour. 1938 a chaff mill was built, and now is regarded as one of the best in Victoria. Its output in one year of approximately 6,800 tons is a State record for a single cutter. During this 30 year period Patience and Nicholson Limited has grown with Maryborough and is now one of the major key industries of Australia. The P&N brand covers precision tools - taps, dies and twist drills - indispensable to the country's economy, and quality is acknowledged equally by an air craft factory in Canada, a dockyard in Thailand, a railway workshop in New Zealand, no less than by our own Australian industries. Maryborough can be proud of the part played by P&N in war when, geared to the needs of the times, it poured countless millions of tools into defence factories and to the armed forces of the Allies, and now in peace when it is providing, hydro-electric undertakings and the manufacture of cars and tractors. From 1858, W Phelan & Sons Pty Ltd has made phenomenal and spectacular growth, becoming incorporated as a private company in 1929. It is without doubt the greatest private development in the history of Maryborough. 1940 joinery manufacture was commenced. The company entered the Ready Built Housing field in `950 - and in 1951 established a factory at Cairns, Northern Queensland to overcome the manufacturing difficulties being experienced due to the shortage of plywood in Victoria. Present activities include: Ready Built Housing Factory, on-site building, a modern joinery, timber yard, drying kilns, etc., and plumbing & electrical & engineering services, a door and panel factory at Cairns, retail hardware store, Melbourne Sales Depot. Hedges & Bell Pty Ltd were est 1945, with a staff of 40 employees are the largest printing firm outside the metropolitan area. The branch of Premier Wireworks is a contribution made by the decentralisation policy of the State.event, official, celebration, broadcasting station 3cv, maryborough. a souvenir of the opening of the new studios and offices of central victoria broadcasters pty ltd. march 2nd, 1956. established 1956, offices in burke street, 21st birthday. coverage bendigo, ballarat, daylesford, castlemaine maryborough. assisting charities and hospitals maldon and dunolly. women's radio club opening 3cv's new premises australian commercial broadcasting stations. writer harold v nunn writes history of district of mayborough. manager ken j parker, central victoria broadcasters pty. ltd. souvenir brochure: deep lead mining. wwi. houses pulled down. new settlements. primary production railway staff. coal fields wonthaggi. 1917 a public meeting was convened in an effort to stem the tide of adversity. mayor george frost, m.l.a., form a progress association, policy of secondary industry, james l drew rejuvenation was revolutionary, employment and economic security. the first of the industries to be formed in 1918 was the butter factory. thus it was a red letter day for the company in 1925 when the first dividend of 5 percent was paid.1955 dividend of 10 per cent. operating it's own trucks serviced local dairymen. maryborough knitting mills est. 1923 largest circular underwear plant in the commonwealth. established subsidiary mills at dunolly, talbot, avoca. interknit hosiery co. ltd., clunes. the maryborough flour mills it was built by mr cadwallader. mr. a land jas. minifie & co. messrs. willersdorf and forbes, build silos for wheat storage capacity is 100, 000 bushels. 1944 power was changed from steam to electricity. 20 sacks an hour. 1938 a chaff mill was built, best in victoria. patience and nicholson limited the p&n precision tools - taps, dies and twist drills. war, geared to the needs of the times, countless millions of tools into defence factories the armed forces of the allies, hydro-electric undertakings and the manufacture of cars and tractors. from 1858, w phelan & sons pty ltd, incorporated 1929. 1940 joinery manufacture. ready built housing field in 1950 - 1951 established a factory at cairns, northern queensland to overcome the manufacturing difficulties being experienced due to the shortage of plywood in victoria. present activities: ready built housing factory, on-site building, a modern joinery, timber yard, drying kilns, etc., and plumbing & electrical & engineering services, a door and panel factory at cairns, retail hardware store, melbourne sales depot. hedges & bell pty ltd were est. 1945, with a staff of 40 employees are the largest printing firm outside the metropolitan area. the branch of premier wireworks is a contribution made by the decentralisation policy of the state. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Warrnambool and District Historical Society Inc.

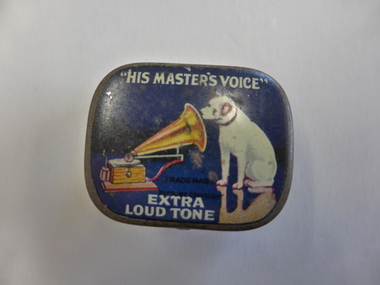

Warrnambool and District Historical Society Inc.Tins, Gramophone Needles HMV, Early and mid 20th century

These gramophone needles were manufactured by The Gramophone Company Limited for use in gramophones that had an arm in which to insert a needle to play an old shellac record. The Gramophone Company was an early recording company based in the United Kingdom and was the parent organization for the His Master’s Voice label of recording devices. The company was founded in 1897 and merged in 1931 with another company to form E.M.I. (Electric and Musical Industries) but the name The Gramophone Company continued in Britain until the 1970s. Gramophones were a popular household item from the late 19th century until the mid 20th century when more sophisticated recording and playing devices were invented. These gramophone needles is of some interest as an example of entertainment devices of the past. It will be useful for display. .1This is a metal box with a lid containing an image of a dog and a phonograph (‘His Master’s Voice’) painted in white and brown on a dark blue background. Inside the tin are about 150 metal gramophone needles, most of them being a little rusted. The needles are covered with a sheet of brown paper with yellow printing. The tin itself is rusted and the printing is discoloured. There is a paper sticker on the back of the box with an early catalogue number (almost obliterated). .2 Small rectangular plastic container with picture of white polar bear with blue background. It contains approximately 30 needles which have red ends and silver points. .3 small plastic bag with a number of needles..1 Front of box: ‘His Master’s Voice, Extra Loud Tone’ Back of box: Approximately 200 English gramophone needles manufactured by The Gramophone Company Limited, Sydney, Australia’. Inside: ‘Use each point once only’ (printed twice). .2 50 semi- permanent needles on front of box. On bottom Made in Germany. gramophone needles, warrnambool, e.m.i., electric and musical industries -

Flagstaff Hill Maritime Museum and Village

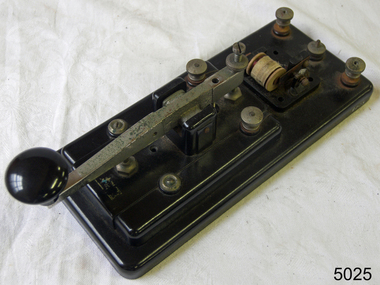

Flagstaff Hill Maritime Museum and VillageFunctional object - Morse Training Key, 1950s

The set consisted of a key battery and buzzer it was used for training potential radio operators in the Morse code. It was manufactured by blue point in the 1950s. The company was founded in the Sydney suburb of Erksville in 1936 by a German immigrant, Frederick Boyd Dirks who named his company F Dirks. The company produced Bakelite products such as ashtrays single strip heaters, and Morse key components, In 1946 the company named was changed to Blue Point products Pty Ltd. The name was inspired by the name “Blau Punkt” a German electrical supplier. in 1973 the company was purchased by Gerard Industries which was known for its line o Clipsal products, An item made in Australia for training purposes of new radio operators and is significant in that it is part of Australia's social history and shows the development of Australian electrical manufacturing. Australian blue point telegraph practice /training set XX20A circa 1950 Bakelite, stamped XX20A under, three terminals - two marked "+" and "-".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

National Wool Museum

National Wool MuseumCarpet Samples, Godfrey Hirst and CO. Pty Ltd, c.1990

Carpet samples created by Godfrey Hirst, a carpet mill whose history spans back to 1865 when the Victorian Woollen and Cloth Manufacturing Company began operations in Geelong and was purchased in the 1890s by the man Godfrey Hirst. Godfrey Hirst’s entrepreneurial skills and knowledge of the industry led to the great success which saw the company expand in multiple forms over the next century and a half. Today, thousands of metres of carpet are produced by Godfrey Hirst every day, and their flooring can be found in millions of homes. These 6 carpet samples date from the early 1990s and each have a unique colour pattern and design.Each carpet sample is made with a pile fibre that is 100% wool. The primary backing of the carpet is a woven polypropylene with a secondary backing a woven jute. Carpet 8102.1's colour name is Slate. It has a dark grey background with a red and blue diagonal stripe. The pattern repeats in a 10cm x 11.5cm block. Carpet 8102.2’s colour name is Terracotta. It is a mostly block pink colour with no repeating pattern. It has occasional flicks of grey. Carpet 8102.3’s colour name is Arctic Night. It has white, light blue and grey colours repeating one after another in a diagonal line. Carpet 8102.4’s colour name is Ivory. It has a brown background with a cream colour diamond. The pattern repeats in a 15cm x 15cm block. Carpet 8102.5’s colour name is Glenwood. It has a thin darker green and lighter green horizontal stripe spanning its entire width. These stripes repeat the height of the carpet. Carpet 8105.6’s colour name is also Ivory. It has a brown background with a cream colour leaf pattern. The pattern repeats in a 92cm x 92cm block.Wording on rear: Numerous. See Media.godfrey hirst, carpet, textile manufacture -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

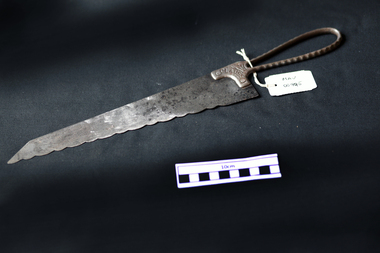

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Bread Knife 'Clauss', c1900

Clauss Cutlery’s long and vivid history started in early 1880’s when John Clauss and his younger brother Henrie established Elyria Shear Works in Elyria, Ohio. At one time the company was the largest manufacturer of scissors and shears in the world and was acquired by Acme United Corporation in 2004. John and Henrie Clauss, of German origin, started Elyria Shear Works from a one-room building in Elyria, Ohio Together with five employees, they began manufacturing scissors, shears, straight razors and serrated kitchen knives In August 1887, the Company moved to Fremont, Ohio to be near an accessible, abundant supply of natural gas which had recently been discovered. 1889, disaster struck as the plant was completely destroyed by fire, In 4 months Clauss built a new plant and was back in full operation and changed the company’s name to Clauss Shear Company. 1919 Clauss Shear merged with Henkel Company, to become Henkel-Clauss Company. Henkel Company was founded in 1906 to manufacture manicure and pedicure files, knives, shears and razors. After World War II, Clauss was unable to compete with European firms producing household scissors and shifted its focus to industrial scissors. In 1967 Clauss was taken over by Alco Standard Corporation who integrated Clauss into its existing structure to manufacture tools for industrial niche markets. Clauss made surgical scissors for eye operations, heavy duty metal cutting shears, poultry shears for gutting chickens and specialty items such as anti-acid, anti-magnetic tweezers for the electronics industry. Clauss had approximately 100 employees and produced about $18 million in annual revenues in the late 1980s, but profits continued to decline. In 2004, Acme United Corporation acquired the Clauss inventory, trademarks and brand names from Alco Industries for approximately $500,000A large Bread Knife with scalloped / serrated edge and looped handle Front : CLAUSS Back : FREEMONT / OHIOcutlery, knives, clauss shear company, ohio, freemont, market gardeners, early settlers, moorabbin, cheltenham,